WATER DRIVEN-BREATHING SKIN

Hydromorph based | Responsive Material

[Introduction]

// Water-driven Breathing Skin – The urban breather

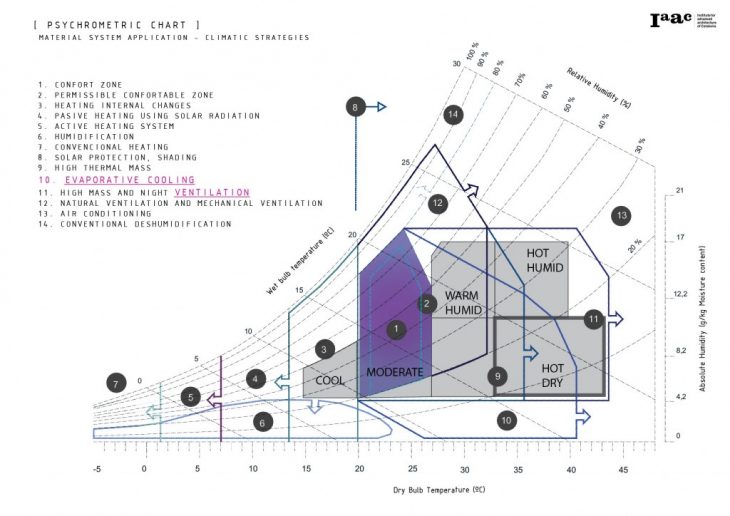

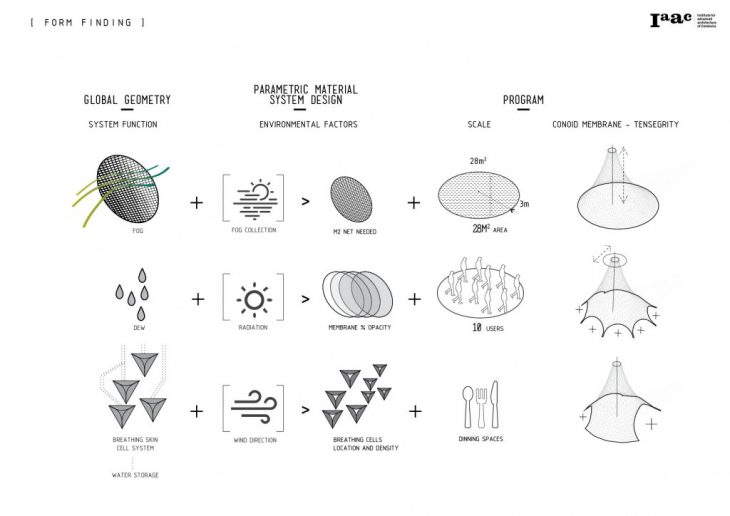

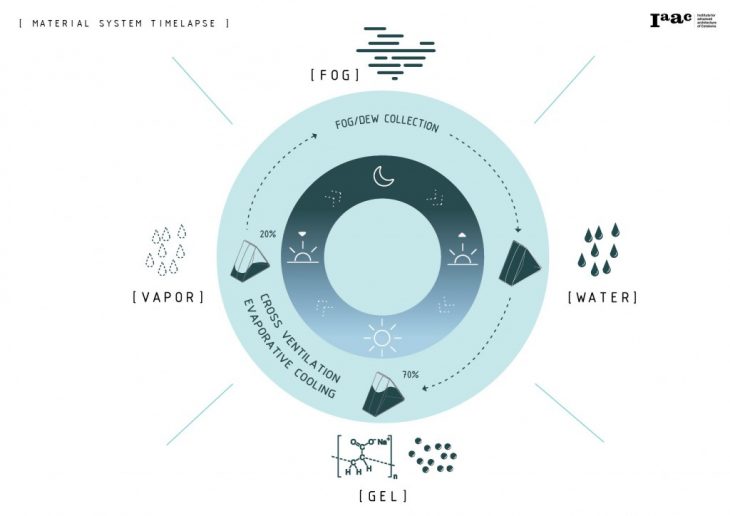

Homeostasis, the genesis of our research in smart materials, is the fundamental mechanism for organisms to maintain an equilibrium in physilogical variables that sustain lives.The question whether a smart material system can function as simply as organic activities leads us into the exploration of a series of materials that resembles such. Breathing, among all others, intrigues us in the sentiment that its resulting mechanism of open/close behavior that enables air exchange and regulation in body temperature resembles that of ventilation to achieve comfort in an enclosed area. This then is oriented to the objective of Water-driven Breathing Skin.

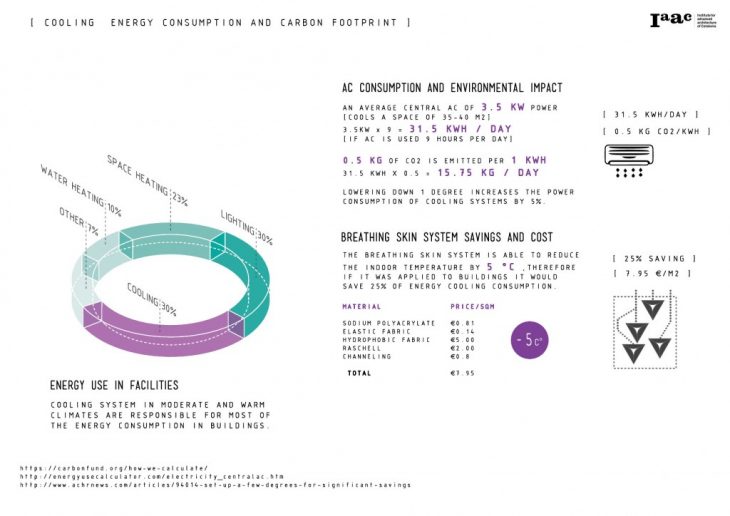

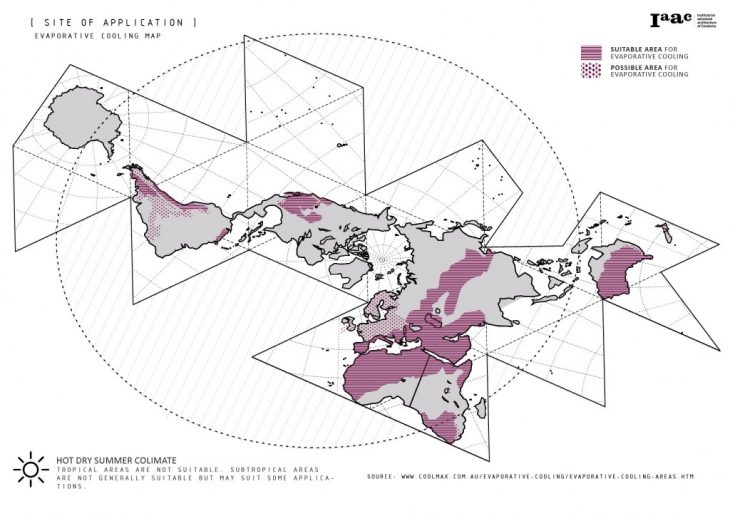

Sodium Polyacrylate, one of the superabsorbent polymers in the hydromorph family, is the major material for the skin system in the wake of the preliminary study for its high capacity of volume change when absorbing water up to 300 times of its volume in a short time span, and the effect of evaporative cooling as it prolongs the evaporation process . The study furthered into the tests of compositing and encapsulating with facilitating materials in understanding material behavior, which has concluded on the encapsulation of sodium polyacrylate with elastic fabrics, followed by a library of experiments in shapes, patterns and size in an attempt to optimize open/close mechanism to capacitate passive ventilation and cooling in hot and dry summer climates.

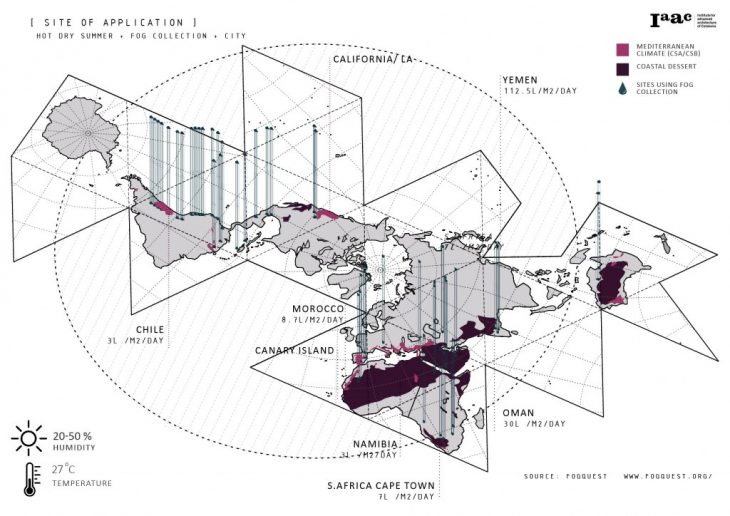

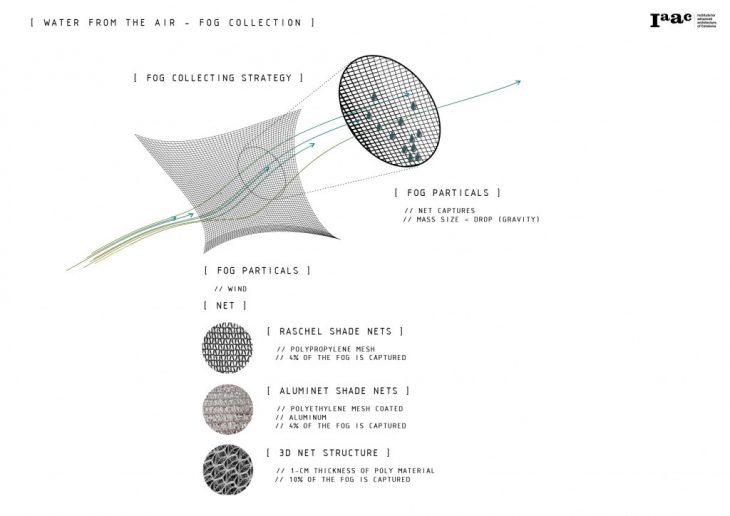

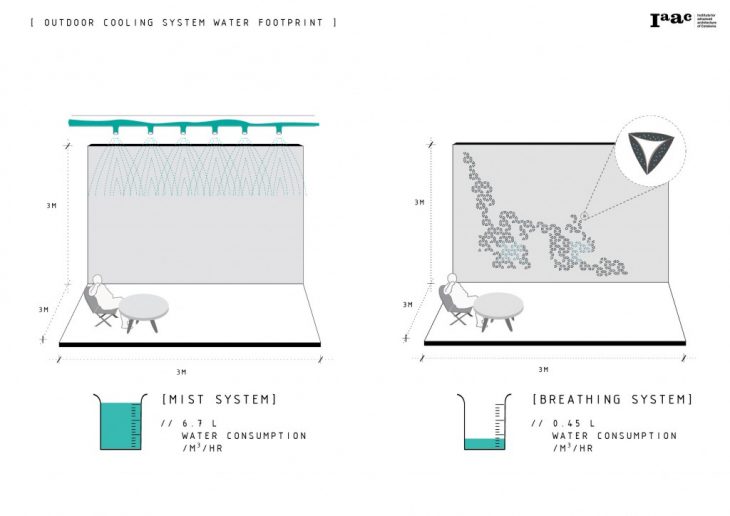

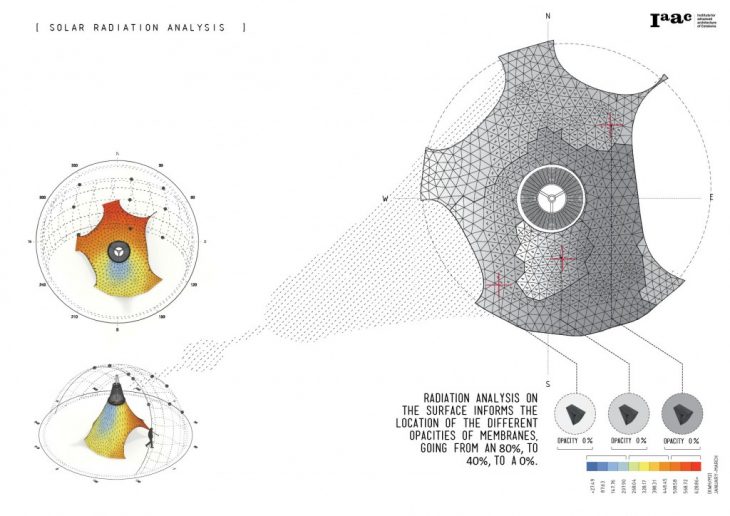

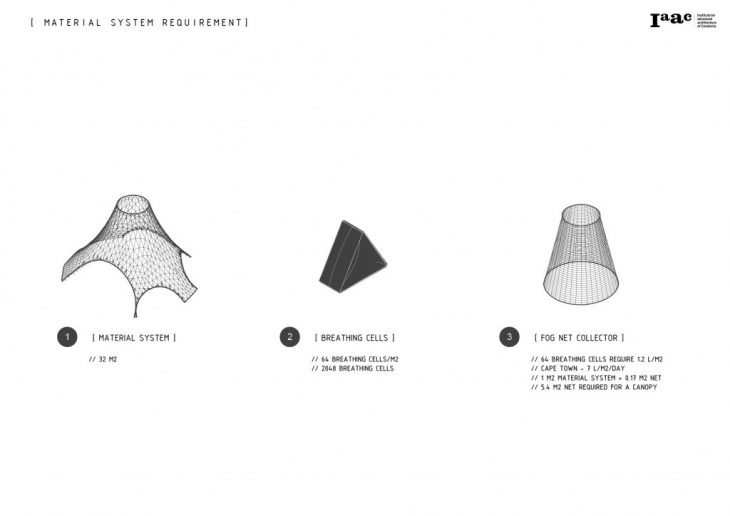

Additionally, taking into account the lack of water in targeted climates, the system design contemplated on the supply of water. Fog/dew collection is adopted as an established local intelligence and is a natural cyclical system requiring no further consumption, and is 15 times more water-efficient than that of a misting system commonly used.

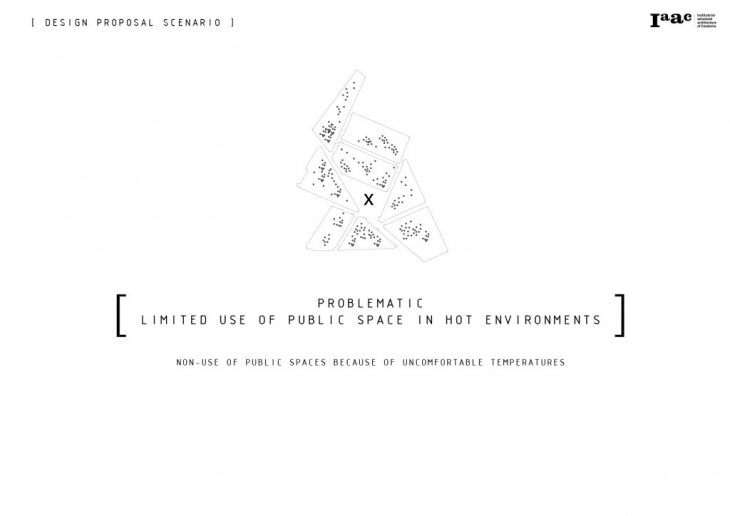

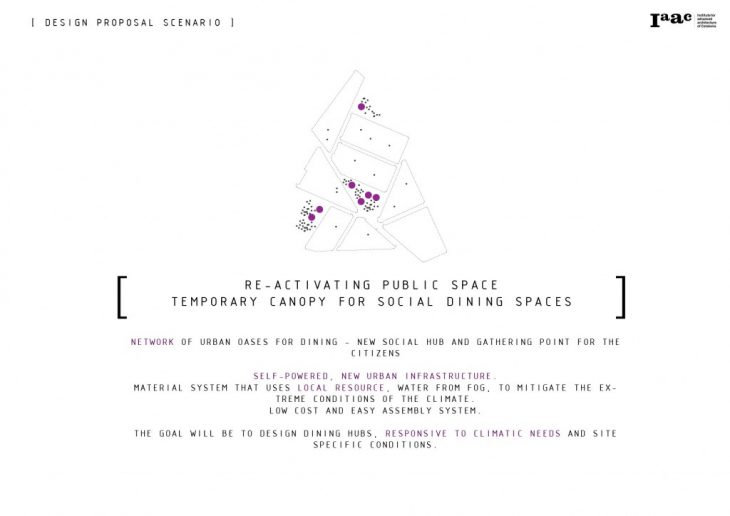

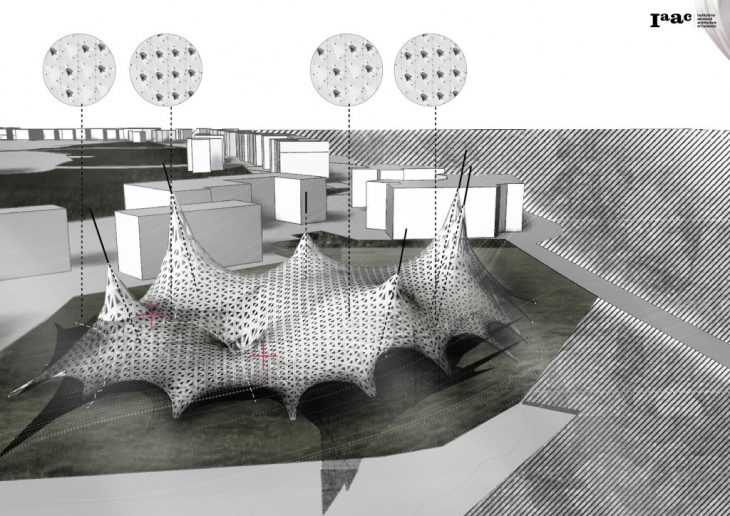

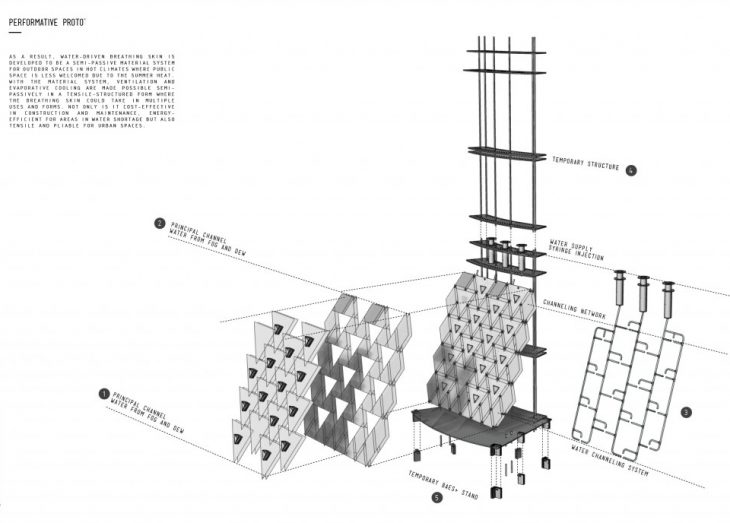

As a result, Water-driven Breathing Skin is developed to be a semi-passive material system for outdoor spaces in hot climates where public space is less welcomed due to the summer heat. With the material system, ventilation and evaporative cooling are made possible semi-passively in a tensile-structured form where the Breathing Skin could take in multiple uses and forms. Not only is it cost-effective in construction and maintenance, energy-efficient for areas in water shortage but also tensile and pliable for urban spaces.

[ Research Question ]

“CAN THE COMBINATION OF FABRICS AND SUPERABSORBENT POLYMERS CREATE A PASSIVE MATERIAL SYSTEM THAT FACILITATES VENTILATION AND TEMPERATURE CONTROL BASED ON AN OPEN/CLOSE BEHAVIOR IN RESPONSE TO ATMOSPHERIC INPUTS? AND CAN THIS MATERIAL SYSTEM BE APPLIED TO TEMPORARY CANOPIES THAT CREATE INDOOR COMFORT, ACTIVATING PUBLIC SPACES, IN HOT CLIMATES? “

[ Research Achievement ]

” THE PROJECT OBJECTIVE IS TO CREATE A BREATHING SKIN MATERIAL SYSTEM THAT PERFORMS OPEN-CLOSE BEHAVIOR TO FACILITATE PASSIVE VENTILATION AND COOLING EFFECT FOR OUTDOOR SPACES.”

[ Material exploration ]

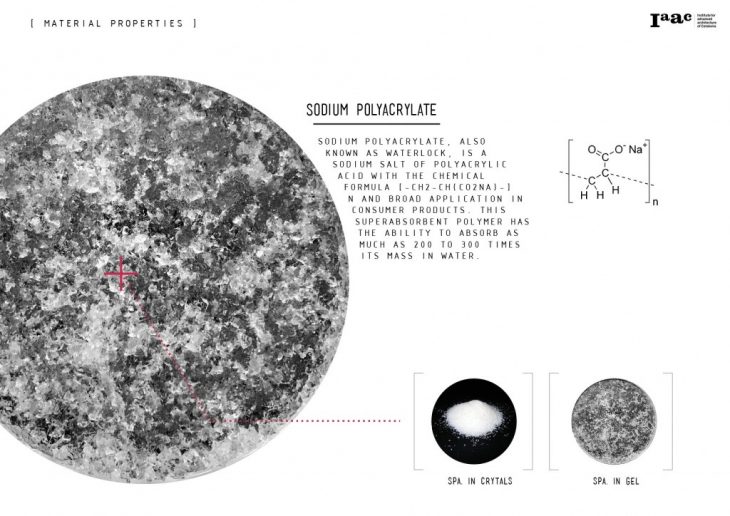

// Sodium Polyacrylate

Sodium polyacrylate, also known as waterlock, is a sodium salt of polyacrylic acid with the chemical formula [-CH2-CH(CO2Na)-]n and broad application in consumer products. This superabsorbent polymer has the ability to absorb as much as 200 to 300 times its mass in water.

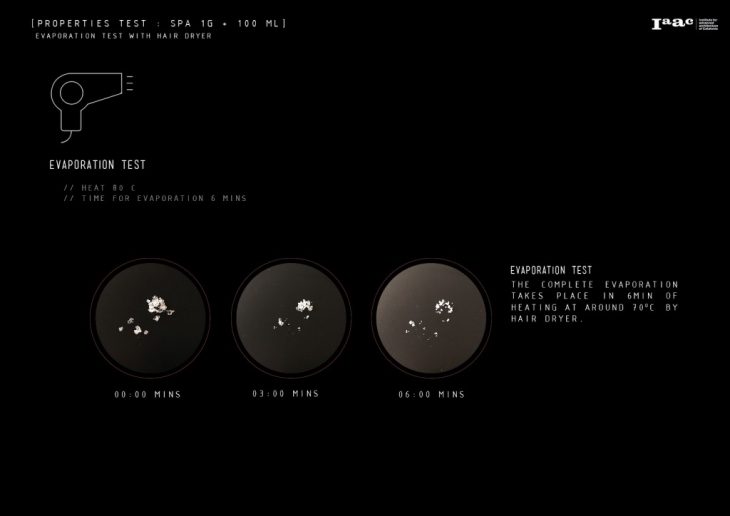

[Material Properties Test]

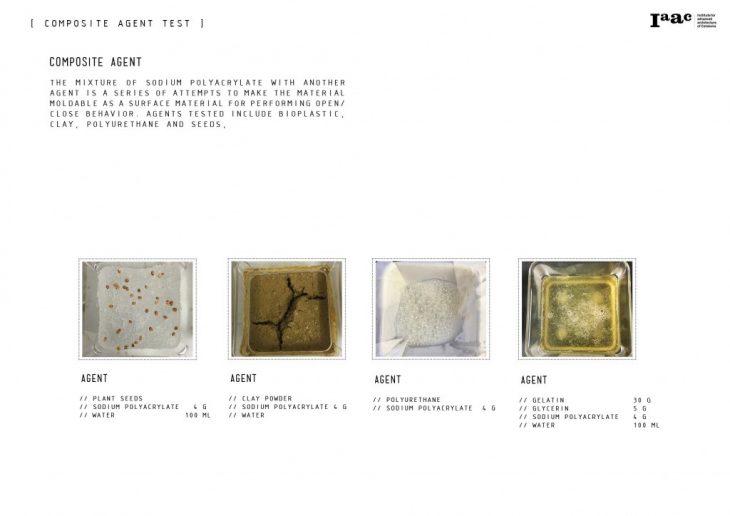

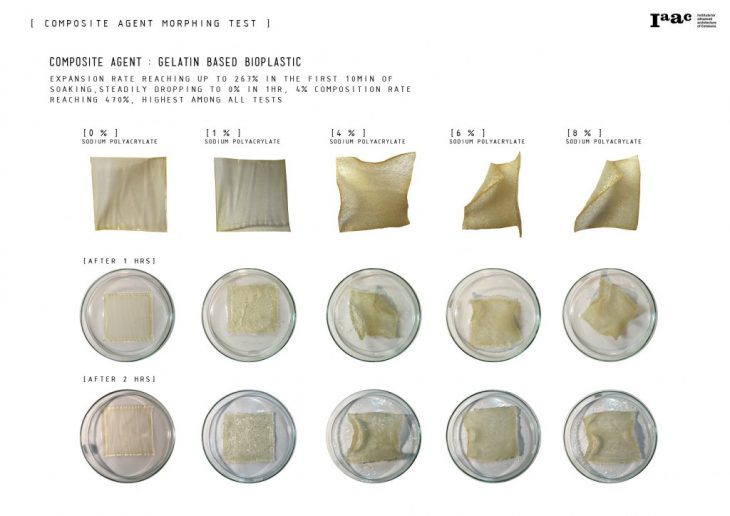

//Composite Agent

The mixture of sodium polyacrylate with another agent is a series of attempts to make the material moldable as a surface material for performing open/close behavior. Agents tested include bioplastic, clay, polyurethane and seeds, in which only bioplastic shows an effective result in coaptation to form a composite at various composition of sodium polyacrylate, while the rest have shown a low level of coaptation. This test results then directs the next test to the patterns of bioplastic composite on elastic fabric.

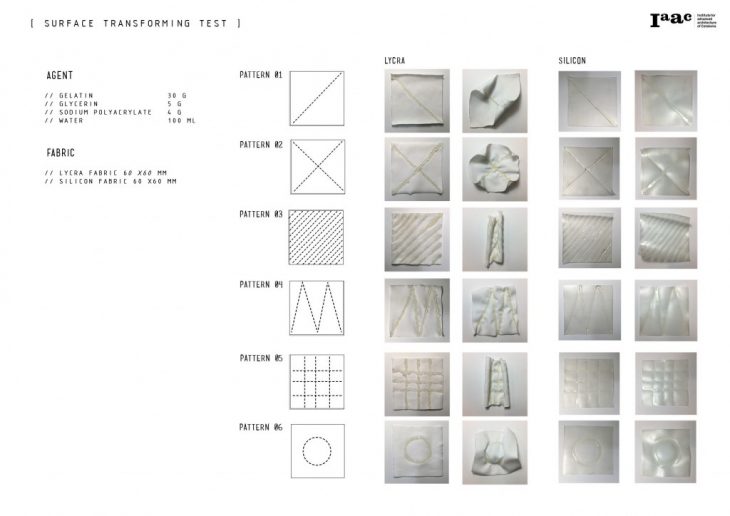

[Surface Transforming ]

//Lycra

Bioplastic-sodium polyacrylate composite is applied to lycra fabric to test how different patterns and composition of sodium polyacrylate could generate different levels of curling effect that simulates open/close behavior. The composite has good attachment to the fabric and the curling effect which closes the fabric is most significant in the end of the composite path. Therefore, diagonal patterns or similar one-direction pattern strengthens the closing behavior. Also, the higher the composition is, the better the curling effect is.

It is, nevertheless, a limiting factor that the composite tends to be breakable when constantly exposed to water and thus have lower reversibility. Additionally, without a constraining force, the control of curling behavior is limited and unpredictable. Therefore, the experiment advanced into encapsulation later on.

// Silicon

Bioplastic-sodium polyacrylate composite is applied to silicone sheet to test how different patterns and composition of sodium polyacrylate could generate different levels of curling effect that simulates open/close behavior. In comparison with test results for lycra, the composite needs to be in a even higher composition of sodium polyacrylate in order for better adhesion to the surface, and the curling effect is more homogeneous across the surface because of lower porosity of the silicone sheet property, which leads to a greater control of the closing effect. Also, the higher the composition is, the better the curling effect is

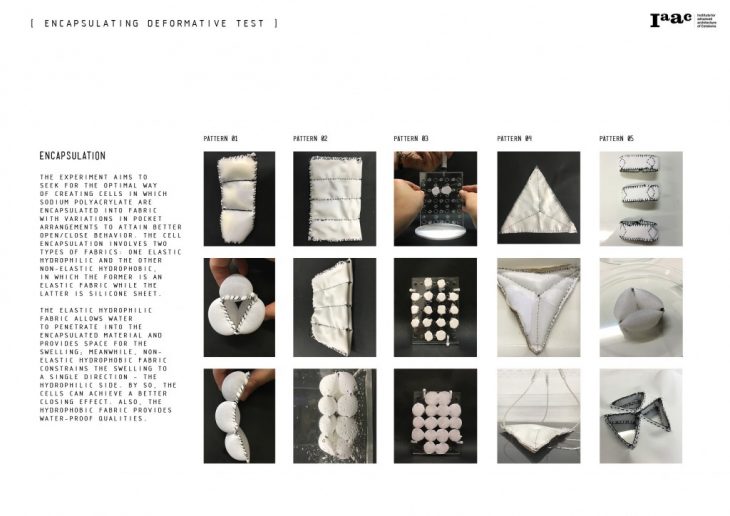

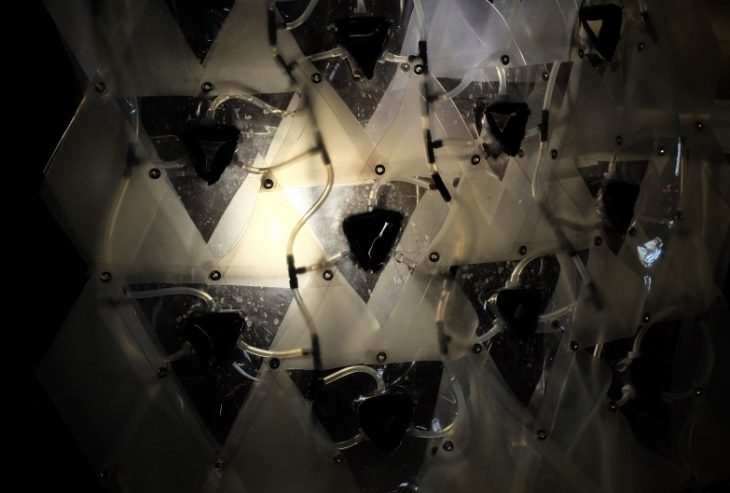

[Encapsulation Test]

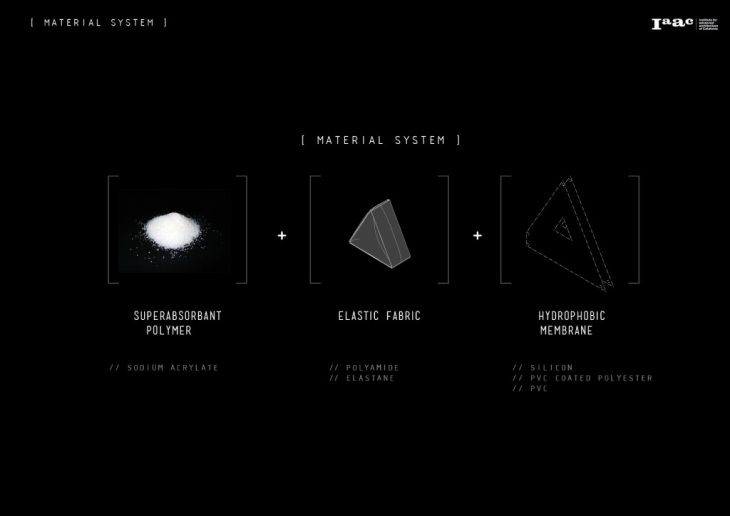

The experiment aims to seek for the optimal way of creating cells in which sodium polyacrylate are encapsulated into fabric with variations in pocket arrangements to attain better open/close behavior. The cell encapsulation involves two types of fabrics: one elastic hydrophilic and the other non-elastic hydrophobic, in this experiement the former is an elastic fabric while the latter is silicone sheet. The elastic hydrophilic fabric allows water to penetrate into the encapsulated material and provides space for the swelling; meanwhile, non-elastic hydrophobic fabric constrains the swelling to a single direction – the hydrophilic side. By so, the cells can achieve a better closing effect. Also, the hydrophobic fabric provides water-proof qualities.

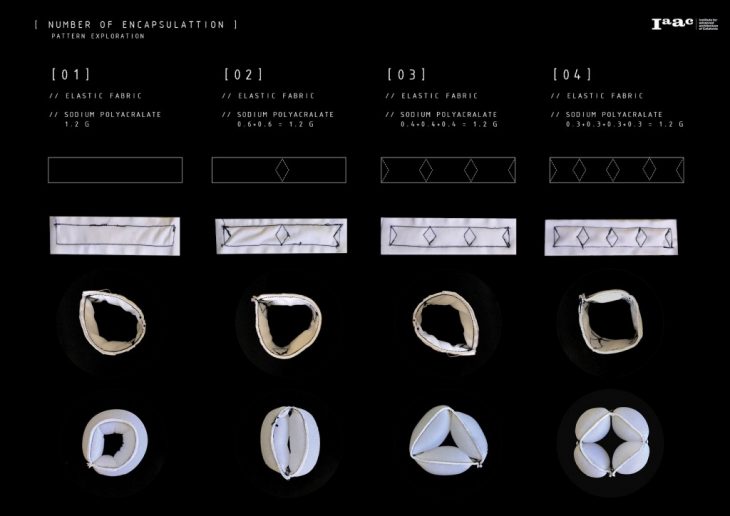

[Pattern exploration : Numer of spacing]

This test explores the relationship between the number of spacings with the firmness and effectiveness of closing behavior.

Conclusion is made that the design of three spacings per cell will provide the best closing effect.

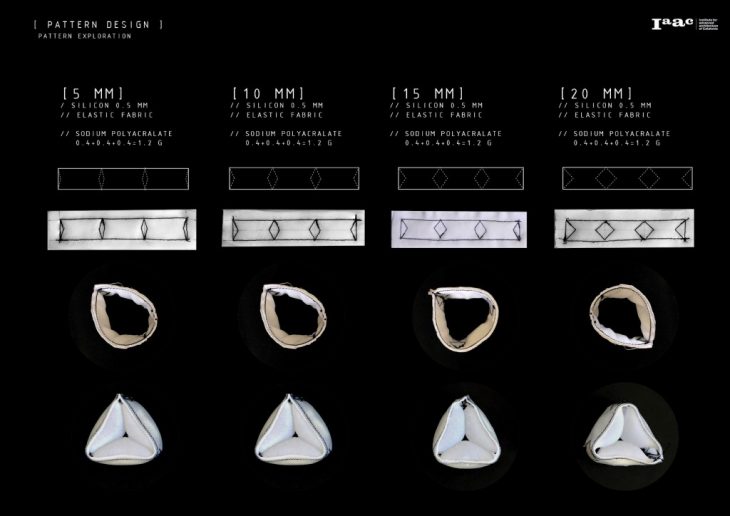

[Pattern exploration : Size of spacing]

After deciding that three-spacing design work the best for closing behavior, this test seeks for the optimal size of the spacing among the test of 5mm/10mm/15mm/20mm. Conclusion is made that the spacing of 15mm will create the firmest closing.

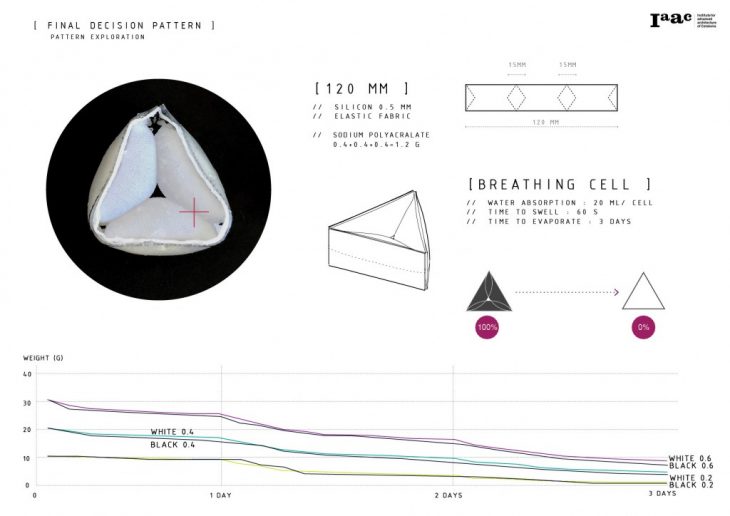

[Pattern exploration : Size of cell]

This test is aimed to certify the suitable cell size with the 15mm-spacing embedded. Conclusion is landed on the design of 120mm for the effective closing it generates.

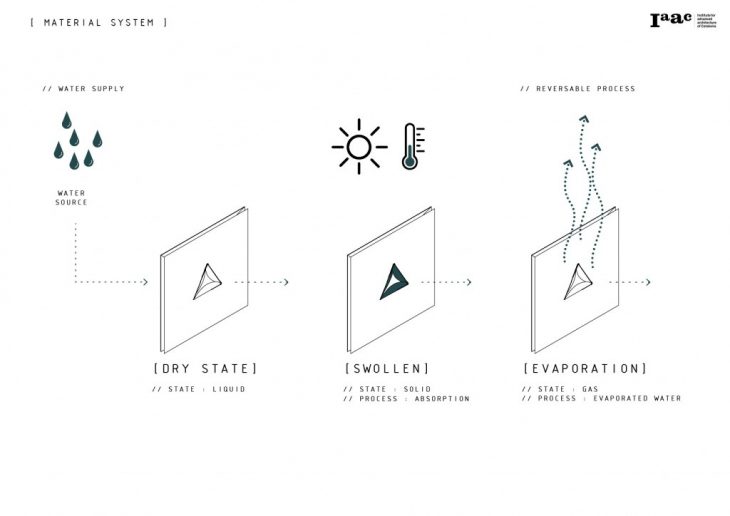

[ The material system ]

The material system is operating on the basis the above cycle where sodium polyacrylate starts from dry state, swollen state by absorbing water, evaporation state that performs cooling and gradually moves towards dry state, repeating the cycle.

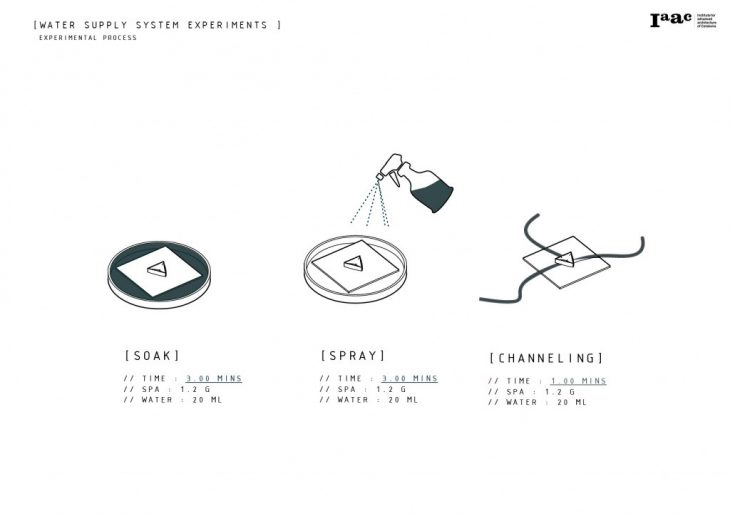

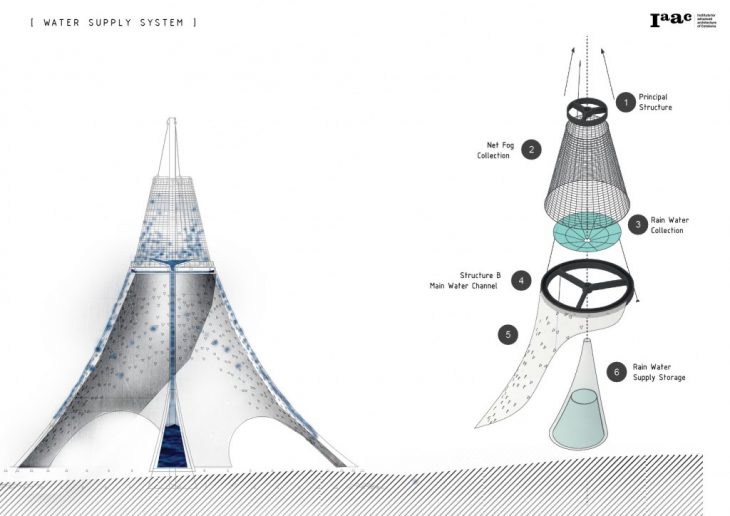

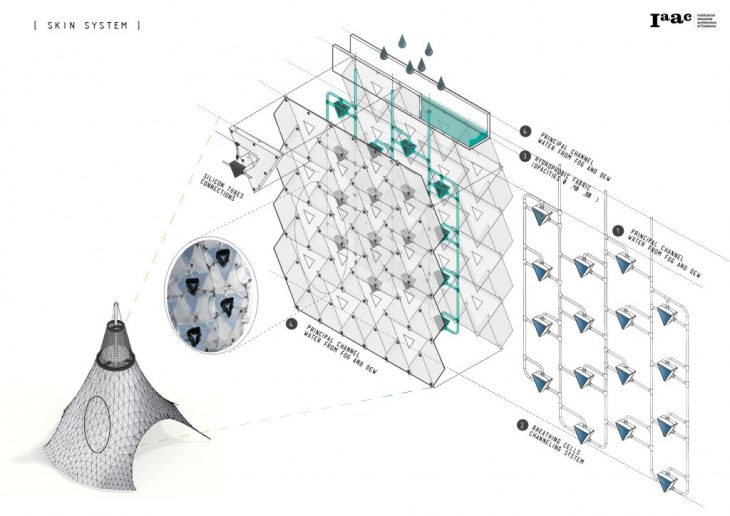

[ Water supply system ]

To increase the responsiveness of the system, three different approaches of water supply for the cell were tested. Among all, the water channeling is tested to be three times faster in swelling cells than soaking or spraying. Therefore, channeling is the optimal means for water supply.

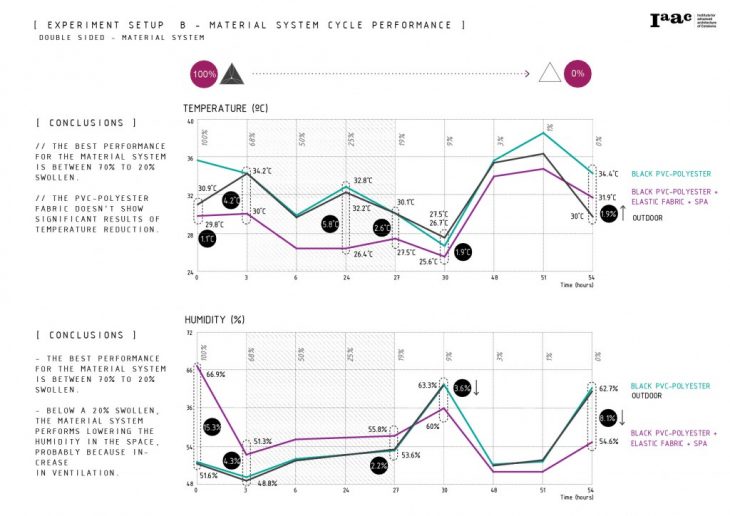

[ Experiment set up ]

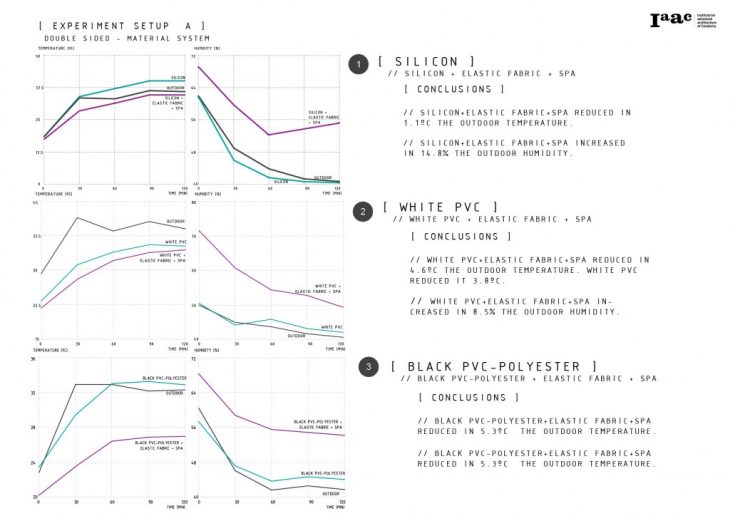

Three constructive elastic fabrics of different levels of opacity and thus heat conductivity are chosen as surface material for the test, all embedded with a SPA cell:

1. silicone sheet

2. white PVC

3. Black PVC coated with polyester

With the test results, we were able to extrapolate the employment of fabrics at different levels of opacity onto the suface of the Breathing system.

The experiment seeks to answer the following questions:

1. Can spa cells create significant temperature reduction/humidity increase for a space than when without?

2. Do surface of different materials and opacity affect the temperature/humidity change resulted from SPA cell? if so, which works the most effectively in temperature reduction and humidity increase?

With the answers to both, we were able to testify the material performance and integrate the suitable fabric material to the surface of the system.

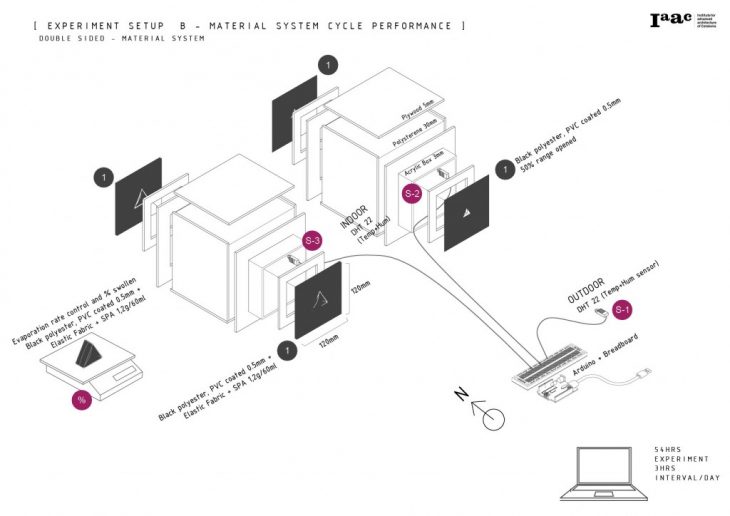

Two experiment setups for the above-mentioned:

1. two boxes with double-sided openings to be covered with experiment variables: one box attached with fabric without SPA cell, and the other with SPA cell. sensors are embeded inside each box and one outside to document and thus compare the datapoints.

2. The above setup is repeated yet covered with different surface materials interchangeably to compare performances.

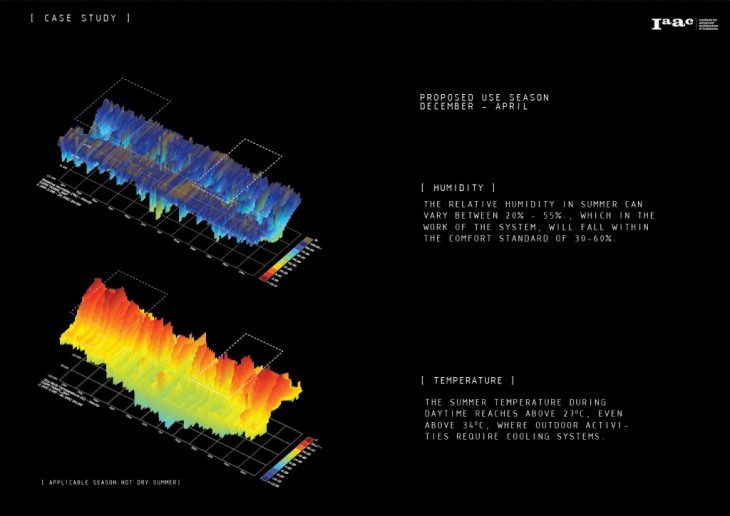

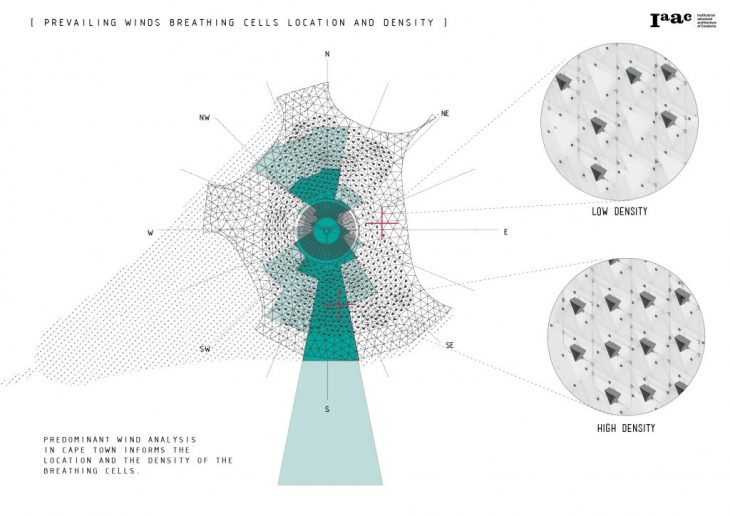

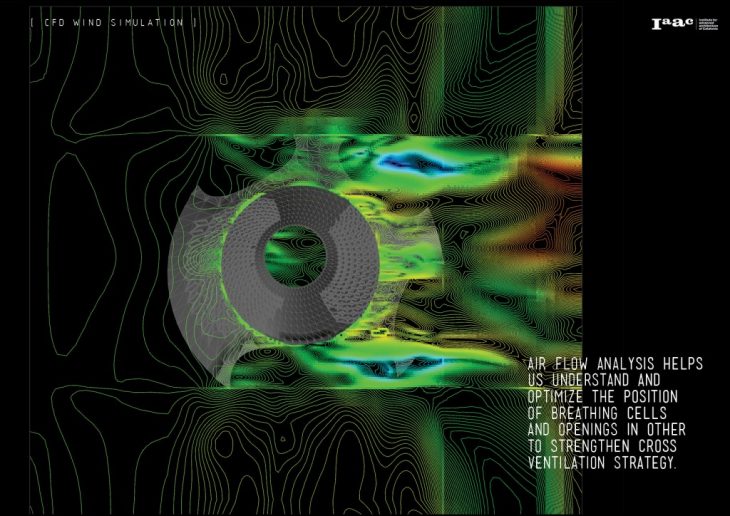

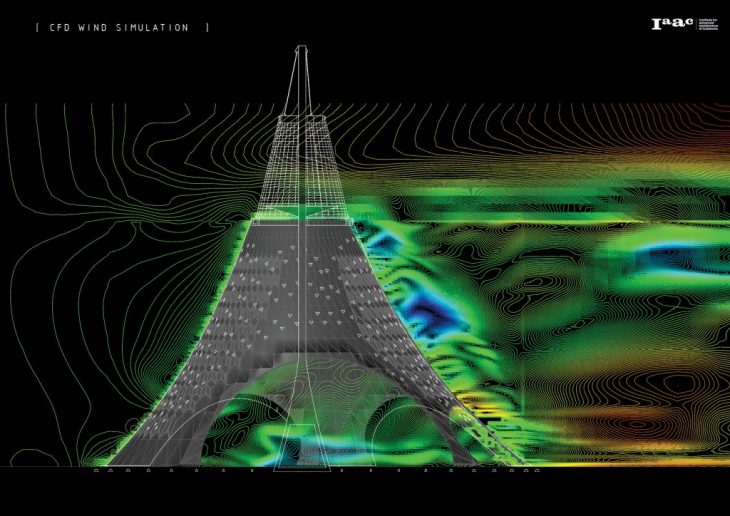

[ Case Study : Cape Town ]

– Temperature: The summer temperature of Cape Town during 8am to 18pm will reach above 27 degrees celsius, and is when the material system will be applicable for the public spaces.

– Humidity: The summer relative humidity of Cape Town can vary between 20% to 60%, so even with the slight increase of humidity along the process of system evaporation, the relative humidity will still fall within comfort standard of 30-60%.

RS3 – Research Studio 3

DIGITAL MATTER – INTELLIGENT CONSTRUCTIONS

// Senior Faculty: Areti Markopoulou

// Fabrication expert: Alexandre Dubor

// Computational expert: Angelos Chronis

// Student : Irene Ayala Castro, Montakan Manosong , Ya Chieh Chang, Zina Alkani