Terra-Performa

OTF 2016-17

How can we optimize a 3d printed geometry to adapt with the material behaviour in a physical and digital simulation feedback loop?

Tutors:

Alexandre Dubor

Edouard Cabay

Research paper advisor:

Mathilde Marengo

Student:

Abdullah Y. Ibrahim

MOTIVATION

3D printing, as known as Additive manufacturing, the beginning of the third industrial revolution. 3D printing originally referred to a process that deposits a binder material onto a bed layer by layer, and one of the main 3d printing categories and the most

famous technique is material extrusion. 3D printing has been always an interest for

everybody because of the potential it has as a technology. On the other hand, the

material properties is also a very important aspect in the 3d printing world.

In this project, the thermal and the structural properties of uncooked locally sourced clay is being explored in order to get a performative 3d printed architecture.

A 3d printing approach that allows optimizing the geometry design to adapt with the material behaviour.

The research is defined based on climatic phenomenons and structure findings and conclusions. In this study, It determined to examine the relationship between physical and digital analysis as two monotonous elements and consider how both can improve the design decision. This will provide essential mutual understanding of the principles and problems which govern each other’s work.

PROBLEM

Structure refers to the methodical investigation of the stability, strength and rigidity of elements.

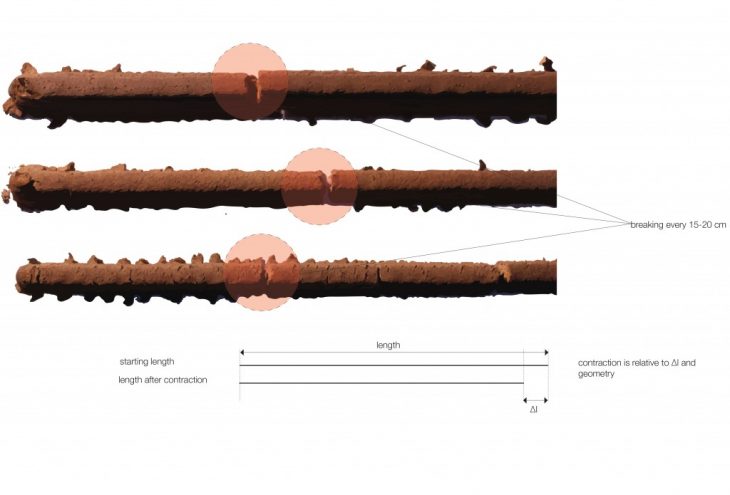

Shrinkage has been always a problematic material behaviour that relates to structure and strength and an unpredictable property to observe and difficult to analyse due to climate, environment, material consistency and other uncontrolled parameters.

Shrinkage is the reduction in volume of hardened clay due to loss of moisture by evaporation. This loss is due to difference in the relative humidity of clay and the

environment, and it increases with higher clay content, higher water content, lower

aggregate content, low relative humidity, high temperature, small thickness of the member, etc, and these parameters cause cracks.

Throughout the process a set of design tool was developed that analyses to get

conclusions out of it. The Flow of this design strategy is applicable for all climatic

phenomenons, however, the focus would be on analysing shrinkage as a part of

structure studies. The comparison feedback loop between digital and physical analysis in order to get the best readings and try to apply these results on the final print. Does it need to be a straight line or a curved line?, if it is a straight line what could be the

longest line and if it is a curved line what could be the suitable radius?

APPROACH

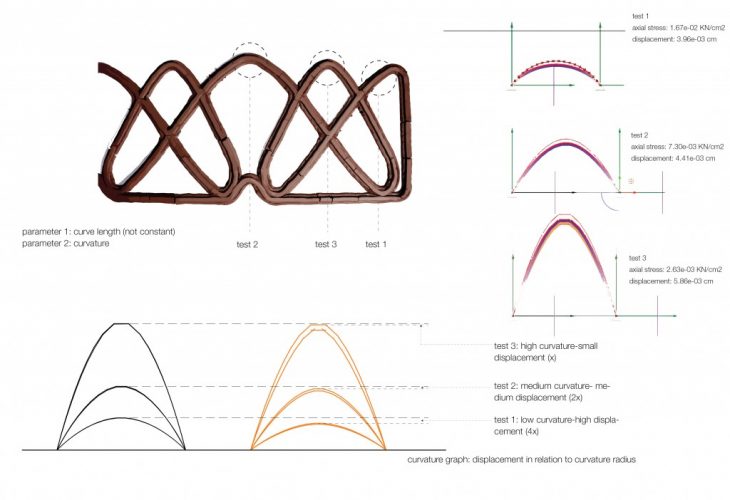

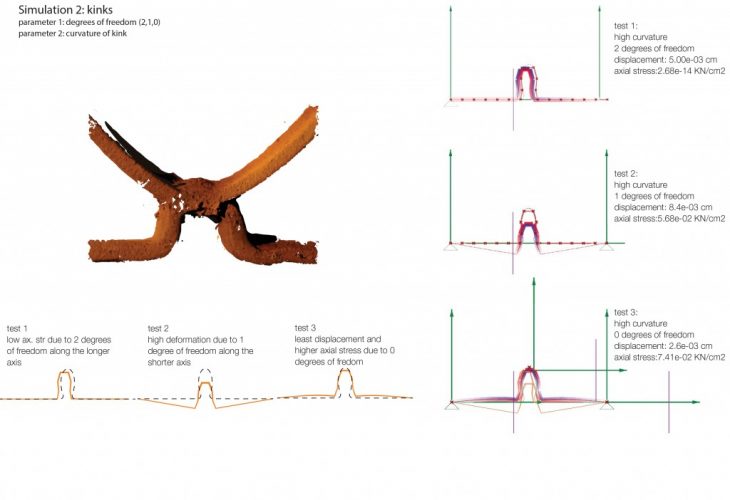

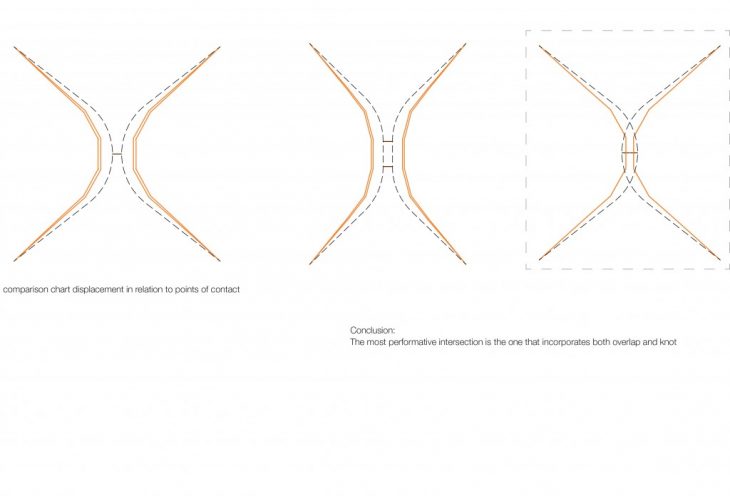

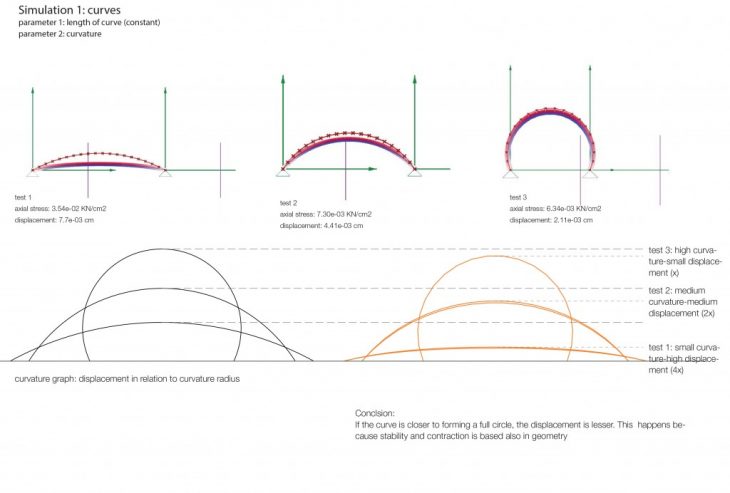

A grasshopper plug-in ‘Karamba’ to simulate and analyse different lines printing

scenarios. There are few parameters that need to be considered and measured while analysing shrinkage such as lines contact, line curvature and kink curvature, under controlled and constant curve length to compare. The target for this project would to have an optimised geometry due to material shrinkage to prevent crackings in the

drying process.

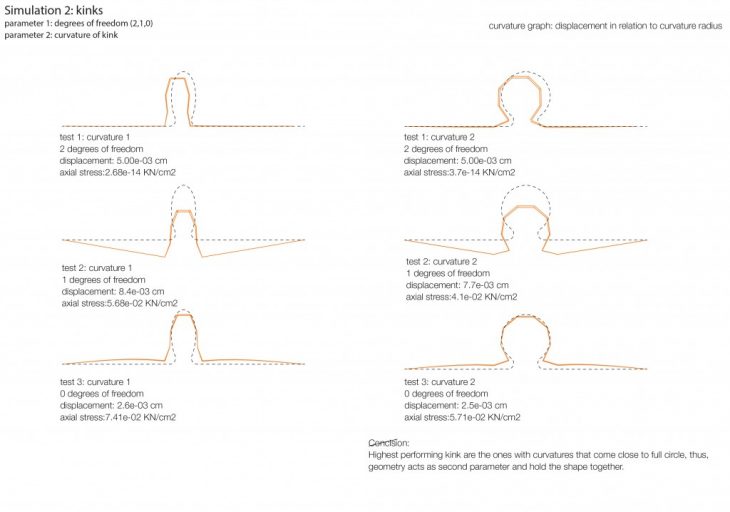

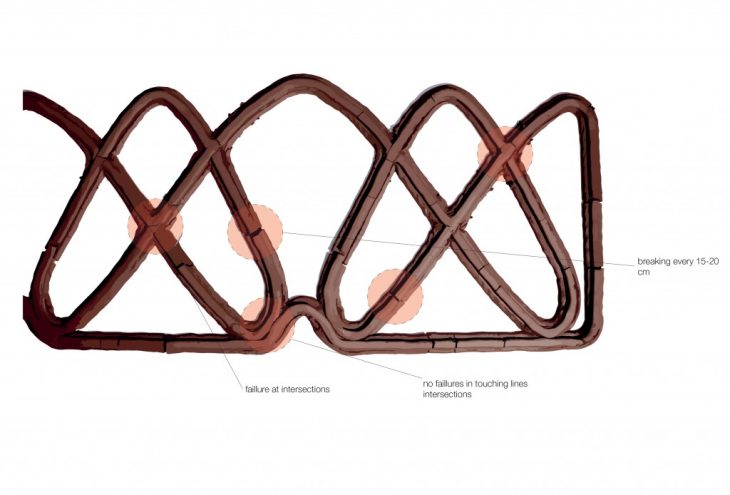

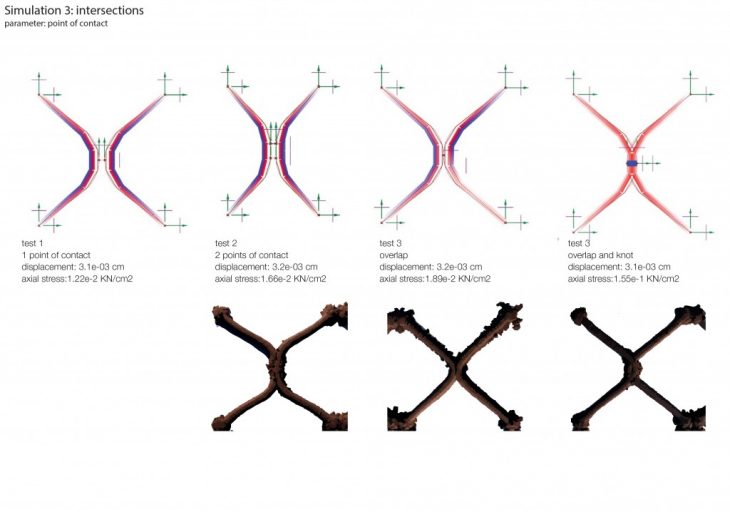

The RESULTS of the three parameters are:

Simulation 01 | Lines Contact

Simulation 02 | Line Curvature

Simulation 03 | Kink Curvature

CONCLUSION

Simulation 01 Conclusion | Lines Contact

Simulation 02 Conclusion | Line Curvature

Simulation 03 Conclusion | Kink Curvature