Light [ air ] Designing a cavity for light paths

Introduction

Light is an important design element in architecture. It can bring out poetic experiences, while also being a practical tool. It allows us to see, work and live inside the architecture we inhabit. When designing to capture natural light from the sun, eliminating heat gain and glare becomes essential. This usually happens at the openings of a building.

When creating openings in 3d printed clay walls, challenges related to printability arise. This is because 3D printing with clay favours shapes that contain a lot of mass. Such forms increase compression and therefore stability of clay printed geometries. The structural goal in 3D printing with clay, is to reduce or eliminate tension forces associated with overhanging . Additionally, to design openings for performance that respond to light; shape, scale, and orientation become an important aspect to consider. They determine the quality and quantity of light beyond wall openings. They also influence the quality of shade and air movement, which can provide relief from direct sunlight.

Our research therefore asks: How can we 3D print clay to create lightness with illuminance in architecture to have performative qualities according to a given climate?

State of the art

References of the state of the art, inform the research through an evaluation of Performance – Climate – and Light in architecture; namely Cloaked in bricks, Iran; where parametrised rotation is used to create privacy and gradients of direct and diffuse light; and the Jaali, India, that has an opening to depth ratio that cools and increases the velocity of air forced through the small opening perforations.

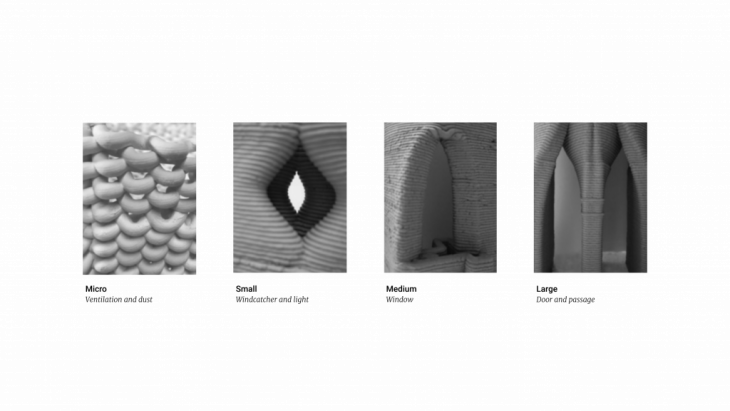

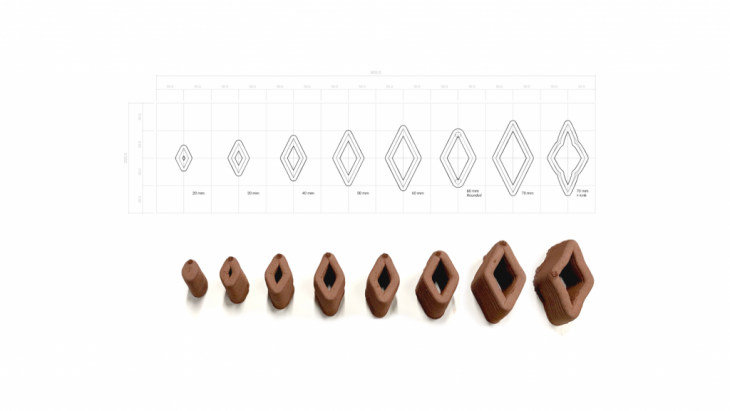

Opening scales

Considering opening sizes of various scales, the small scale is selected as a suitable focus for response to light and air.

Methodology

The research methodology makes use of digital simulation and physical printing, which are tests for stability and printability in clay. This process reveals stable geometries which become the basis for creating small scale openings that will respond to direct and diffuse light. The stable geometries are then analysed within an experimental setup to evaluate light quality.

Printability tests

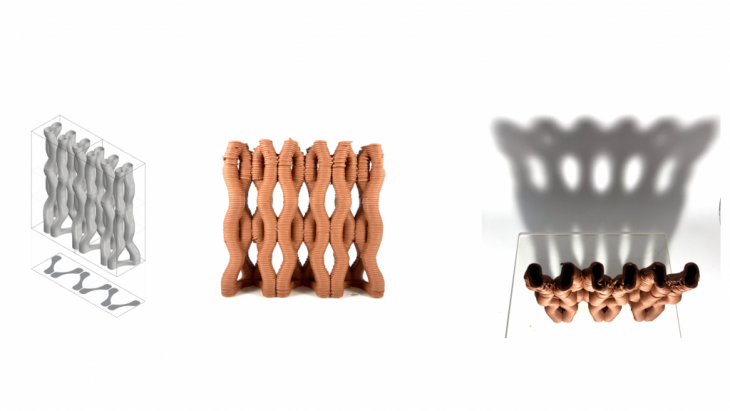

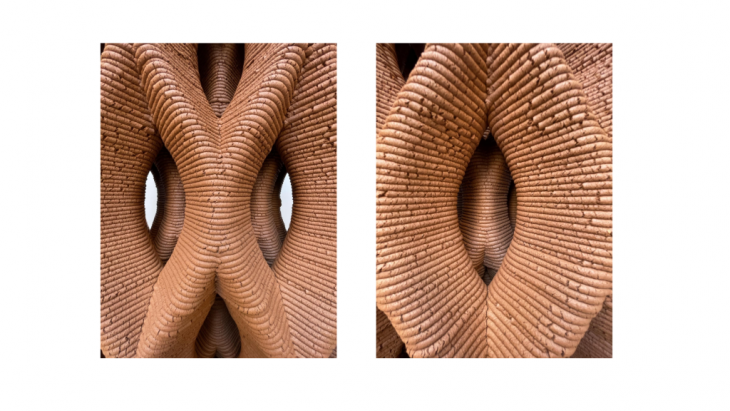

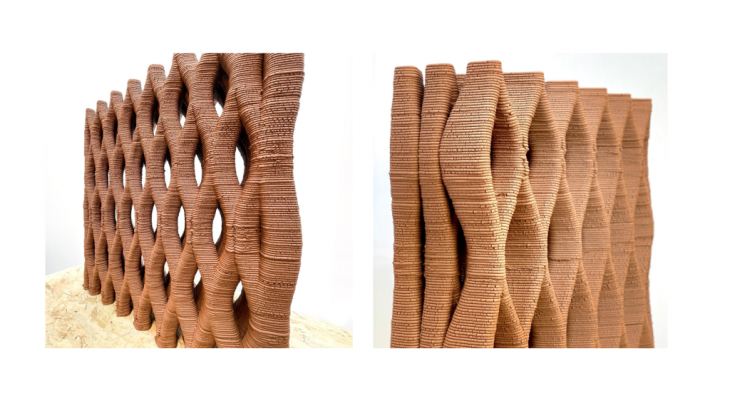

Printability tests reveal that creating openings within thin layer surfaces introduces failure due to local inertia. Individual column like elements which maximise compression perform better structurally and have a better quality of print. These become the basis for the creation of openings.

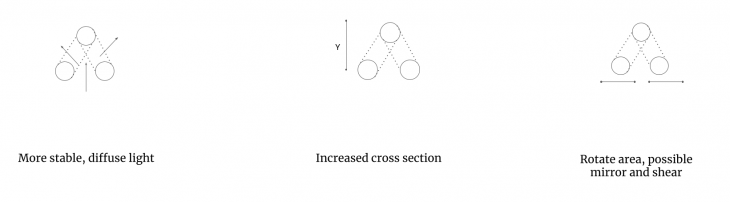

Structural parameters for opening geometries.

A system for optimising the physical characteristics of the column element is developed to create geometries that can allow in more light. The slenderness, cantilever in X and Y directions and amount of material connection are iterated on to establish geometries that have structural stability with properties that will allow in more light.

Parameters are established to optimise the geometry further to respond to light

Experimental Setup for evaluating light quality

Experimental Setup for evaluating light quality

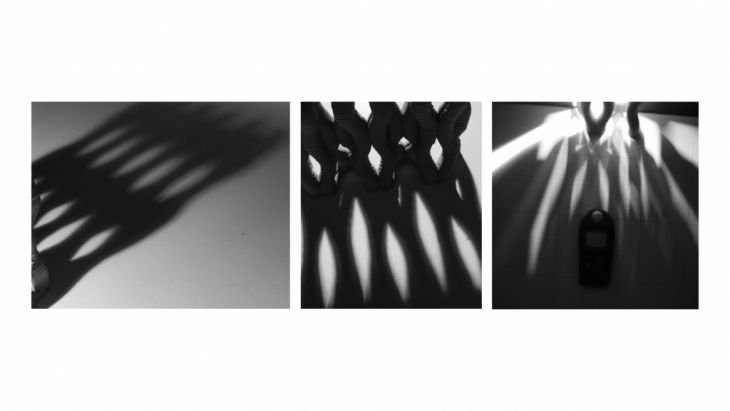

An experimental setup to evaluate the quality of light of the printed geometries is developed. The setup simulates different light angles from the sun as would be experienced in Barcelona in the summer and the winter. The light quality beyond the geometry is photographed and the shadow quality evaluated to understand whether diffused or direct light is being achieved by the geometry.

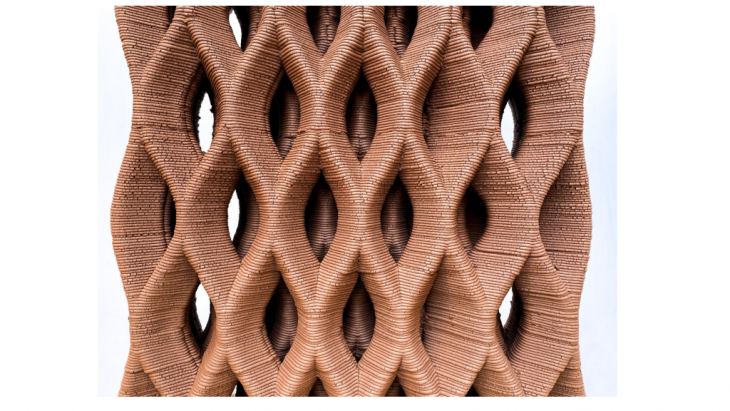

This informs the final form of the small scale geometry which has a dense cross section to maximise compression and structural stability, and an array of layered slender elements that allow in different qualities of light, depending on vantage point of view

This informs the final form of the small scale geometry which has a dense cross section to maximise compression and structural stability, and an array of layered slender elements that allow in different qualities of light, depending on vantage point of view

Optimising geometry for Direct light and diffuse light

The geometry is then optimised for light by establishing two explicit points, A and B that represent direct light and diffuse light. These serve as the basis for refining the cross-section geometry, rotation and layer count and spacing, to achieve opening geometries that respond very specifically to light. A consequence of this approach is that the geometry also demonstrates a privacy gradient in addition to letting in light and air.

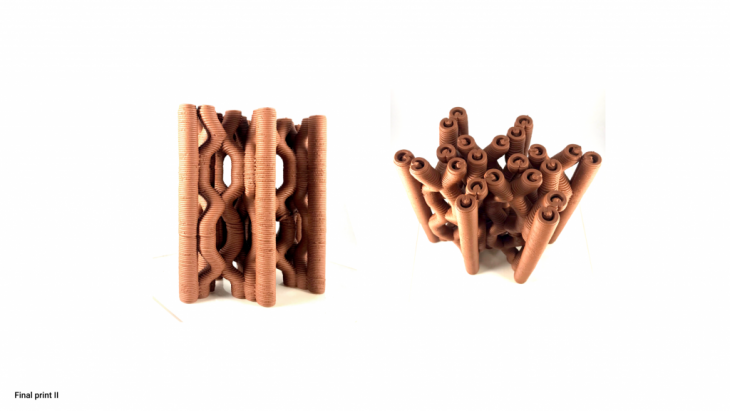

Optimising geometry for Prototype printing

Final prototype print

Light [ air ] is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Open Thesis Fabrication in 2020/2021 by Students: Luis Buerba | Lynette Masai | Tapiwa Mirirai Manase, Faculty: Edouard Cabay | Alexander Dubor | Kunaljit Chadha | Ashkan Foroughi Dehnavi