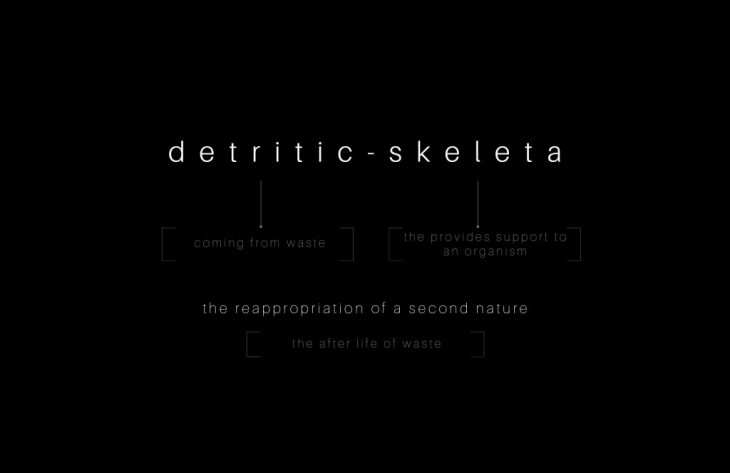

Detritic Skeleta : The Reappropriation of a Second Nature

Student : Johana Monroy

Tutor : Marcos Cruz

C.Bio.Ma Thesis Studio

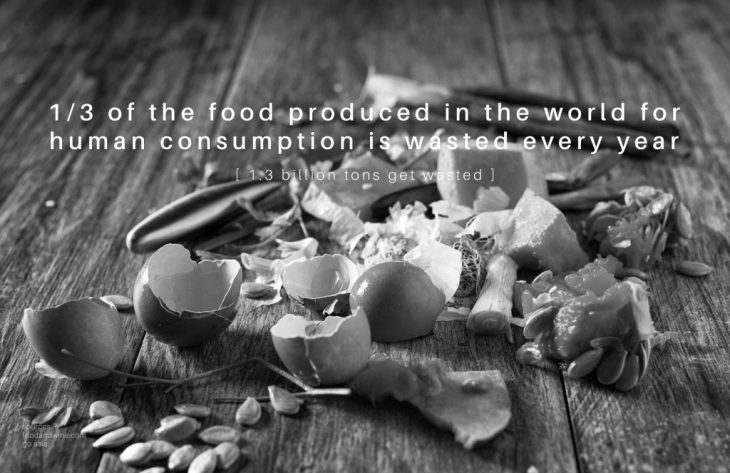

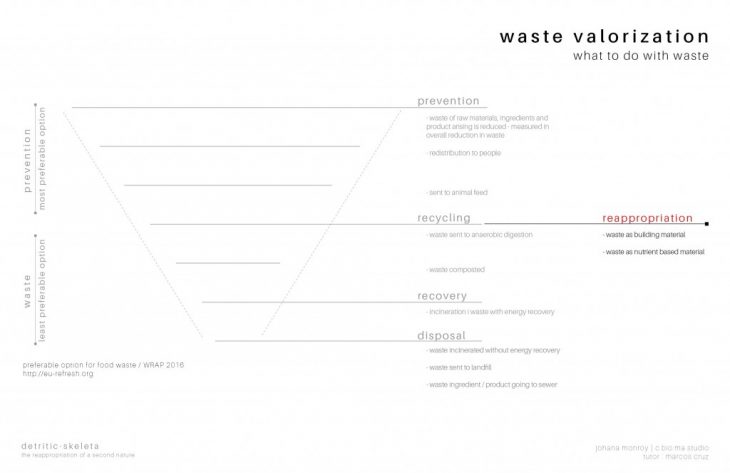

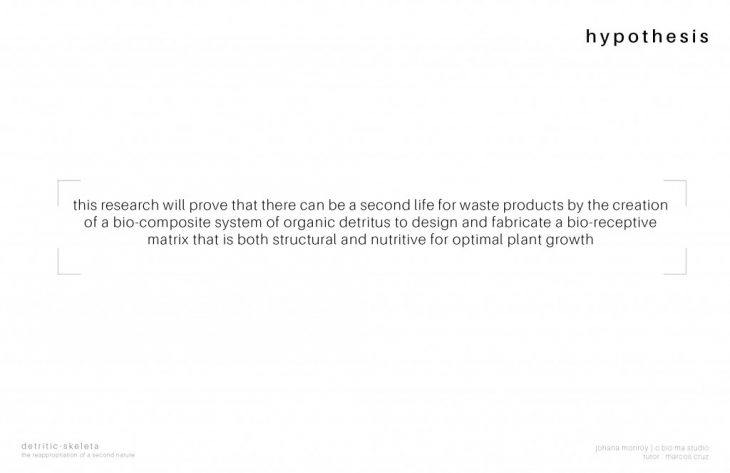

The basis of the research revolves around the idea that there can exist a second life for waste products as opposed to the current notion of throwing waste away and forgetting its existence. Piles of waste keep accumulating around the world, polluting our air and water, while if we just take the time to re-examine the material industry, we can find a way to re-purpose the forgotten by giving it a new meaning.

The focus of the project is the re-approapriation of organic detritus as a nutrient based system that not only serves as structure in the material sense, but that is also capable of supporting plant growth with the remaining nourishment found in food waste.

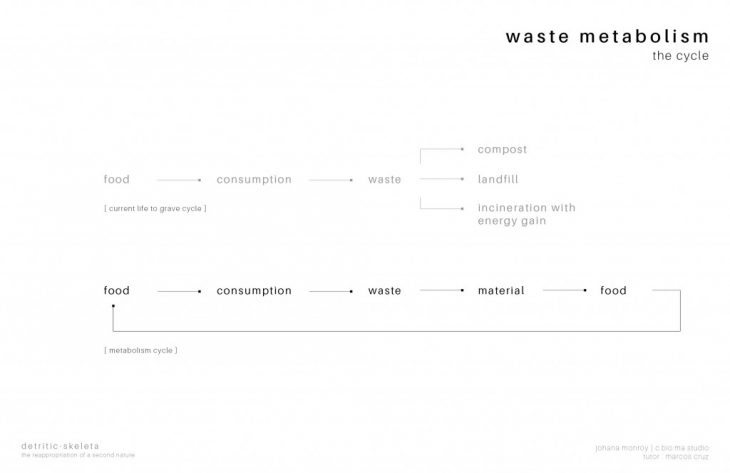

The current life cycle of food waste exists in the “cradle to grave” sense. Food being grown to support life but then all the waste is simple thrown away at landfills.

This project wants to redirect this idea to a “cradle to cradle” cycle which metabolically looks at products in which one cycle is a closed loop that helps sustain itself.

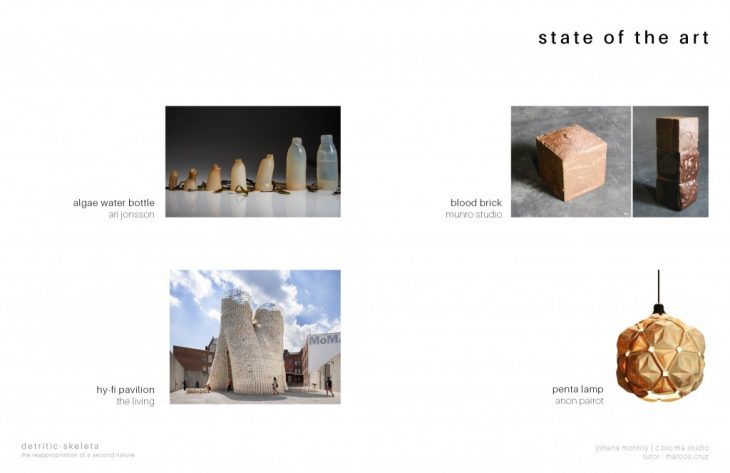

Currently, we see projects that are already working with this metabolic idea, using waste as a material. Aside from the Hy-Fy pavilion mentioned above, most projects are of small scale, targeting the industrial design world of lamps and other objects.

Detritic-Skeleta aims to work in a bigger scale, proving that organic matter can be used in an architectural scale.

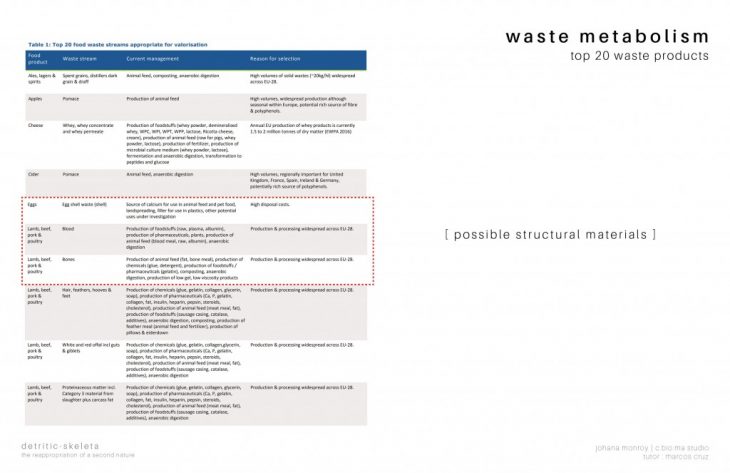

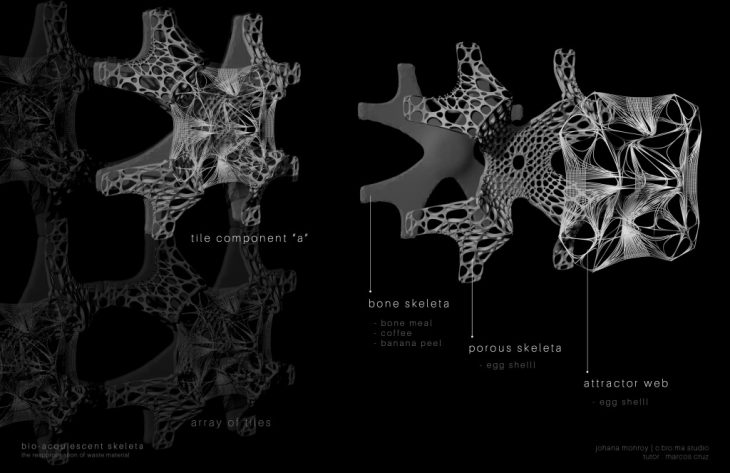

While researching current waste products, bone and eggshell are 2 major products that would have a possible structural value.

To support plant growth, other waste materials were researched, focusing on coffee grounds and banana peels, which are not only vastly available but that also filled with nitrogen and potassium, 2 major components needed for plant development.

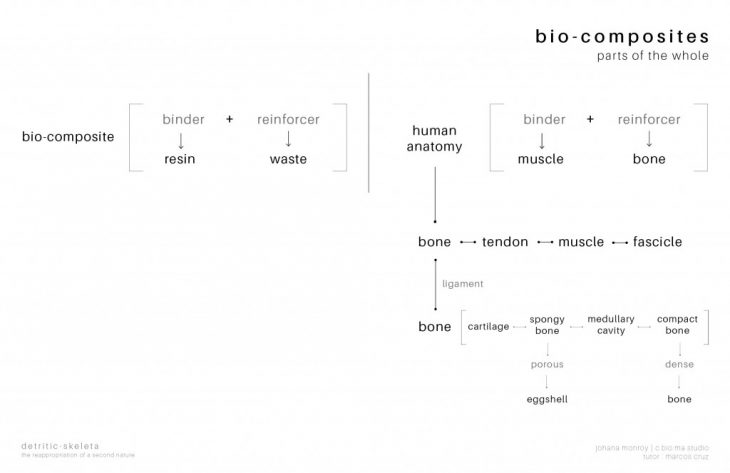

Many sample were made to discover the best mix for structural support of the system. The main components being bone and eggshell.

Bricks were produced with said material and some were cnc’d proving that the material could be used in digital fabrication.

[Prototype 1.0]

The first set of prototypes were casted in latex moulds, having both a structural base and a nutrient like shell that would assist the plant.

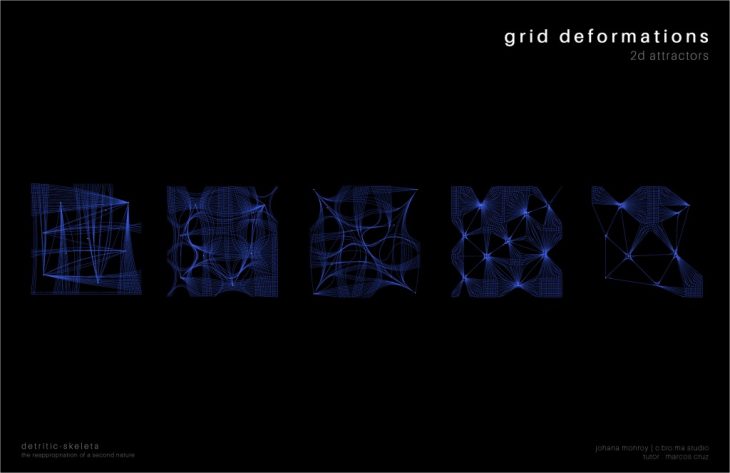

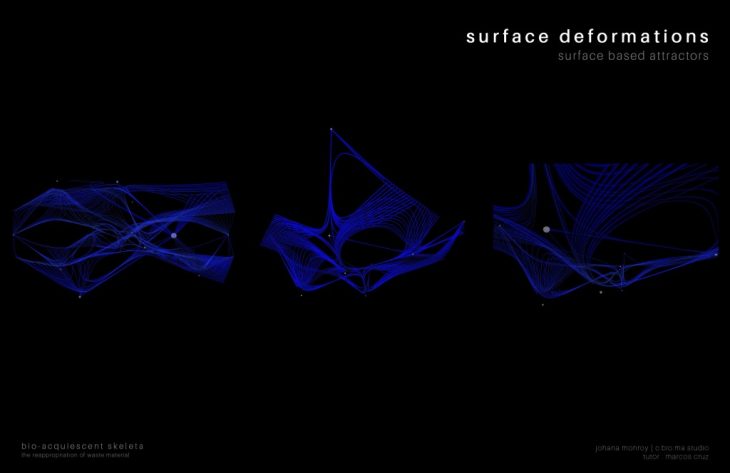

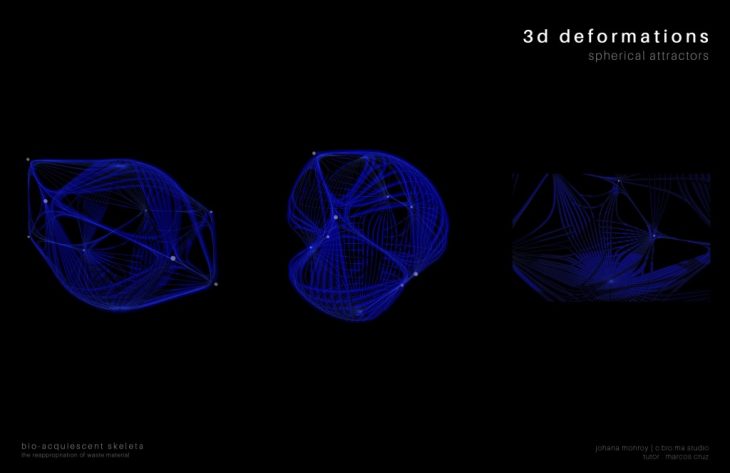

The geometry was then later explored more through grasshopper, where the shape was given further texture and made to be a web-like attractor that would not only help with the development of plants, but that might also attract other organisms.

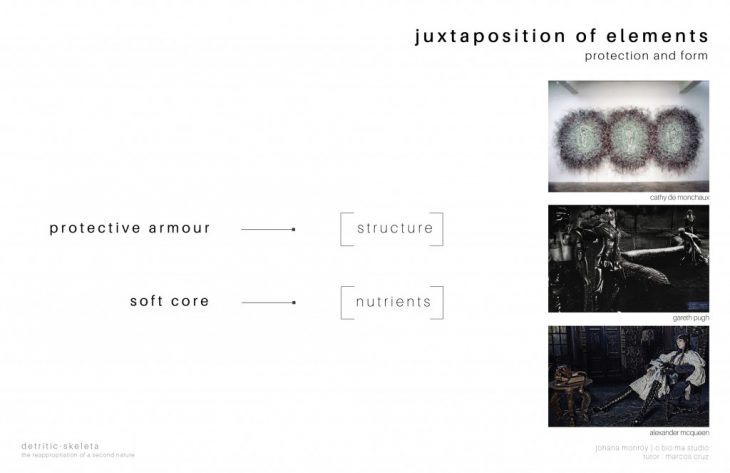

Through the analysis of the first prototype, it was seen that the tile itself lacked many other aspects needed in optimal plant growth. Prototype 1.0, had 2 hard shells that served as structure but had no soft components that held nutrients.\

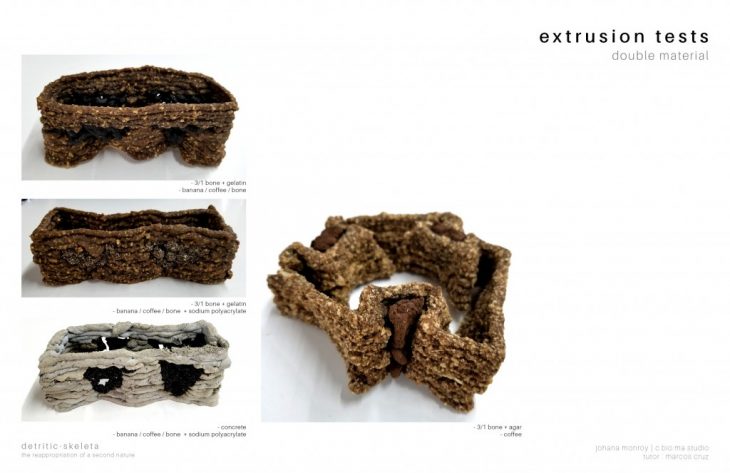

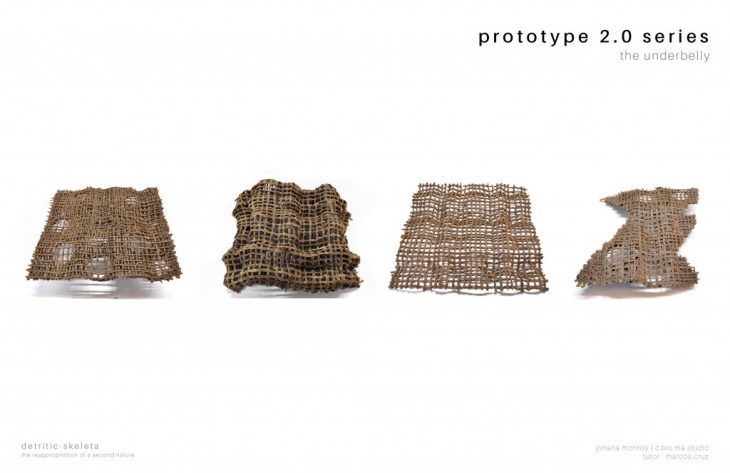

As seen in nature and even in other disciples such as sculpture and fashion, there exists a play on the hard and the soft, on the structure and the nutrient. The next set of prototypes were to not only deal with the structural aspects of the project, but also look for ways to develop a soft, flesh like component where nutrients were to be stored.

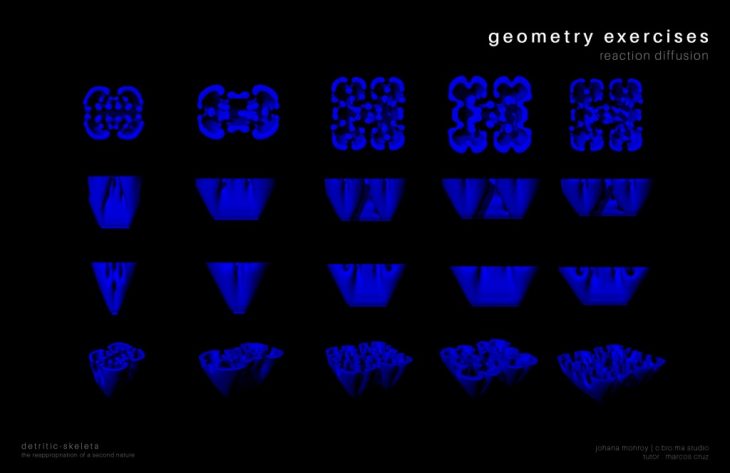

This set of geometrical studies not only focused on the possible design of the project but also on its fabrication method. With the above studies, a new set of physical prototypes were developed which dealt with additive manufacturing.

The new method of fabrication led to new mixtures of the waste products which were 80% waste and 20% gelatin.

[Fibers in Time]

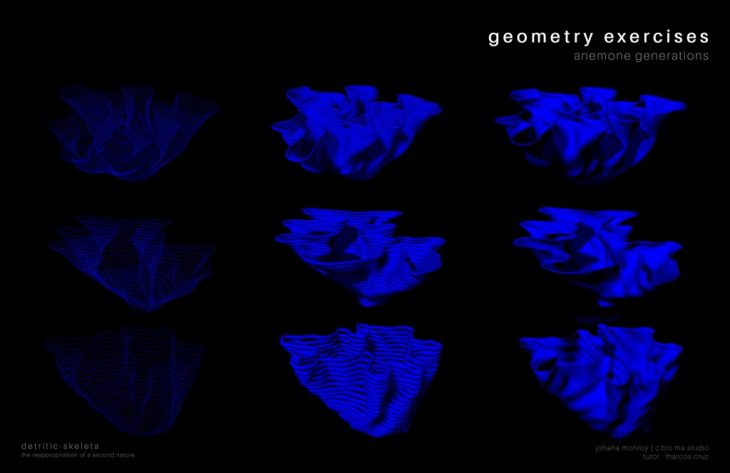

The geometries that are currently being explored are fibrous in appearance while being structurally sound in physicality.

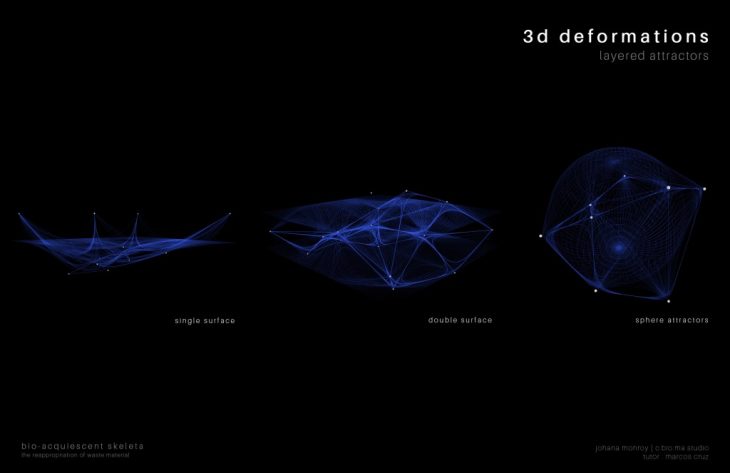

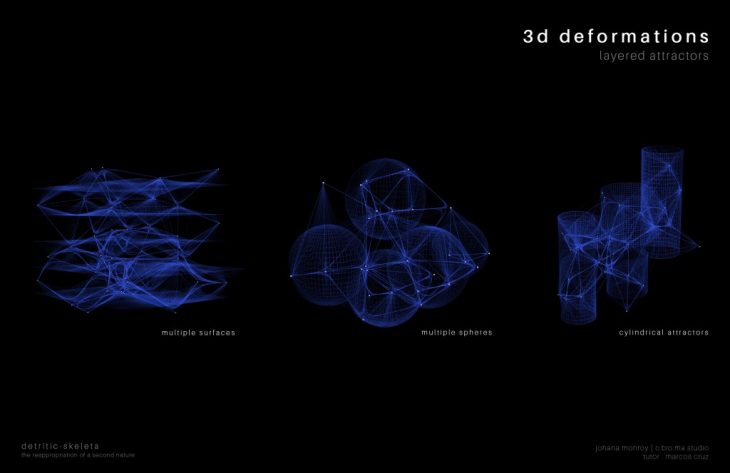

The first set of geometries were of 2d nature, consisting of deformations of grids that were being pulled by set attractor points.

Later, these grids were seen as surfaces that would be altered not only in the x and y axis but also in the z axis, producing these fibrous meshed that led to different spaces as the grid was deformed in time.

These explorations led to the idea that these organic structures have a life-span, a life-cycle, allowing them to change in time as these begin to decompose and degrade.

As the surfaces changes as it is exposed to nature, its nutrients would be slowly dissolved into the ground, where it would provide nutrients to the plant life that it was serving as a scaffold to.

Through additive manufacturing, the above geometric studies were produced into physical form.

Here we can see how the various layers of material lead to different geometries, creating a landscape for plant growth.

The next steps for this research is to use the robotic arm to produce these detritic landscapes and find the plants that would benefit from the structure and its nutrients.