Introduction to Digital Fabrication

DATA

Material: Wood

Technique: CNC milling machine

CONCEPT

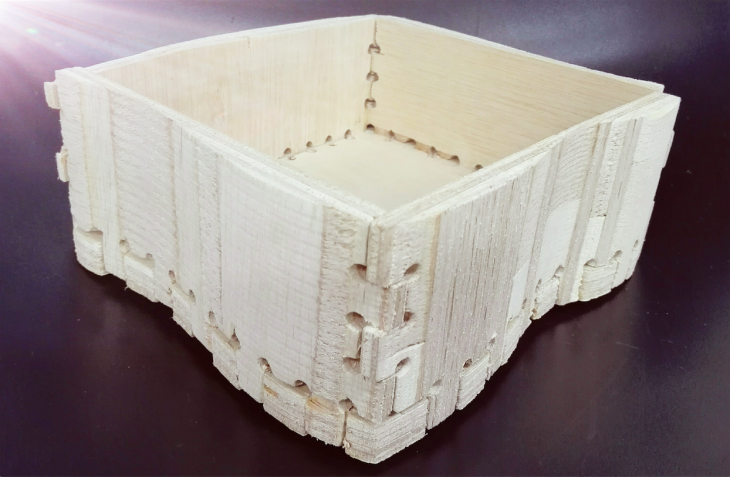

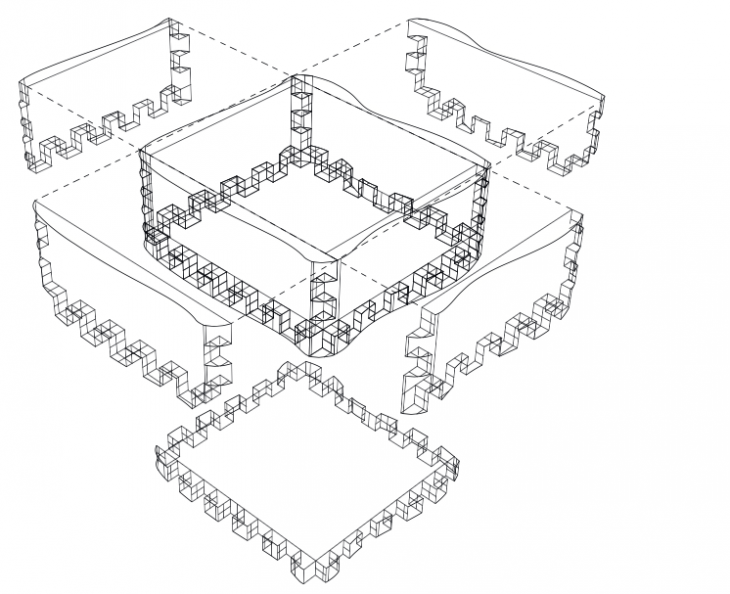

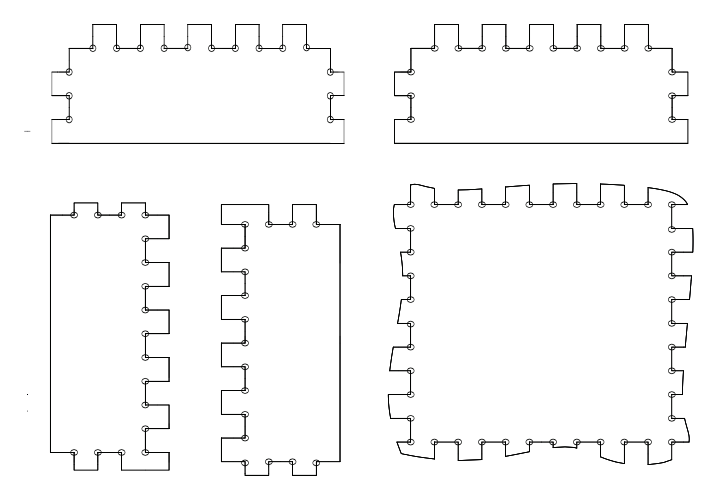

This week’s assignment is using CNC milling machine to print the design of a box. The significant difference of CNC milling machine and laser machine which we used 1 week earlier is that milling machine can do cutting on 3 dimensional. So the design of our box is to make the best use of the feature of the machine. We create curves on every side of the box not only to test the milling machine’s function on cutting on the Z-dimention but also to break the obsolete definition for a cubic box. It have the curved surfaces, showing its characteristic as liquid and fluid. This is our design of the box.

TUTORS

Djordje Stanojevic

Ricardo Valbuena

COURSE IAAC Master in City and Technology

EXERCISE 2: CNC milling machine

PROJECT TITLE: Curved Box

Students:

Chenghuai Zhou

Rahul Pudale

Sherine Zein

LASERCUT

DATA

Material: 5mm cupboard

Technique: laser cut

CONCEPT

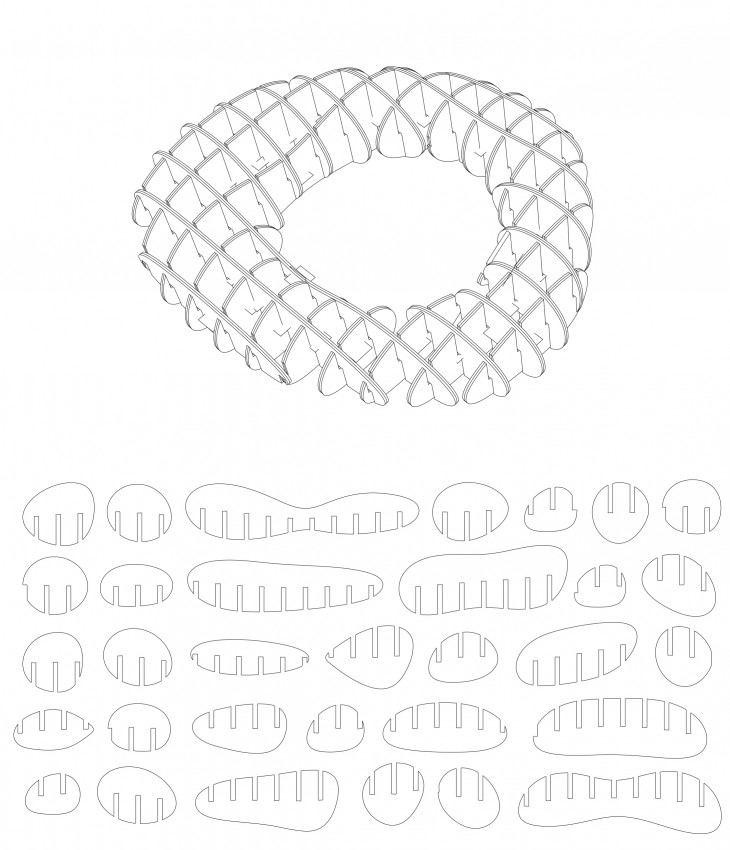

The Torus is a surface or solid formed by rotating a closed curve, especially a circle, around a line

that lies in the same plane but does not intersect it. The shape of the torus was inspired by the

traditional mountain and river landscape paintings. It involve a complicated and rigorous set of

almost mystical requirements for balance, composition, and form.The curved surface and the liquid

and fluid feature of the design showed the change in the weather.

METHODS

First, Create the shape we designed.

Second, properly scale the object in the designated area for grasshopper script.

Thirdly, apply the grasshopper script on the object and bake the results.

For the final object we sent to the laser cut machine, we need to put the object on the “0,0”

point and make sure all the proper parameter for printing cardboard was settled in “en route”.

TUTORS

Djordje Stanojevic

Ricardo Valbuena

COURSE IAAC Master in City and Technology

EXERCISE 1: Laser Cut

PROJECT TITLE: Torus

Students:

Chenghuai Zhou

Chiara Dallolio

3D PRINTING

DATA

DATA

Material: Plastic

Technique: 3D Printing

CONCEPT

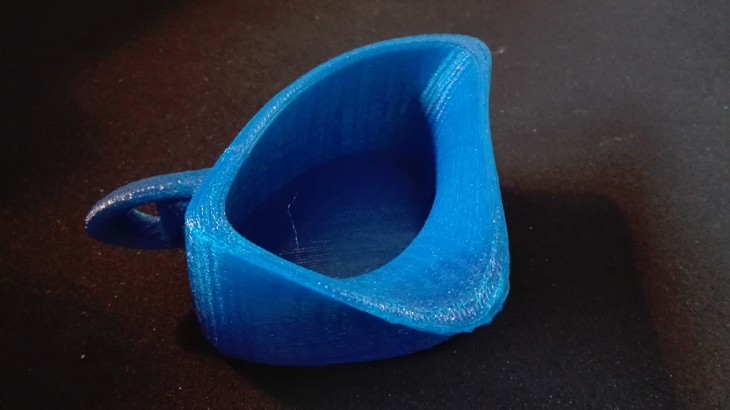

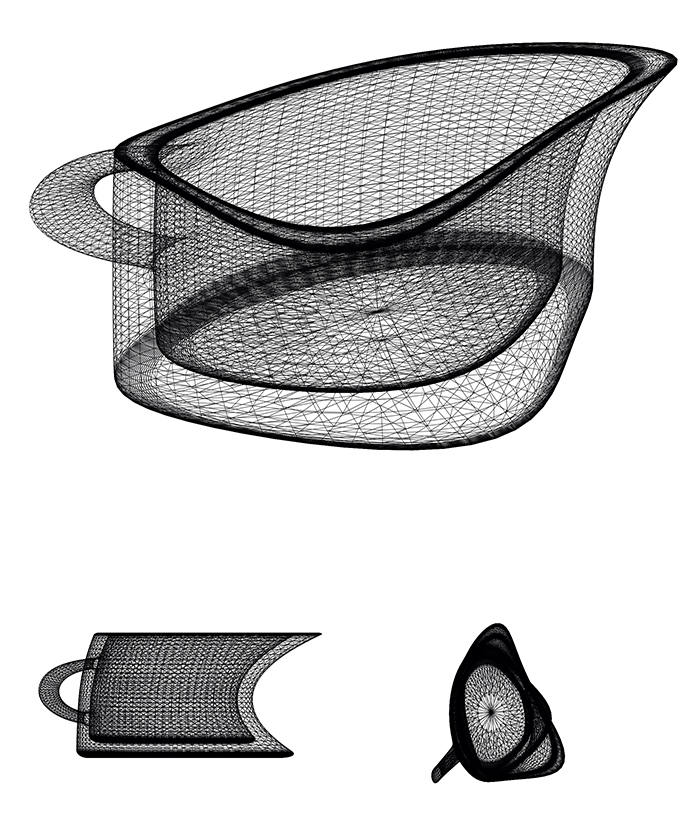

The Melting Mug is the result of the modification of a cup. The original solid was stretched along

the x and y axis and was compressed on the z axis. The shape of the cup was inspired by the

process of 3D printing itself: a thread of plastic is melted by the machine to shape the mug. If we

melt the mug once is made, plastic will go back to its original state.

METHODS

First, create the primary shape of the mug.

Second, deform it in order to have the final shape that we designed.

For the final object, we configured the printing using Cura software and then we sent the draw to

the 3D printing machine.

TUTORS

Djordje Stanojevic

Ricardo Valbuena

COURSE IAAC Master in City and Technology

EXERCISE 3: 3D printing

PROJECT TITLE: Melting Mug

Students:

Chenghuai Zhou

Chiara Dallolio