SE.10 – Elective Seminar

EARTHEN SHELLS FABRICATION

Faculty : Stephanie Chaltiel

Keywords: on site analysis and on site fabrication, fluids analysis, feedback loops between material fabrication and simulations, 3d texturing, perforations, passive ventilation, wind flow.

Intro

This Iaac digital fabrication seminar proposes to the participants to build up on knowledge gained from Phriends* for Shells Iaac seminar 2016 on robotic fabrication for mud shells.

This time we will be building a large quantity of small (20 cm side) earthen shells.

We will be preparing our own ‘earth mix’ for construction using Valldaura’s local clay, actively participating in its self-sufficiency global aim.

Earthen Shells perforations & Natural ventilation performance

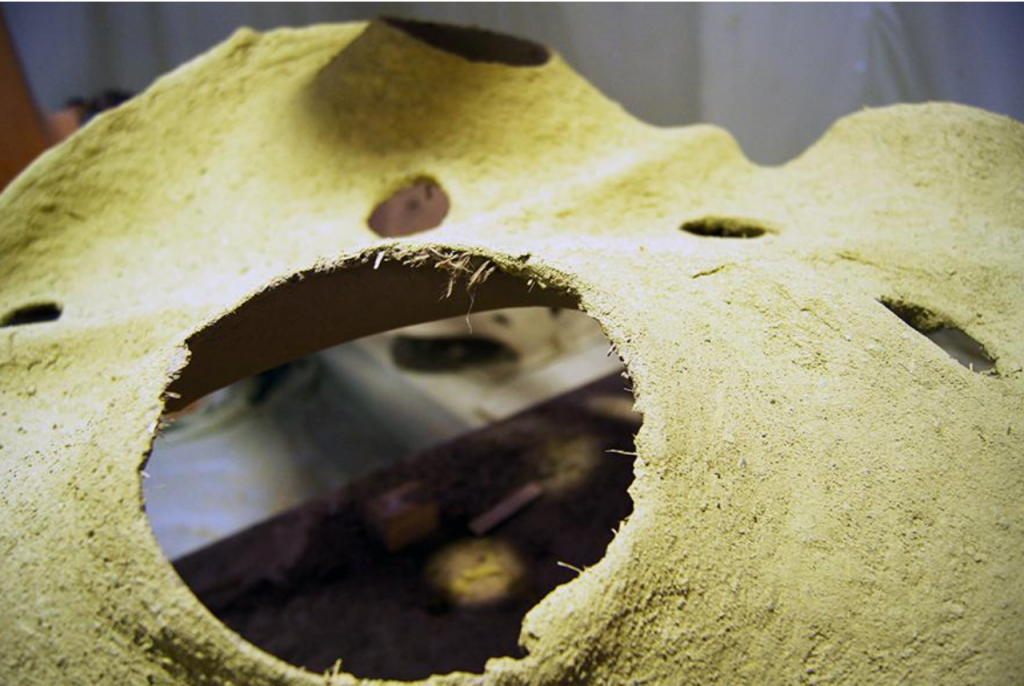

We will be exploring the Morphology of the openings and defining regions on the shells to analyse and fabricate those micro morphologies with deep influence on the wind flow. See Fig1.

We will be running a series of cfd analysis to understand where it is better to have the openings, defining regions of the shell.

We will then vary they density and simulate its effect on the wind flow. We build a large series of small perforated shells of 20 cm side varying a parameter at the time.

Our main goal here is to investigate the relationship between the shell’s main nerves and feet with the perforations type & density. We will also simulate and fabricate by hand thickness shell variation in the perforations regions and analyse its effect on passive ventilation.

Fig1- perforated earthen Shells- robotically sprayed. group 2 during Iaac Digital Fabrication seminar- May 2016. Photo S. Chaltiel

Earthen Shells inner and outer skin’s roughness

Enjoyable manual craft will be creatively put in place to find new forms of inner and outer membrane roughness and textures constantly recalibrated by analysis on karamba and rhino cfd.

The outer and inner skin texturing can be interactive. See Fig2.

Fig2- Mud shells with textures. Svenja Keune’s work at Smart geometry cluster’ mud, fabrics and robots for large structures’ led by s. Chaltiel and A.Dubor- April 2016. Photo S. Chaltiel

We will be looking through the simulations at passive ventilation performance but as well wind flow surprises thanks to the unusual geometries and textures fabricated.

We will be doing a very large quantity of small earthen shells varying their geometry + 3d texturing and proportion to their bounding box, their inner and outer skin textures, and their perforations.

https://www.iaacblog.com/life/iaac-at-smartgeometry-workshop-2016-hybrid-domains/)