LASER CUT

LASER CUT

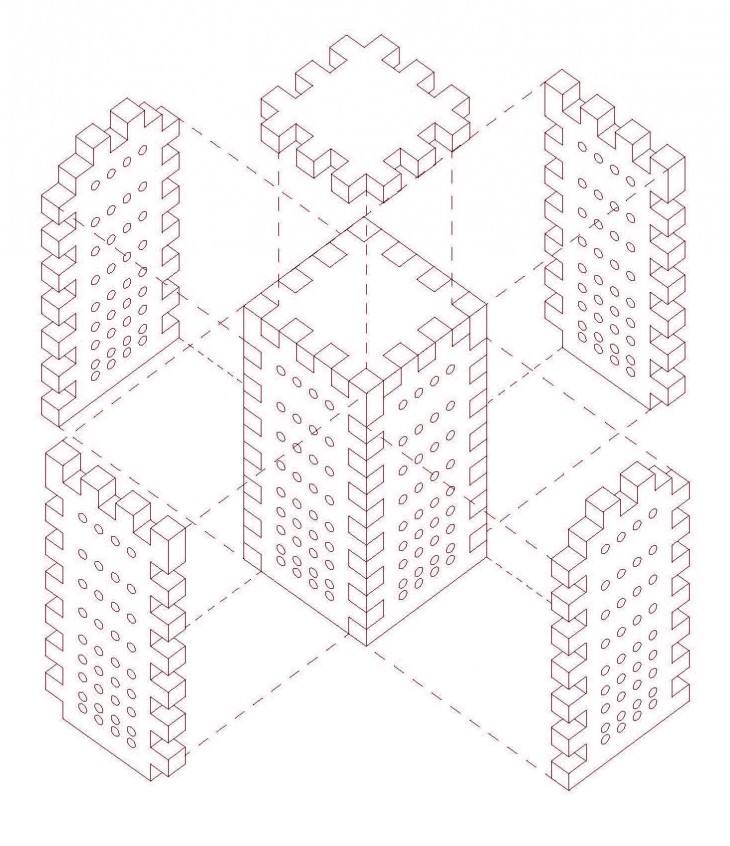

The idea was to understand the advantages and disadvantages of laser cutting process, in which kind of situations we prefer rather than the other techniques and which materials are more suitable for laser cut which are not.

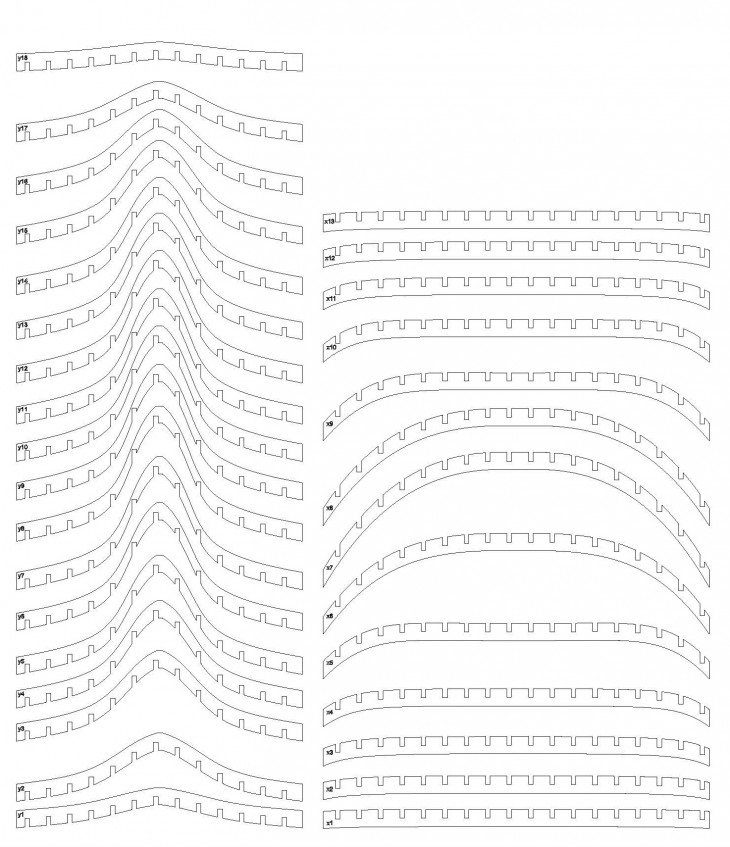

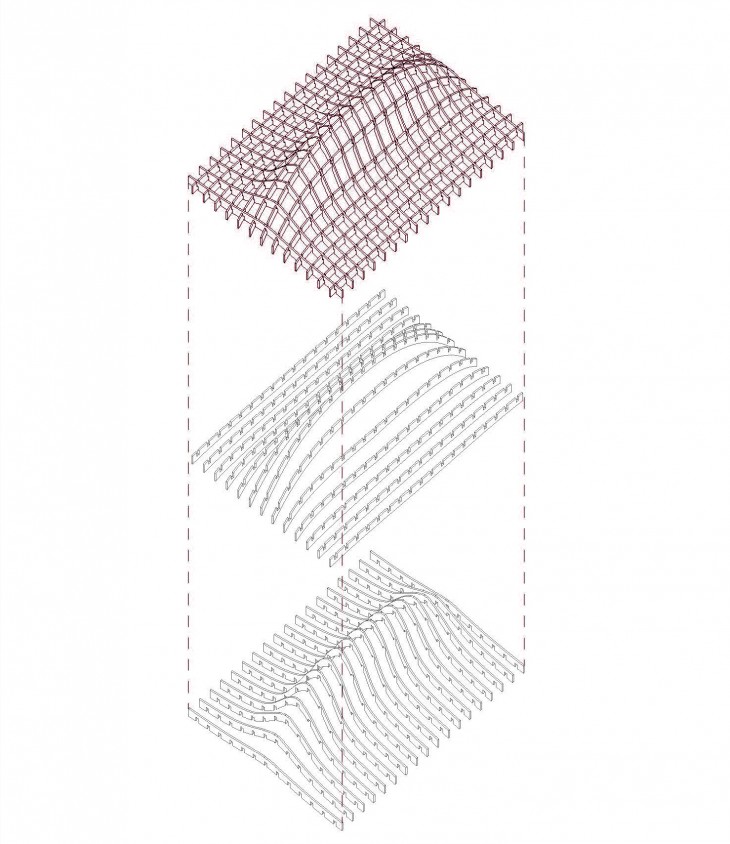

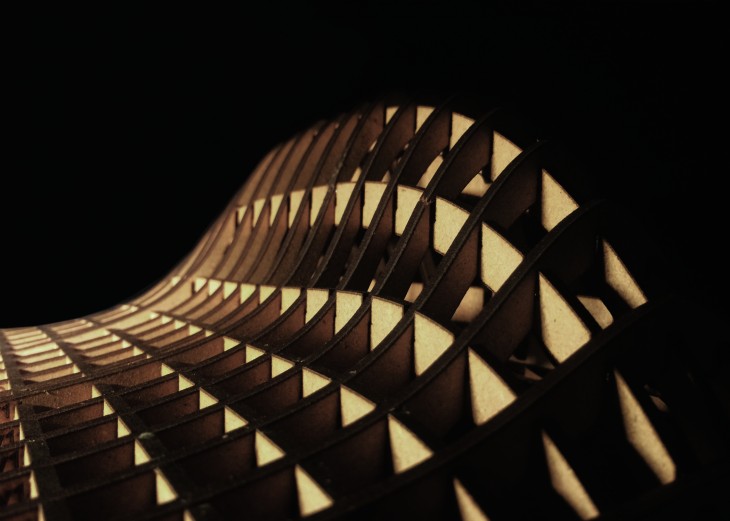

We first build the 3D Model on Rhino and then through Grasshopper Plug-in, which is to create the slices for waffle structure of this model, we created the pieces. Then we made the 2D drawings of these slices as an output and made a .dxf file. We sent these files directly to the computer connected to laser cutter and set with remote controller the required values, such as speed etc. for the machine. After having the pieces of waffle structure only step left was to connect them.

We first build the 3D Model on Rhino and then through Grasshopper Plug-in, which is to create the slices for waffle structure of this model, we created the pieces. Then we made the 2D drawings of these slices as an output and made a .dxf file. We sent these files directly to the computer connected to laser cutter and set with remote controller the required values, such as speed etc. for the machine. After having the pieces of waffle structure only step left was to connect them.

Students:Caglar Gokbulut, Ilkim Er

MILLING

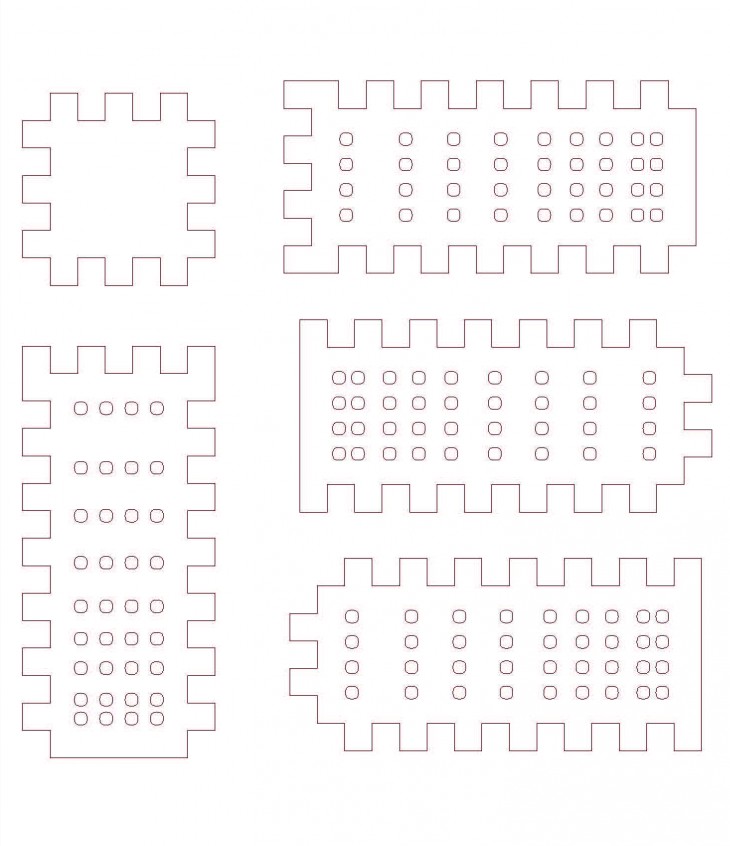

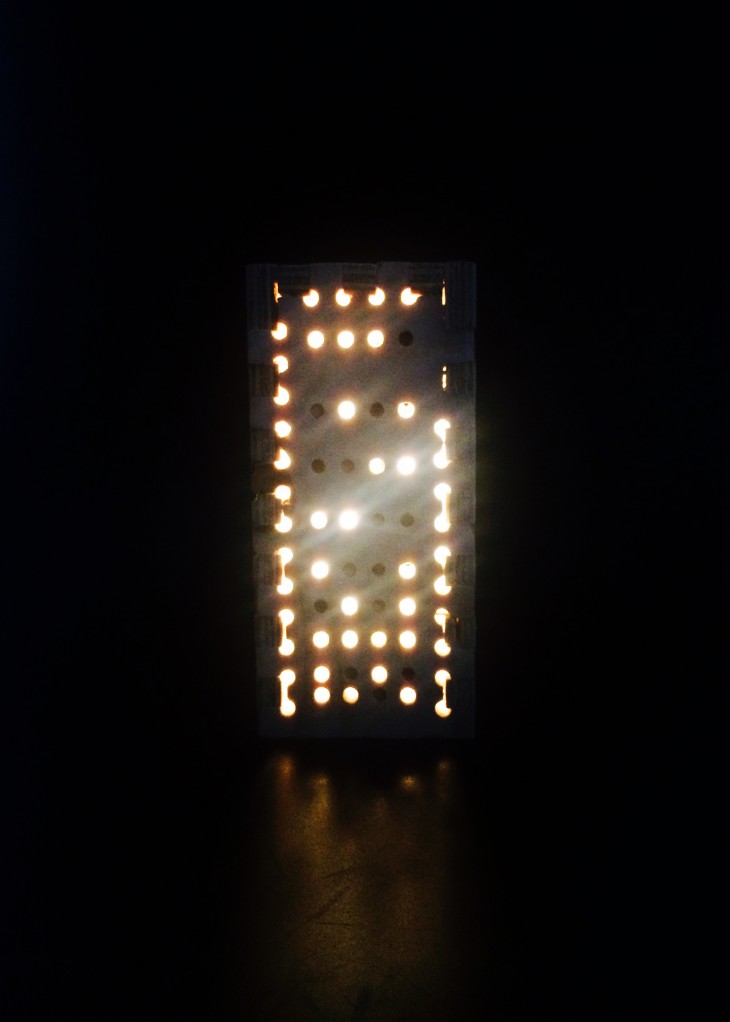

The idea for designing a object to mill was to experiment the potentials of the machines with the available material. Our Team decided to create a basic box which would act as a lamp when a source of light is placed inside.

The process started with creating number of equally sized holes on each side of the box. The next step was about creating a pattern with the holes and playing with the opening depth of the holes. Finger joints were used to connect the sides and the top part.

The process started with creating number of equally sized holes on each side of the box. The next step was about creating a pattern with the holes and playing with the opening depth of the holes. Finger joints were used to connect the sides and the top part.

Students:Caglar Gokbulut, Mohit Chaugule

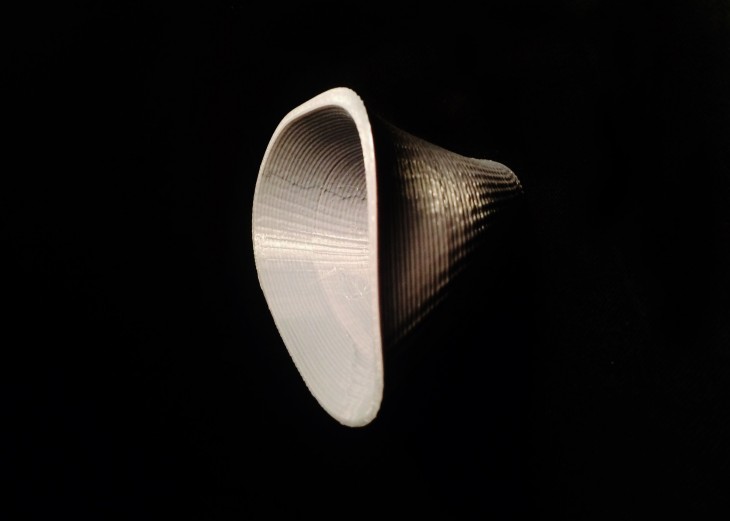

3D PRINTING

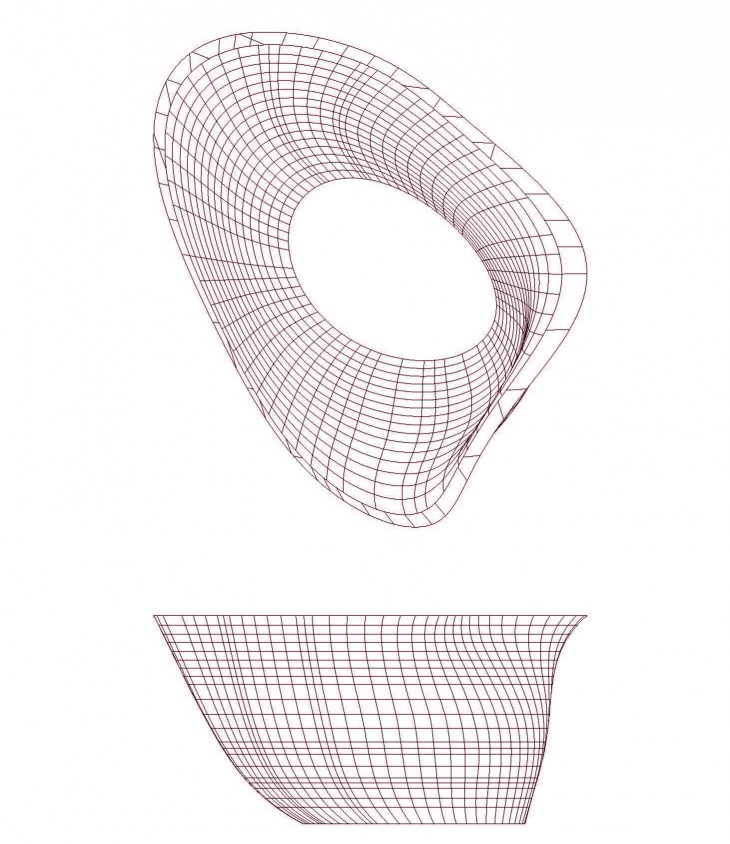

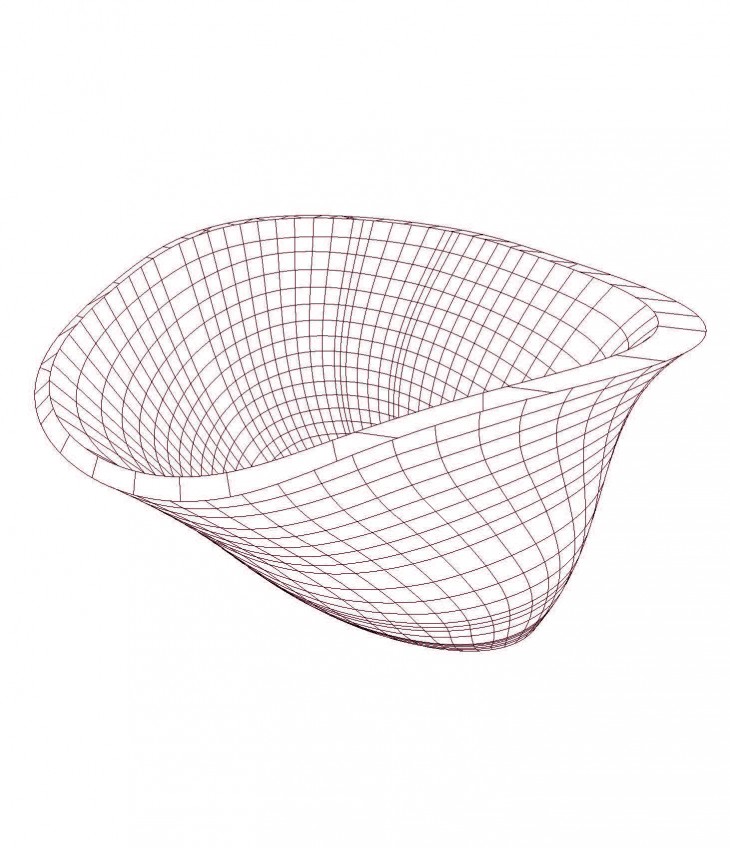

The idea was to understand the advantages and disadvantages of 3D printing process, in which kind of situations we prefer rather than the other techniques and which materials are more suitable for 3D printing which are not.

First we created the model we wanted to print on Rhinoceros, then we modified the first shape we created. After creating the shape we wanted to print, we uploaded the model to a program called slic3r, then we sent to the machine after making the pre-setups on the 3D printer.

First we created the model we wanted to print on Rhinoceros, then we modified the first shape we created. After creating the shape we wanted to print, we uploaded the model to a program called slic3r, then we sent to the machine after making the pre-setups on the 3D printer.

Students: Caglar Gokbulut, Ilkim Er

IaaC, Institute for Advanced Architecture of Catalonia

Master in City and Technology in 2016

Student:Ilk?m Er, Caglar Gokbulut, Mohit Chaugule

Faculty: Djordje Stanojevic, Ricardo Valbuena