IAAC – Master in Robotics and Advanced Construction

Workshop B

–

Faculty: Wes McGee.

Faculty Assistant: Kunaljit Chadha.

FROM DESIGN TO CONTROL:

Developing Materially Intelligent Robotic Processes

Syllabus

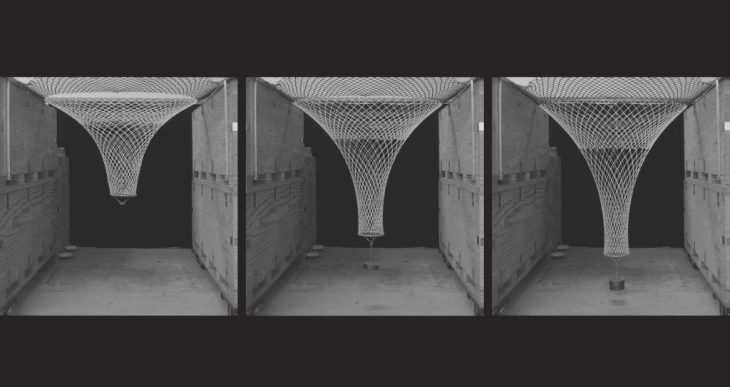

This workshop will investigate design and fabrication methodologies for local tailoring of material performance. These methodologies include systems which are tailored geometrically (for example the Infundibuliforms project) as well as those which are tailored materially, such as a multi-material extrusion process. By locally tailoring material properties, components can be designed which embed performance at a nuanced level while simultaneously minimizing material usage. For example, a variable density mesh can be deformed into non-minimal geometries, or a mixture of variable durometer elastomers can be extruded to produce a continuously variable stiffness.

Credits: “Infundibuliforms” Dan Tish, Wes McGee, Geoff Thun, Kathy Velikov.

Credits: “Infundibuliforms” Dan Tish, Wes McGee, Geoff Thun, Kathy Velikov.

In order to design and fabricate such systems, there are two requirements. The first is a software design framework which allows process parameters to be locally specified along a machine trajectory, and the second is a hardware interface which allows this specificity to be synchronously communicated between a robotic / CNC motion control platform and an end-effector.

A simple example would be the variation of the extrusion rate as a tool moves along a path. The implementation of low-level synchronous process control varies widely and depends on the specifics of the machine control language chosen. Additionally, real-time sensing and process feedback presents the potential to create adaptive processes.