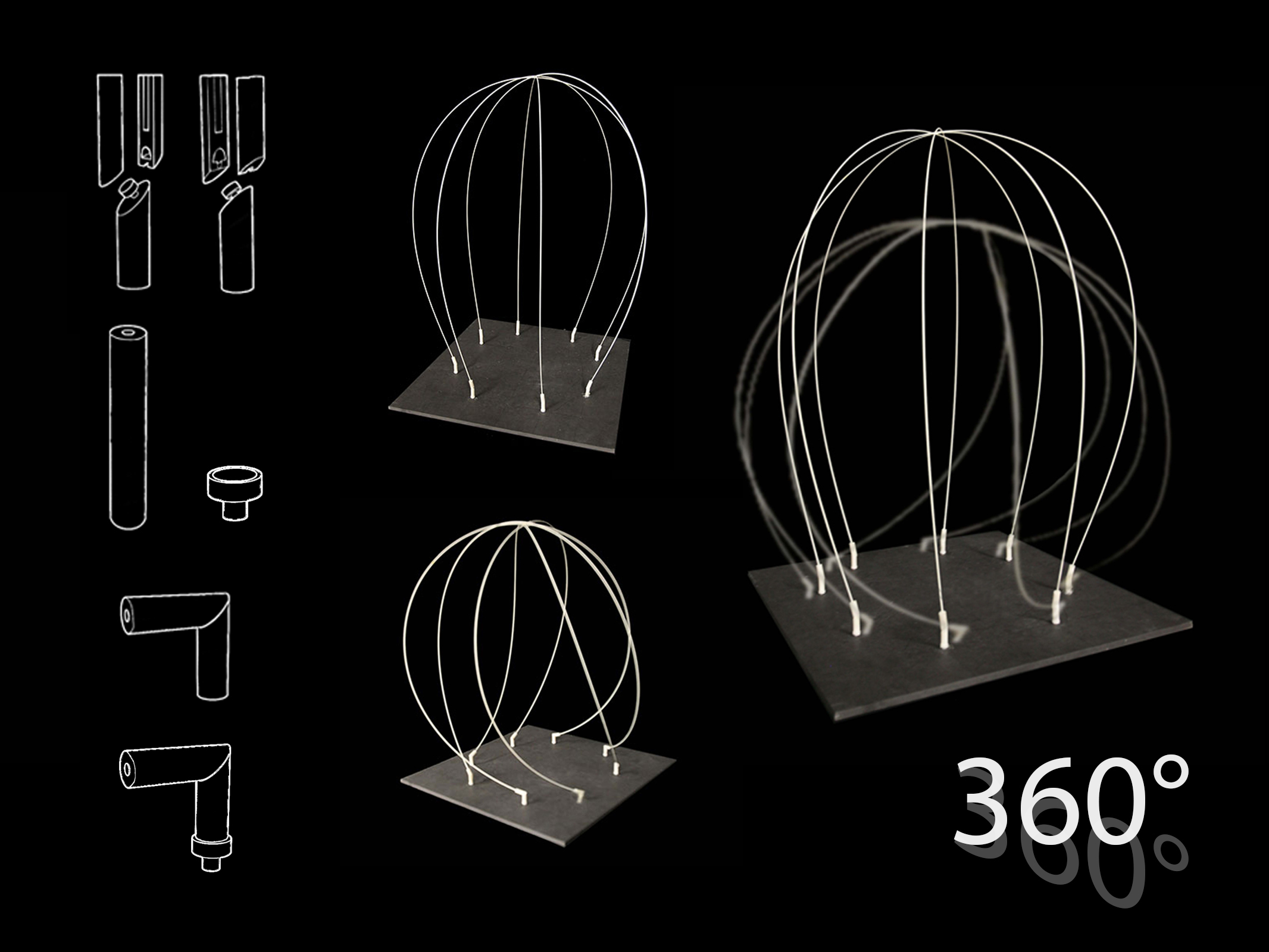

Our approach to the exercise was to create joints that by its own movement could change the shape of the structure, for which we created two types of joints, one that allowed us to make the assembly with the base and another that allowed the movement of structure. During the process we had some challenges , the first approach was to create a two-part piece that attached by a swivel joint allows to rotate on its axis at 360 degrees that due to the constructive system of the 3D printing was impossible to manufacture. The solution that we came out with was to simplify the system , so that one half of the joint contained a circle on which would rotate the mechanism and the other half that contained the hole where the circle fits will be separated in two pieces, and by joining all the pieces together will allow the mechanism to function properly.

By having joints that rotate 360 degrees allows a variety of positions so that the structure moves , rotates , compresses , stretches , and gives us a lot of versatility for the final shape using the different angles that the design permit. We decided for the final shape to rotate the joints 90 degrees to allow us to turn the rods into loops compressing the structure into a different position from the one at the beginning.