raDar /Deformed to formed // Software III M.L.

raDra is a project by MRAC 01 students: Abnaoub Nagy, Andrea Najera, Alberto Martinez, and Grace Boyle during the third software seminar of the third term. Third software seminar was taught by faculty Mateusz Zwierzycki, Nikol Kirova.

During the software seminar , students had to explore ::

Machine Learning in particular Supervised machine learning and create the full pipe line from data accusation to a train modeled.

ABSTRACT

Introduction

Deformation in the additive manufacturing process with clay is a real problem that takes a lot of time to experiment with so our approach is to feed the computer through neural network and prediction of drying distortions in robotic clay 3D printing . By that it can reduce the time of testing and the trained model will give the optimized model for printing.

THE PIPE LINE

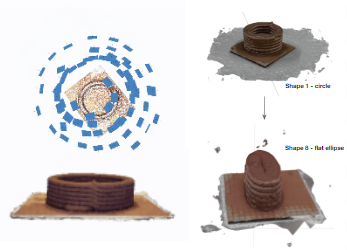

Test Samples

—— the print video—–

4 sets of samples

8 geometries / set

120-200 photos / geometry

Total ~3500 photos as input for photogrammetry models

Data Accusation

Consist of three steps :

A- Scanning througth photogrametry

Per_geometry.psx

Align photos

Build dense cloud

Build mesh

Export .obj

B- Orienting

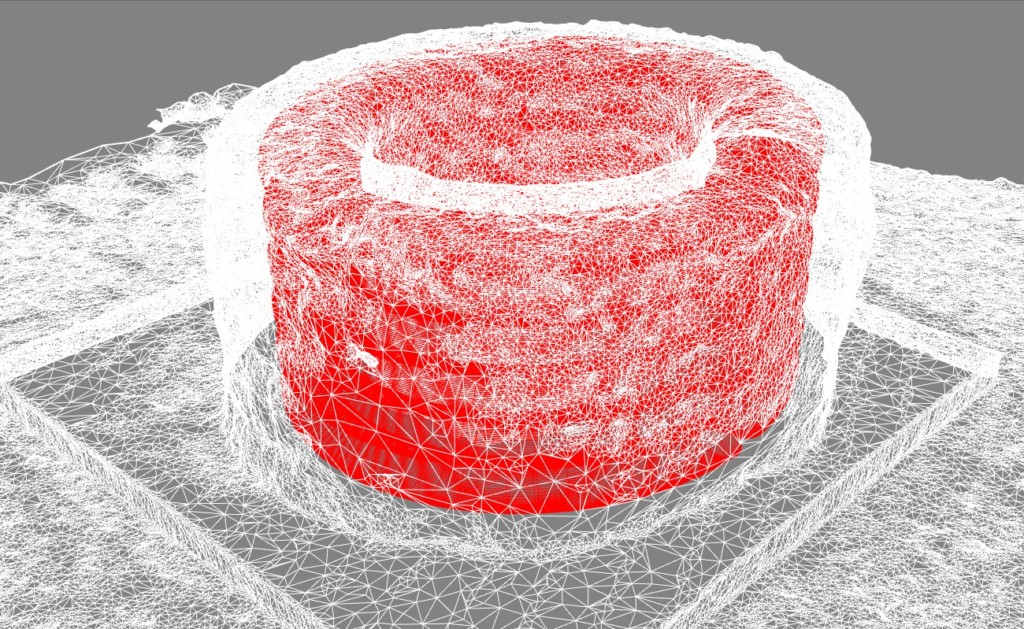

Red CAM model & source of robot toolpath

White Digital model of resulting dried print piece, created via photogrammetry

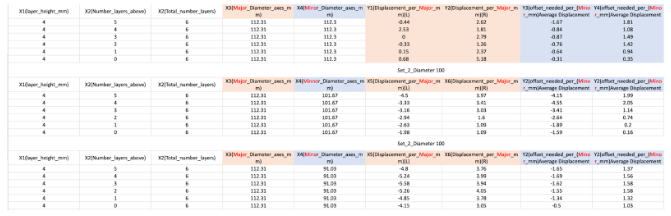

C- Distortion measurements

| Reorient photogrammetry model & overlay with CAM model

| Front view reveals minor axis / Right view reveals major axis of geometry

| Measure absolute values of layer offset, per layer & per edge

Centre of model located on node in 3D environment, so:

|Left edge:

Shrink ? -ve

Swell ? +ve

|Right edge:

Shrink ? +ve

Swell ? -ve

Peeping the date set

Training

Use the trained model to predict

Thank You