Introduction

The Digital Fabrication Introductory course focuses on utilizing production techniques by learning the use of three different machines: CNC Milling, Laser Cutting and 3D Printing. The focus of the course was to fabricate different modular recursive geometries with different fabrication techniques along with the learning-by-doing manifesto. Through this course we learned the safety protocols for using each machine, and how to set up each machine for fabrication.

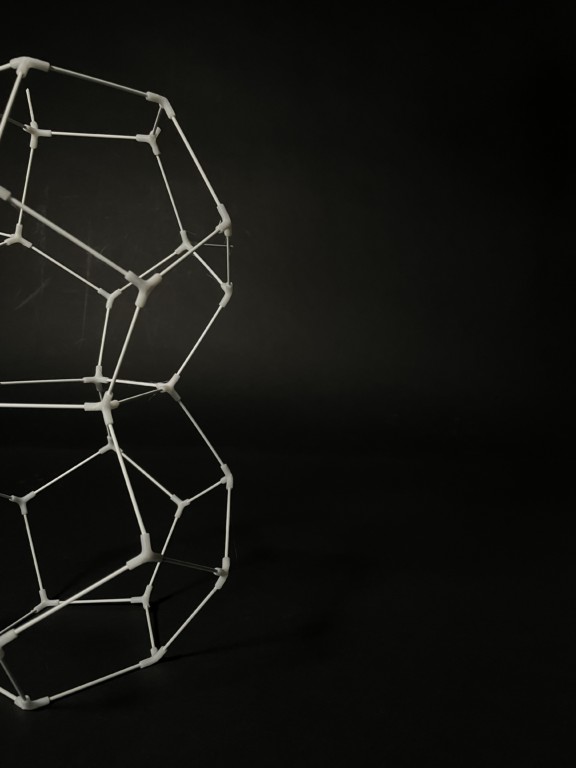

Geo Egg | 3D Printing

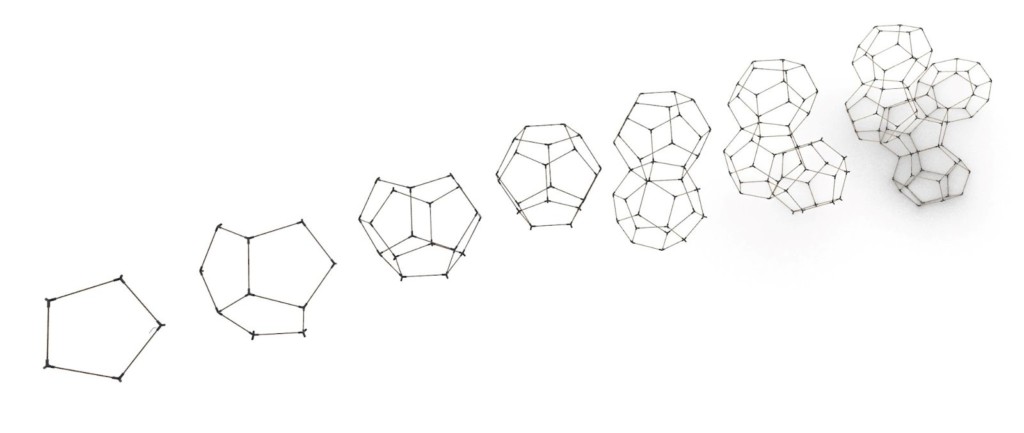

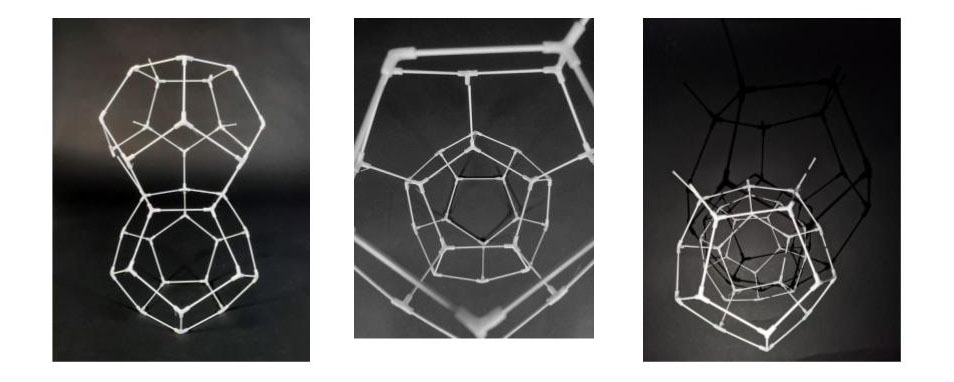

This project operated with the constraints of developing a node that could be integrated into a three dimensional recursive shape constructed of 2 mm fiberglass rods. The form was developed by having a pentagonal surface joined together to form a polyhedron. The nodes were 3D printed in a way to allow one module of the polyhedron to join and form multiple polyhedrons in a recursive pattern. The polyhedron was the choice of geometry as it is self supportive from any angle.

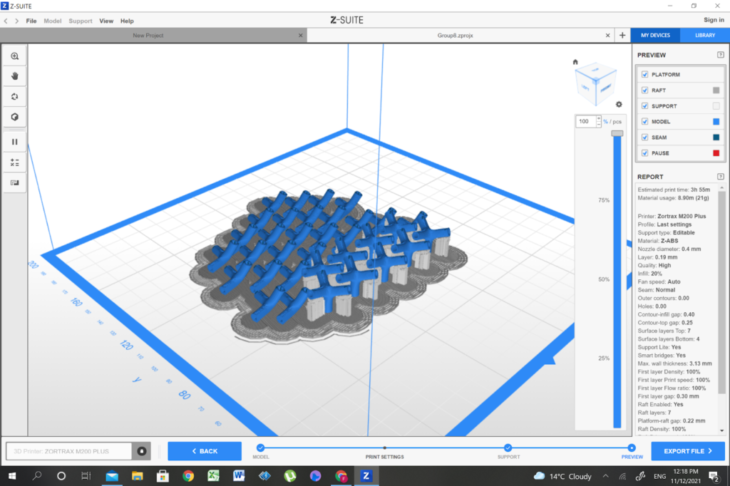

Working Parameters

Material usage: 8.90m (21g)

Printer: Zortrax M200 Plus

Material: Z-ABS

Nozzle diameter: 0.4 mm

Layer: 0.19 mm

Quality: High

Infill: 20%

Fan speed: Auto

Support Density: 2.00 mm

All supports were placed manually in order to decrease the production time.

Digital Exploration of Aggregation Strategy

Final Geometry

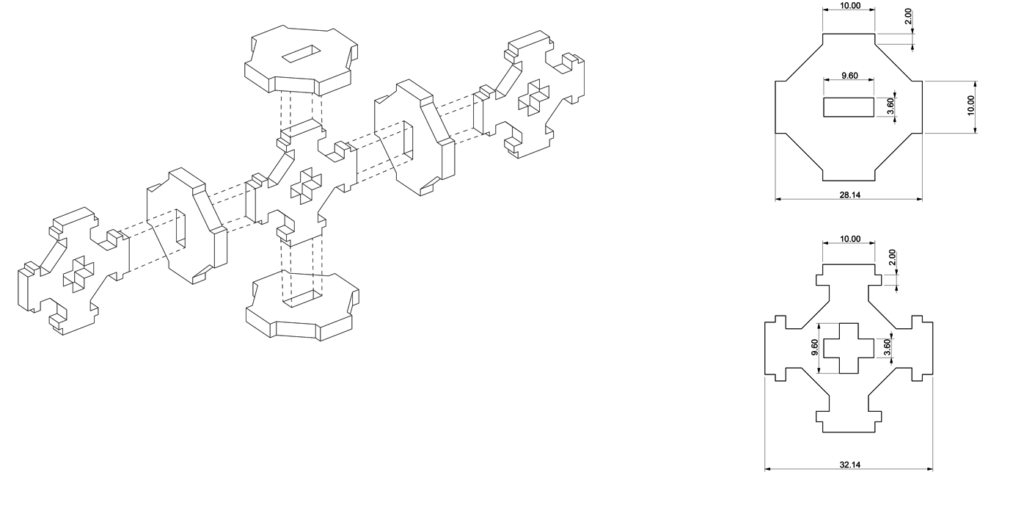

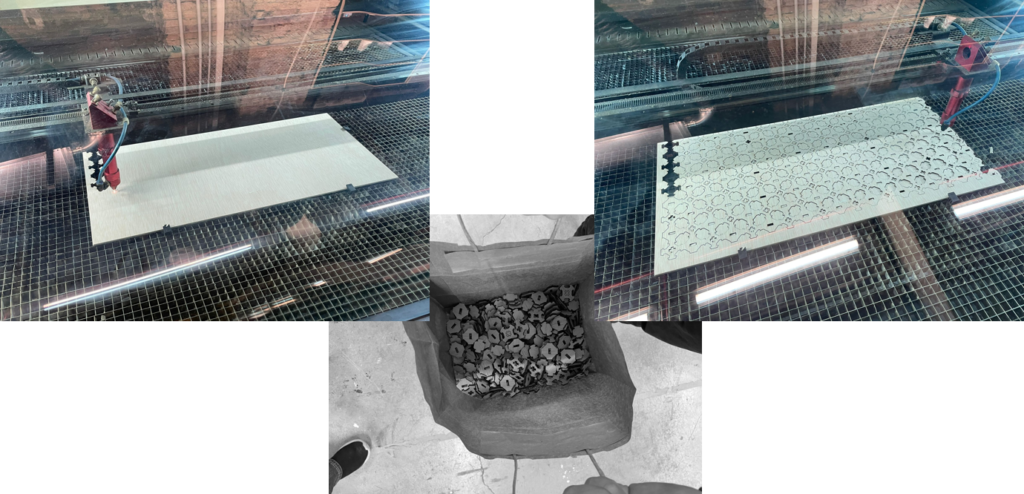

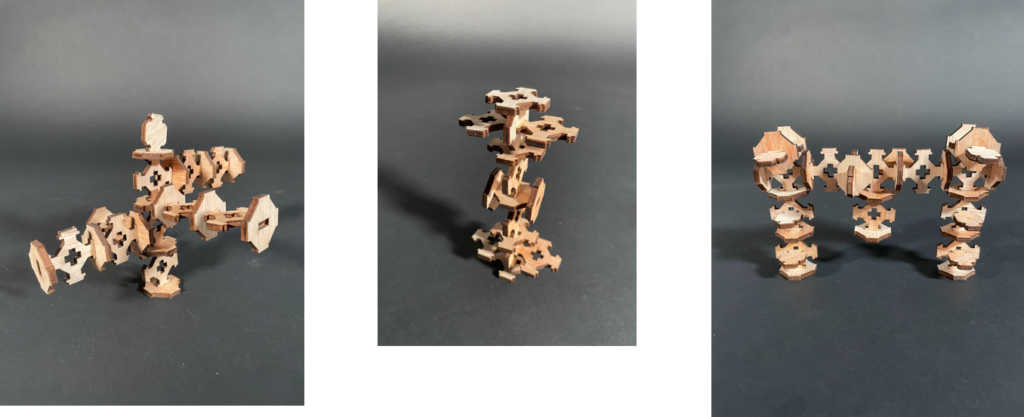

The Cross of Truth | Laser Cutting

The Cross of Truth was a design that mimicked the ways two interlocking pieces could come together and grow as more are added. As more pieces are added together different types of shapes can form from 45 degrees and 90 degrees.

Working Parameters

Machine: Rayjet500

Power: 42

Speed: 1.8

Material: PLYWOOD

Workpiece volume: 620x310x40m

Tolerance: 0.2 mm (to accomplish a solid connection between pieces the slot has been made 0.2 mm smaller than the plug.

Process

Final Result

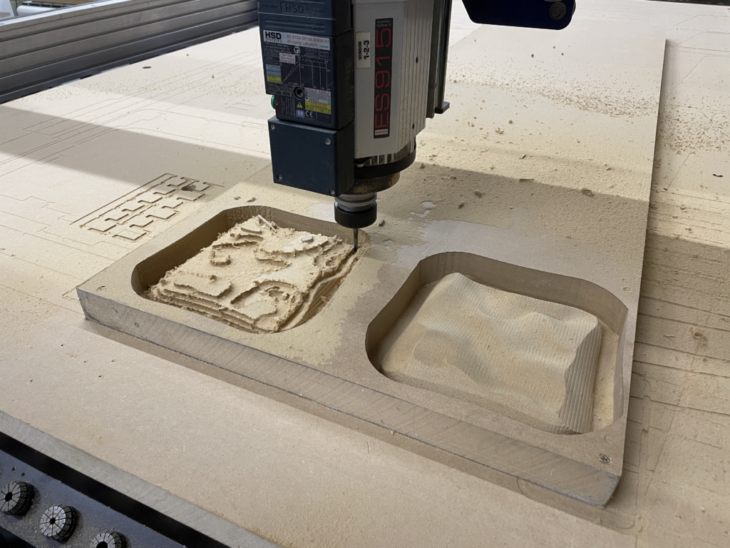

Cloud 9 | CNC Milling

The goal was to investigate the versatility offered by the CNC machines to realize curved and smooth 3D surfaces with the possibility of seamlessly merging them into a unique and organic shape. This is strengthened by the flawless and dynamic pattern of grooves created by the 6 mm Ball Mill during the finishing process.

Working Parameters

Material: MDF

Machine: ShopBot_MPC

Post Processor: .sbp

Workpiece volume: 200x200x80mm

CNC Milling Strategies

Engraving

Flat Mill

Flute: 2

Diameter: 10

Spindle Speed: 12000

Feed Rates: 2000

Transfer Motion: 4000

Cut Direction: Upcut

Total Cut Depth: 2 mm

Stepover Distance: 70%

Total mill time: 0.26 minutes

Horizontal Roughing

Flat Mill

Flute: 2

Diameter: 10

Spindle Speed: 12000

Feed Rates: 2000

Transfer Motion: 4000

Cut Direction: Upcut

Stock: 1.5

Stepdown Control (dZ): 50%

Stepover Distance: 60%

Total mill time: 28.74 minutes

Parallel Finishing

Ball Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Feed Rates: 2000

Transfer Motion: 4000

Cut Direction: Upcut

Stock: 0

Stepdown Control (dZ): 50%

Stepover Distance: 25%

Lowest Z Containment: -38.5

Sorting: minimum distance

Total mill time: 32.12 minutes

2 ½ Axis Profiling

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Feed Rates: 2000

Transfer Motion: 4000

Cut Direction: Upcut

Cut Direction: Conventional

Cut Side for Closed Curves: Outside

Stock: 0

Stepdown Control (dZ): 50%

Total Cut Depth: 40.5 mm

Finish Depth: 5.5 mm

Finish Depth/Cut: 5.5 mm

Rough Depth: 35 mm

Rough Depth/Cut: 35 mm

Bridge Heigth: 2 mm

Bridge Length: 4 mm

Nº of Bridges: 4

Entry/Exit Motions: none

Sorting: minimum distance

Total mill time: 2.23 minutes

Process

Final Result

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021/2022;

Students: Zack Eisenberg, Federico Caldi, Tanvee Joshi

Faculty: Shyam Francesco Zonca, Lana Awad and Ricardo Mayor

Course: Introduction to Digital Fabrication