REINFORCEMENT STRATEGIES FOR CONCRETE PRINTING (TOOL DEVELOPMENT + A.R. FEEDBACK)

CONTEXT

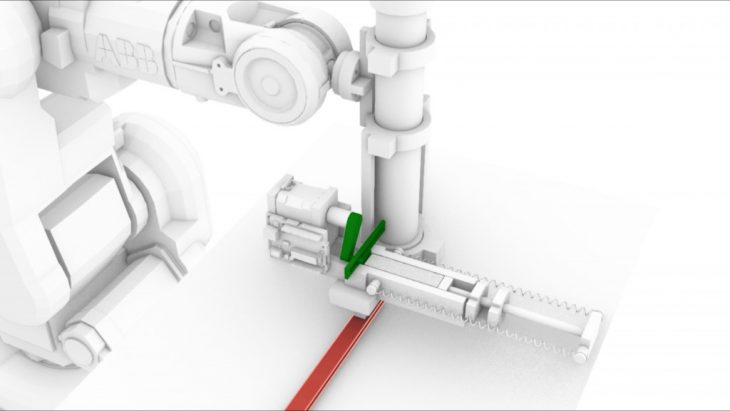

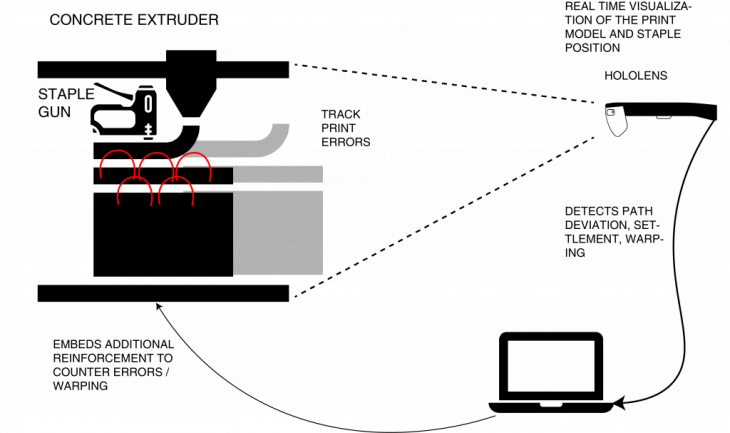

This project evolved from another studio project where we attempted to print concrete using a robotic arm while simultaneously embedding steel reinforcement in the shape of a staple with the help of a modified staple gun trailing the extruder. The project was an experiment in printing reinforced concrete that would could tackle tensile forces using an additive manufacturing process.

TOOL CONCEPT

INITIAL CONCEPT

SECOND ITERATION

FINAL SETUP

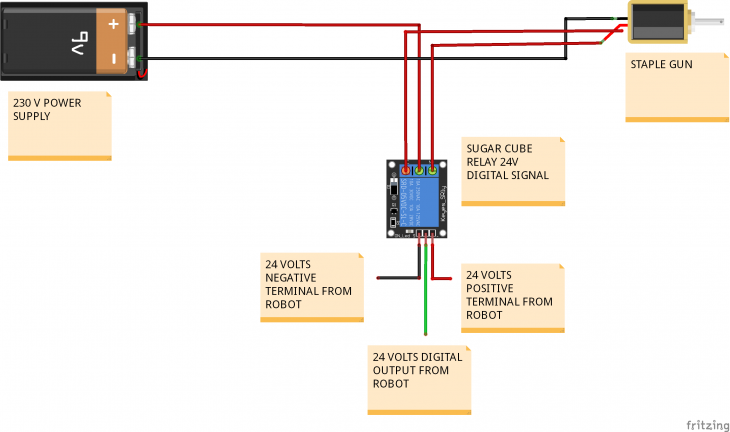

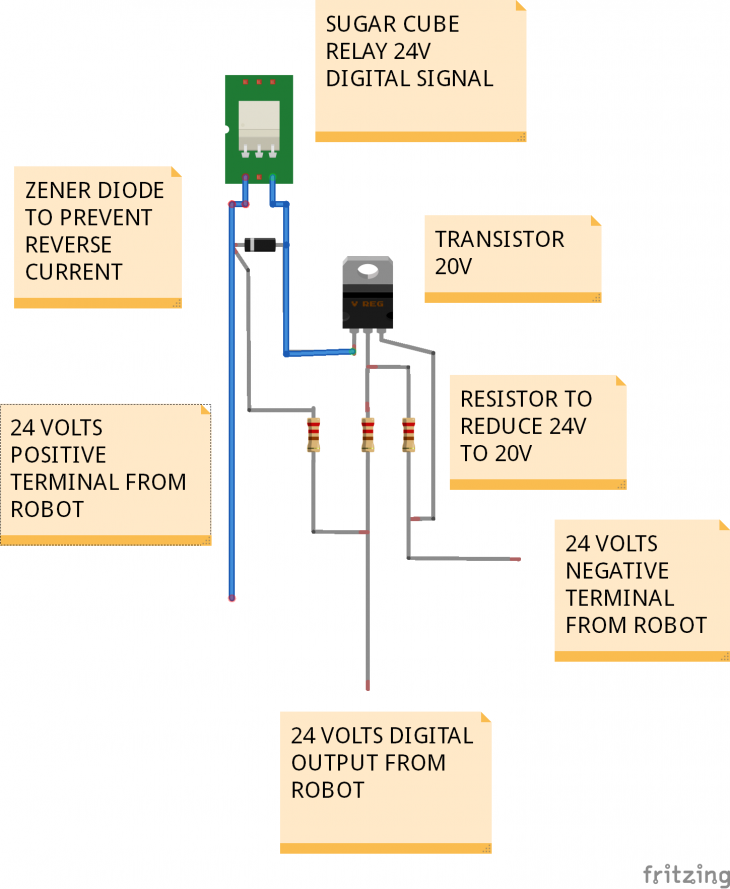

The staple gun is powered by a 230 Volt power supply and a switch that triggers the firing mechanism. The switch in the staple gun could be modified by replacing it with a relay with a 24V digital input so that it can be powered by the robotic arm.

Diagram for the construction of a relay with a 24Volt digital input.

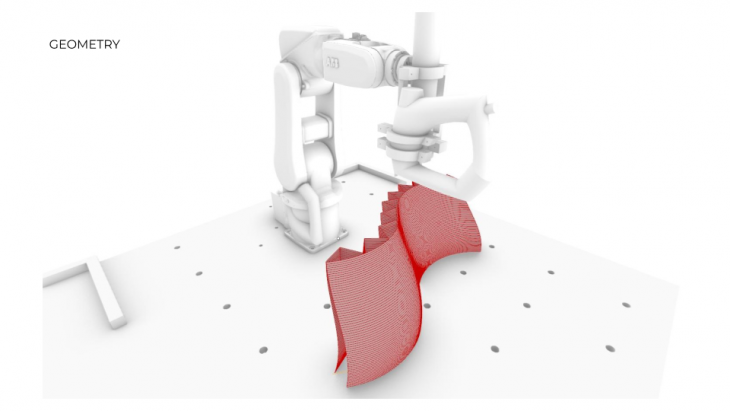

TOOLPATH

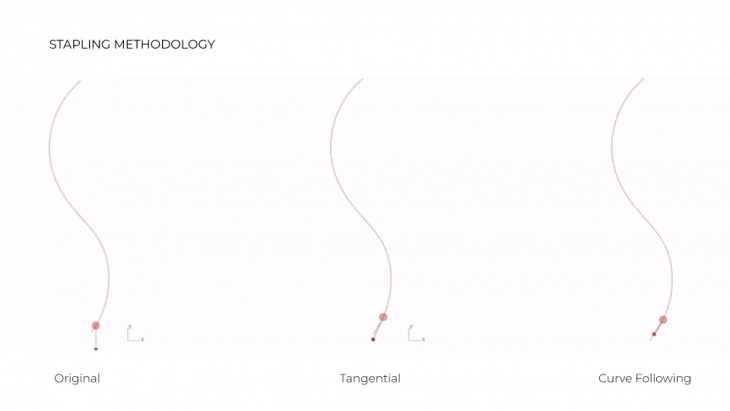

The toolpath for this setup had to be developed to ensure the the nozzle tip of the extruder and the staple gun pass over the same path to avoid errors.

AUGMENTED REALITY FOR REALTIME FEEDBACK

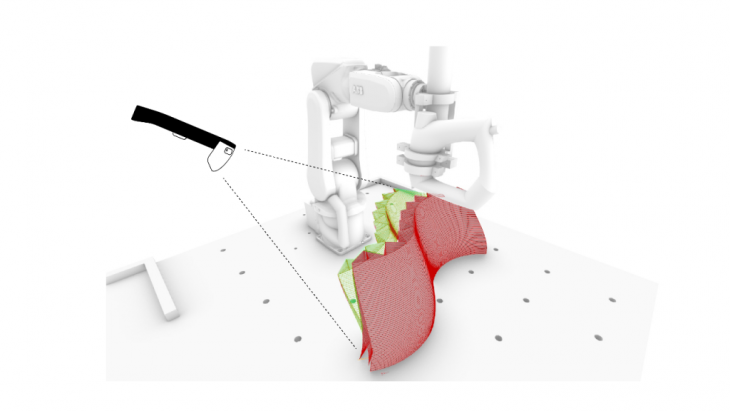

Offset 3d printing of cementitious material is extremely challenging due to errors caused by eccentric loading such as warping or bending, settlement of material etc. This results in a complete change in the form and stability of the structure. This needs to be detected and rectified in real time. hololens can help detect this errors and provide a real time feedback that can modify the toolpath to account for the changes based on these errors.

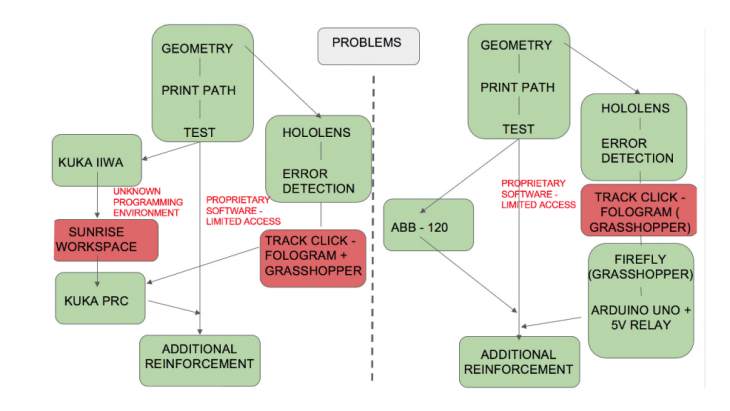

Workflow for a realtime feedback for printing

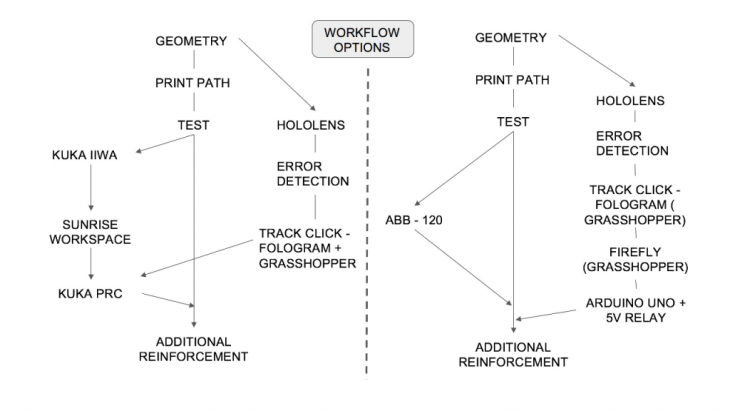

REALTIME SENSING WORKFLOWS:

PROBLEMS WITH REALTIME WORKFLOWS.

REINFORCED CONCRETE PRINTING (TOOL DEVELOPMENT + A.R.) is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

Students: Sujay Kumarji, Omar Geneidy

Faculty: Angel Munoz