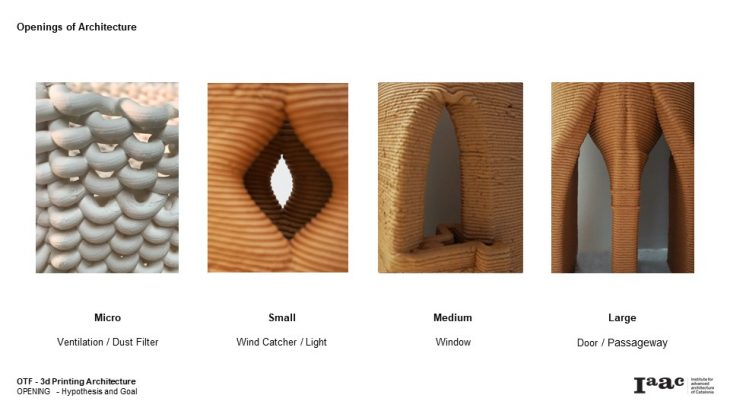

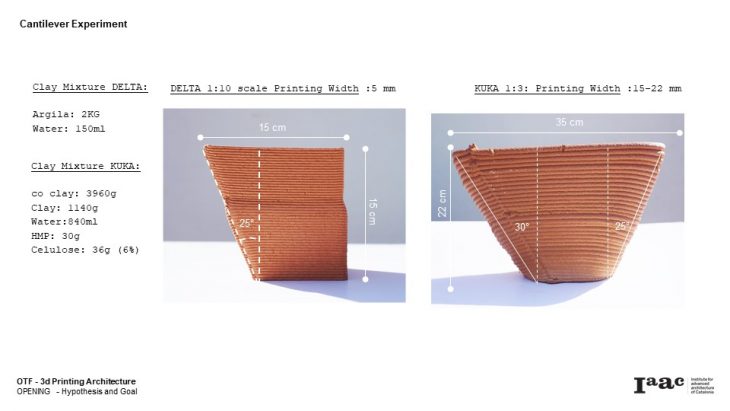

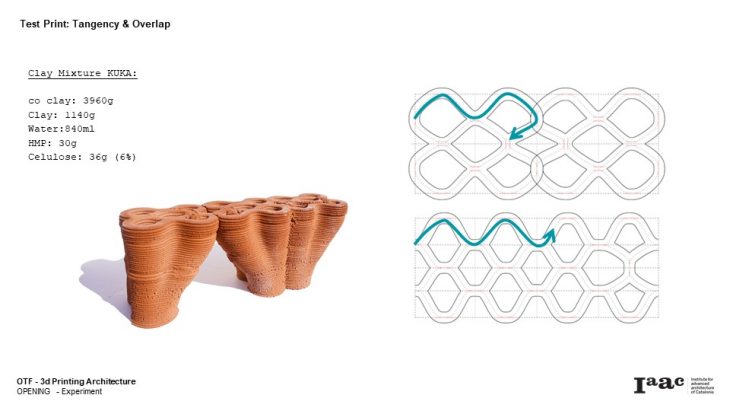

After 6 months of research in collaboration in IAAC, we were able to develop a new language in architecture by converging the ideology of additive manufacturing concrete to clay. We have discovered that working with clay is not only a natural material that can not be fired, but it is sustainable, recyclable, and offers the freedom of form in which could not be constructed or manufactured previously. Through our research, we have first explored the multiple possibilities of openings at a micro-scale (1:10) using a Delta printer, to a large scale model (1:3) using a 6 axis robotic arm.

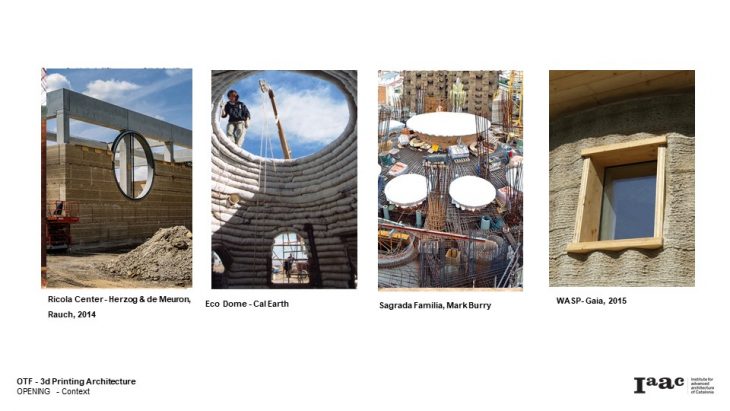

Context / State of art

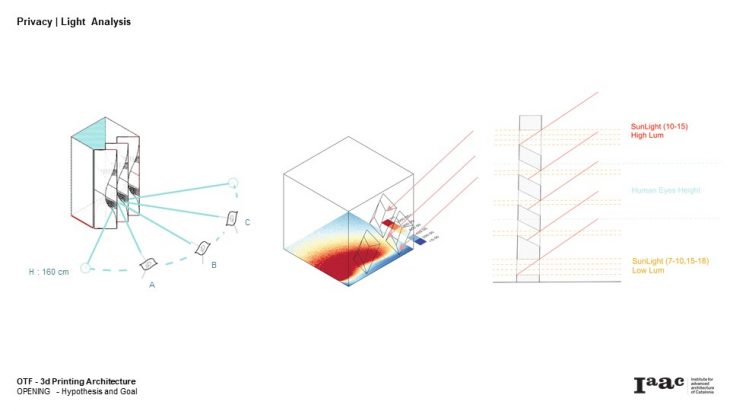

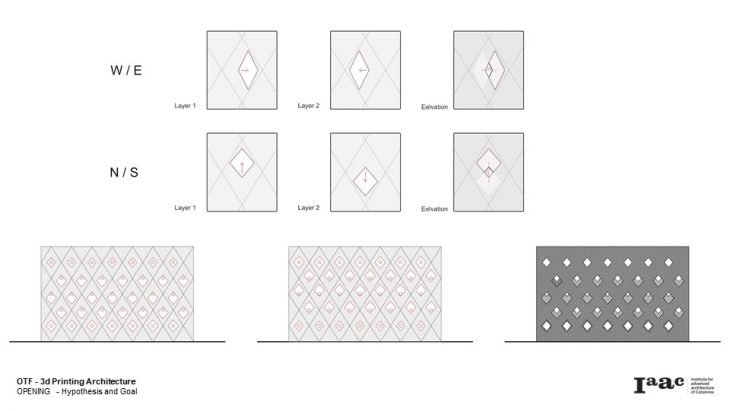

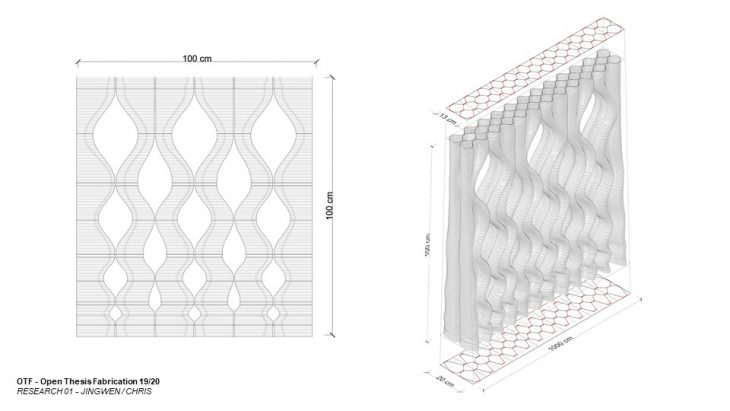

Our goal was to design an aesthetic wall to bring enough brightness in the interior while maintaining its privacy by the use of 3D-printing clay technologies on-site without support. The thickness of the wall behaves with the window giving different kinds of perspectives, and different ways of perceiving spaces by creating an experience that could not be done with another manufacturing technique. We now have the possibility to bring into our contemporary world and buildings a variation of openings that is controlled by light and privacy and integrated into something that is stable and printable. We can now adapt, change, and have a huge diversity of openings in earth buildings in relation to the environment with sustainable principles.

Our goal was to design an aesthetic wall to bring enough brightness in the interior while maintaining its privacy by the use of 3D-printing clay technologies on-site without support. The thickness of the wall behaves with the window giving different kinds of perspectives, and different ways of perceiving spaces by creating an experience that could not be done with another manufacturing technique. We now have the possibility to bring into our contemporary world and buildings a variation of openings that is controlled by light and privacy and integrated into something that is stable and printable. We can now adapt, change, and have a huge diversity of openings in earth buildings in relation to the environment with sustainable principles.

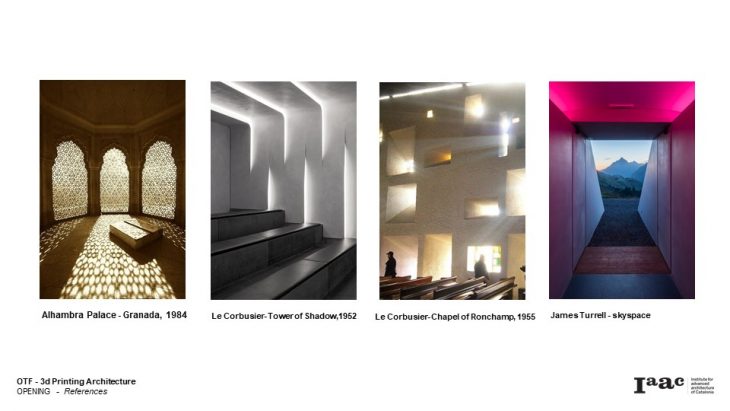

References

Scales of Architecture Openings

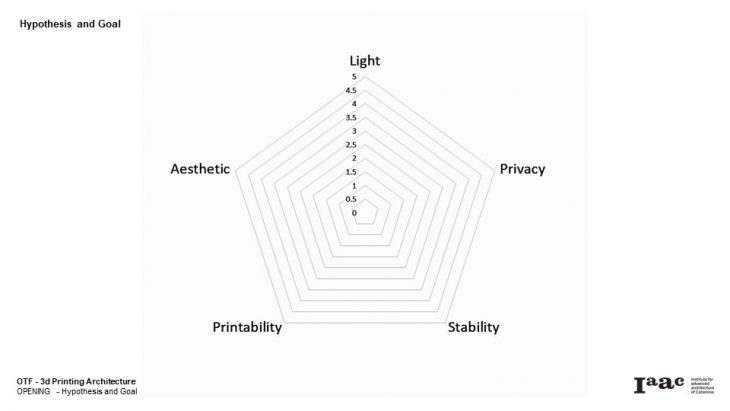

Hypothesis and Goal

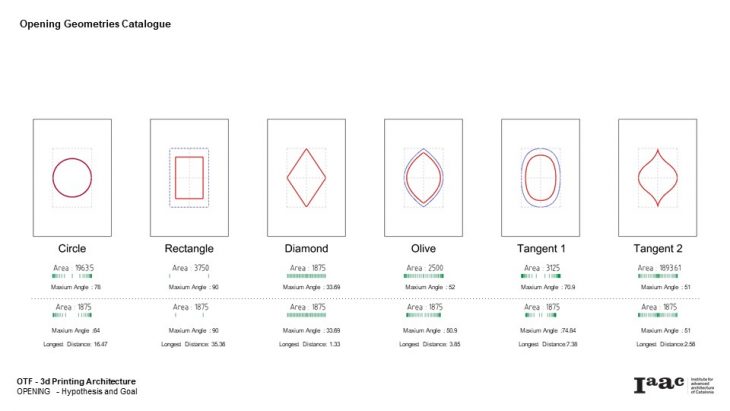

There are 5 main goals we had considered and reached to improve the earth printing openings, which are LIGHT, PRIVACY, STABILITY, PRINTABILITY and AESTHETIC.

The score of Light and Privacy depends on how the geometry performs and how easy it can be controlled, Printability and Stability are always crucial parts for any kind of 3d print architecture. Hence we marked as diagrams to compare the pros and cons of each experiment.

Light

Privacy

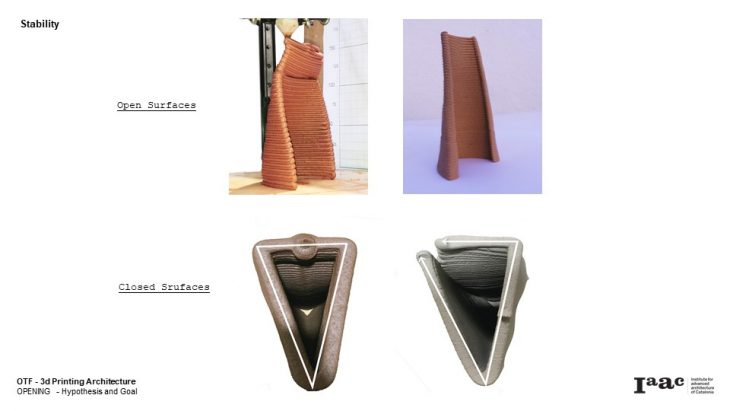

Stability

Printability

Aesthetic

It is difficult to get scientific data to evaluate it. Thus, between the two of us, we discussed the quality of the print, how the print deals with light, and the complexity of its geometry.

Final Prototype (1:3)

Robot: Kuka150-240

Layer Height: 4mm

Print Width: 20mm

Printing Length: 115.3M

Total Weight: 252 kg

Printing Time: 18 hr/5 days

IAAC OTF 2019 - 20 Students: JingWen Chiou, Christofer Bierach, Faculty: Alexandre Dubor, Kunaljit Singh Chadha Assistant: Ashkan Foroughi Dehnavi