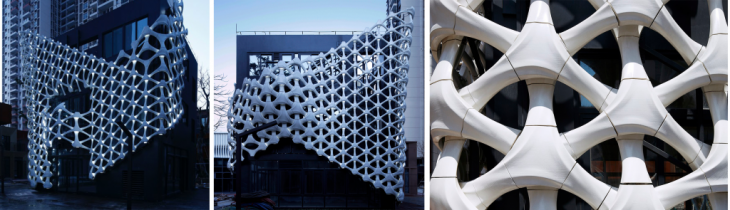

Arachne

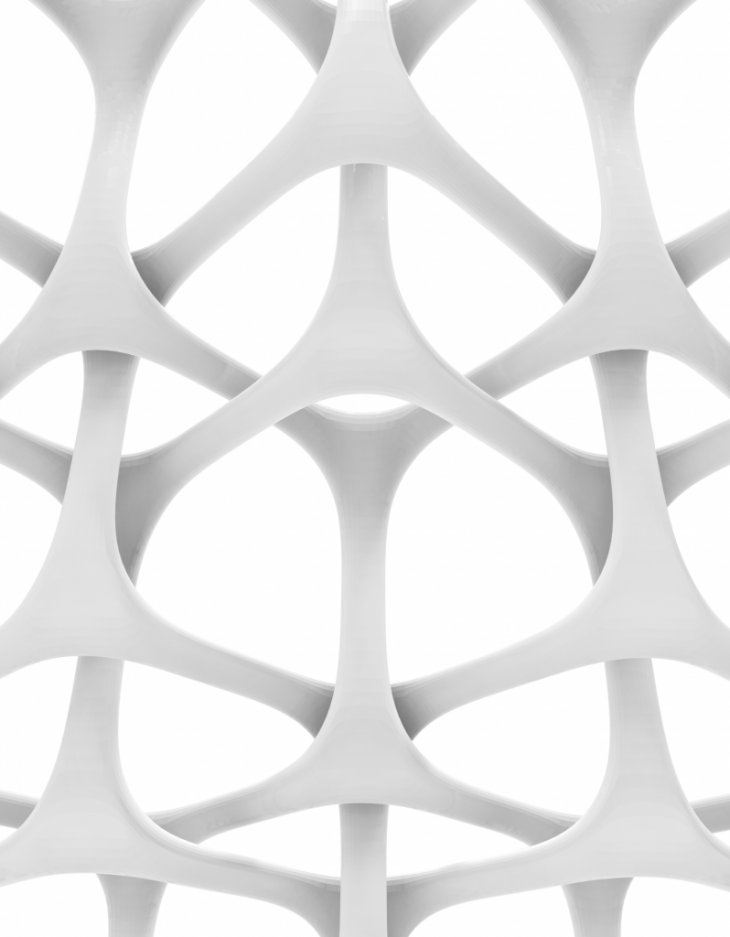

Arachne is a 3D fabricated façade system that undertakes an existing curtain wall mechanism, which is of a three floor building of 10 meters in height and 12 meters in width. The motivation of this design was revealed through systems of controlling a prototype that engages as a “strong iconic articulation.”

Arachne uses 3D printing to realize component parts [Pla plastic] and the composition as a whole. The design group Lei Yu and Yanxin Wang, created an innovative system of parts that would be feasible to construct through use of fabrication.

Workflow

A Workflow Diagram allowed to sketch a series of actions studied under both 3D Modeling and script based designing.

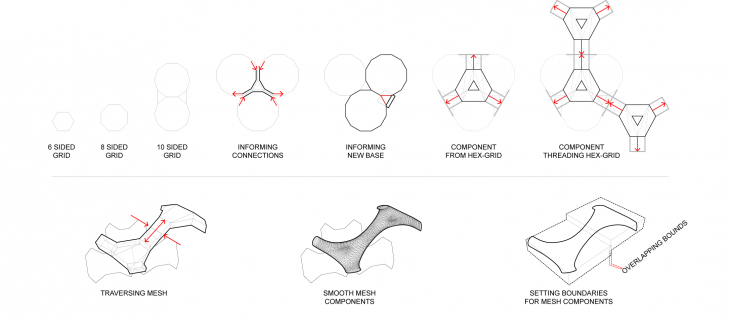

Component Design

Using geometric constraints, the 3D modeling techniques allowed to use scaled proportions and means of partitioning the component. Further, the geometric study successfully translated into relaxing a low-poly mesh to a high poly mesh.

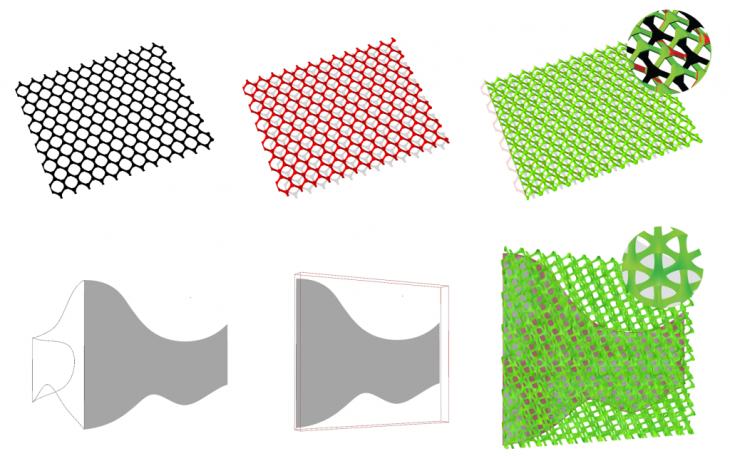

Scripting the Facade

Three grids were prevalent in the Arachne facade and demanded accurate joining with neighboring components. This meant that spacing, clearance and depth of components are critical in preparation for aggregating onto the selected surface of the facade.

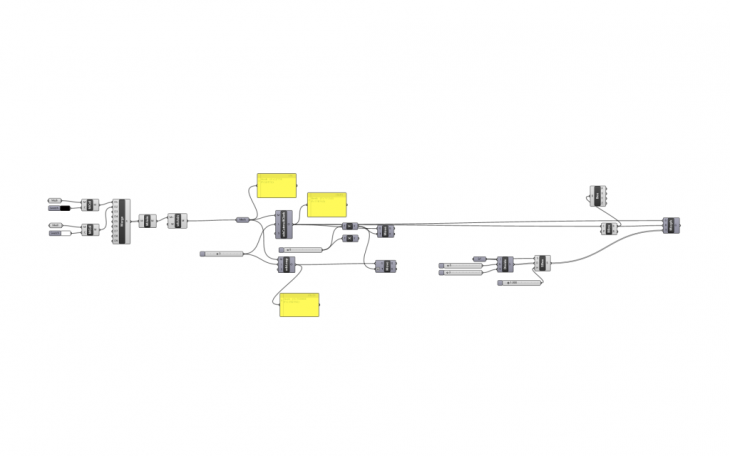

Grasshopper Script

The grasshopper script created utilized a bounding box onto the primary facade surface. Further, allowing to place a perimeter of the components into the bounds of the selected surface. The components were then relaxed from low-poly to high poly. Resulting in the preliminary steps to prepare for fabrication. Attention was carefully emphasized in being certain that meshes were welded, joined or space properly to reduce jagged edges. The results led to imagining possible routes to interpret facade components.

Link To Fabrication Study: Arachne: 3D Printed Facade

Arachne: Computational Facade Study is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the MAA01 2020/21 by Students: Rigoberto Moreno and Faculty: Rodrigo Aguirre, Ashkan Foroughi Dehnavi, Andrea Giacomo De Stasio