Education of robotics in the fabrication and construction sectors

Robotics is increasingly being adopted across different industries. This has posed both a threat, and an opportunity in workplaces from different sectors, and there has been little attention received on what factors influence this integration to have a positive or negative effect on work. Using the digital fabrication and construction sectors as a focal point, we looked into what challenges the industry may face when integrating robotics. We conclude that, although robotics education is limited and accessible to few, showcasing examples of other industries can serve as a starting point for arguments on how to — or how not to — introduce people to robots in construction and fabrication.

June 1951: Operators connecting calls through the switchboard in one of the Continental English speaking sections at the Trunk, Continental and Toll Exchanges of the Long Distance Telecommunications Region at the Faraday Building in London. (Photo by Harrison /Topical Press Agency/Getty Images)

The challenge we are facing is to make the education in robotics and digital fabrication accessible in order to adapt the labour force to the transformation in industries.

Therefore, we can start our research by testing the following statement:

The learning curve and access to robotics education will directly affect the industries labour, market and production system.

On this process we are putting in value the following topics as key factors:

Design Research

An activity to produce knowledge through design. Subjectivity is not allowed in scientific research, but neither in artistic research, combined with creativity and validation bringing to discussion every decision. The results obtained should be explicit, arguable, transferable and combinable.

Resilient Culture

Many of the distributed systems aim for proximity, self-sufficiency and localizing their economies, in order to be more resilient against any possible crisis. Therefore we must get more resilient by continuously experimenting and increasing diversity.

Distributed Fabrication

A 4th innovation wave is shaking the dominant tendency in production and global consumption by merging smaller and more efficient machinery through social media, aiming for better integration within multiple actors. Global experimentation can be held by design and fabrication systems with high technology capacity at small scale as maker-spaces or FabLabs. (1)

Research Plan

OBJECTIVES

- Learn about the motivations and barriers of using digital fabrication in a work environment.

RESEARCH QUESTION TOPICS

- Personal experience with robotics

- Robotics in their work environment

- Education and training around robotics/ digital fabrication

- Future prediction of robotics in fabrication

RESEARCH METHOD

- Semi-structured interviews

- Open-ended question surveys

RESEARCH PARTICIPANTS

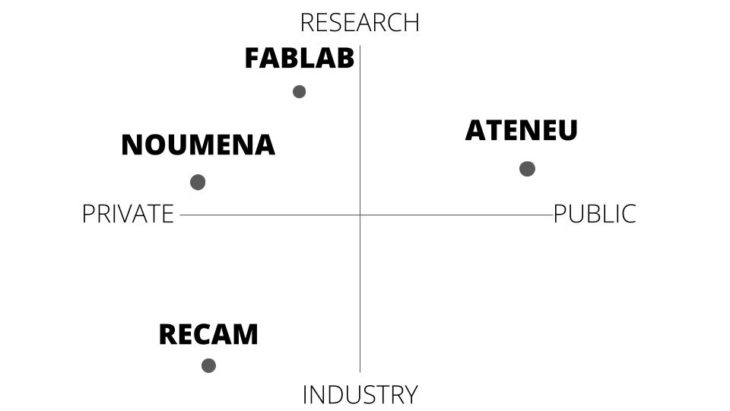

- Josep Martí – FabLab (Educational field)

- Victor Vidal – Ateneu de Gràcia (Public organisation)

- Pere Barrios – Recam Laser (Private industry)

Interview Results

Interview 1

Josep Martí. FabLab Faculty

Instructor at Fabacademy, Fabriacademy and MDEF.

- 11 staff members skilled on Digital Fabrication and 1 in robotics.

- The learning curve is not immediate, need to understand the whole process, prevent accidents, test and fail.

- Increase of no. axis to get complex results, as well as its precision once programmed.

Complete interview

Interview 2

Victor Vidal. Technician at Ateneu de Fabricació de Gràcia.

Experience on Digital Fabrication

- Team formed by 2 technicians and 2 project managers

- Very few projects regarding robotics

- Robotics learning can break digital barriers, but with a more complex approach

- Popularizing technologies should not avoid keeping the knowhow transfer

- Teaching everyone how to program as a common language will facilitate to understand some technologies.

Complete interview

Interview 3

Pere Barrios. Recam Laser CEO

- Against 4.0 industry concept, over 25 years, the change in the industry is much slower than what it is thought.

- Welding robots avoid uncomfortable and toxic issues

- From 1 to 10 robots, and from 100 to 400 workers

- Operators focus on programming, quality control, setup of the robot

- Welders should learn 3D design, mechatronics and programming; otherwise, they’ll assist the robot on the most difficult pieces to access.

Complete interview

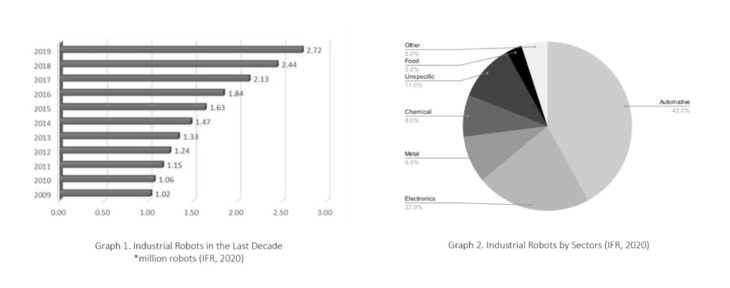

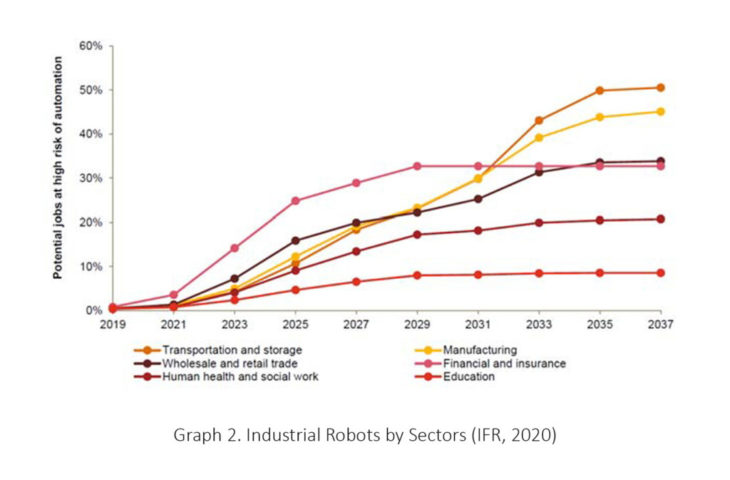

Automation Data

“According to The Future of Jobs 2020 report of World Economic Forum (WEF) (2020a), by 2025, 85 million jobs may be displaced, while 97 million new jobs may emerge. Chiacchio et al. (2018) find that an additional robot per thousand workers reduces the employment rate by 0.16 to 0.2 points. However, in the analysis of Graetz and Michaels (2015) covering 17 countries, it is suggested that industrial robots increase labor productivity and added value and contribute approximately 10% to economic growth. PWC (2017) supports this claim and finds new technologies could contribute up to 14% to GDP.”

Da?l?, ?., & Kösekahyao?lu, L. (2021). (rep.). THE RACE BETWEEN INDUSTRIAL ROBOTS AND HUMAN LABOR IN SMART FACTORIES (pp. 7–13). Isparta, Turkey: Researchgate.

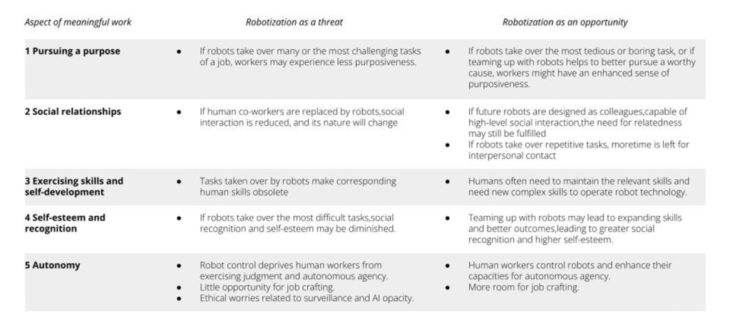

Aspects of meaningful work and the possible impacts of robotics

Smids, Jilles & Nyholm, Sven & Berkers, Hannah. (2020). Robots in the Workplace: a Threat to—or Opportunity for—Meaningful Work?. Philosophy & Technology. 33. 10.1007/s13347-019-00377-4.

Robots and exercising skills and self-development

Source: davincisurgery.com

A threat?

“Obviously, if robots take over one or more complex tasks from human workers, several human skills may become obsolete […] The dangers of deskilling due to reliance on automation technology are real and established by research, and apply to robotization as well.”

An Opportunity?

“However, robots might equally well have the opposite impact by enhancing the need for workers to maintain their skills, and, moreover, by requiring them to acquire new and additional complex skills”

The human has to maintain all the traditional skills and to acquire new complex skills for overseeing and handling robotic technology. The introduction of robots in the workplace impacts the human development of skills in multiple ways and the overall impact needs to be assessed on a case-to-case basis.

Smids, Jilles & Nyholm, Sven & Berkers, Hannah. (2020). Robots in the Workplace: a Threat to—or Opportunity for—Meaningful Work?. Philosophy & Technology. 33. 10.1007/s13347-019-00377-4.

An industry example

Do welders get upskilling when robots are brought in?

“This doesn’t happen to us because we have a large variety of types of work. Robots are mainly used for long series of simple pieces. Our welders work mainly on really small or big pieces that are also too complex for a robot. Our welders still carry welding functions for those individual pieces, the only thing is that when we add a robot, we need to find a programmer, and an operator to assist the robot.”

Pere Barrios, CEO/Founder Recam Laser

Main takeaways

Source: Faude.de

- Robots require expert knowledge to program for use compared to other digital fabrication tools.

- Introducing robots in the workplace impacts the human development of skills in multiple ways, but there is no consensus on what these [impacts] are across fields.

- Not all prospective robotization to the labour force is bad news. There are opportunities to enhance current skills or acquire new and complex skills that are meaningful to their work.

- Education around robotics is limited

What questions might we ask next?

- Why the construction companies hesitate to transition to more up-to-date technologies?

- How can advance construction tools become more accessible to local communities?

- How would the locals be affected by the introduction of new technologies to the construction industry?

- What levels of qualification or working skills should be asked to the workers?

- What is the real impact of regulations on construction?

Literature references

https://www.iconbuild.com/technology/mars-dune-alpha

https://www.dezeen.com/2021/04/23/mario-cucinella-architects-wasp-3d-printed-housing/

Frase, P. 2016. Four Futures: the end of Capitalism. Ed. Verso. (link)

Brynjolfsson, E. and McAfee, A. The Second Machine Age: Work, Progress, and Prosperity in a Time of Brilliant Technologies, 2016. (link)

Benedikt, C. and Osborne, A. The Future of Employment: How susceptible are jobs to computerisation? OxfordMartin.ox.ac.uk, 2013.

Drum, K. Welcome, Robot Oerlords. Please Don’t Fire Us. Ed. Mother Jones, 2013.

Ford, M. Rise of the Robots: Technology and the Threat of a Jobless Future. 2016.

Jeremy Rifkin, El fin del trabajo. Nuevas tecnologías contra puestos de trabajo: El nacimiento de una nueva era, Barcelona: Booket, 2014. (summary) (full)

Stanley Aronowitz and William Difazio, The Jobless Future: Sci-Tech and the Dogma of Work, Minneapolis: University of Minnesota Press, 1994.

Tyler Cowen, The Great Stagnation: How America Ate All the Low-Hanging Fruit of Modern History, Got Sick, and Will (Eventually) Feel Better, Nueva York: Penguin, 2011

Doug Henwood, “Workers: No Longer Needed?”, Lbo-News.com, 2015.

Drum, “Welcome Robot Overlords”. (link)

Leanna Garfield, “These Warehouse Robots can Boost Productivity by 800%”, TechInsider.io, February 2016.

Ilan Brat, “Robots Step into New Planting, Harvesting Roles”, Wall Street Journal, April 2015.

Da?l?, ?., & Kösekahyao?lu, L. (2021). (rep.). THE RACE BETWEEN INDUSTRIAL ROBOTS AND HUMAN LABOR IN SMART FACTORIES (pp. 7–13). Isparta, Turkey: Researchgate.

Pan, Wei & Chen, Le & Zhan, Wenting. (2019). Implications of Construction Vocational Education and Training for Regional Competitiveness: Case Study of Singapore and Hong Kong. Journal of Management in Engineering. 36. 5019010. 10.1061/(ASCE)ME.1943-5479.0000750.

Image references

http://www.criteriasistemas.com/blog-de-telefonia-para-empresas/centralitas-telefonicas/historia-de-la-centralita-telefonica

https://edgaar.design/es/web/fablab-bcn-web/

http://www.oliverasboix.com/es/ateneu-de-fabricacio/55

https://www.industr.com/en/collaborative-robots-end-user-industry-insights-2284062

Project accreditation

This is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction in 2021/2022 by students: ?pek Attaro?lu, Alberto Martínez and Jordi Vilanova, and faculty: Mathilde Marengo.