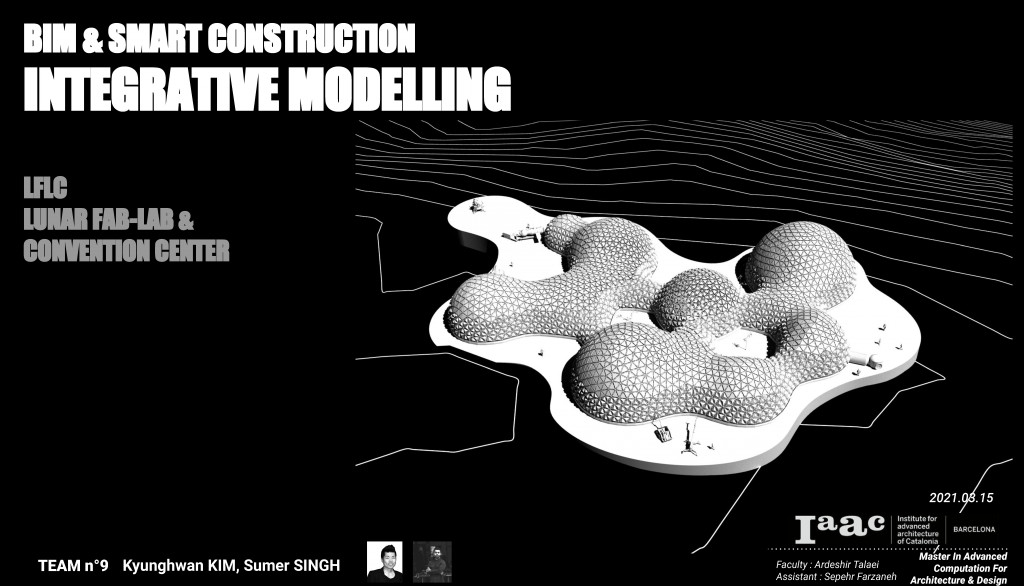

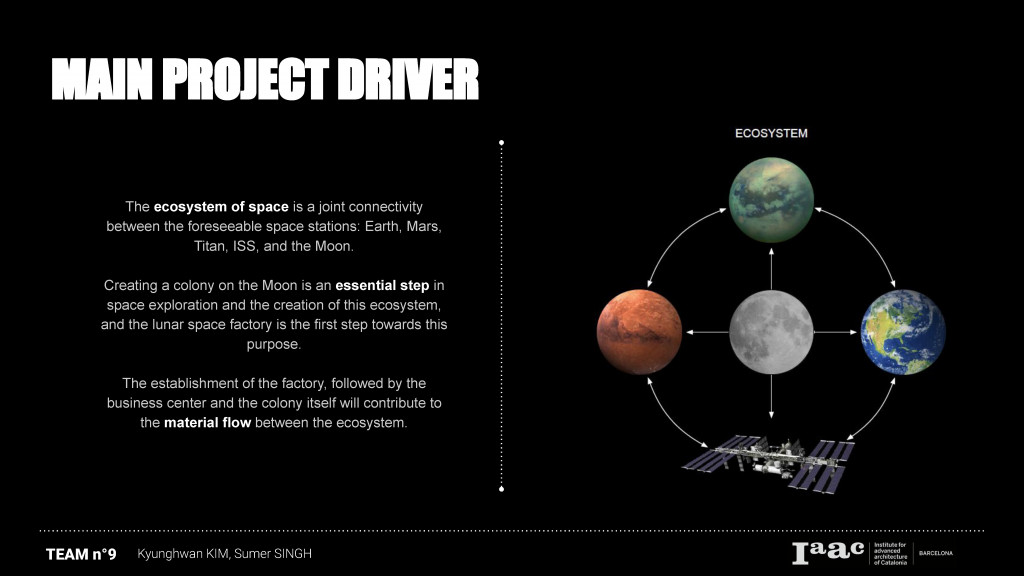

The LFLC (Lunar Fab Lab and Convention Center) is a 70 m diameter factory and business center on the Moon that seeks to establish a material ecosystem between the major space stations. This includes the ISS, Titan, Mars, and Earth. The LFLC is the first major step towards this ecosystem, and it does this by harnessing materials such as regolith for laser sintering, basalt for reinforcement material, and the farming of space junk using satellite drones for capturing. The material flow at the factory itself creates a system of sorting, repurposing or reusing, quality checking, assembly and fabrication, and dispatch for a panel based construction system that not only self-builds the factory and business center, but also the rest of the colony. The business center provides programs such as conference rooms, meeting rooms, a showroom, and a space depot where inhabitants of the colony can come and procure or order material and fabrication projects.The panels used for the building contain the following: solar panels, regolith panels for the base, window panels, and interior panels. Therefore, the building uses the same panel typology in varying compositions and thicknesses, which was designed and applied in revit as an adaptive panel family.

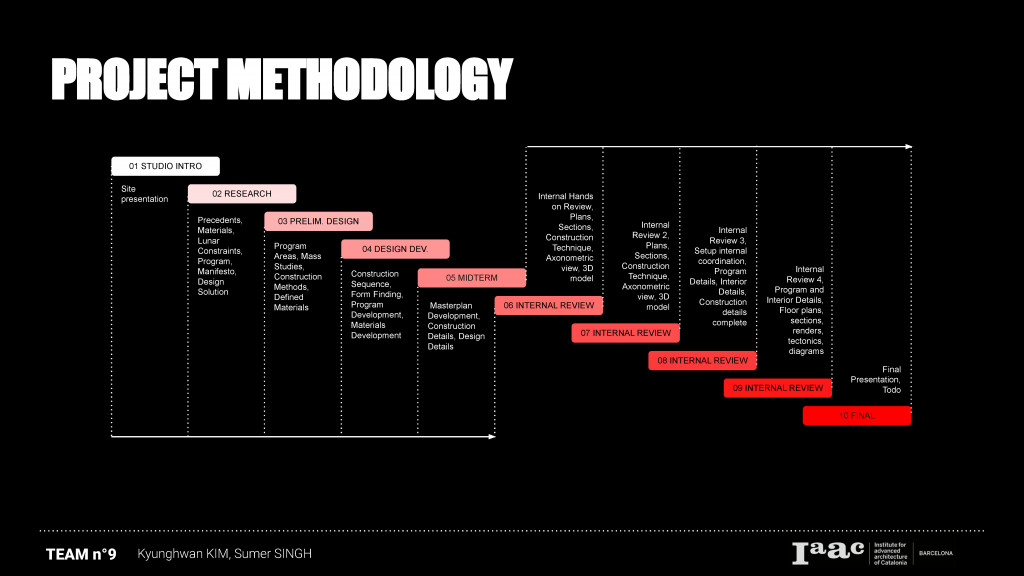

Here is the work process of this project for 10 weeks. 10 weeks was very short time to understand enough the Moon environment and its constraints so that this project can be developed further by complementing feedback of our result from the research and design step.

Here is the work process of this project for 10 weeks. 10 weeks was very short time to understand enough the Moon environment and its constraints so that this project can be developed further by complementing feedback of our result from the research and design step.

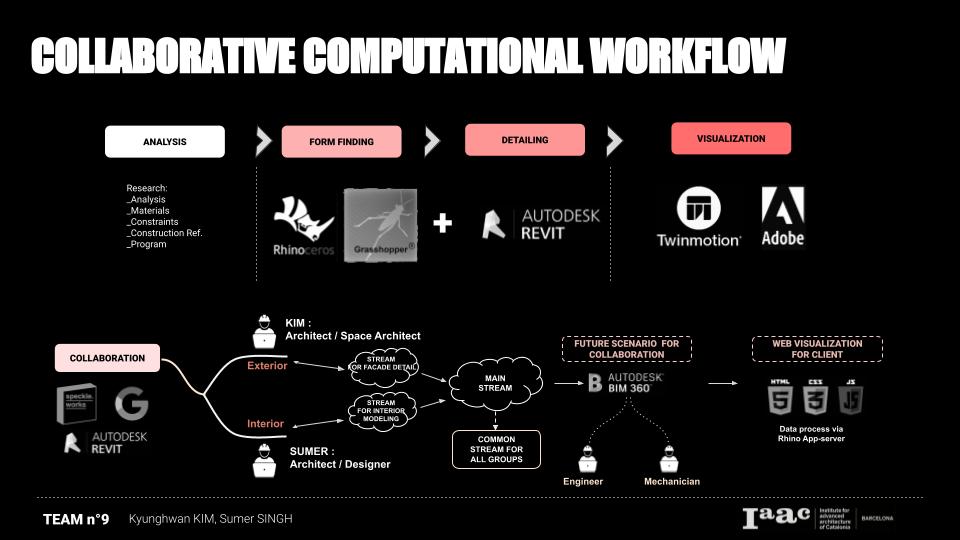

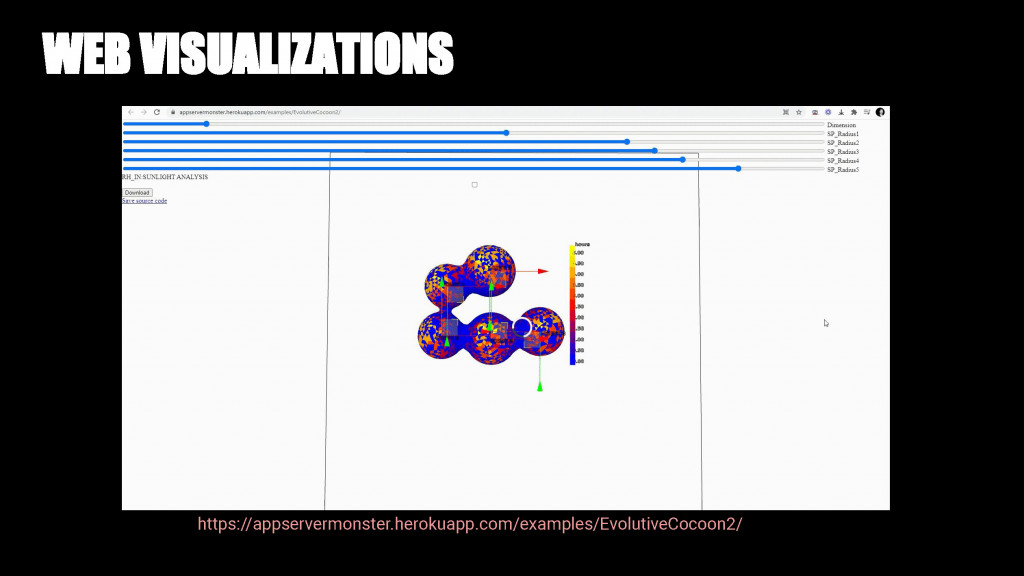

The collaborative computational workflow for the project started with the Analysis of the project using any means necessary. The form finding was done using Rhino and GH and the detailing in Revit. The visualization was finally done in Twinmotion, Maya and Photoshop. Our collaborative workflow included a Speckle stream that was used internally between the 2 group members. This fed into the main overall studio stream. In the future we see ourselves using BIM 360 and also creating interfaces for clients using web visualization tools.

The collaborative computational workflow for the project started with the Analysis of the project using any means necessary. The form finding was done using Rhino and GH and the detailing in Revit. The visualization was finally done in Twinmotion, Maya and Photoshop. Our collaborative workflow included a Speckle stream that was used internally between the 2 group members. This fed into the main overall studio stream. In the future we see ourselves using BIM 360 and also creating interfaces for clients using web visualization tools.

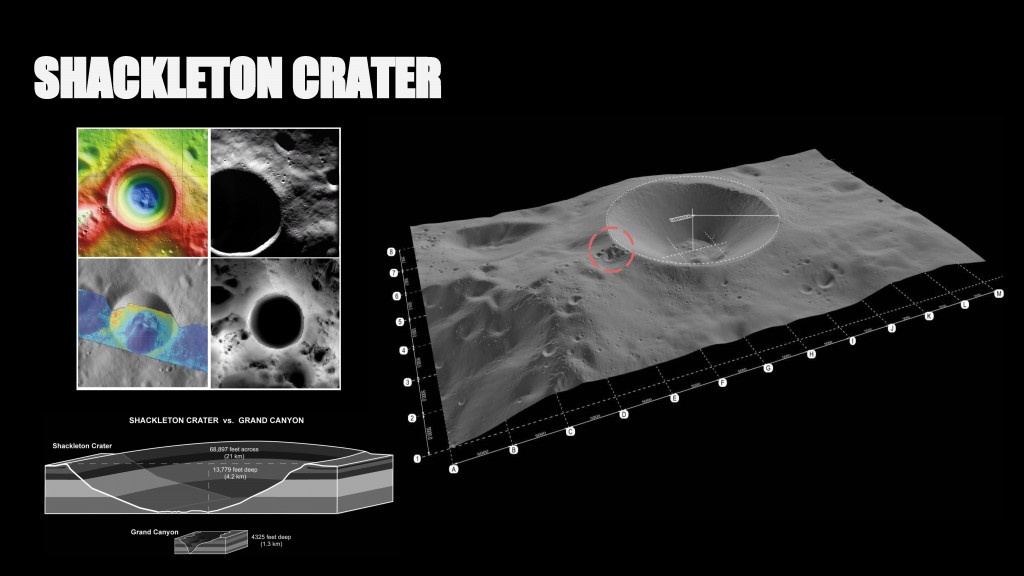

The site was selected as the Shackleton crater as a group decision. There are advantages on this site such as solar radiation exposure, communication time with earth, visibility with earth, and also the presence of ice in the crater.

The site was selected as the Shackleton crater as a group decision. There are advantages on this site such as solar radiation exposure, communication time with earth, visibility with earth, and also the presence of ice in the crater.

Our building was placed at the periphery of the colony, close to the solar power plant in order to draw a connection between the 2 programs. We also have proximity with the VR and entertainment center.

Our building was placed at the periphery of the colony, close to the solar power plant in order to draw a connection between the 2 programs. We also have proximity with the VR and entertainment center.

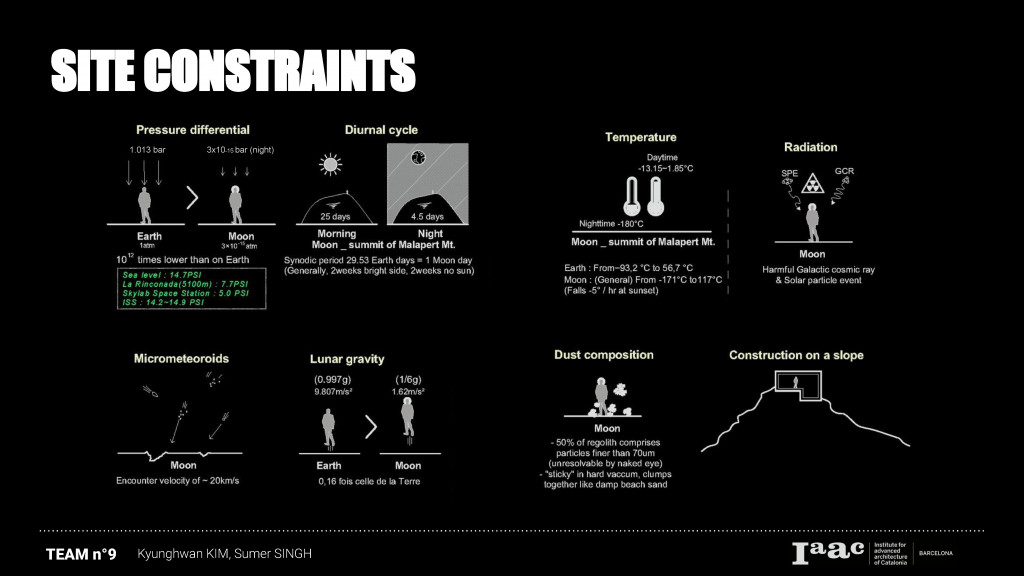

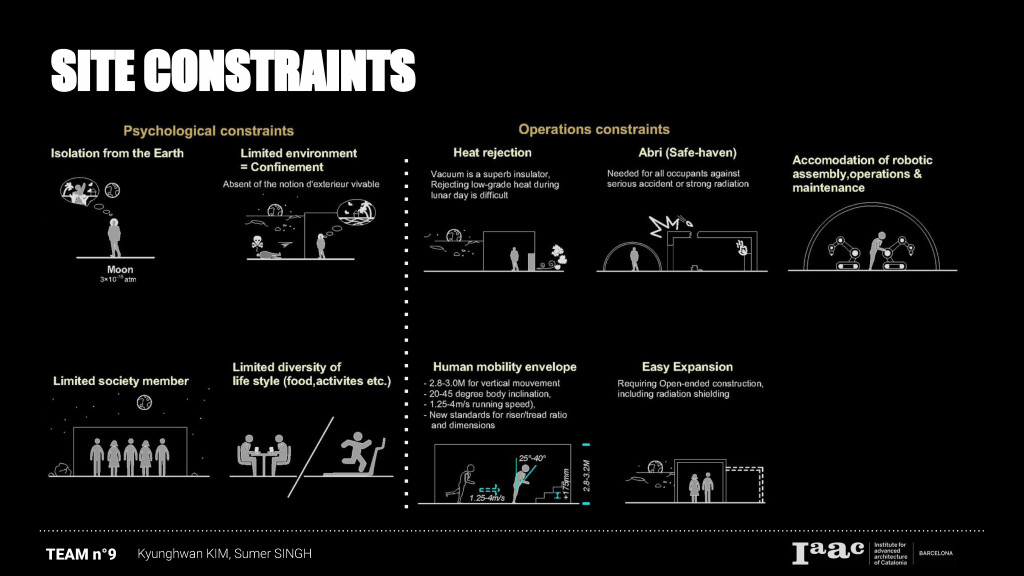

Living on the Moon surface, there are many constraints in Lunar environment.

Living on the Moon surface, there are many constraints in Lunar environment.

But also, we have to think about psychological constraints for better habitability. A building on the Moon surface would have different operational criteria such as, stairs height, ceiling height because of low gravity, redundancy of abri against an unforeseen accident.

But also, we have to think about psychological constraints for better habitability. A building on the Moon surface would have different operational criteria such as, stairs height, ceiling height because of low gravity, redundancy of abri against an unforeseen accident.

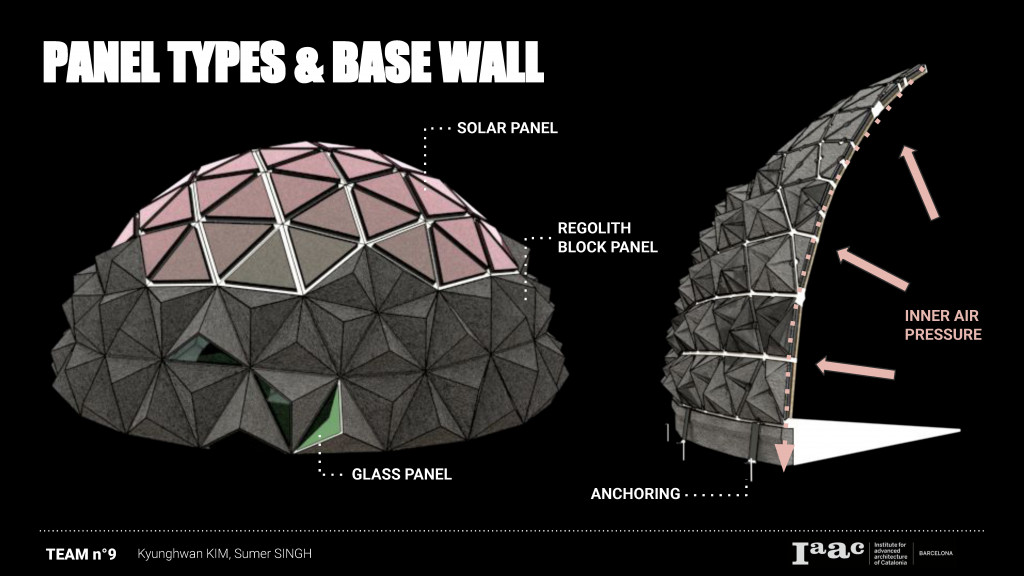

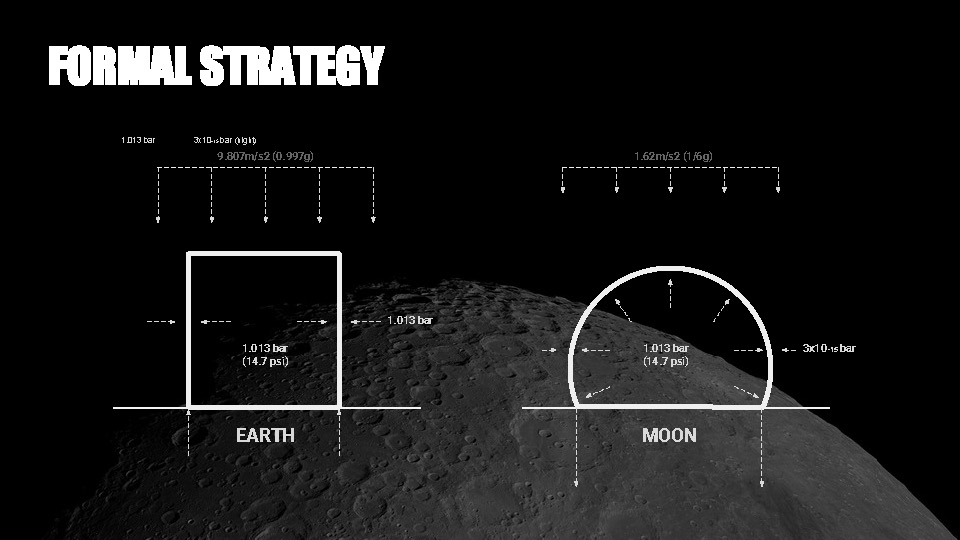

A geometry or shape of architecture on the Moon is a bit complicate than the earth’s one. The gravity is effect highly for a form terrestrial architectural, however the Lunar architecture has to be considered the fact that there is almost no atmosphere. It means that the force of inner air pressure of the habitat is higher than outer pressure. Therefore, we choose a simple dome shape for this project by focusing on its constructability for being more feasible project.

A geometry or shape of architecture on the Moon is a bit complicate than the earth’s one. The gravity is effect highly for a form terrestrial architectural, however the Lunar architecture has to be considered the fact that there is almost no atmosphere. It means that the force of inner air pressure of the habitat is higher than outer pressure. Therefore, we choose a simple dome shape for this project by focusing on its constructability for being more feasible project.

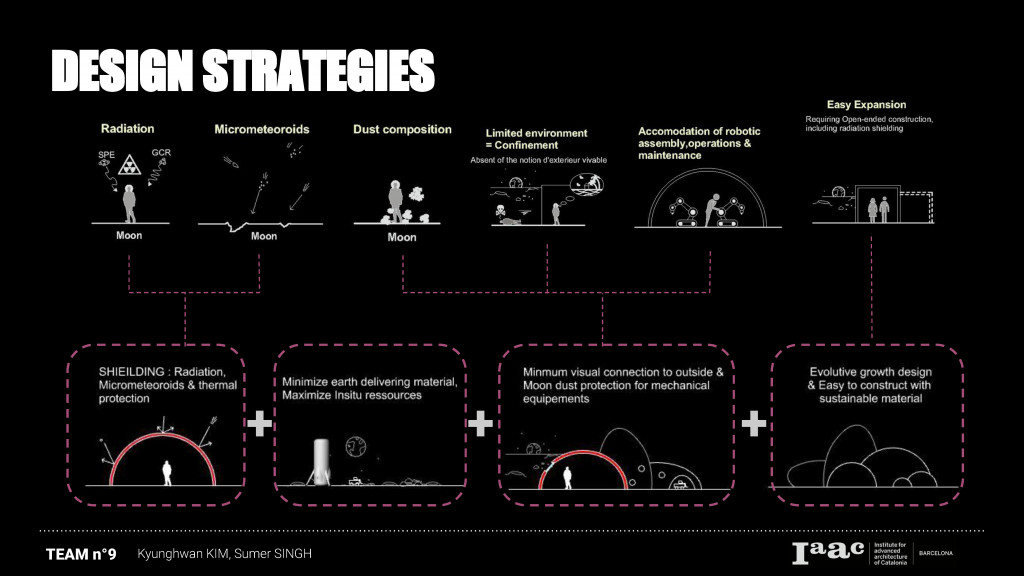

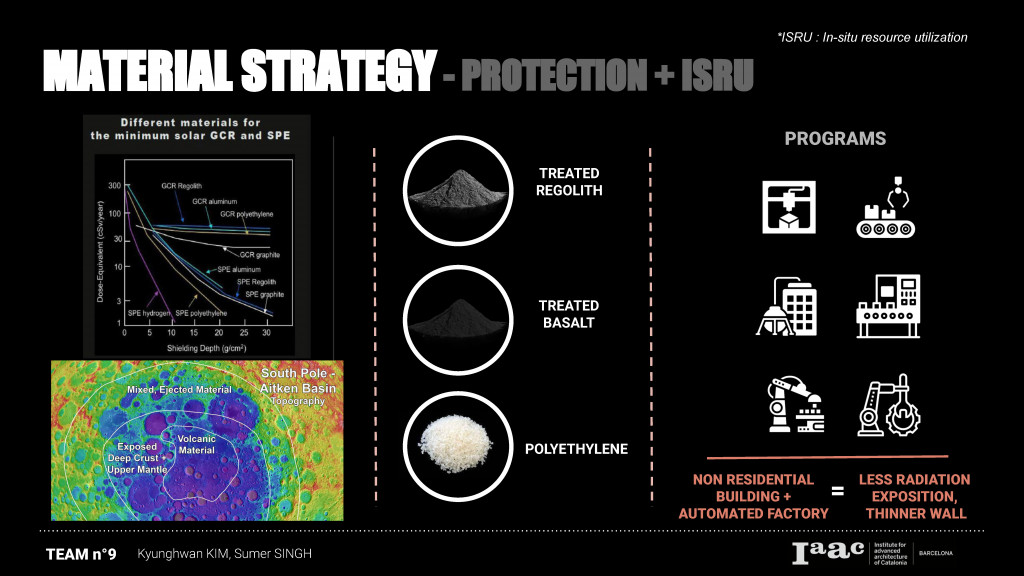

For the design strategies of Lunar Fab-lab and Convention center, 6 constraints were mainly treated for its concept. Generally, a thickness of the wall of residential building on the Moon should have minimum 50-70 cm in order to protect crews against radiations of SPE and GCR. As this architecture is non-residential building, the thickness of the wall can be relieved until 40 cm, but the radiation safety should be confirmed by future simulation.

For the design strategies of Lunar Fab-lab and Convention center, 6 constraints were mainly treated for its concept. Generally, a thickness of the wall of residential building on the Moon should have minimum 50-70 cm in order to protect crews against radiations of SPE and GCR. As this architecture is non-residential building, the thickness of the wall can be relieved until 40 cm, but the radiation safety should be confirmed by future simulation.

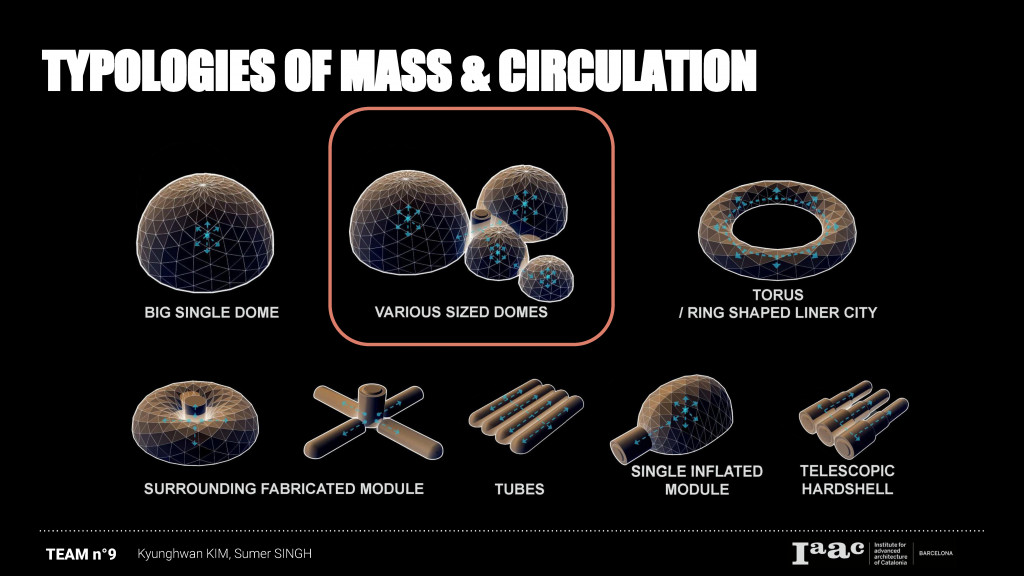

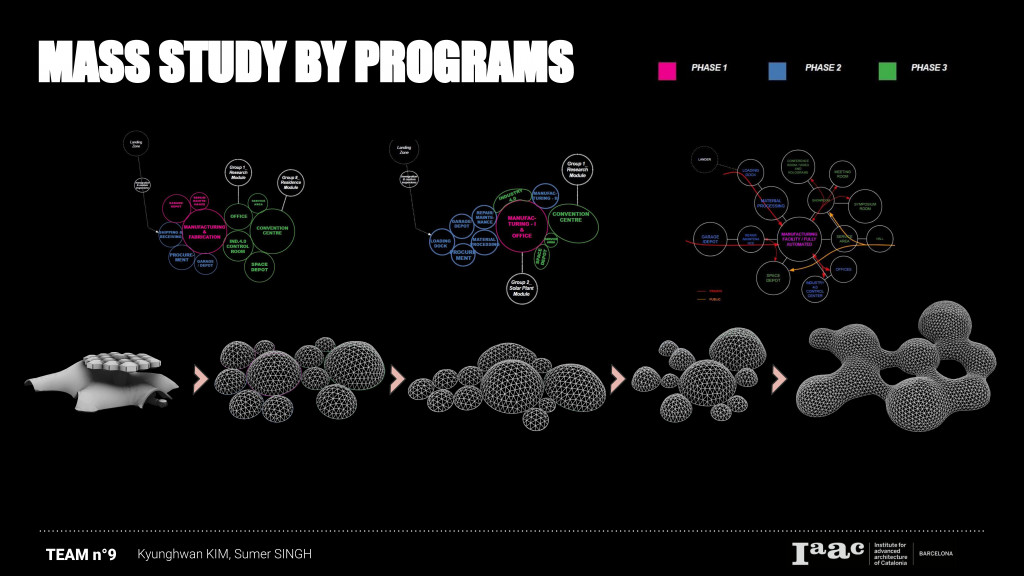

Several typologies of building mass were studied. And then, we choose to have various sized domes which allows to have various circulation and spatial perception for crews.

Several typologies of building mass were studied. And then, we choose to have various sized domes which allows to have various circulation and spatial perception for crews.

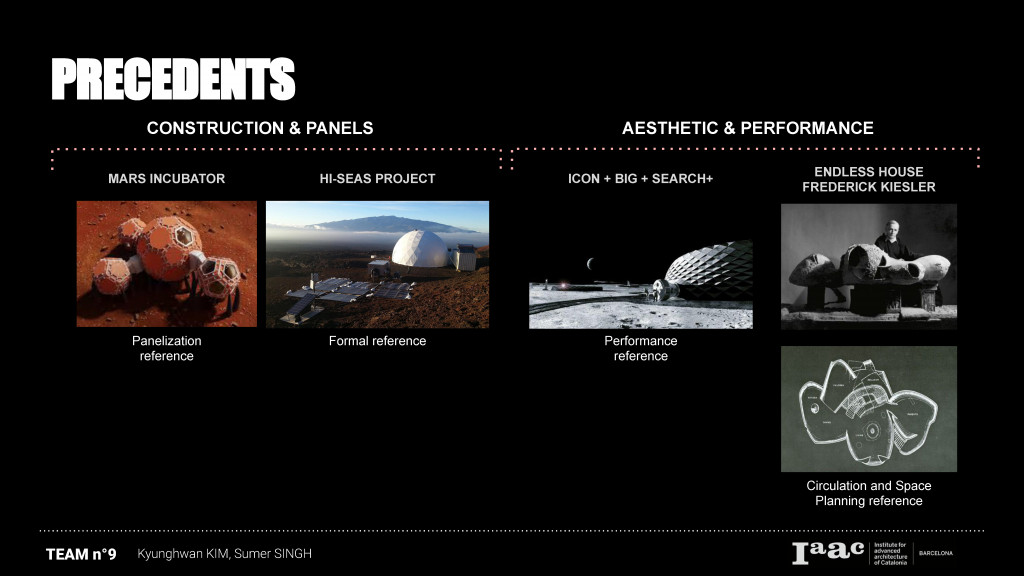

We took inspiration from the Mars Incubator and the Hi-seas project for the penalization and formal strategy of our building. The ICON+BIG+SEARCH+ project was used as a reference for the performative aspect of the form and facade.The Endless house was the inspiration for the space planning and circulation.

We took inspiration from the Mars Incubator and the Hi-seas project for the penalization and formal strategy of our building. The ICON+BIG+SEARCH+ project was used as a reference for the performative aspect of the form and facade.The Endless house was the inspiration for the space planning and circulation.

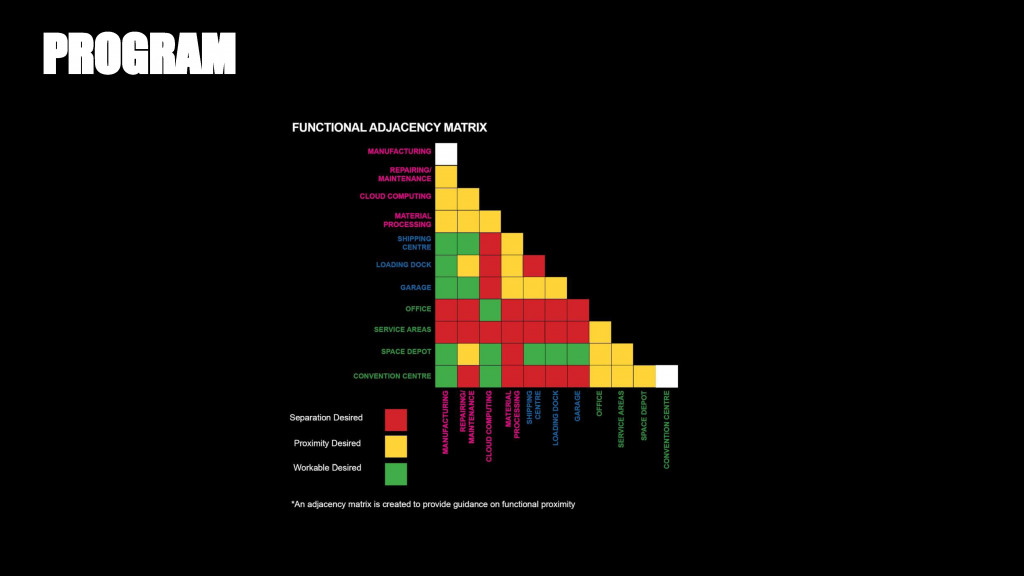

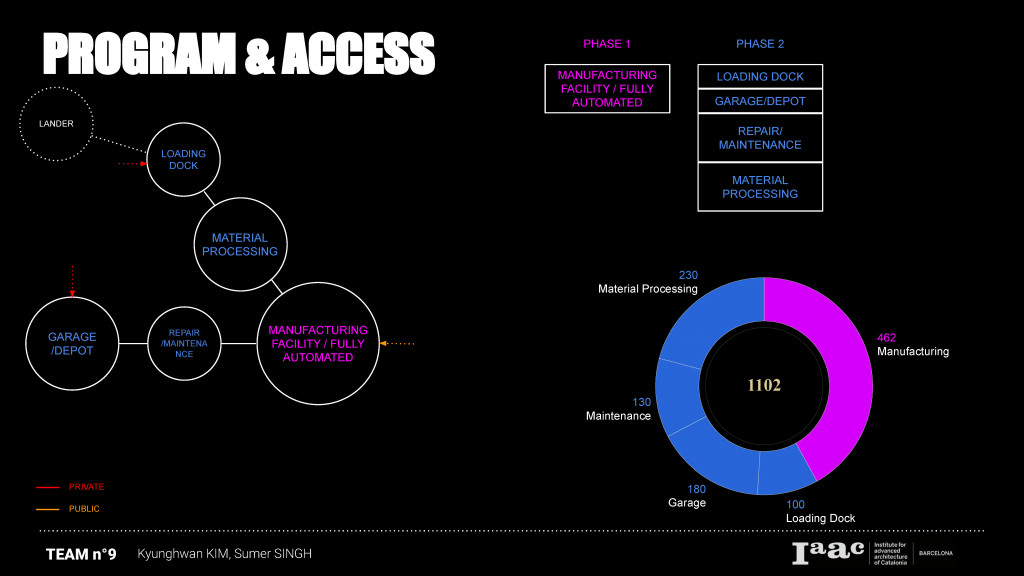

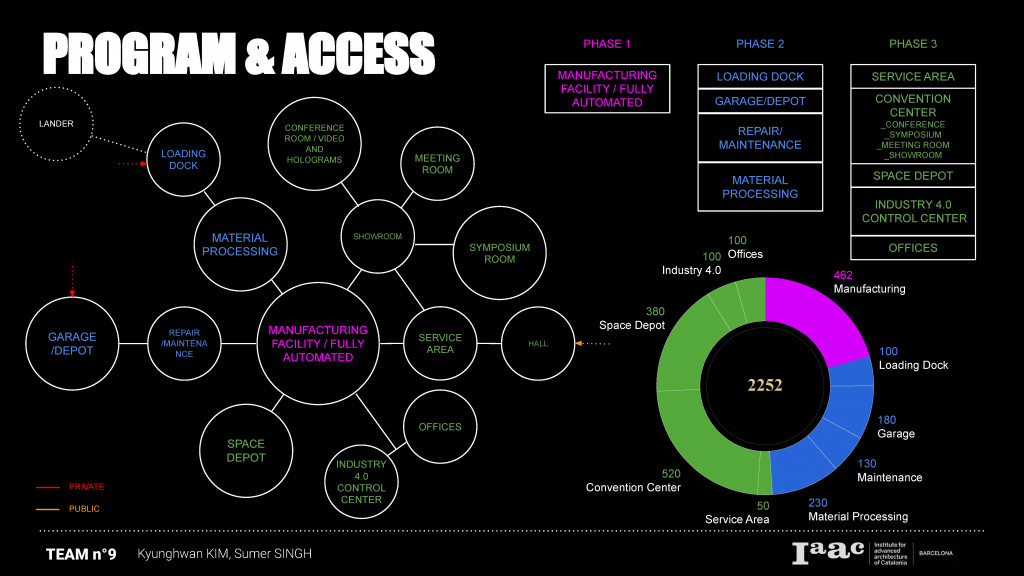

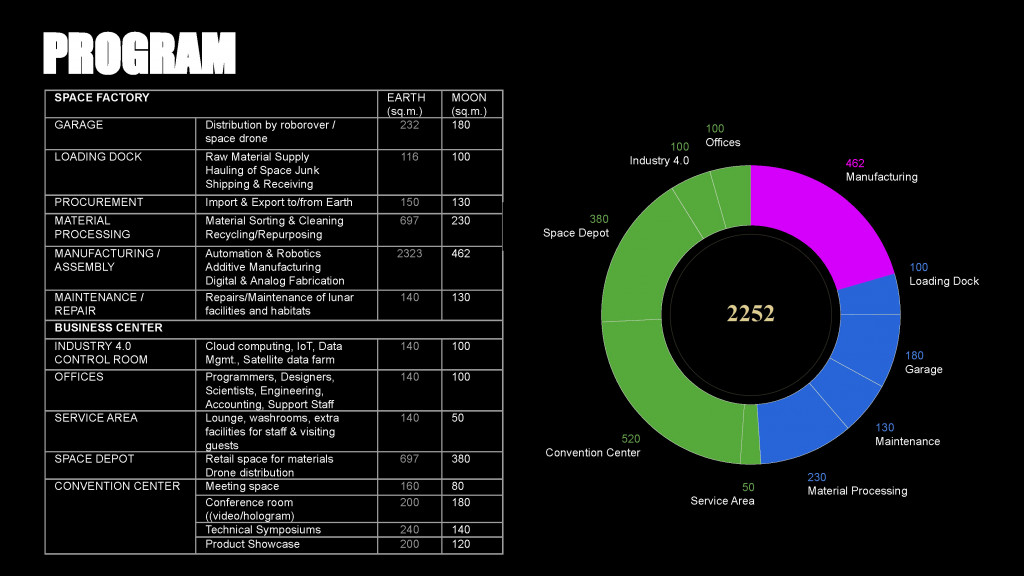

We compiled a list of the programs that would be used for our main programs of a Space factory and Business Center, and these program areas were then compared between what we would require on the Earth vs the Moon. We also used the functional adjacency chart to visualize the proximity of programs to one another.

We compiled a list of the programs that would be used for our main programs of a Space factory and Business Center, and these program areas were then compared between what we would require on the Earth vs the Moon. We also used the functional adjacency chart to visualize the proximity of programs to one another.

At this point we started to consider and iterate between the various forms that could be used to embody our programs, while using program areas and our precedents for the form driving parameters.

At this point we started to consider and iterate between the various forms that could be used to embody our programs, while using program areas and our precedents for the form driving parameters.

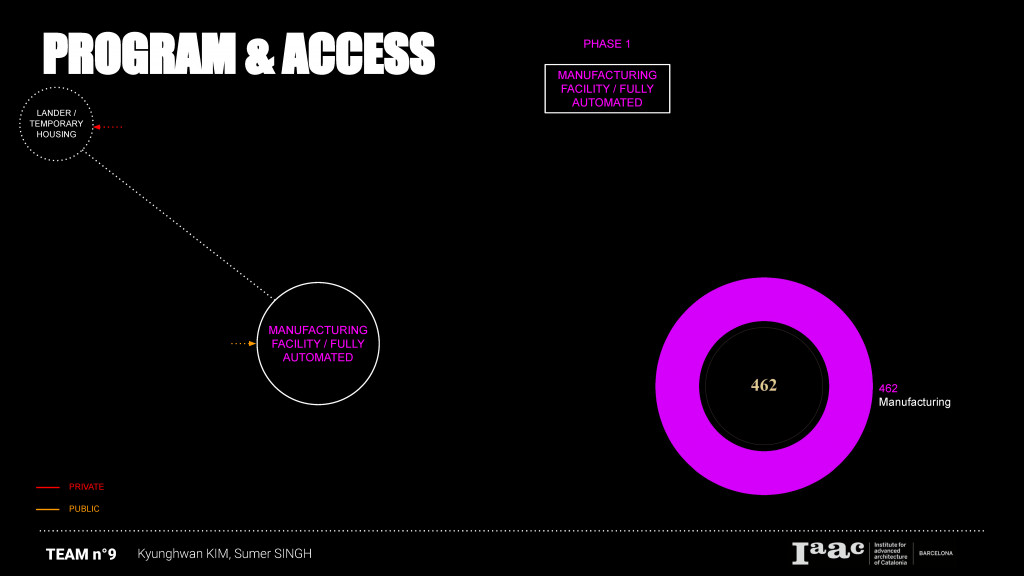

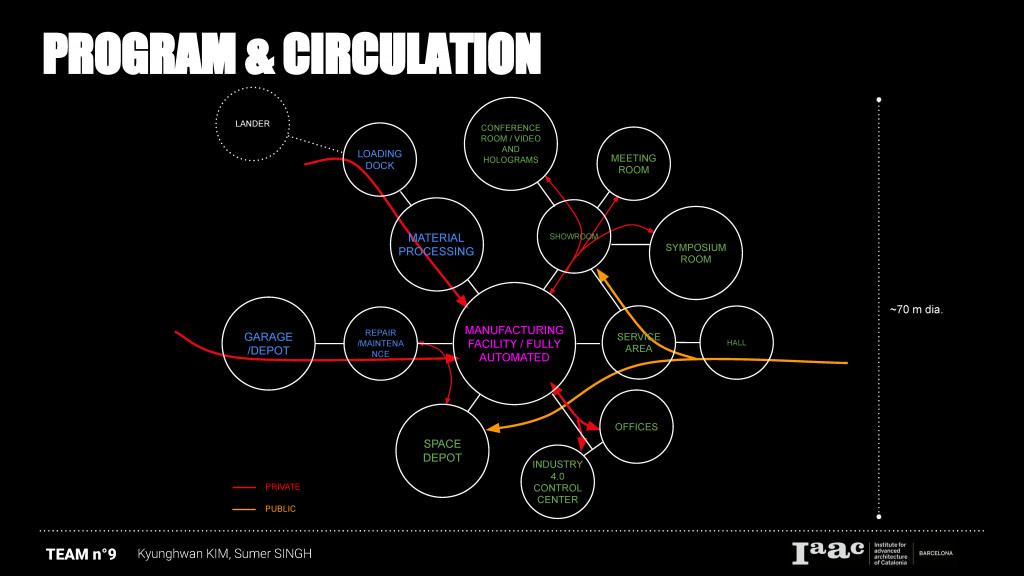

These diagrams display the different phases of the program development on site as it would relate to the building development and construction. The circulation and access was also considered during this development while keeping in mind the private and public realms.

These diagrams display the different phases of the program development on site as it would relate to the building development and construction. The circulation and access was also considered during this development while keeping in mind the private and public realms.

We started off by considering an inflatable structure for our building. This research was mainly focused on different volume development in low gravity to find effective anchoring system on lunar surface.

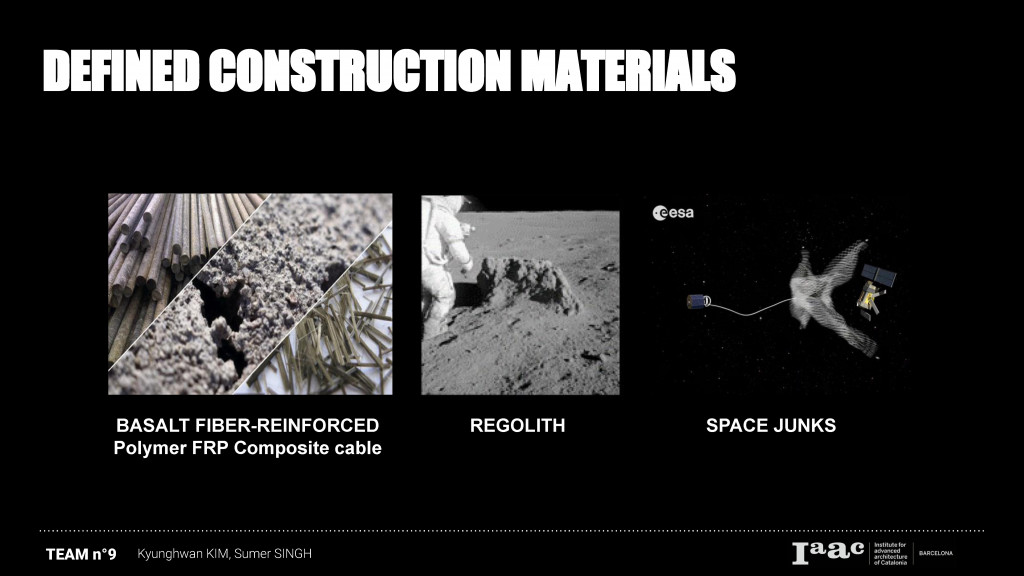

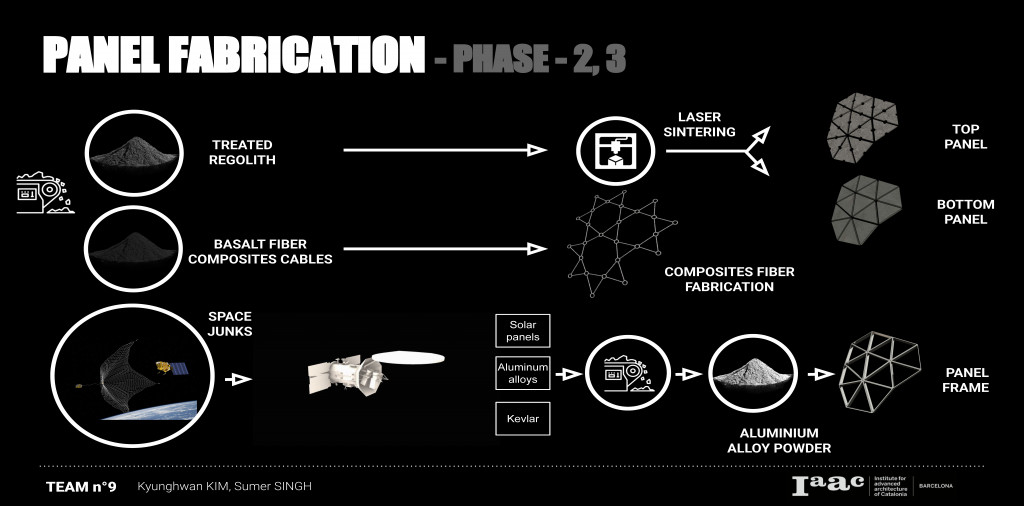

Then, we decided to simplify the complexity of the various materials with inflatable material. Indeed, we moved on to more locally available materials for making a permanent construction element by using regolith for sintering, basalt fiber composites material and space junk that is available in abundance and can be farmed from the moon.

Then, we decided to simplify the complexity of the various materials with inflatable material. Indeed, we moved on to more locally available materials for making a permanent construction element by using regolith for sintering, basalt fiber composites material and space junk that is available in abundance and can be farmed from the moon.

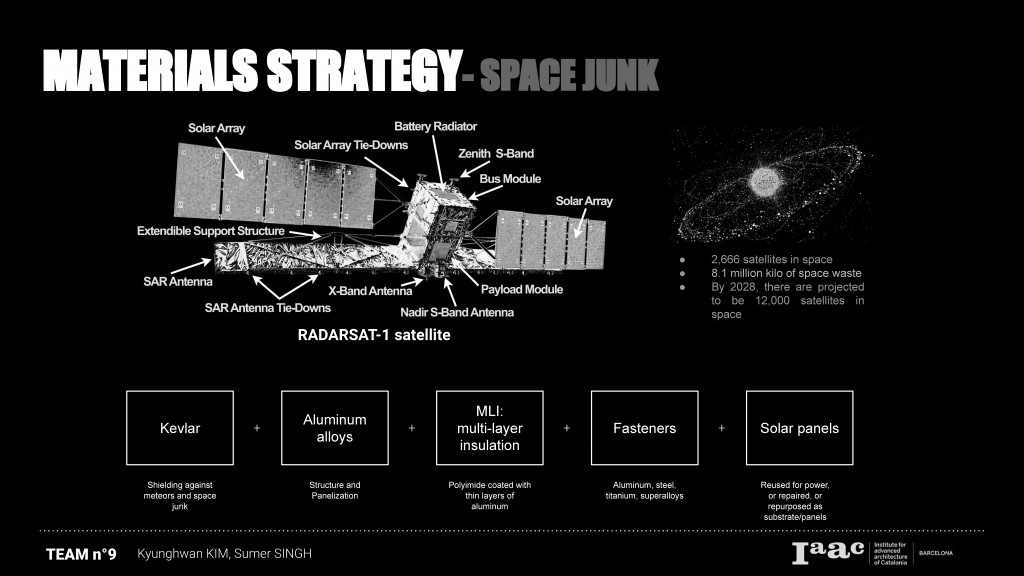

Space junk is a growing issue that is a threat at many levels. There are currently over 2000 satellites in space and by 2028 there will be over 12,000. The materials available are suitable for use in space and can be repurposed or recycled at the space factory on the moon.

Space junk is a growing issue that is a threat at many levels. There are currently over 2000 satellites in space and by 2028 there will be over 12,000. The materials available are suitable for use in space and can be repurposed or recycled at the space factory on the moon.

Regolith is a good material because it is in-situ material but also, good for protection against radiations if it has a certain thickness. Polyethylene is a very effective material for radiation protection with a small quantity.

Regolith is a good material because it is in-situ material but also, good for protection against radiations if it has a certain thickness. Polyethylene is a very effective material for radiation protection with a small quantity.

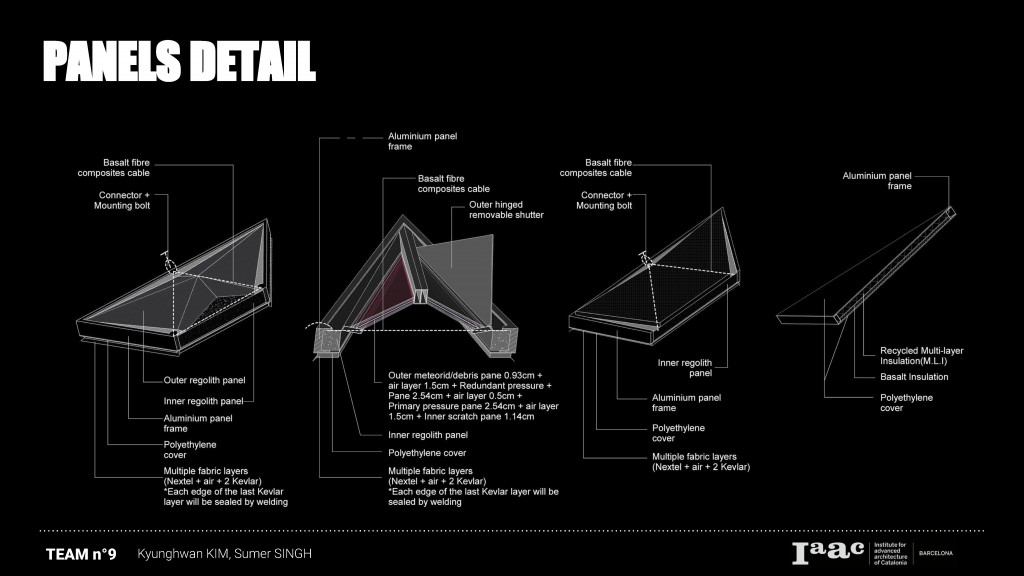

Each panel has a basalt fiber composites cables between 2 layers of regolith panels. Every fiber composites cables are linked together. This can be successfully used in compression and bending active structures as well as in tension active structures. Basalt based materials are environmentally friendly and no hazardous against pure lunar regolith. The fiber extruder will build to draw 30km of 30um diameter fiber from the reservoir, metal coat it with calcium and wind around a collecting reel. It may use 75kW thermal solar concentration. Tensile test on a 25um fibre indicated approximate strength of 5000kg/cm2 which is equal 70,000 psi. The regolith panels are fixed by panel aluminum frames which is covered by polyethylene at the bottom. Then in side there are Nextel for thermal protection and Kevlar for the protection against micrometeorites.

Each panel has a basalt fiber composites cables between 2 layers of regolith panels. Every fiber composites cables are linked together. This can be successfully used in compression and bending active structures as well as in tension active structures. Basalt based materials are environmentally friendly and no hazardous against pure lunar regolith. The fiber extruder will build to draw 30km of 30um diameter fiber from the reservoir, metal coat it with calcium and wind around a collecting reel. It may use 75kW thermal solar concentration. Tensile test on a 25um fibre indicated approximate strength of 5000kg/cm2 which is equal 70,000 psi. The regolith panels are fixed by panel aluminum frames which is covered by polyethylene at the bottom. Then in side there are Nextel for thermal protection and Kevlar for the protection against micrometeorites.

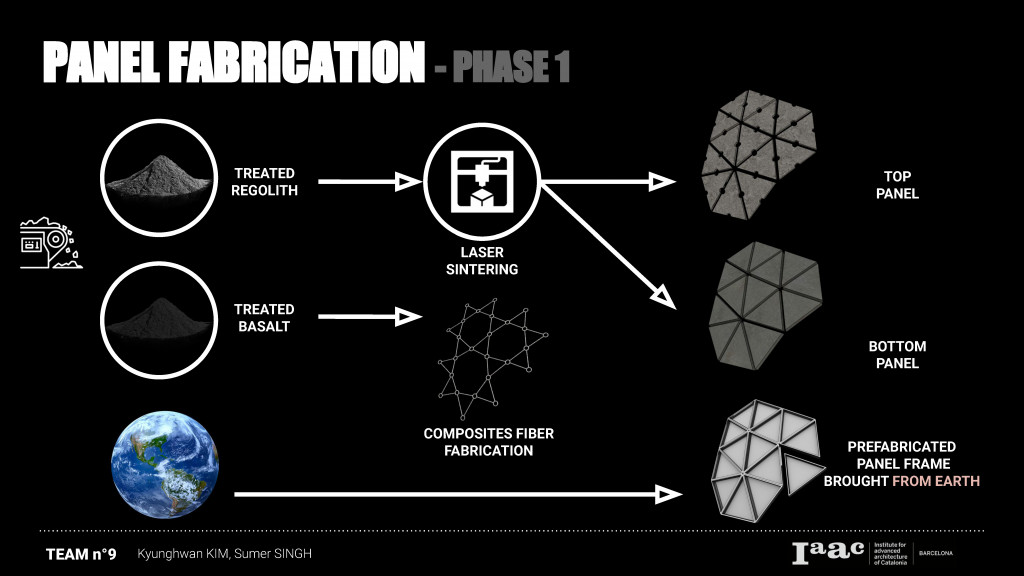

For the 1st phase, we bring fabricated panels from the Earth except regolith panels.

For the 1st phase, we bring fabricated panels from the Earth except regolith panels.

Then, at the second and third phase, we may have a capacity to produce more materials for panel parts by using space junks. Especially, composites fiber fabrication capacity in our fab-lab would improve the structural stability of the building.

Then, at the second and third phase, we may have a capacity to produce more materials for panel parts by using space junks. Especially, composites fiber fabrication capacity in our fab-lab would improve the structural stability of the building.

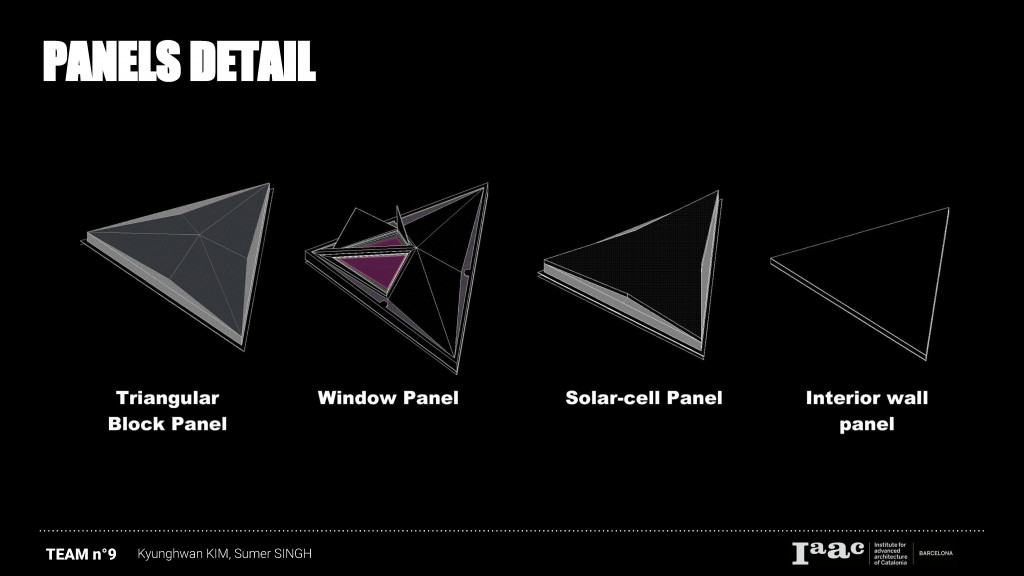

As you can see at the image above, the L.F.L.C has a simple dome geometry because of supporting inner air pressure in the low gravity (1/6 of Earth). The inner air pressure is 14.7 psi because, if it is too low like a skylab or sâce shuttle, it has an advantage of less inner force and it takes less time to depressurize for crews when we go outside. Inner fabric material of Kevlar can be welded to keep inner air pressure. For the outer shell, we have 3 different panels for the outer wall of the dome. The three triangle panels are below ;

- Solar panel : Electricity for self-sustainable architecture

- Regolith block panel : Reduce space radiation (SPE, GCR)

- Glass Panel : Giving an opportunity to observe outside not only for the security reason but also, for the psychological comfort. However, not too many windows because of radiation. Each window will have attachable aluminum shutters.

Instead of having big concrete foundation which is ineffective and can be risky, we choose a anchoring system to fix the dome.Furthermore, the weight of regolith panels would add self-weight of building to fix on the low gravity environment

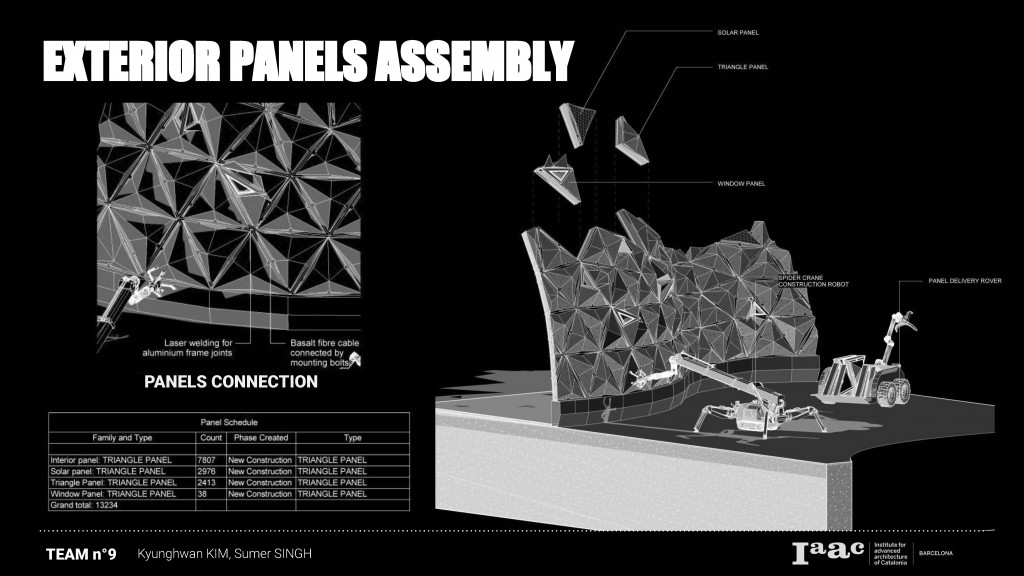

Here are 3 types of outer panels and one type of panel for interior space separation.

Here are 3 types of outer panels and one type of panel for interior space separation.

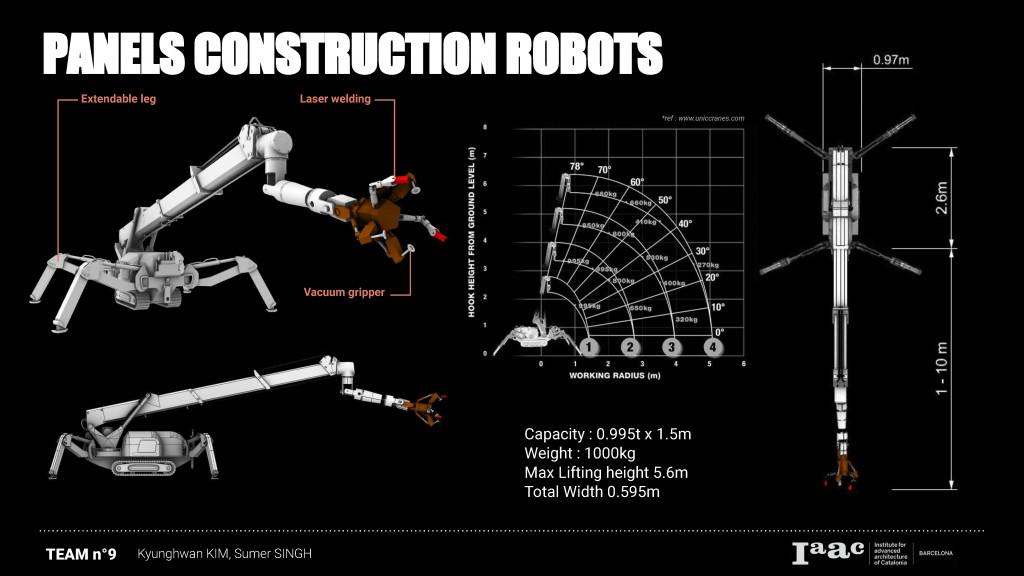

To assemble panels, a system of spider crane on the earth is used because of its high capacity and transportability although its small size.

To assemble panels, a system of spider crane on the earth is used because of its high capacity and transportability although its small size.

But also, there are 4 more different types of robots for construction.

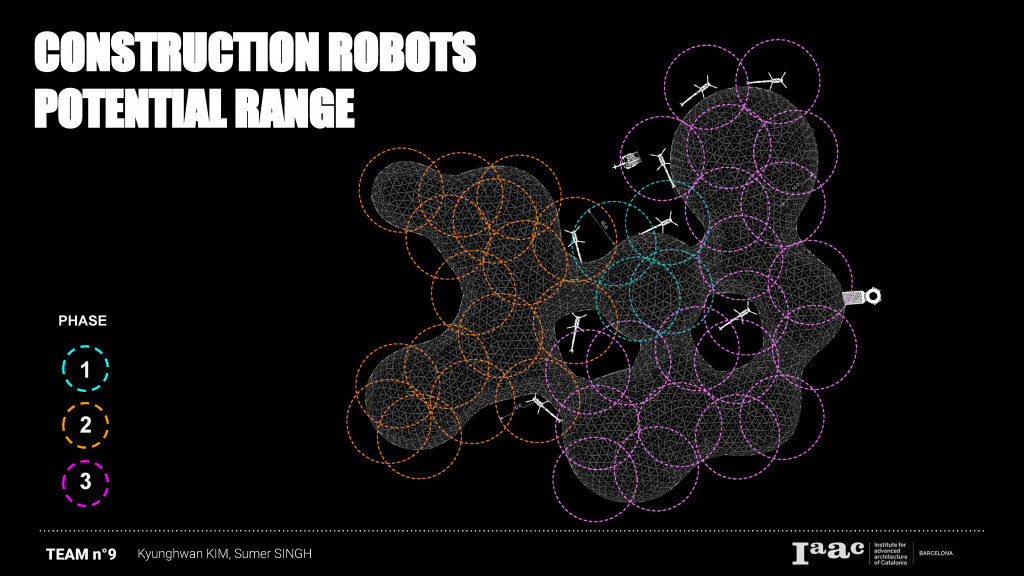

But also, there are 4 more different types of robots for construction.  The spider crane rover has a capacity of 10m of radius to reach its arm from his body. So it has to move several times in order to reach out every points for assembly.

The spider crane rover has a capacity of 10m of radius to reach its arm from his body. So it has to move several times in order to reach out every points for assembly. Construction sequence : 1. Surface landing

2. Autonomous rovers & robots travel

3. The rovers & robots are positioned to start construction.

4. Leveling ground rover are working to make a flat terrain.

5. Sintering the surface of the flat terrain by the rovers

6-7. Crews of 4 members arrive from the Earth and deploy solar panels and settle down a temporary factory and habitat. Then, spider crane rover is start to assemble fabricated regolith base wall.

8. Solar panels assembly

9-10. The one dome for Lunar Fab-lab is operated to fabricate construction materials by using space junks. Phase 2 constrcution starts.

11-14. Airlock connected with the center dome. The phase 3 construction starts.

15. Airlocks connected with Convention center and offices.

16. Cover up airlocks by panels and detach airlocks.

17. Visiting people from earth and neighbor modules.

The base walls under the panels are fixed by fiber reinforced metallic bars and anchors. Base floor has also rubber bearing to absorb vibration from the Moon quake.

The base walls under the panels are fixed by fiber reinforced metallic bars and anchors. Base floor has also rubber bearing to absorb vibration from the Moon quake.

For 3 phases, there are 5427 panels are used for outside shell and 7807 panels for interior walls.

For 3 phases, there are 5427 panels are used for outside shell and 7807 panels for interior walls.

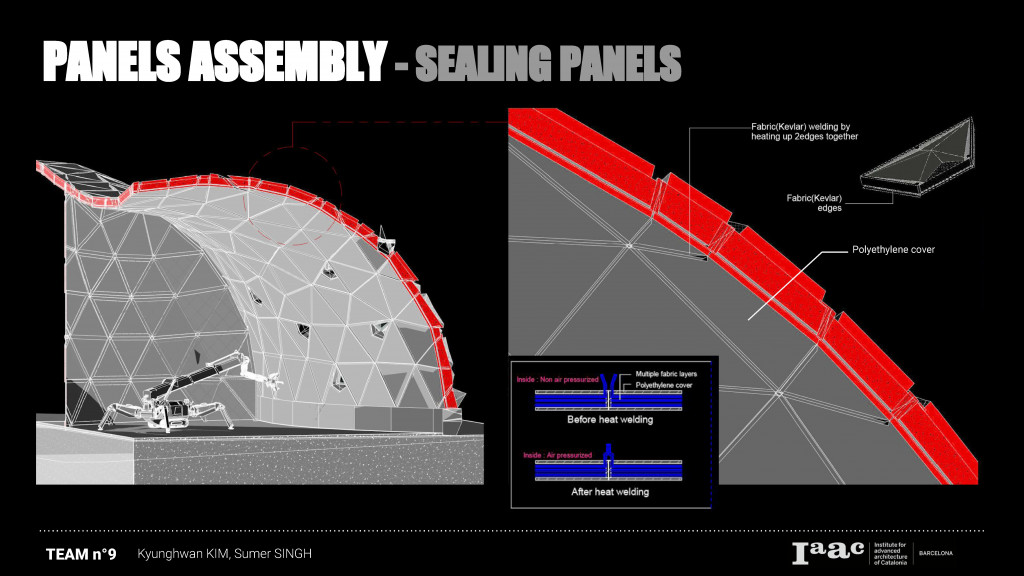

The inside of outer shell panels have a finishing material of Kevlar fabric and they are welded by heat. This allow us to keep the air pressure without leaking outside.

The inside of outer shell panels have a finishing material of Kevlar fabric and they are welded by heat. This allow us to keep the air pressure without leaking outside.

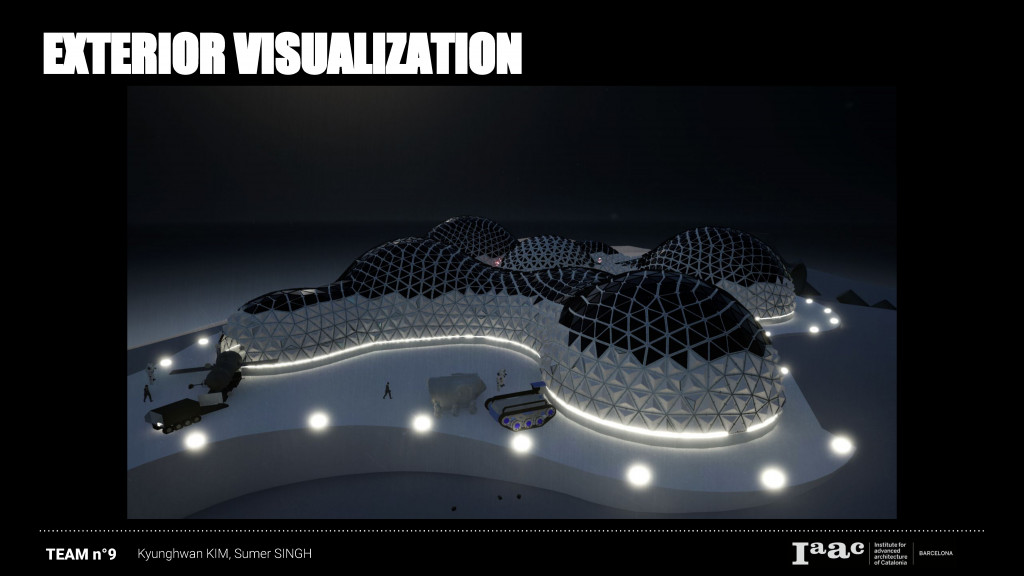

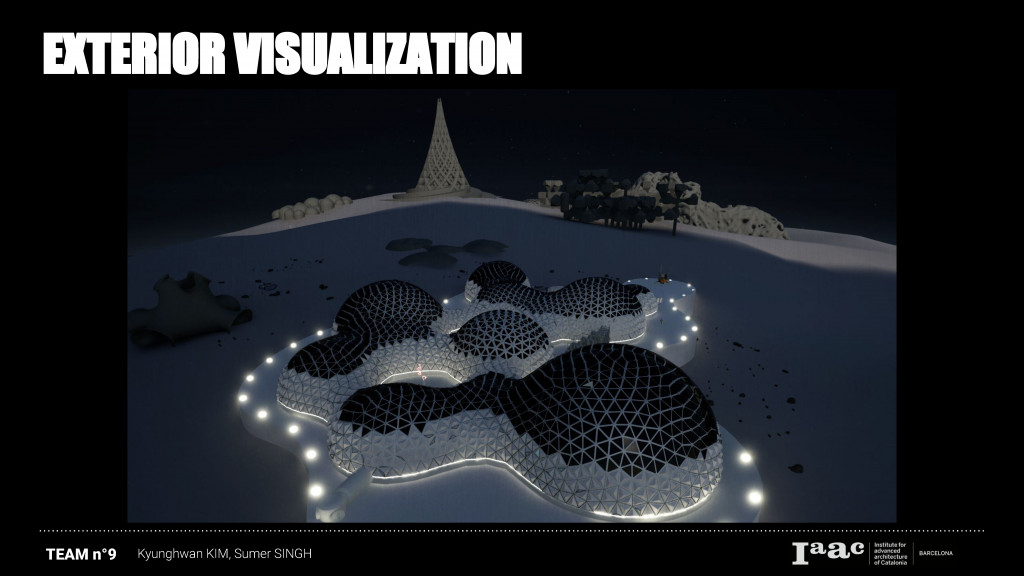

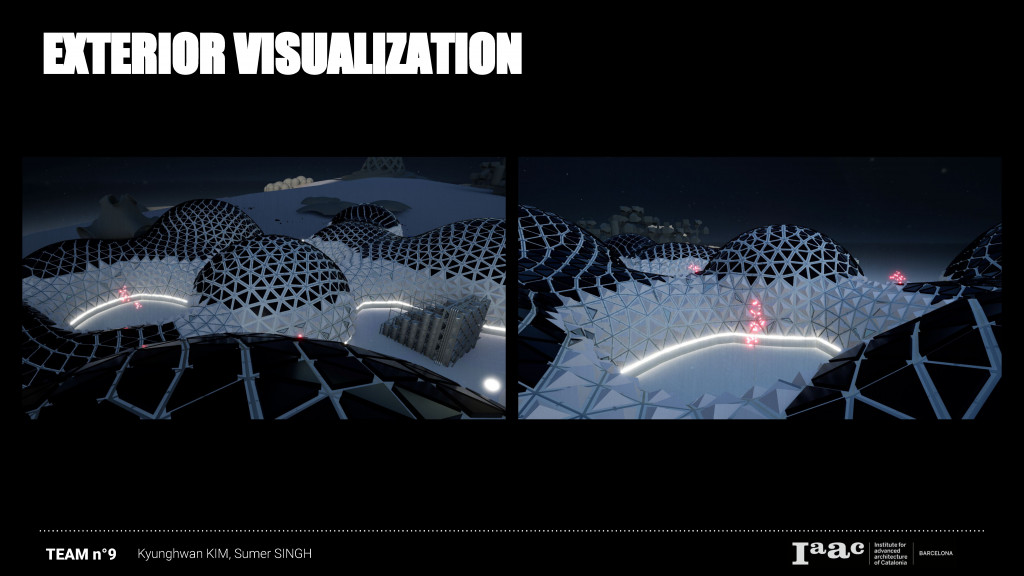

These are rendered views showing the contrast between the various types of panels on the building. The loading area for the sorting facility can be seen to the left with a satellite waiting to be loaded. To the right we can see the garage and repair facility.

These are rendered views showing the contrast between the various types of panels on the building. The loading area for the sorting facility can be seen to the left with a satellite waiting to be loaded. To the right we can see the garage and repair facility.

A view of the building with the rest of the colony in the background

A view of the building with the rest of the colony in the background

Detailed close-ups of the panels.

Detailed close-ups of the panels.

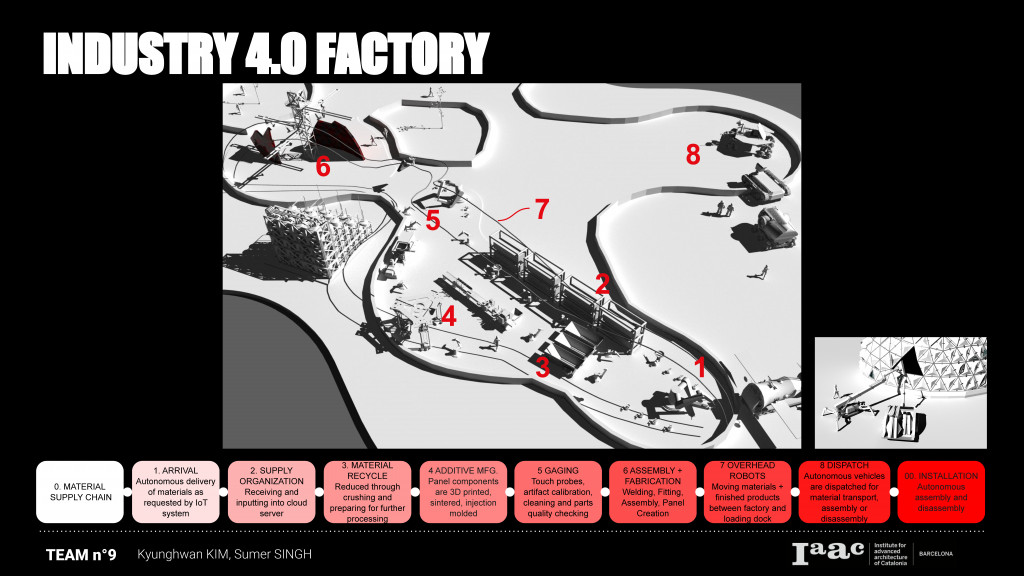

This is the view of the lunar factory where the material flow can be observed as it arrives at the factory to getting fabricated and assembled, and then finally departing the factory to be installed on site. The semi-automated factory utilizes the principles of Industry 4.0.

This is the view of the lunar factory where the material flow can be observed as it arrives at the factory to getting fabricated and assembled, and then finally departing the factory to be installed on site. The semi-automated factory utilizes the principles of Industry 4.0.

3_Factory produces panels based on digital twin on cloud server

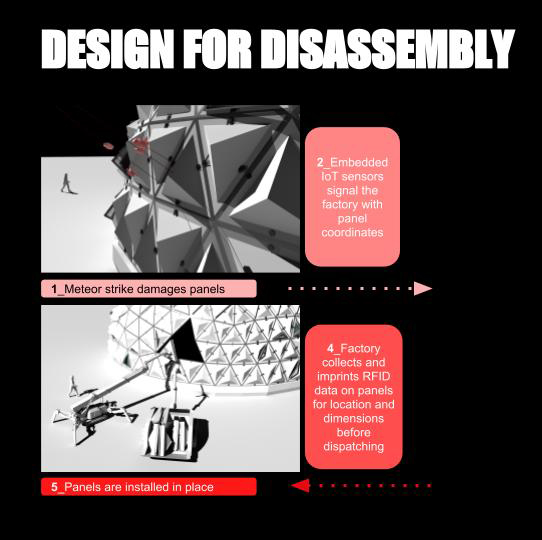

One of the concepts being established by the Industry 4.0 factory is Design for Disassembly. This slide gives an example of meteors striking the panels on the facade, which would send a signal to the factory through the embedded IoT sensors, which would prompt the factory to reproduce those particular panels by using a digital twin model, after which the panels would be dispatched to site to replace the damaged panels immediately.

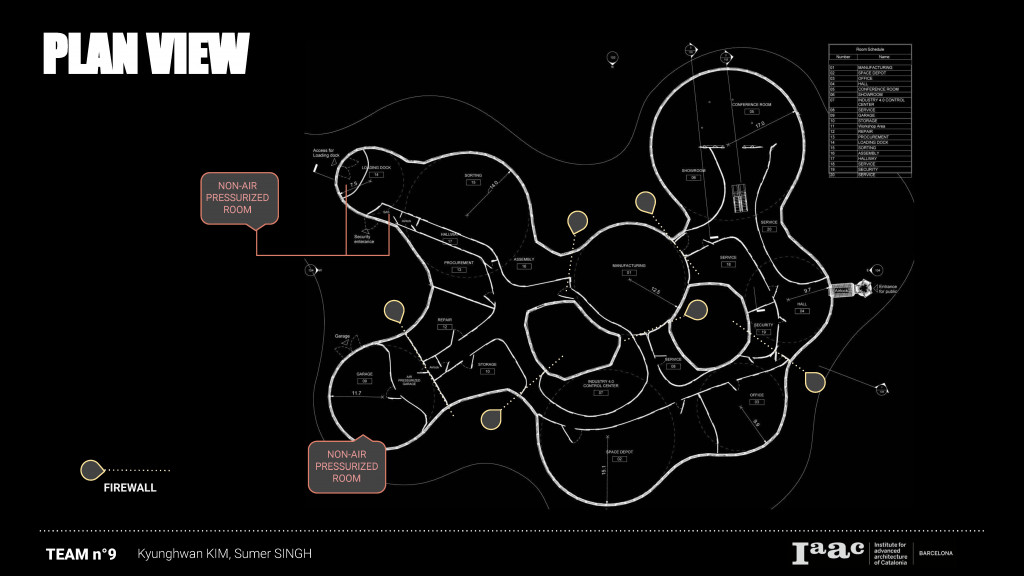

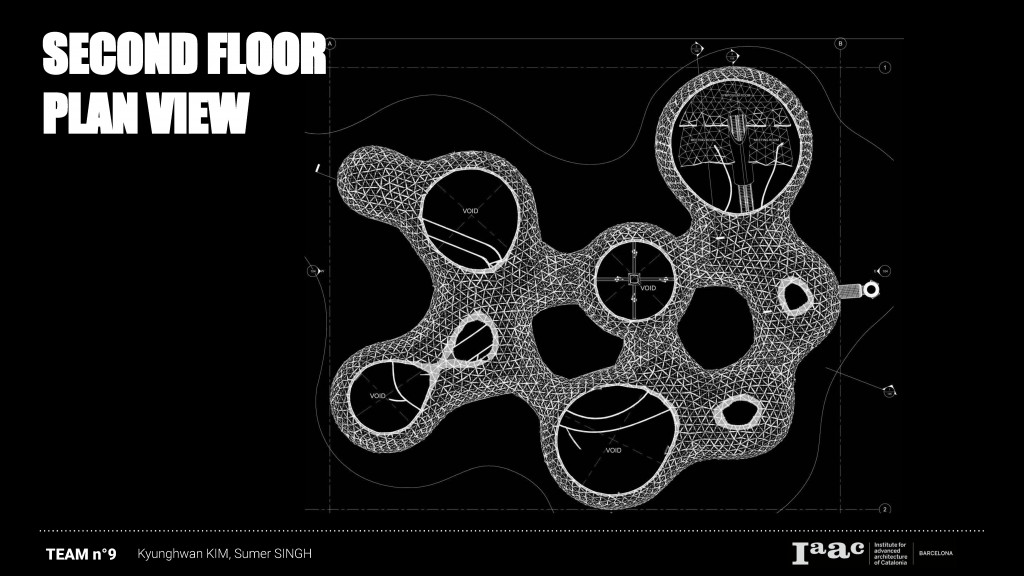

The floor plan shows the various programs in the building and a special emphasis is on the distinction between the pressurized and non-pressurized rooms. The only portion of the building that has a second floor is the convention hall where the conference room, showroom, symposium area, and meeting rooms are located.

The floor plan shows the various programs in the building and a special emphasis is on the distinction between the pressurized and non-pressurized rooms. The only portion of the building that has a second floor is the convention hall where the conference room, showroom, symposium area, and meeting rooms are located.

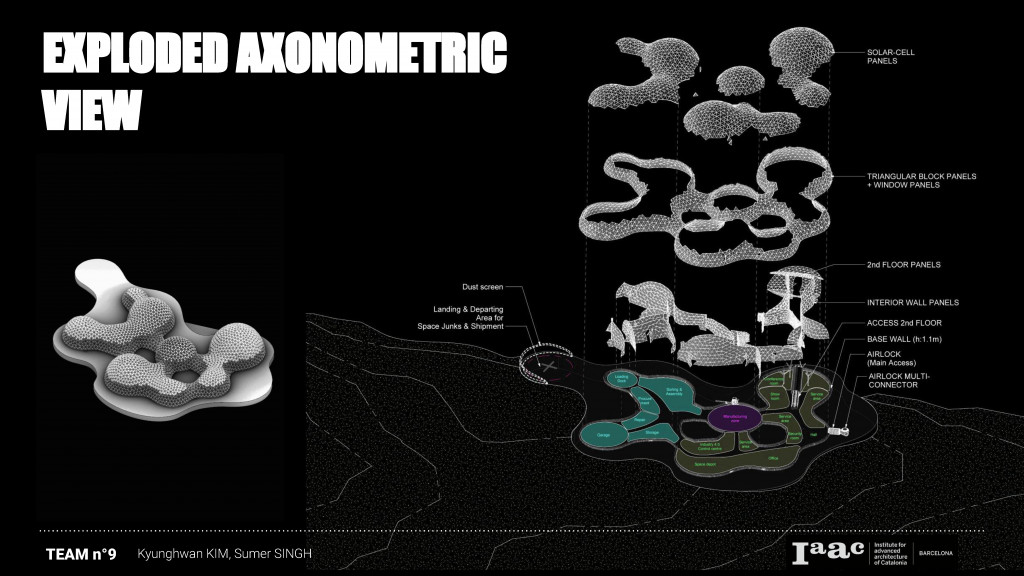

The exploded axonometric view displays the interaction between the various layers of panels that make up the building, and also how they relate to the floor planning and the interior walls.

The exploded axonometric view displays the interaction between the various layers of panels that make up the building, and also how they relate to the floor planning and the interior walls.

The sections display the continuity and relationship between the spaces where the circulation flows from one program to the other. This is in line with the idea of material flow that is representative of the program of the building. The inspiration is drawn from the Endless House.

The sections display the continuity and relationship between the spaces where the circulation flows from one program to the other. This is in line with the idea of material flow that is representative of the program of the building. The inspiration is drawn from the Endless House.

This image shows the showroom to the left, located in the Business Center, where colony inhabitants can stop by to view and specify the products that they can use for their purposes. Another purpose is for visitors from other space stations to be able to see the products in person as well. The elevators lead up the conference hall.

This image shows the showroom to the left, located in the Business Center, where colony inhabitants can stop by to view and specify the products that they can use for their purposes. Another purpose is for visitors from other space stations to be able to see the products in person as well. The elevators lead up the conference hall.

The Factory Sorting center is where the material is crushed and repurposed/reused to create the various layer compositions for the panels produced in the building.

The Factory Sorting center is where the material is crushed and repurposed/reused to create the various layer compositions for the panels produced in the building.

| VIDEO

Click ‘HERE’ to play and control

Blog for the web visualization : Link

Students: KIM Kyunghwan, Sumer Singh.

Lead faculty: David Andres Leon

Faculty assistant: Oana Taut