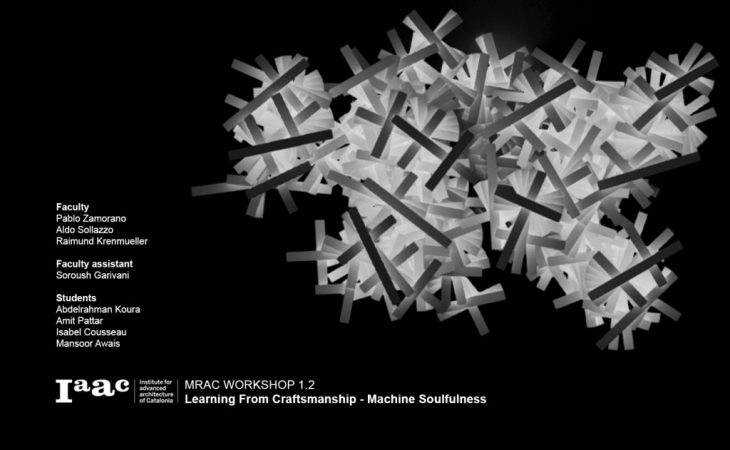

Craft usually makes us think about extraordinary exquisite objects, usually wonders of technique and use of material, always accomplished through immense expertise, repetition and mastery. Processes developed through generations of craftsmen and carried out as knowledge that continues to evolve through the years.

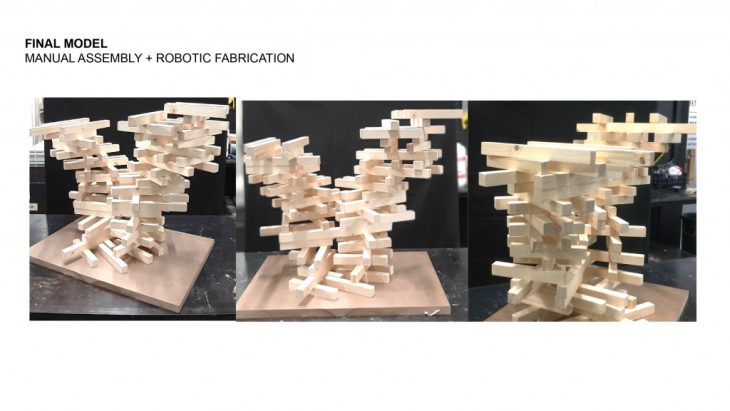

Robotic fabrication provides a digital protocol to manipulate physical components, defining hardware operations engineered to perform specific material transformations. Robotic fabrication and assembly will translate into the physical world digital design and structural simulations, re-configuring material constraints into innovative protocols of construction.

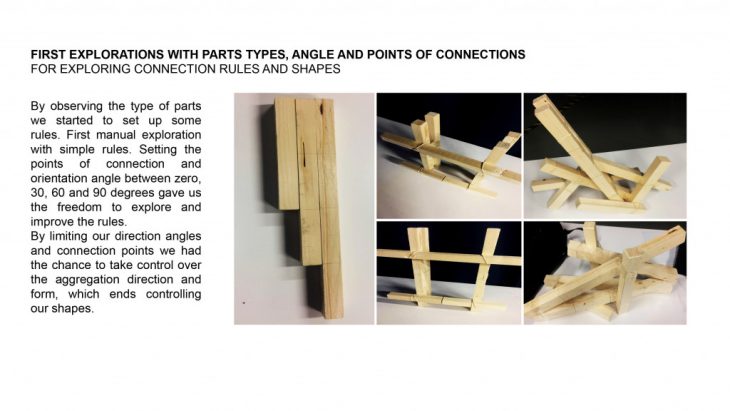

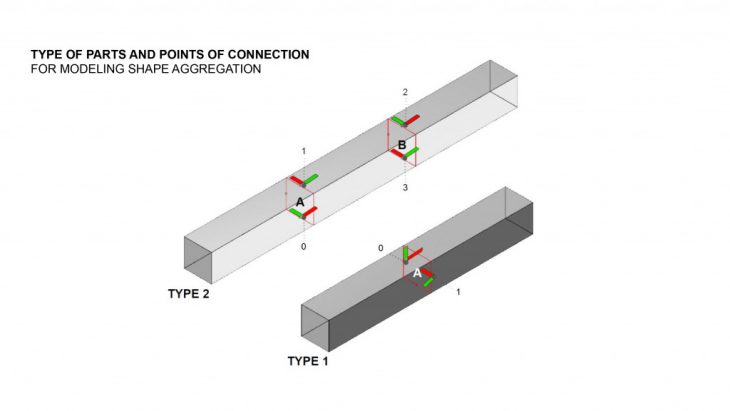

Start by defining the rules for connection of both Types according to each parametric Properties. Where we can also define how it will generate the aggregation and the way of generating the form by setting the points and angels of connection, we also set the generator to false for same point (sequence) and same type connection.

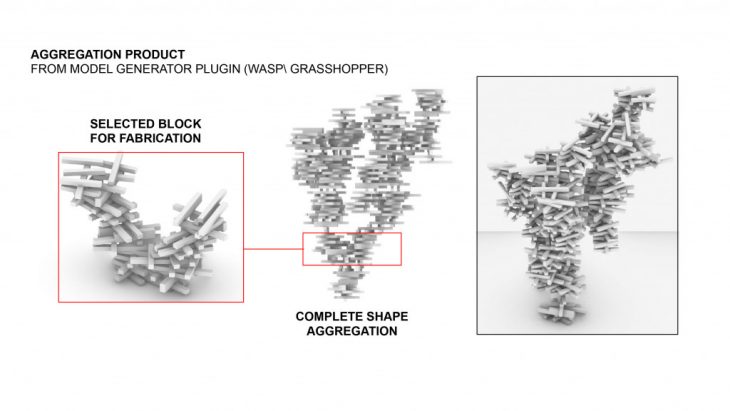

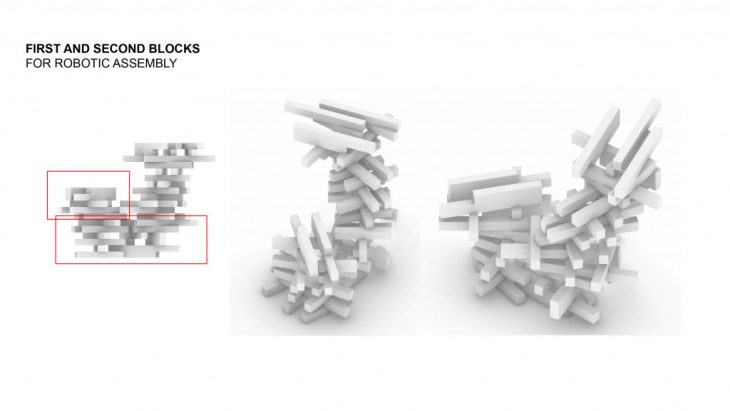

Generating an aggregation without shape constrains allowed exploring the application of the rules.

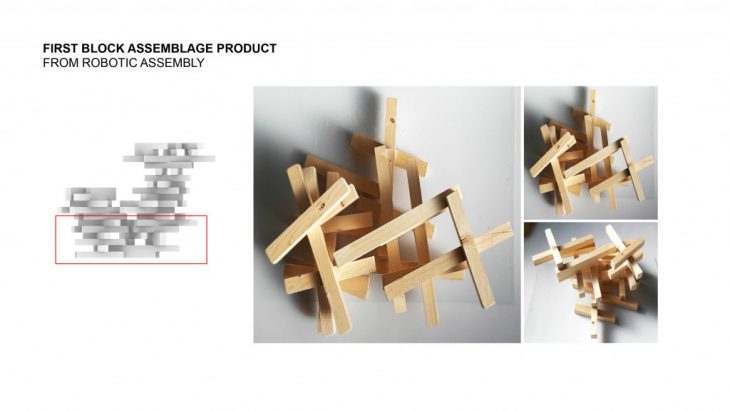

Therefore after considering structure stability , number of parts and total shape parameters, a selection was made to part of the complete shape aggregation to be assembled by the robot.

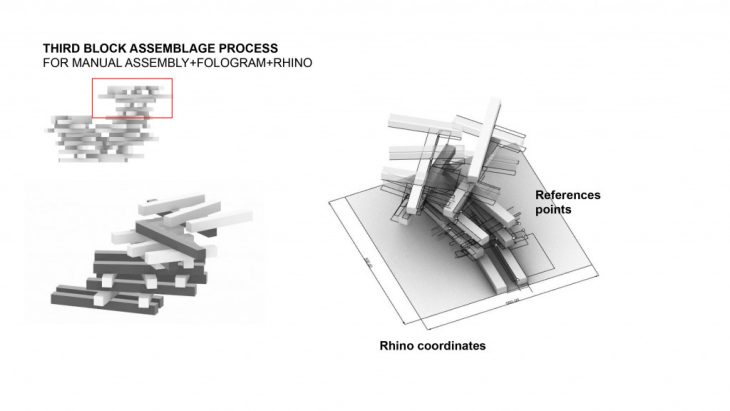

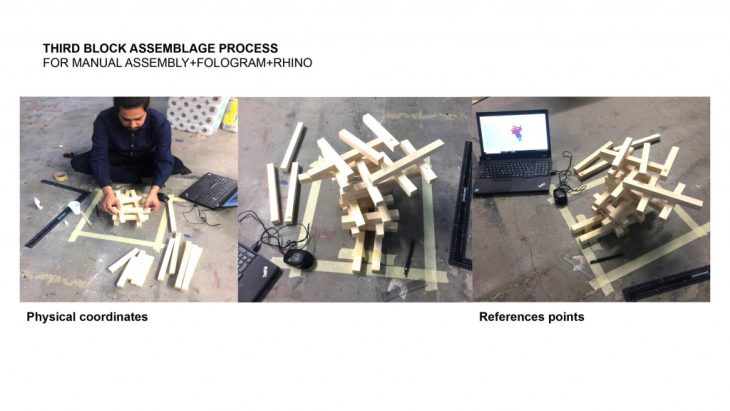

A combination of digital tools and manual assembly was made for the assemblage of the third block, By introducing Fologram on Rhino and Manually assemble the parts together within a reference perimeters.