This project is a timber assembly made of curved timber elements with the help of design modeling tools. The material specifications and the structural performance of the assembly were analyzed.

With the constraint of the tools available, a fabrication strategy was devised. The Design-Development-Strategy phase was carried out in smaller groups while the final assembly involved the students of the Digital woodcraft seminar – MAA01.

FORM EXPLORATION

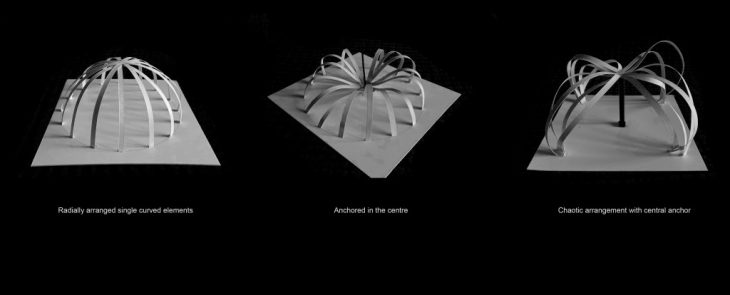

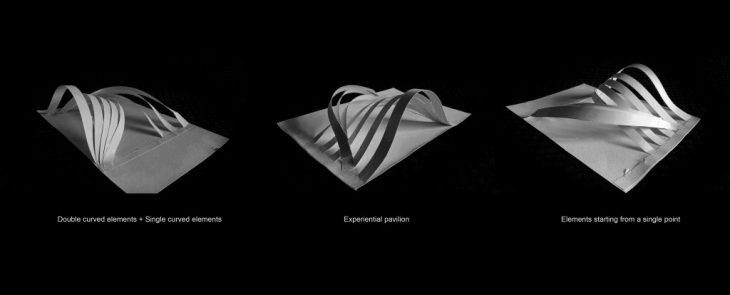

The process began with form-finding using paper strips and dry spaghetti. These were used to replicate timber in scaled-down forms.

Centralized forms

Mixed iterations

Density and shading

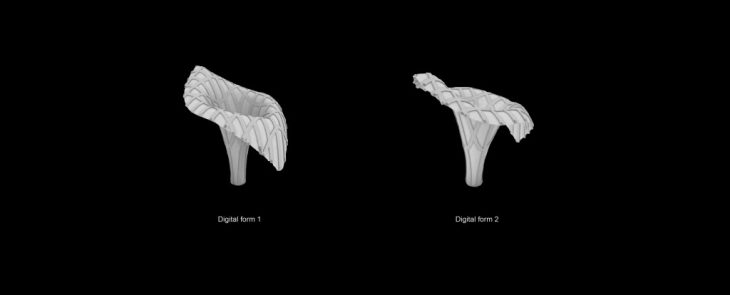

Glulamb Grasshopper

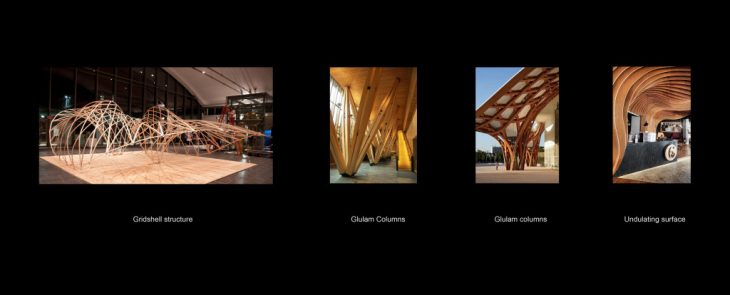

REFERENCES

Few references were looked at to derive ideas for a temporary form

Inspiration

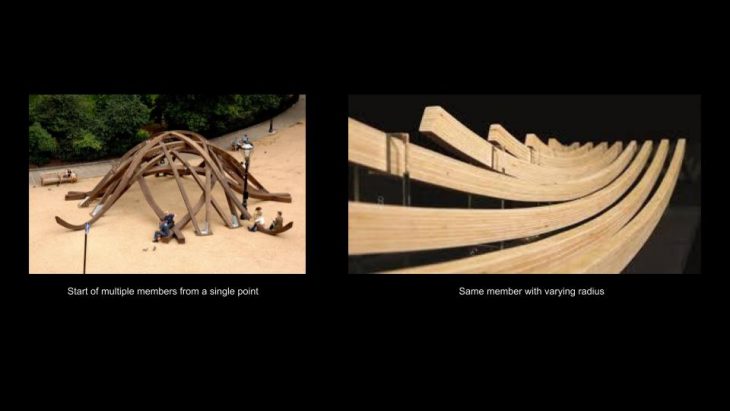

CONCEPT

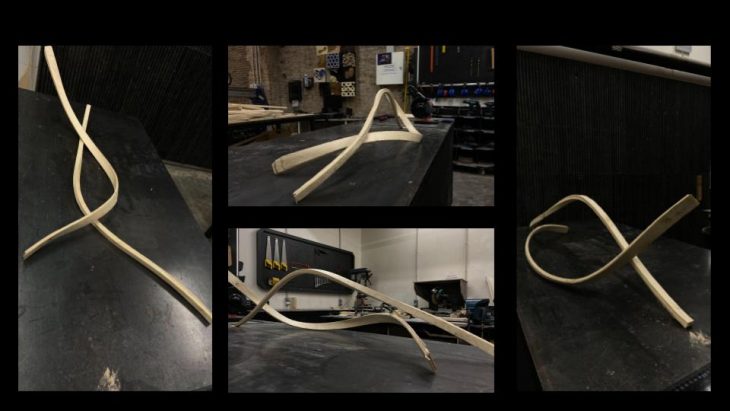

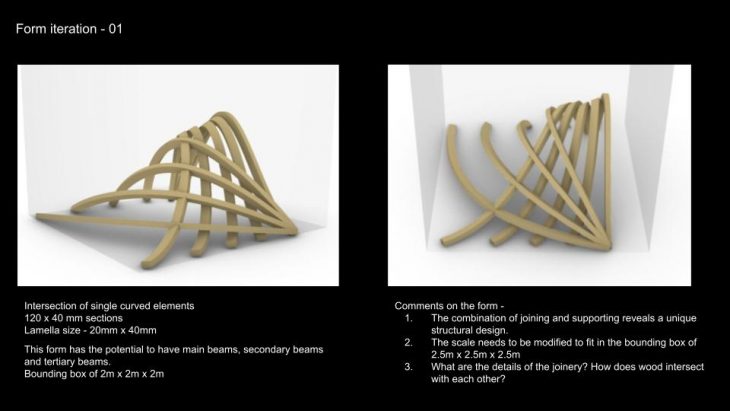

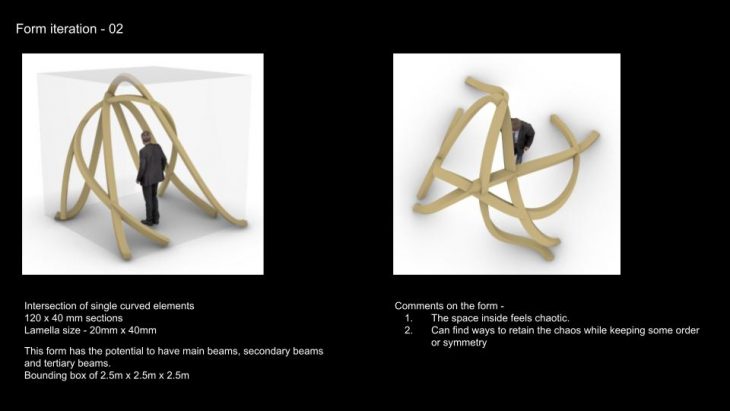

- The idea was to create a tangle of curves that are visually complex.

- Use of long and doubly curved elements.

- Explore with density and twisting of linear elements.

- Transform curves into long-span arches.

Concept

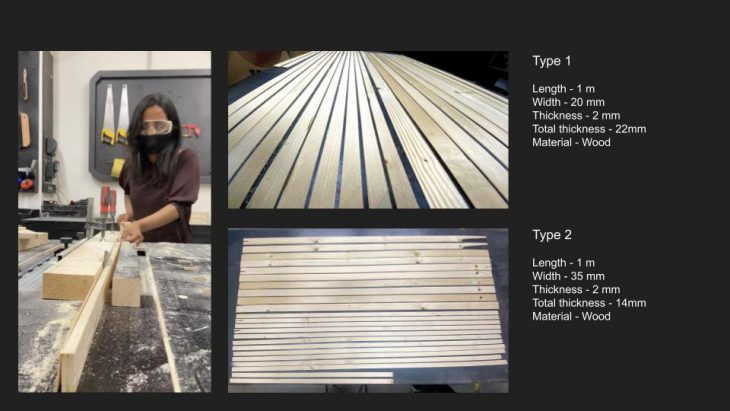

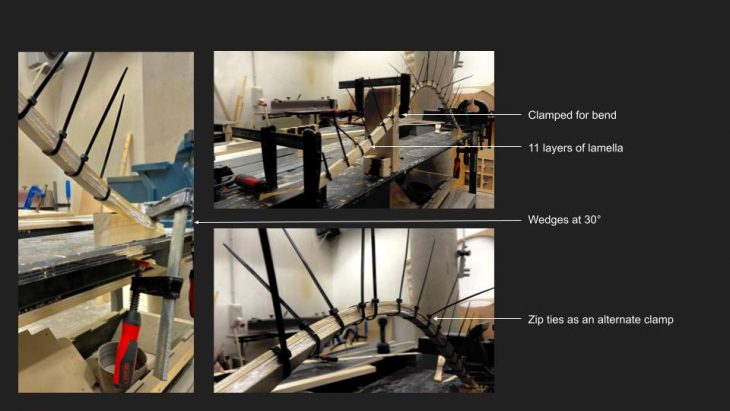

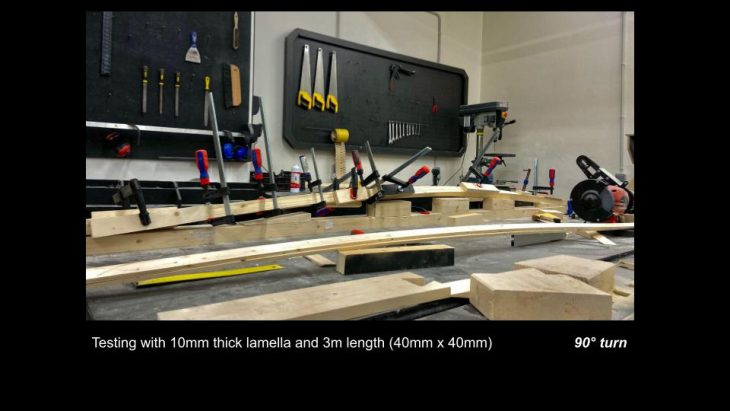

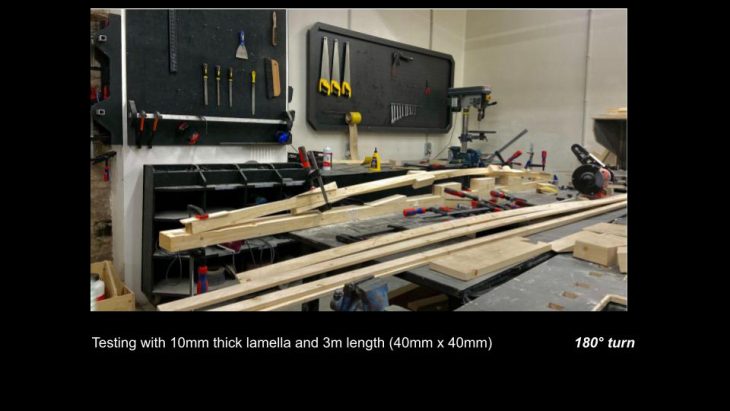

TESTING

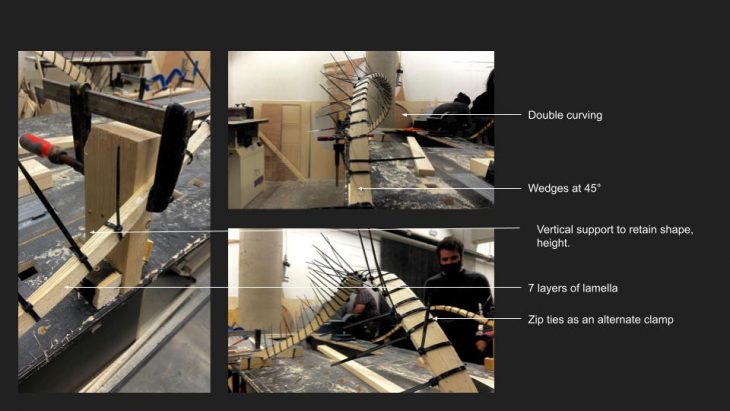

To test the bending of timber, we used 2mm thick lamella, glued them, and clamped it into position. It was let to dry until it took the final form.

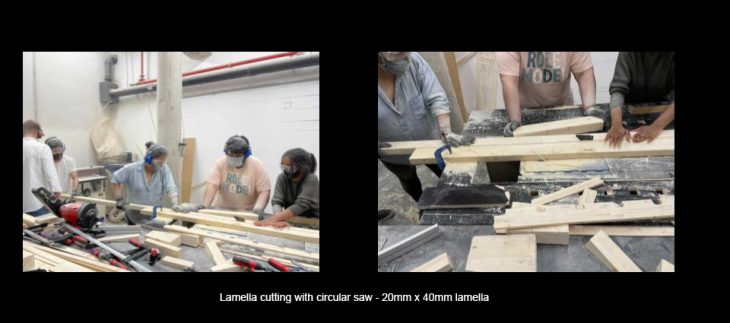

Lamella cutting

Assembly of model 1

Assembly of model 2

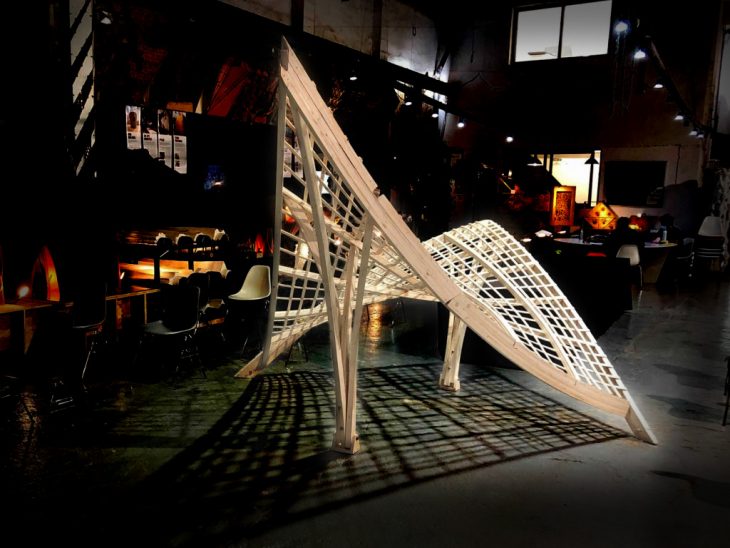

Result

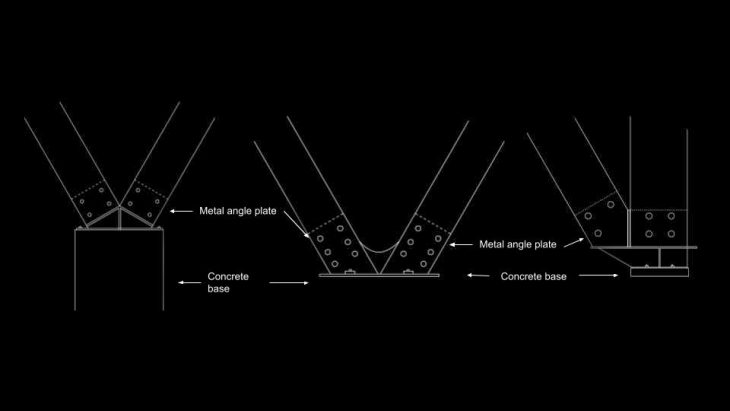

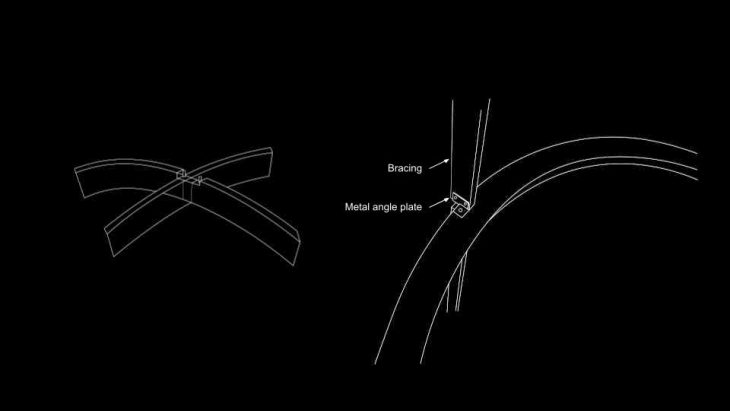

JOINERY

Arched form connection to ground

Glulam arched connection to bracing

FORM ITERATIONS

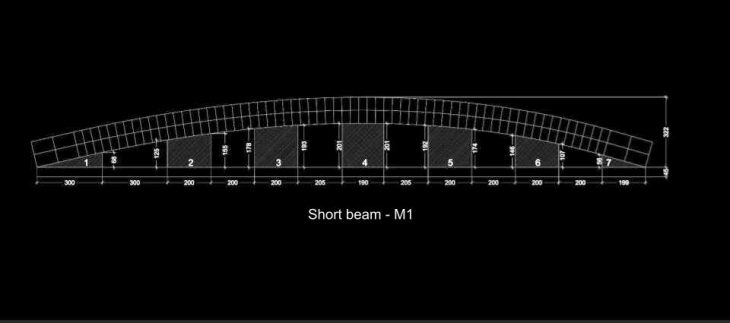

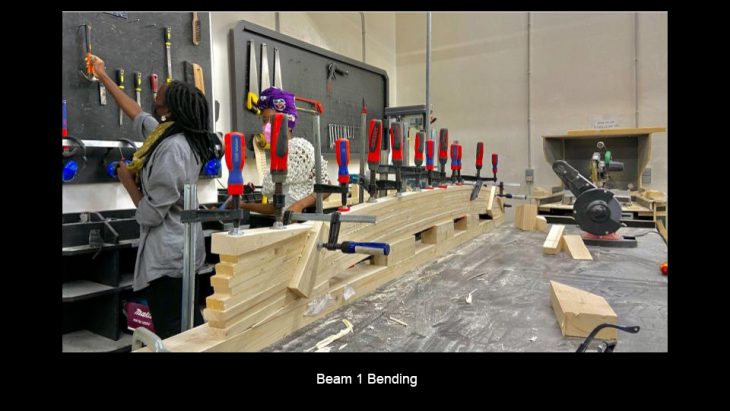

FINAL PROCESS // Primary Beams

- CNC milling 45mm timber to 40mm to avoid machining constraints

- The 40mm thick timber was cut into 20mm x 40mm slices using the circular saw

- Marking of Beams and supports for clamps

- Creation of formwork

- Gluing of Lamella

- Assembling Primary beams

- Primary Beam bending

- The final result of Primary beams

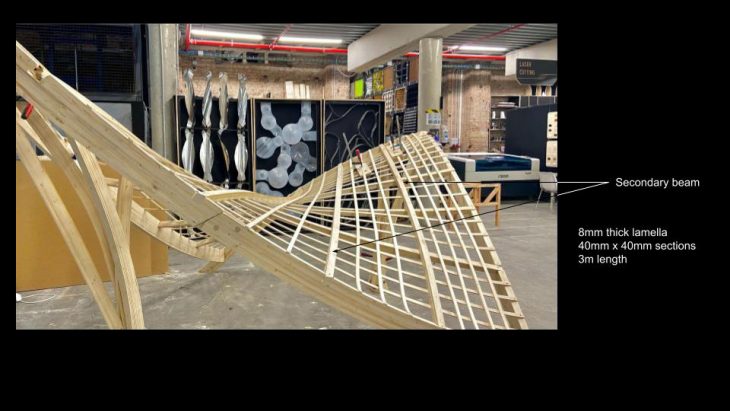

FINAL PROCESS // Secondary Beams

Secondary beam-double curve testing

Secondary beam-double curve testing

Secondary beam result

Credits

Casting Curve is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2020/21 by students: Abrar Ali, Chirag Shah, Prarthana Sudhindra, Faculty: Tom Svilans & faculty assistant: Shyam Zonca.