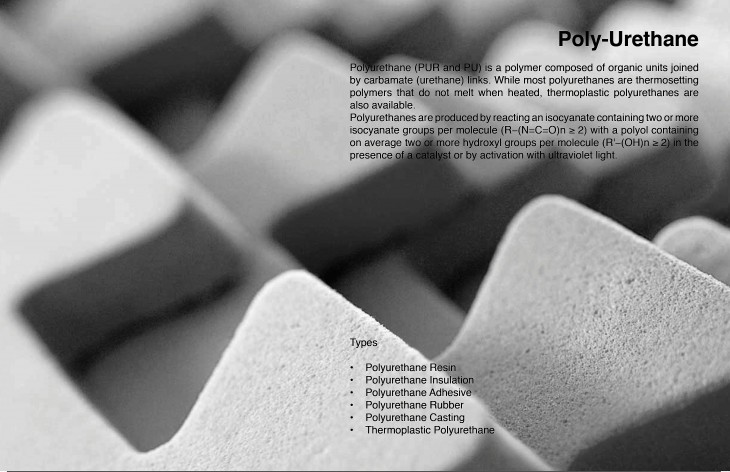

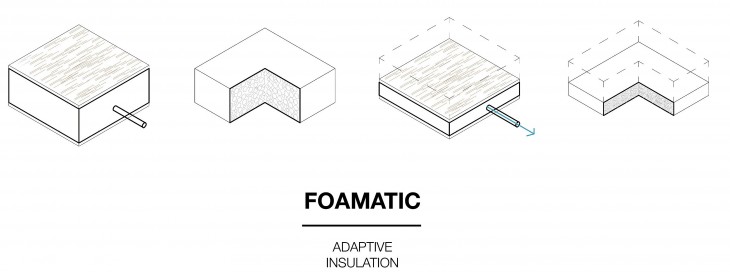

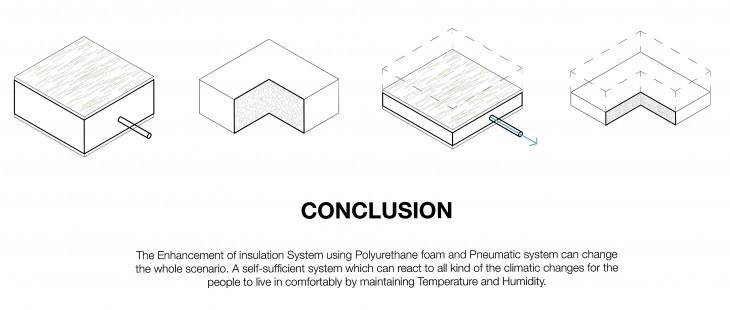

FOAMATIC- Polyurethane Foam with Pneumatic Insulation System

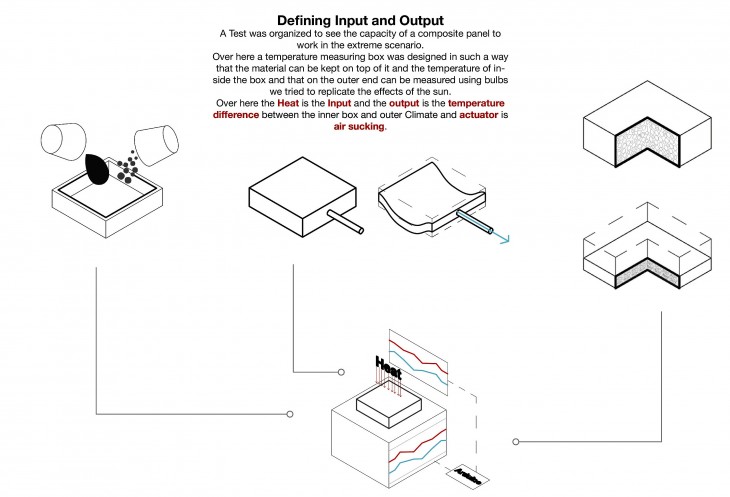

This project was developed around the framework of new insulation system which can work discretely for winter and summer during the year.

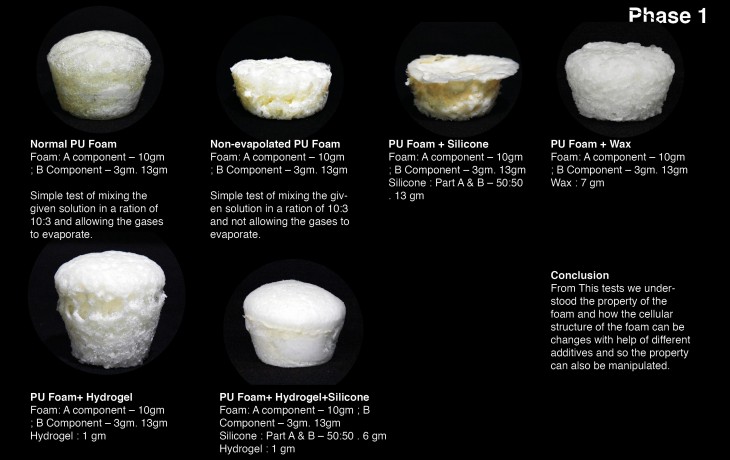

EXPERIMENTS

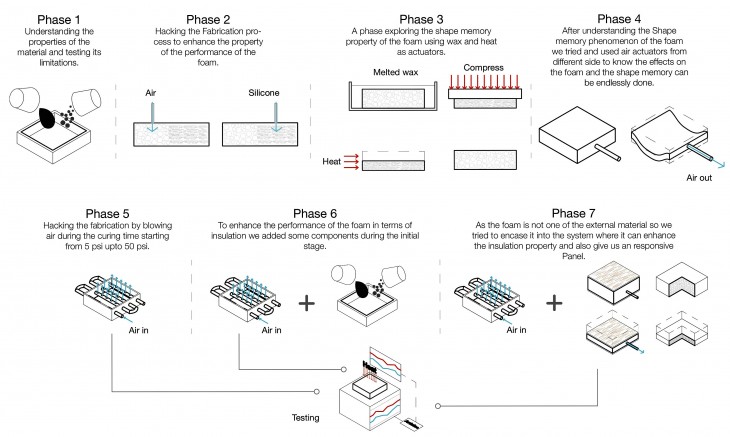

Initial test were done by adding different chemicals like hydro gel, silicon and paraffin wax.

Experiment done with hydro gel gave porous foam then the regular open cellular structure that one obtains by just mixing the isocyanate and polyol. Also the porosity increased with the silicon but the stiffness of the foam increased.

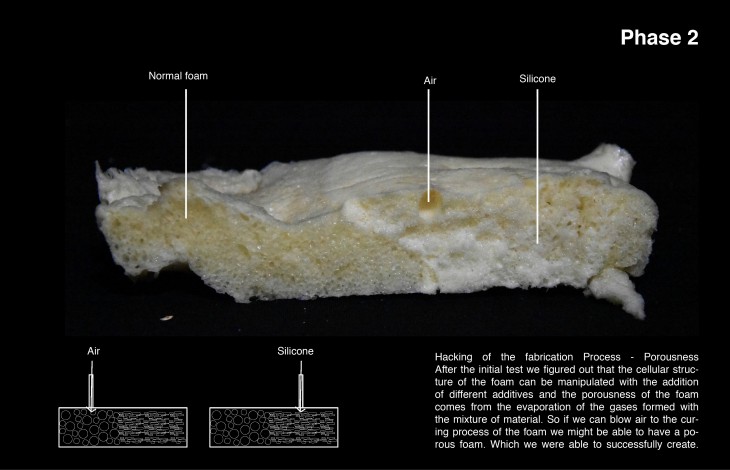

A test was also conducted of hacking the process during the curing time of the foam by blowing air into the process

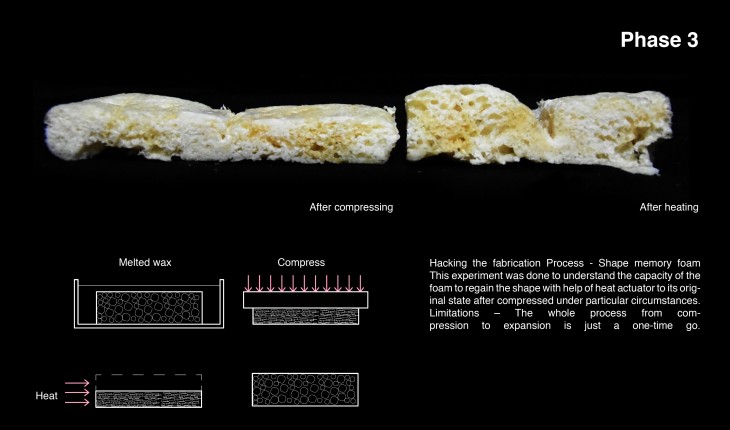

A test was also conducted of hacking the process during the curing time of the foam by blowing air into the process While paraffin wax was used to get the shape memory foam. But it was just a one time effect. Once the foam is dipped in hot wax and then compressed and when reheated it will transform itself back to the original state.

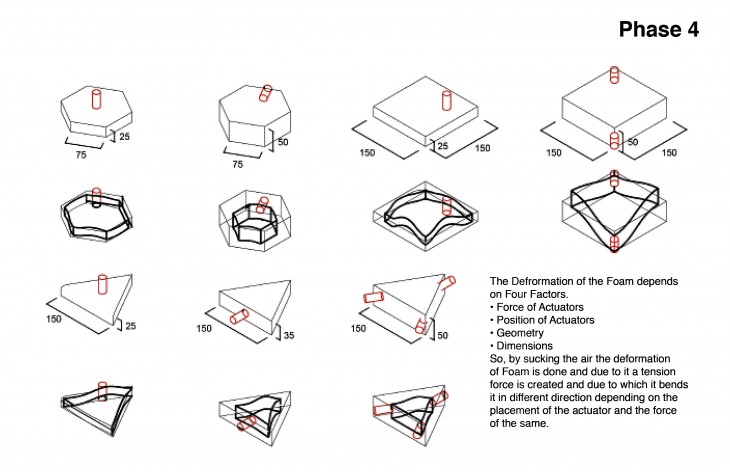

While paraffin wax was used to get the shape memory foam. But it was just a one time effect. Once the foam is dipped in hot wax and then compressed and when reheated it will transform itself back to the original state. The Fourth phase about how the pneumatic system works with the polyurethane foam with different geometry

The Fourth phase about how the pneumatic system works with the polyurethane foam with different geometry

</p>

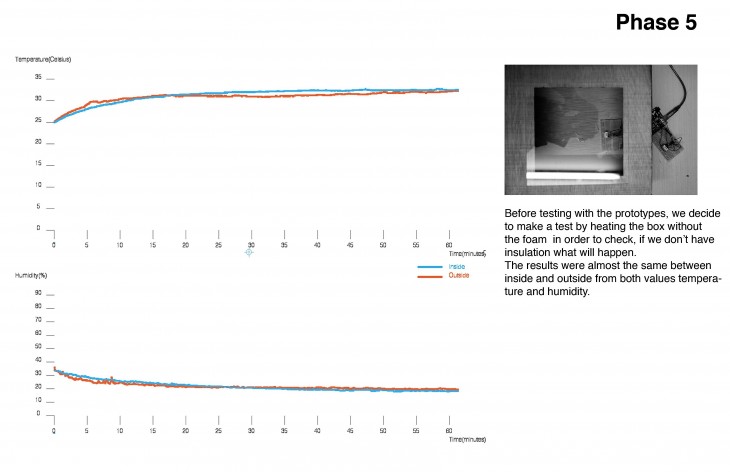

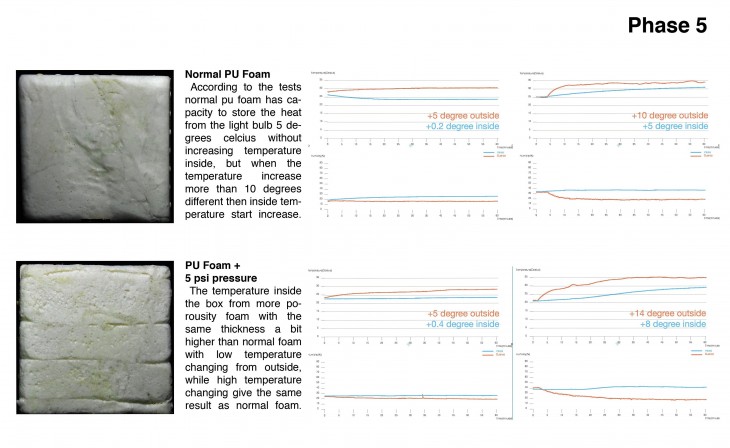

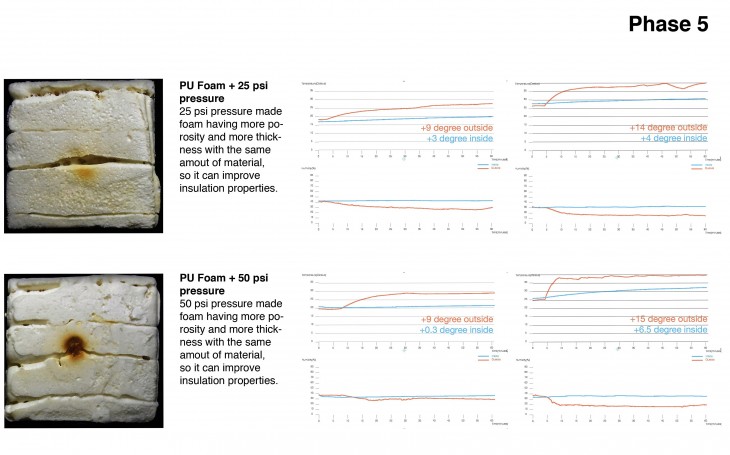

Phase 5

</p>

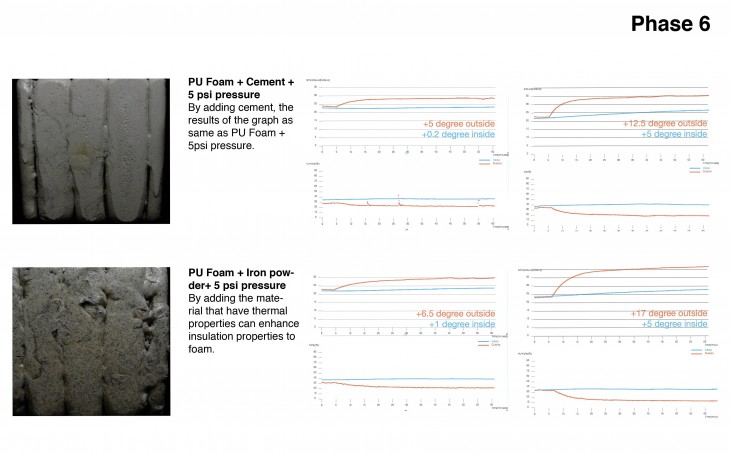

After the Hacking the Fabrication phase, test on changing the properties of the foam by adding materials like iron powder, concrete powder, saw dust etc. were done.

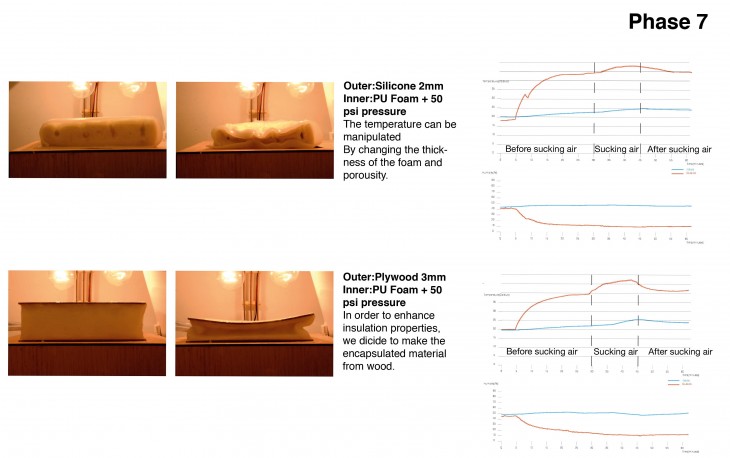

Later, on all of the samples where tested in a scenario created using bulb to create the hottest temperature outside by raising it up to 70 degrees.

</p>

During this test, different foam with different properties gave different results. The Maximum result was obtained in the Polyurethane foam developed by hacking the fabrication process by blowing in the air at 50 psi.

FOAMATIC is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master of Advanced Architecture in 2015/16 by:

Student:

- Nisarg sheth

- Inthat ueasak-aree

- Naitik Shah

Faculty:

- Areti Markopoulou

- Alexandre Dubor

- Angelos Chronis