ROBOTIC HYBRID MANUFACTURING

Hybrid Manufacturing combines two or more established manufacturing processes into a new combined set-up whereby the advantages of each discrete process can be exploited synergistically.

(2010, CIRP – International Academy of Production Engineering)

INTRODUCTION

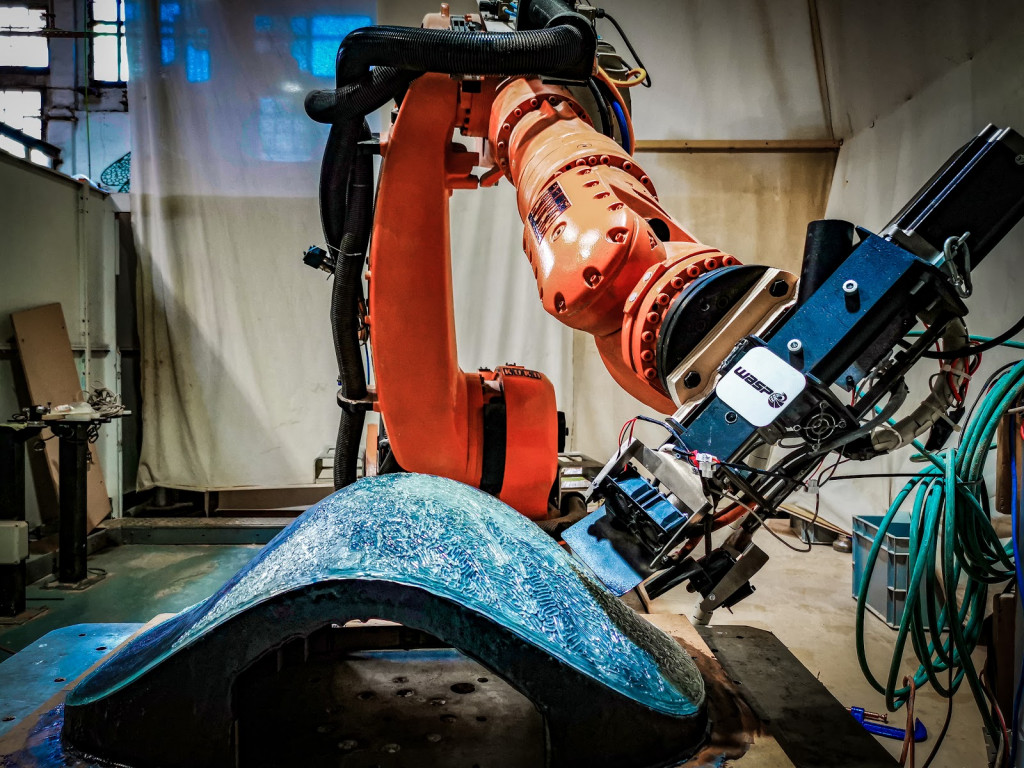

Hybrid Manufacturing, as in our case, it is simply the senseful combination of subtractive methods like cnc-milling and additive methods like 3D-printing in a fabrication system, has still reached the market in the metal industry. Other industries, handling with custom big scale 3d shapes, still try to improve fabrication speed, waste reduction or surface quality by focusing on just producing with one of these methods. The combination of both methods together with a robotic system with a greater freedom of movements and reachability could save time and waste and increase the quality and accuracy of big scale objects. The freedom of a subtractive and additive process in one setup could also create the possibility of producing designs which where not feasible to produce before. Furthermore materials are needed which are hybridable, means they could be milled and also 3d-printed. In that case, thermoplastics, which are thrown as non compostable waste in a landfill are now the most interesting material for hybrid manufacturing. This project is trying to reactivate the interest to thermoplastics as an important resource for creating a new kind of manufacturing big scale products. This project tries to point out the economical relevance of a possible regional robotic setup, for fast production between unique and mass product.

WHY

As Designers, Architects, Engineers we get more and more advanced software based tools in the hand to develop the future of how we live , where we live and how the shapes of the future would look like. We also talk a couple of decades about customization in terms of “mass customization” but this is mostly just a combination of different parts of the same mass produced product. We are still addicted to the mass production and big companies ruling the market.

With the industrialisation we got plastics, which changed the way we handle objects. And now we throw them away as landfill and created a big ecological problem out of it.We discovered a new way to get use of robotics used in the automotive industry but it still didn’t found the way out of mass producing companies. We have 2 prototyping methods which are used to create complex shapes but both have his very own issues.Combining all these facts in a robotic hybrid manufacturing system we think we can create a new kind of manufacturing complex shapes in a closed material loop system much more material and time efficient and we can close the economic gap between production of unique pieces and mass production.

BUSINESS FIELDS

We have complex shapes nearly everywhere in our lives and besides the mass production industrie a wide range of business fields who could be very interested in the potential of hybrid manufacturing.

AUTOMOTIVE INDUSTRIE

The automotive industry is mostly making their molds for prototyping out of a milled foam block and a clay coating on top which ist processed manually or milled again by a CNC-machine. But the coating process is mostly done by manual labour . That takes time and money and could be automated by HM . Also the inner Styrofoam core could be avoided by printing a stable wall instead.

MOVIE INDUSTRIE

Creating futuristic movies means shaping the future superlatively in case of props . These props should show how the future could look like and the props are unique products which were never produced before. Time and money are very important in the movie industry and to find smarter solutions for these two issues and creating a setup which could produce a wide range of different novel shapes is a necessity besides the growing digital production.

ARCHITECTURE

For architecture it’s crucial to find a way to produce a high amount of unique big shapes, matching together in a much bigger scale. So moldmaking could be quite interesting .

PRODUCTDESIGN

Finding new shapes , testing new designs and functions is an important part of product design and a tool which could give the possibility to test designs not only in the right scale but also in the right surface finish and physical behavior could help for decision making but it also gives the possibility to create small series of products besides the mass production industry and brings the designer even closer to the end user.

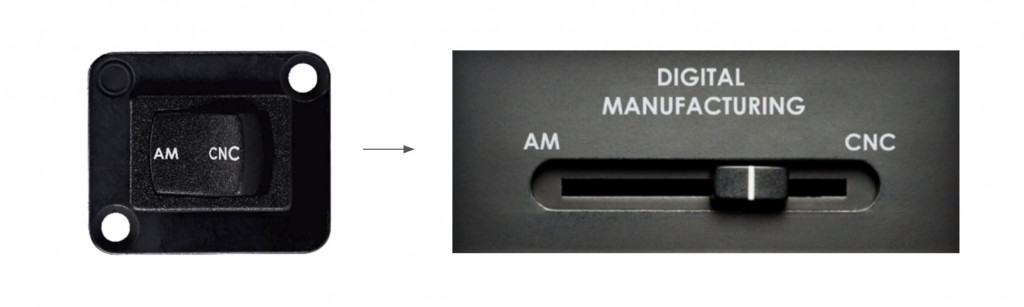

ADDITIVE MANUFACTURING AND CNC-MILLING

In the direct comparison of both prototyping methods , the advantage of the one is mostly the disadvantage of the other method. In terms of accuracy and surface finish cnc-milling is much better than AM. Trying to reach a high accuracy and surface finish with AM means increasing the time of producing by having a decreased layer height. But that could effect the probability of printing errors like over- or underextrusion . But in terms of the amount of material for producing or the programming effort, Additive Manufacturing is much better.

So the combination of both methods could be the combination of all advantages of both in one system without any disadvantage.

So in the future of big scale manufacturing the desicion is not between AM or CNC-Milling , its more the question in which relation they both come together according to the part which should be produced.

HYBRID MATERIALS

For hybrid manufacturing it is neccessary to take materials which could be used for both methods. The metal industry is still working with hybrid manufacturing. But also thermoplastics and thermoplastic polyurethanes work for both methods.

Luckily the most problematic material for our enviroment today is one of the materials we could use. Thermoplastics are considered as the evil because we throw too much of them away and this material will stay for the next hundreds of years until it decomposes. But this material could be recycled many times without loosing too much physical properties. By heating up thermoplastics they melt and become reusable for additive manufacturing. And the waste of CNC-milling could be recycled again to new printing material.

All the problematic thermoplasts we find in oceans and landfills like PP (Polypropylene), ABS (Acetylbutadienstyrene ), PS (Polystyree), HDPE (High Density Polyethylene), LDPE (Low Density Polyethylene) and many more, are the most used thermoplastic materials for different industryfields where parts have to work longer then coffeecaps and foodpackages. So we can reuse all these materials a couple of times for the next decades while we develop bio-based thermoplasts to replace these petroleum-based once.

FRAMEWORK

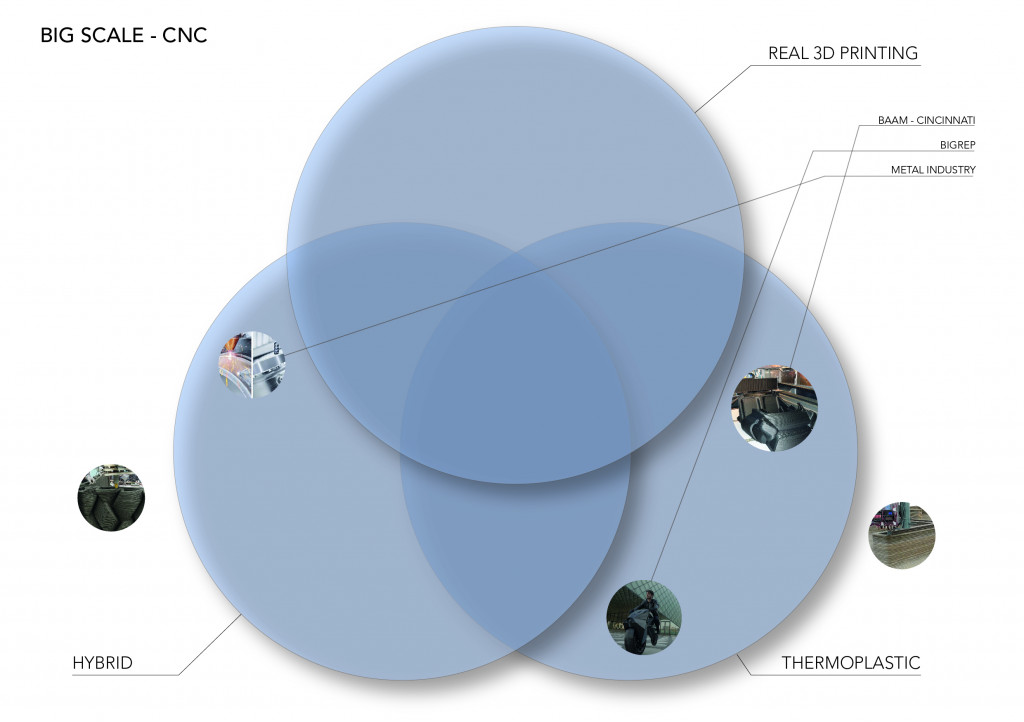

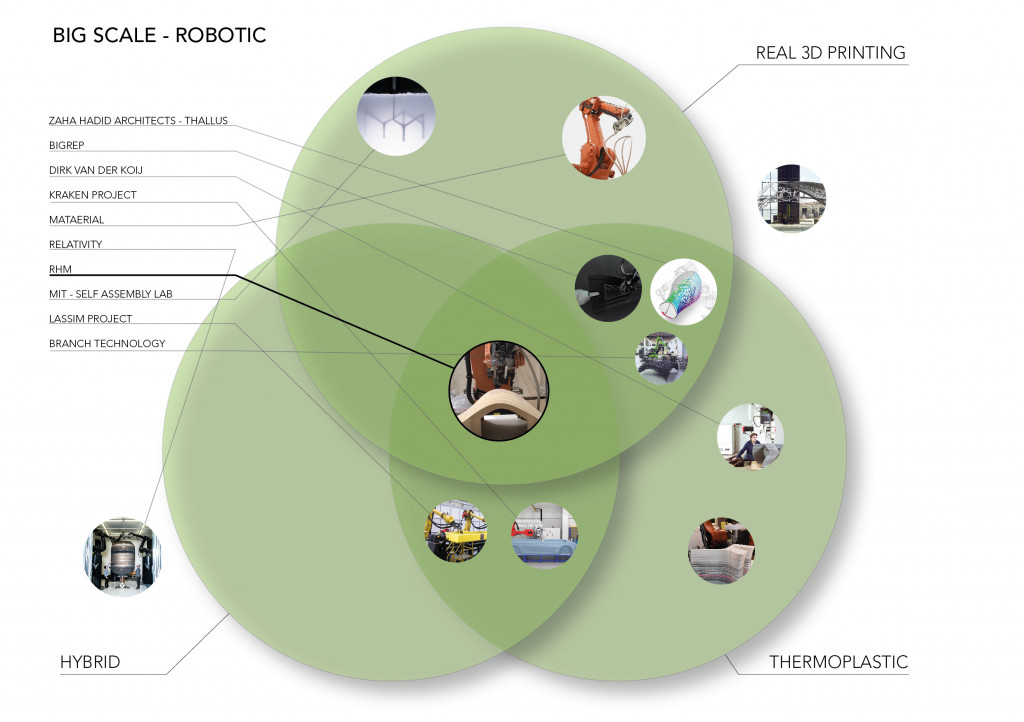

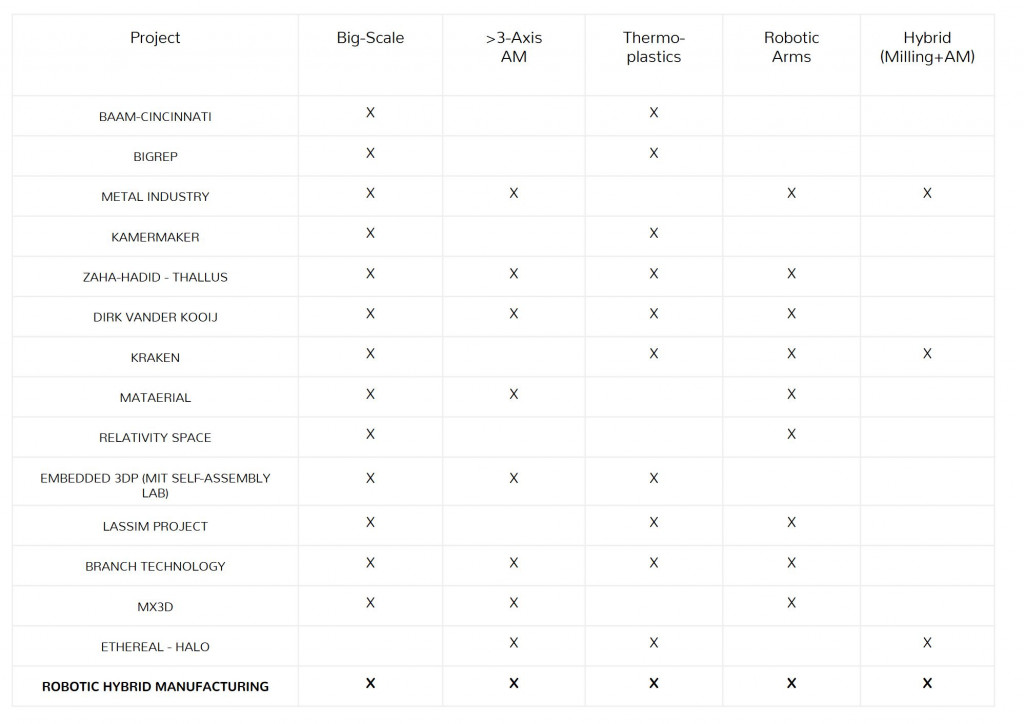

For manufacturing big scale shapes we have to take a closer look into CNC-machines as well as in robotic systems. The big CNC-machines promise mostly more accuracy but are much more expensive, need a lot of space and have less freedom of axis the robotic arms. But in both cases we find companys tackling interesting fields like Real 3D-Printing (Multi-Axis-Additive Manufacturing), the use of thermoplastics and hybrid manufacturing. But there is no company which combines all 3 fields .

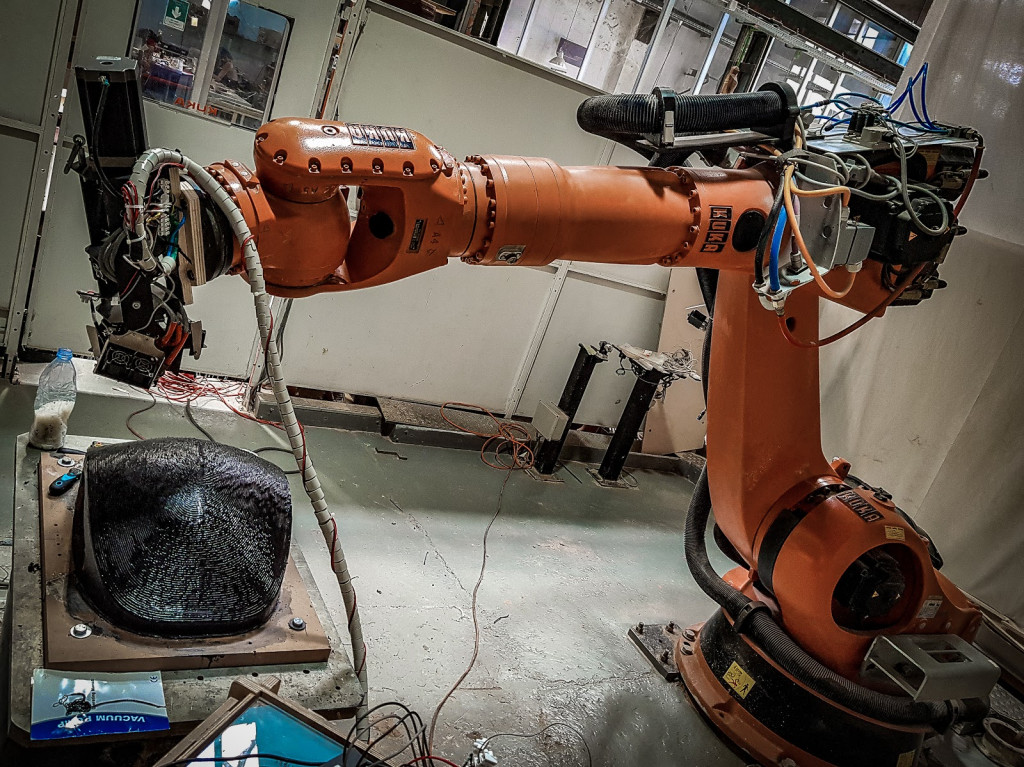

PROOF OF CONCEPT

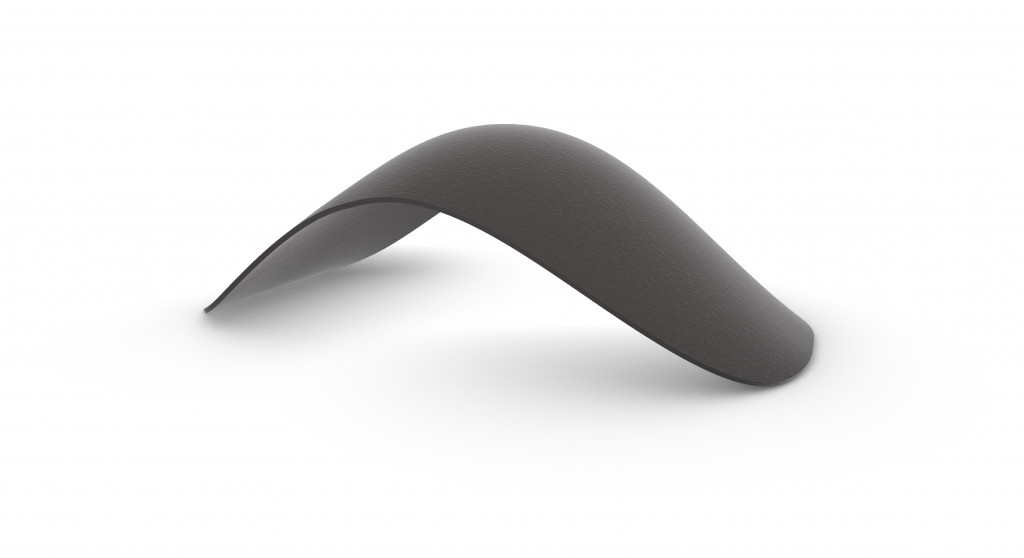

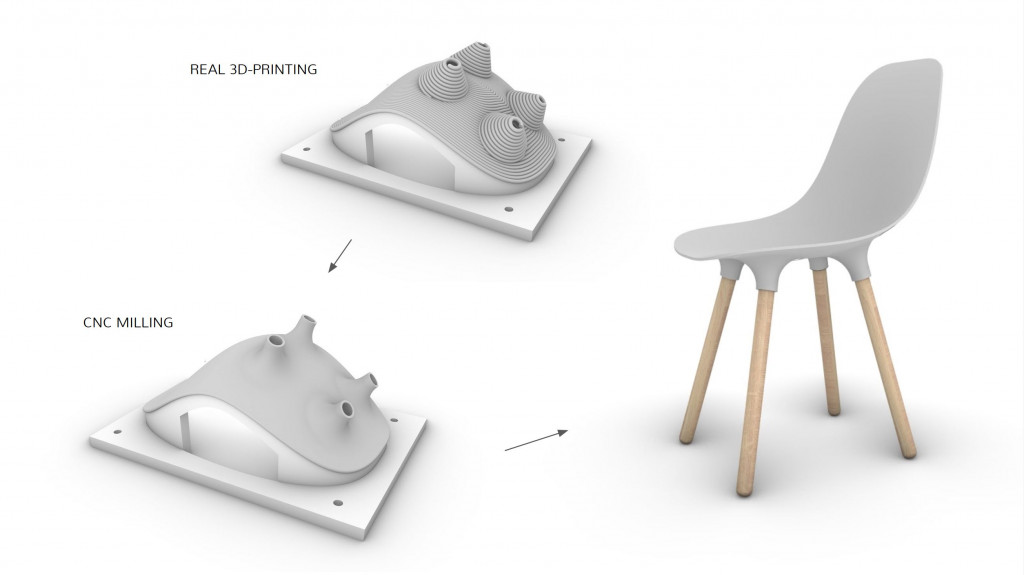

As the proof of concept a double curved surface like a chair could not only proof the feasability of hybrid manufacturing in context of robotics and thermoplastics, we can also create a physical working prototype. On this shape we can proof if there is an economical relevance compared to unique and mass production as well as structural behaviors of multi-axis-printing and productlike surface finishing. For the chair we will use different advanced printing strategies such as algorithmic design, generative design and topology optimization to improve the tensile strength of the structure and to show the potential of different driven design possibilities.

FABRICATION PROCESS

A double-curved surface was discretized into 32 elements that could be milled out of a straight MDF(Medium-Density Fibreboard) board of the dimensions (*2.5×0.6*0.03* meters). The geometry allowed using a 3-axis CNC machine for the operations involved. The milling strategy involved:

- Roughing

- Profiling

- Finishing

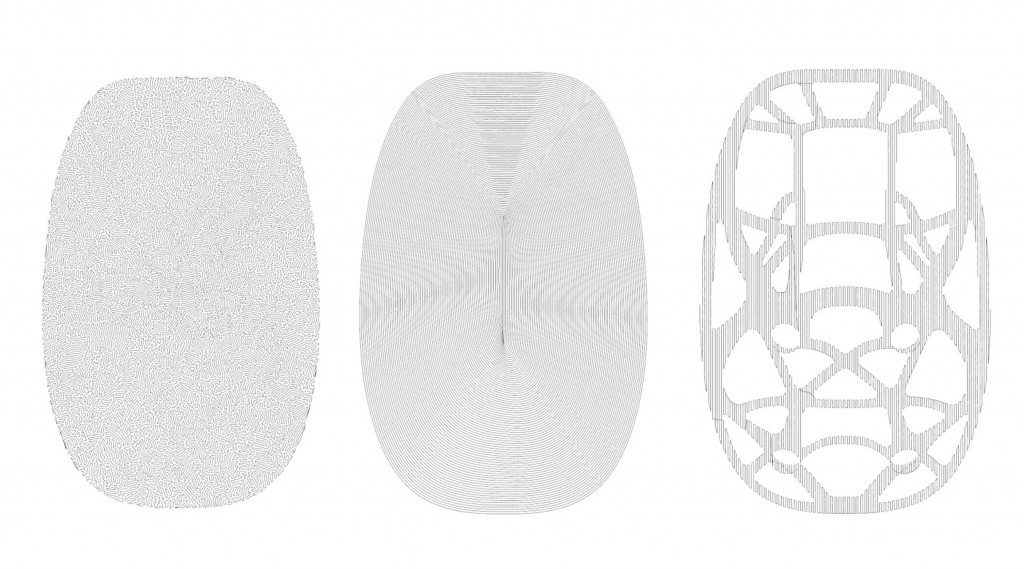

FIRST LAYER : ALGORITHMIC DESIGN

SECOND LAYER : SPIRAL DESIGN

THIRD LAYER : SPIRAL DESIGN FOR PRINTING THE LEG ATTACHMENT POINTS

RESULTS

We made the proof of concept with our prototype that we can hybrid manufacture a freeform shape in a very short time and with good physical properties like tensile strength using advanced printing strategies. Even if we finally couldn`t finish our chair with the 3 missing printlayers and the final surface finish my CNC-milling, the chair holds the load of a human with around 100 kg sitting on them by just having an own weight of 2.5 kg . Compared to other plastic chairs (5mm thickness), the hybrid chair was in some areas just 3 mm thick .

FUTURE

Finally we want to finish the process like it was actually planned. In the future this project can lead to a new type of manufacturing between production of unique pieces and mass production for architecture, movie industrie, prototyping and may more.

But there are still many things to develop on the way :

the hybrid tool | hybrid software solution | sonsor feedback for production control | closed material loop with feeding back the milling waste for 3d-printing| …

This project is one big step to get away from :

PRODUCTION ORIENTED DESIGN TO DESIGN ORIENTED PRODUCTION

ROBOTIC HYBRID MANUFACTURING is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2019 by,

Students: Apoorv Vaish | Sebastian Voigt | Subhash Prajapat | Owaze Ansari

Faculty: Alexandre Dubor | Aldo Sollazzo.