Introduction

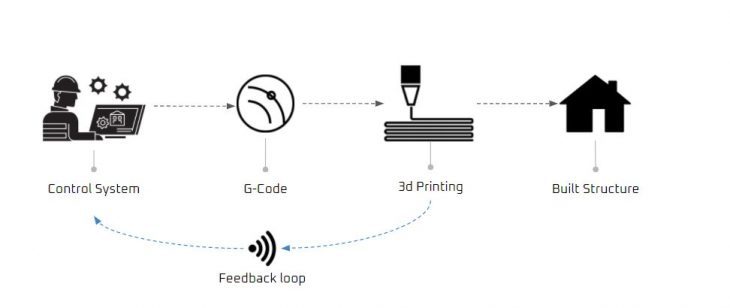

Goal is to make real time connection for 3d printing in order to change the parameters to adapt the changes in environment and model during 3d printing.

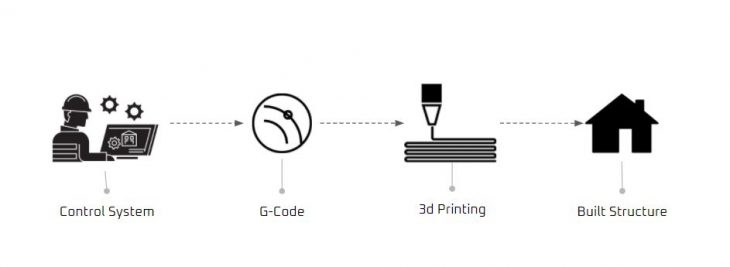

Linear vs Proposed Workflow – Additive Manufacturing

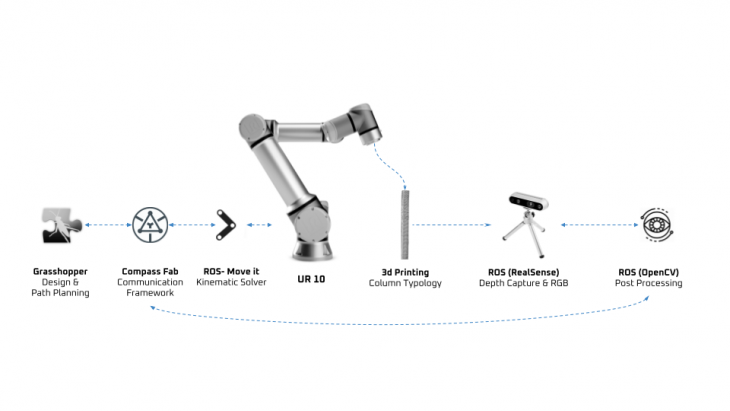

Setup

The robot to be used is Universal Robot 10e which has built in force torque sensors to be safe for human-machine collaboration. The connection is with compass fab framework and ROS Move it is to be used for path planning while considering the obstacle avoidance.

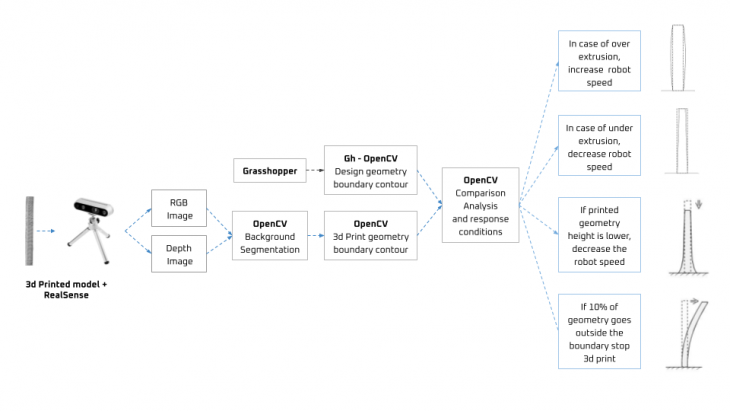

There are 4 different conditions for robot actuation after processing the data through sensors.

Objectives

The objective is to actuate robot with sensors feed back information. The data gathered through sensors can also be used for simulation of 3d print model to predict the errors.