Moiré Pattern generating a 3D surface

Concept:

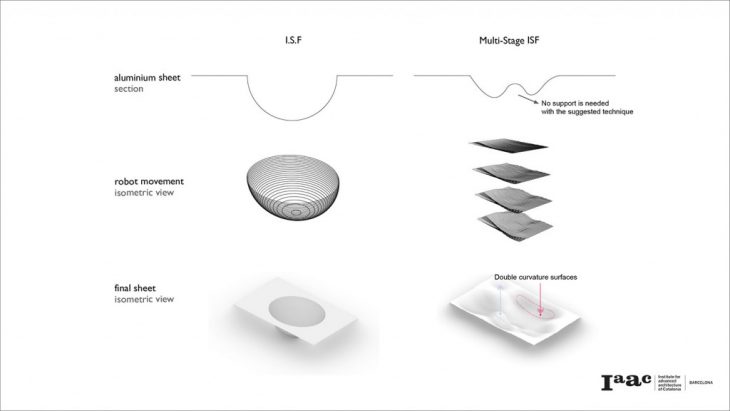

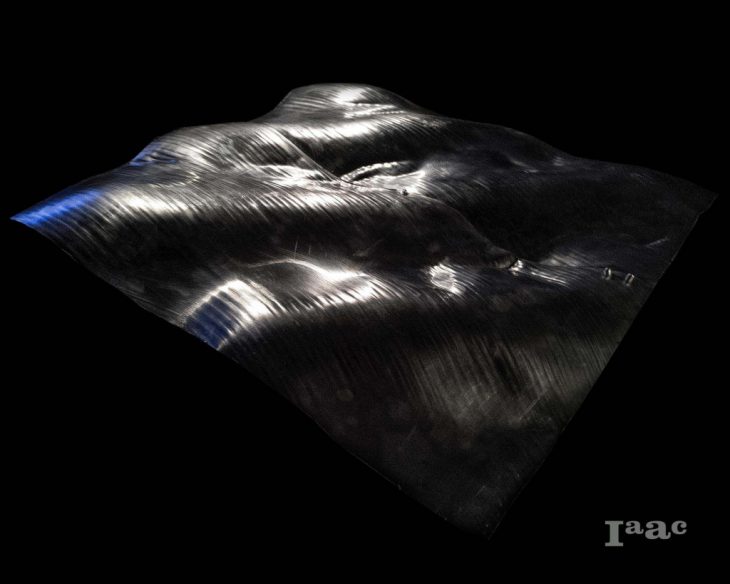

Use multistage incremental sheet forming and plastic deformation on a flat aluminum sheet to generate various forms and textures.

Method:

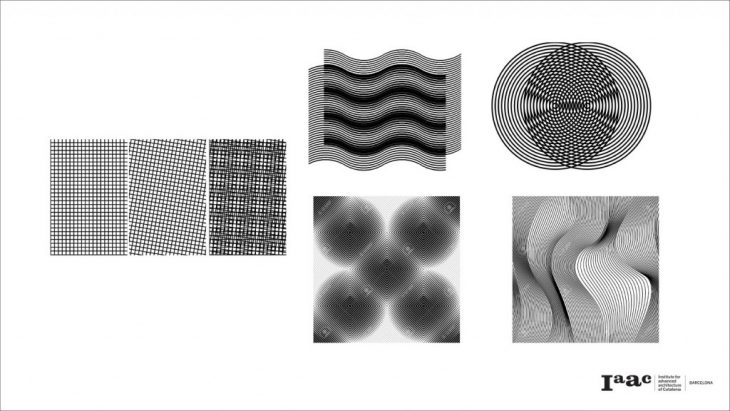

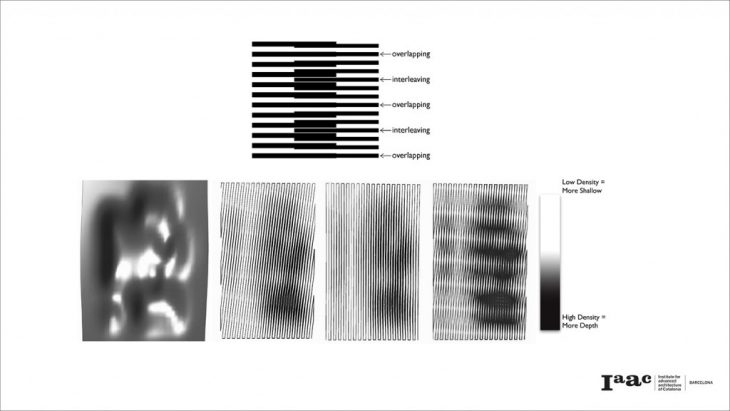

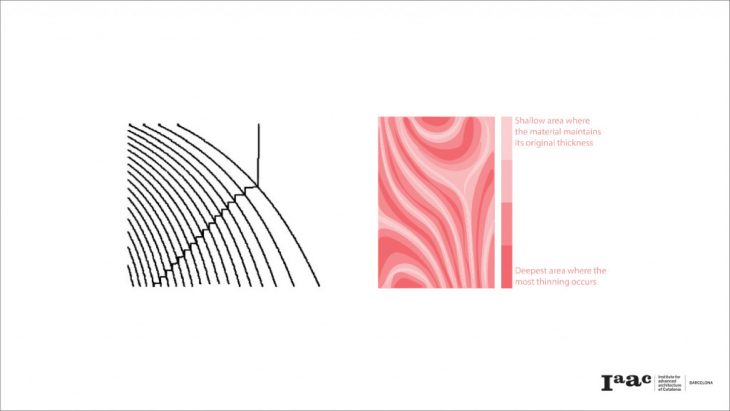

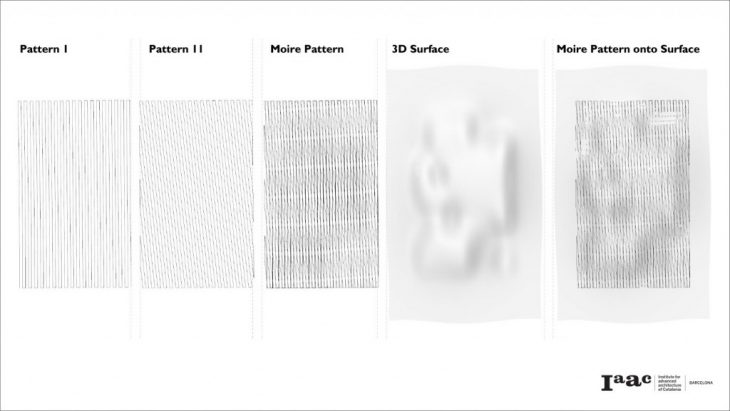

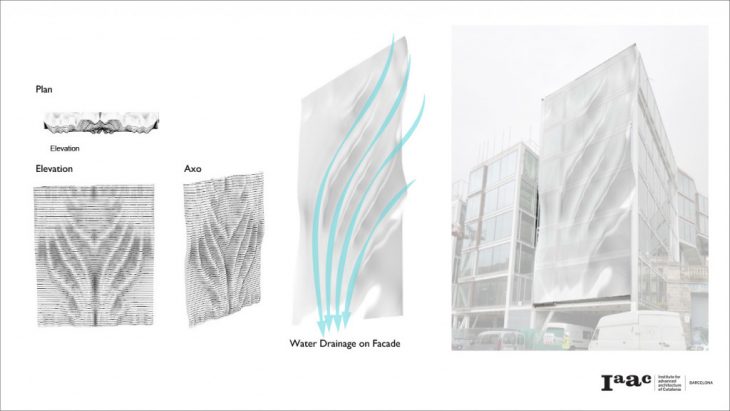

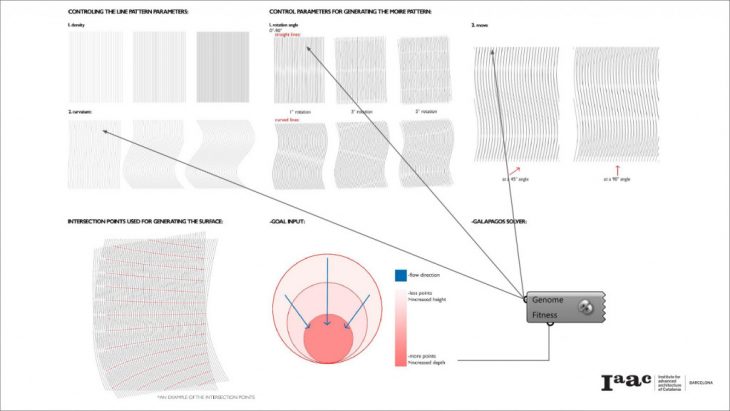

By using Computation Design methods, a set of rules was defined to create a variety of Moiré patterns that would later be used to generate a 3D surface. The primary rule is related to the density of the pattern; where there are more intersection points the surface-deformation is more drastic. In terms of architectural expression, this approach could be applied to a building facade. In this case, the facade acts as a water collection system. This further defines the direction of where the deformation is happening in order to guide it to the desired direction.

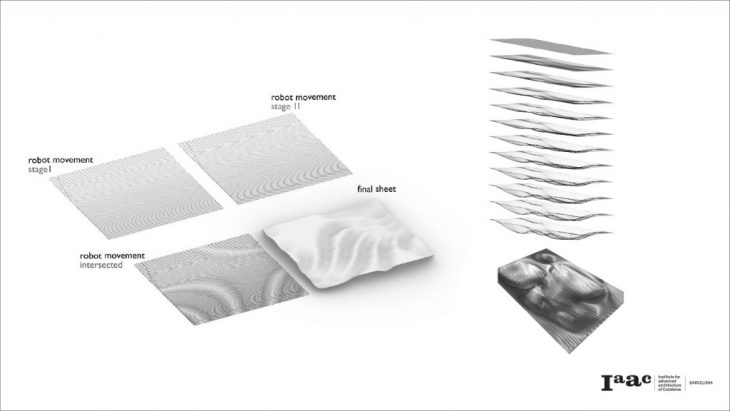

All this information was put into a code and processed by the KUKA to develop the final physical shape.

The multi-stage incremental sheet forming allows the material to be more evenly distributed throughout and avoid puncture.

Step-down = 5 mm with constant step depth to achieve texture

Step-over = 7 mm

–

Moiré patterns are large-scale interference patterns that can be produced when an opaque ruled pattern with transparent gaps is overlaid on another similar pattern. For the moiré interference pattern to appear, the two patterns must not be completely identical, but rather e.g. displaced, rotated or have slightly different pitch.1

Different examples of Moiré pattern

The approach of the Moiré pattern in the project

Possibility of creating double curvature surfaces without any support with the suggested technique

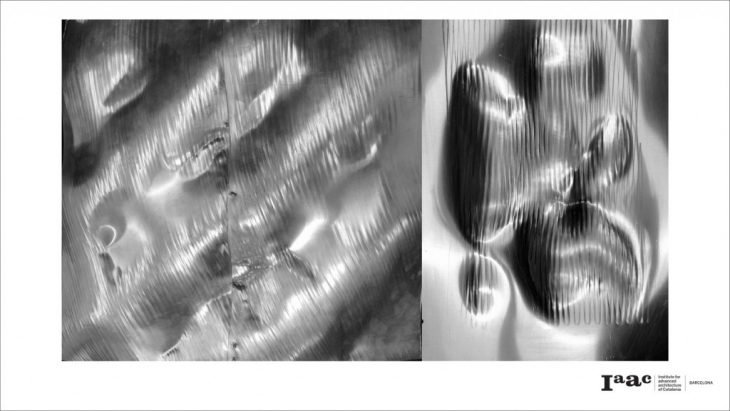

Process and stages of the tool path with the final sheet

Tool path and color mapping depth analysis

Initial Explorations

Initial Explorations

Architectural Expression – Design Outcomes: Water Drainage on Facade

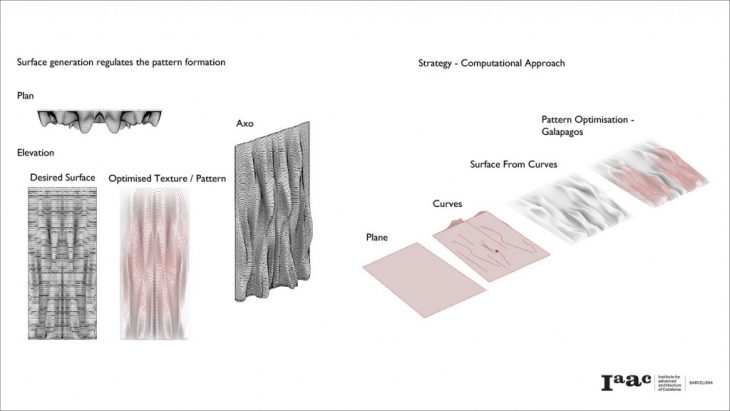

Pattern to surface creation

Surface generation regulates the pattern formation

</p>

Moiré is a project of IAAC, Institute for Advanced Architecture of Catalonia

developed at Master in Robotics and Advanced Construction in 2019 by:

Students: Alexandros Michail Varvantakis, Cedric Droogmans, Elena Jaramazovic, Gjeorgjia Lilo, ?rem Ya?mur Cebeci, Roberto Enrique Vargas Calvo

Faculty: Laura Puigpinós, Kunaljit Chadha

References:

1: Gustafsson, M. G. L. (2000). “Surpassing the lateral resolution limit by a factor of two using structured illumination microscopy”. Journal of Microscopy. 198 (2): 82–87. doi:10.1046/j.1365-2818.2000.00710.x.