//ADVANCED ROBOTICS FABRICATION_COLUMN

Abstract

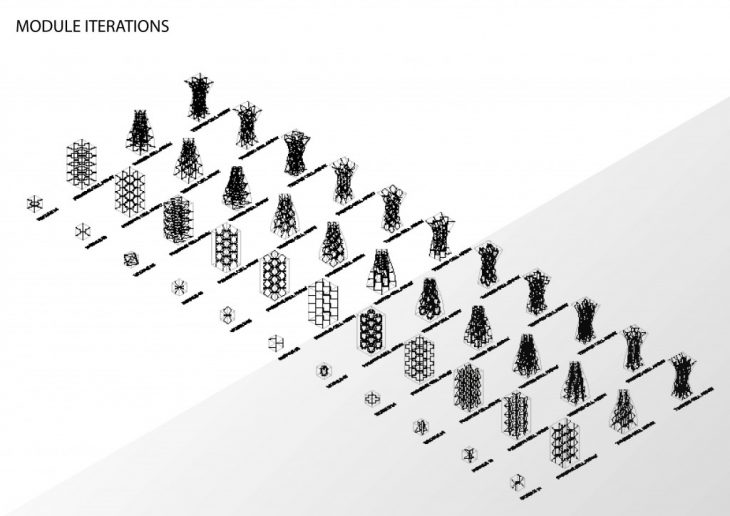

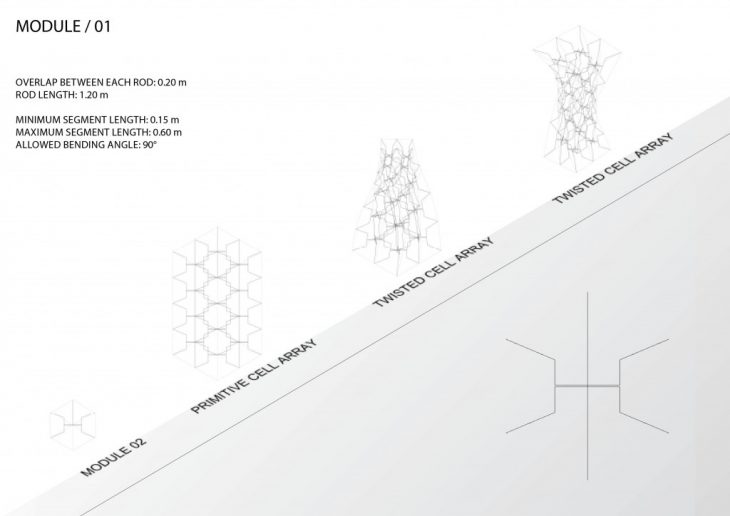

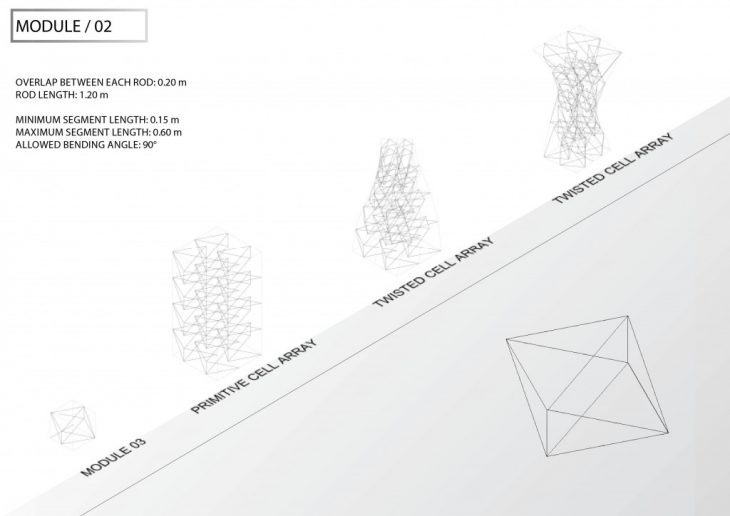

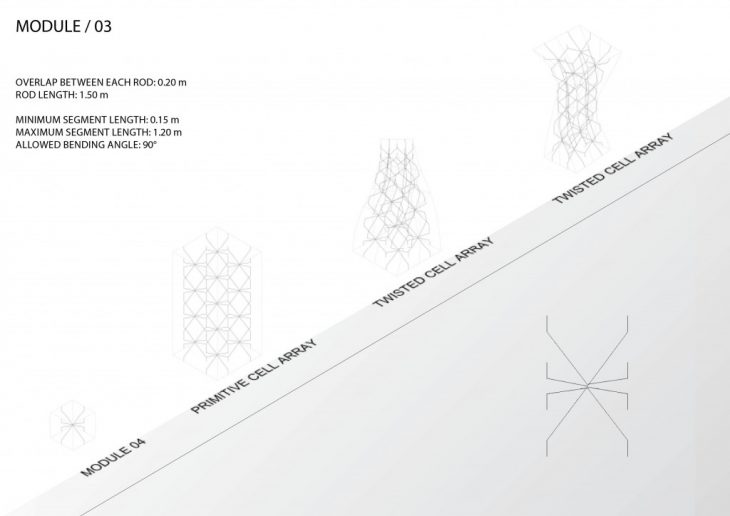

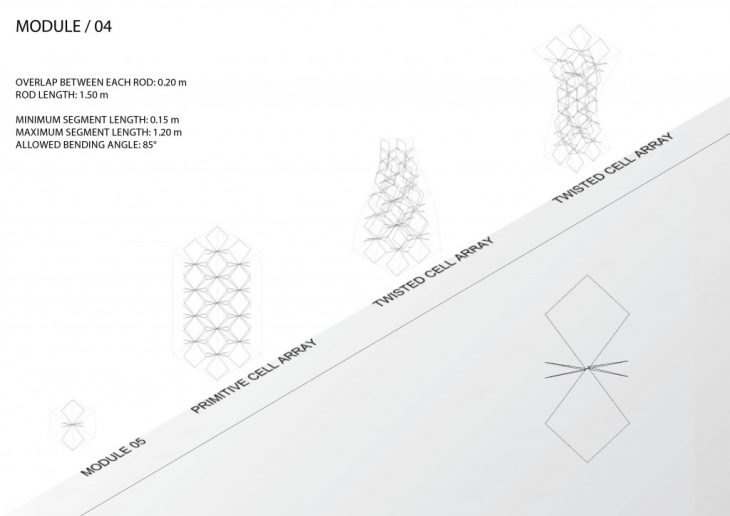

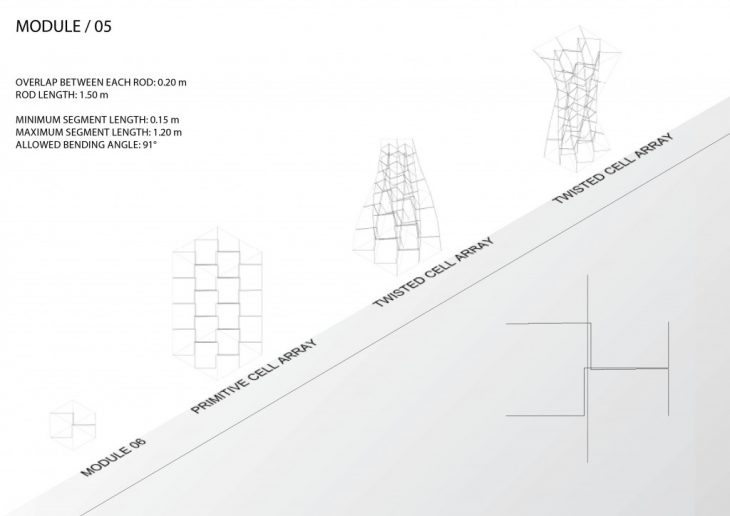

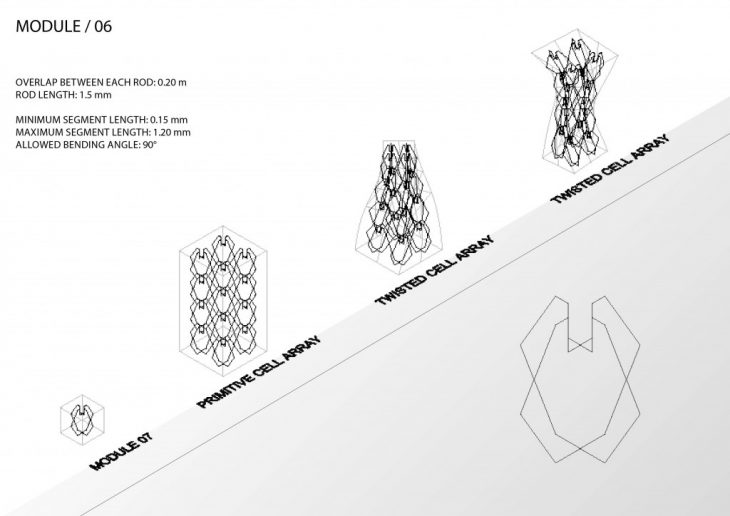

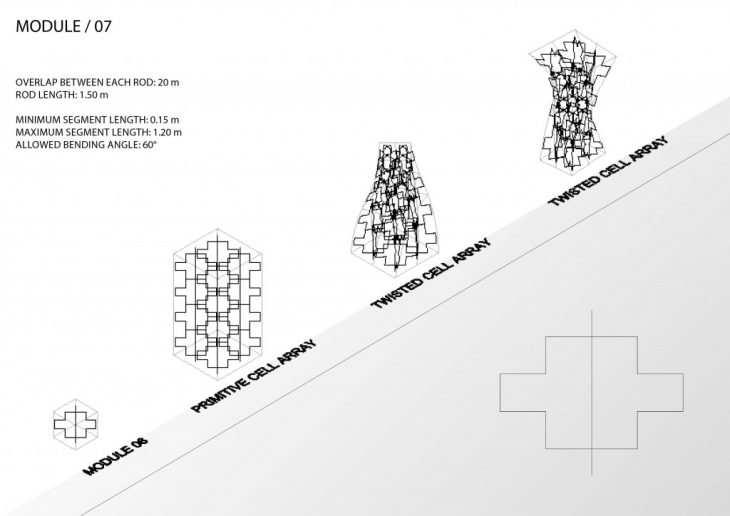

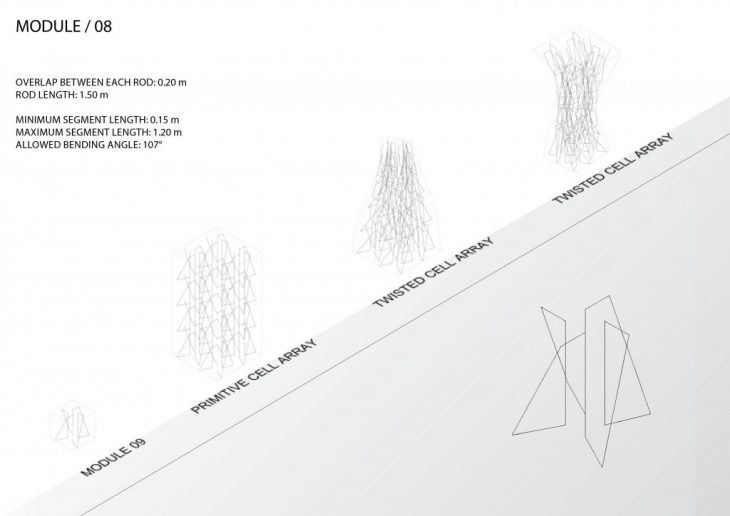

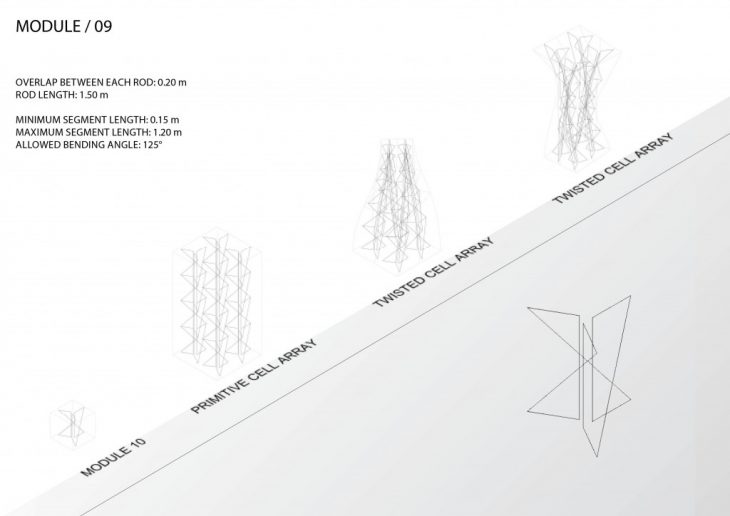

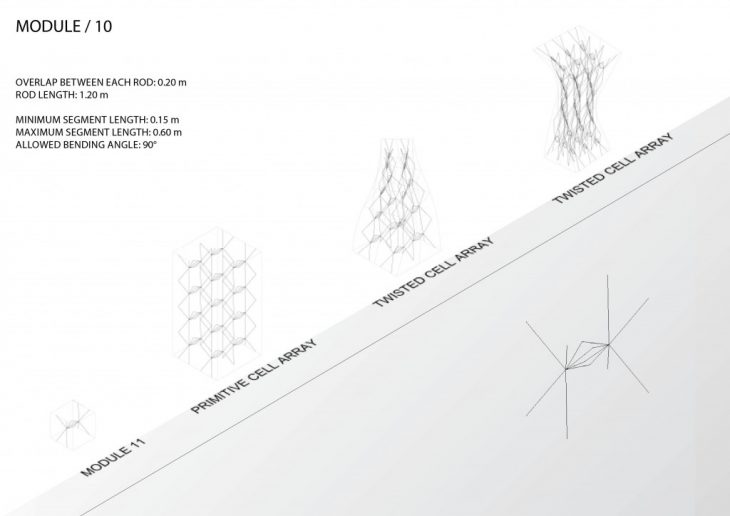

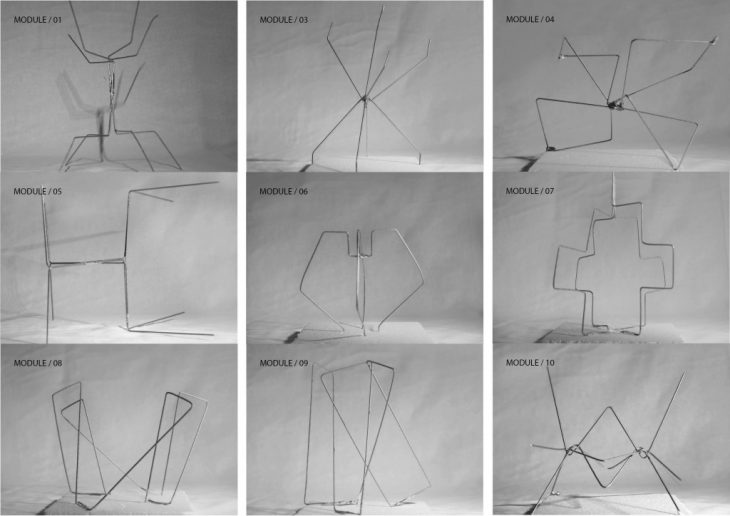

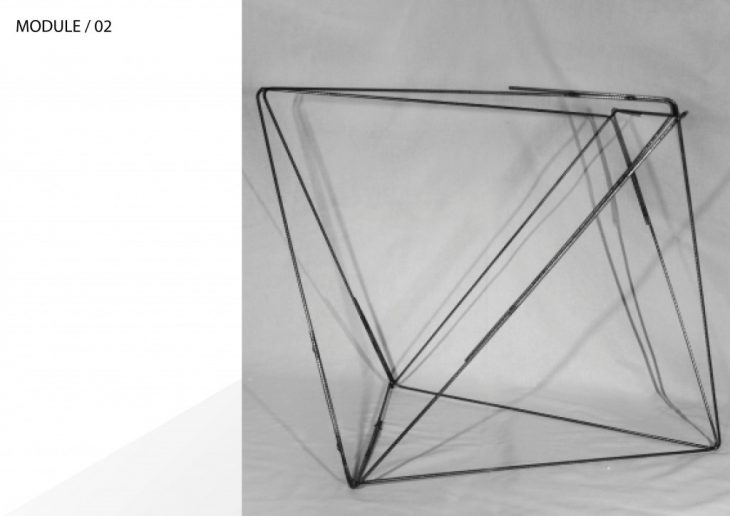

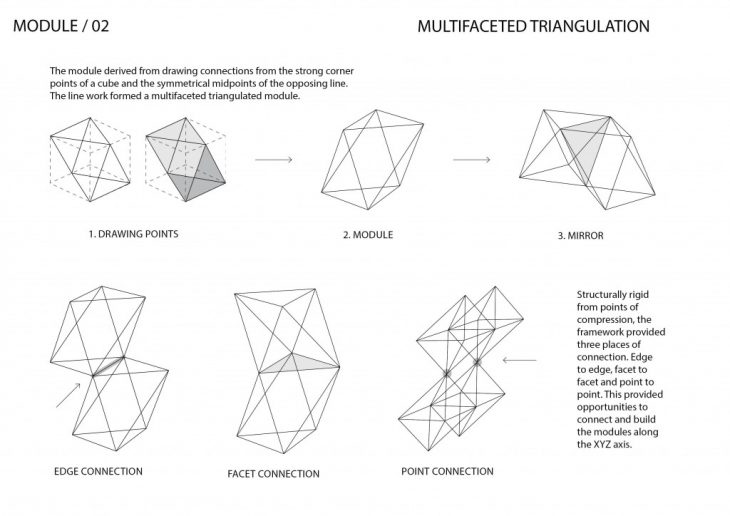

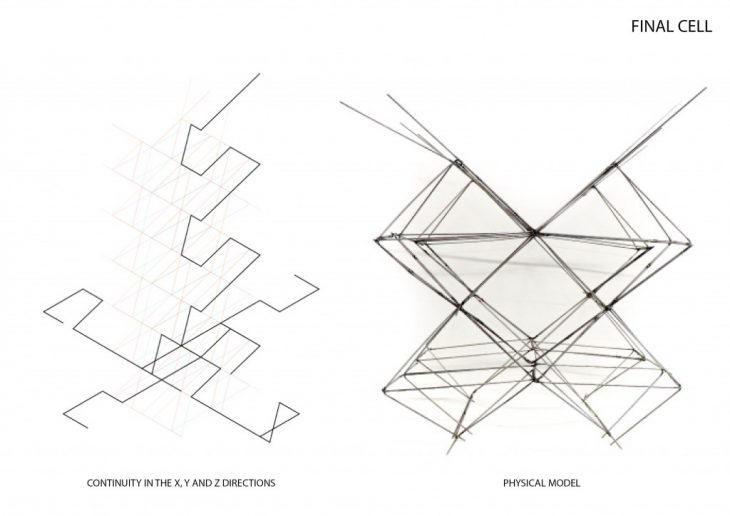

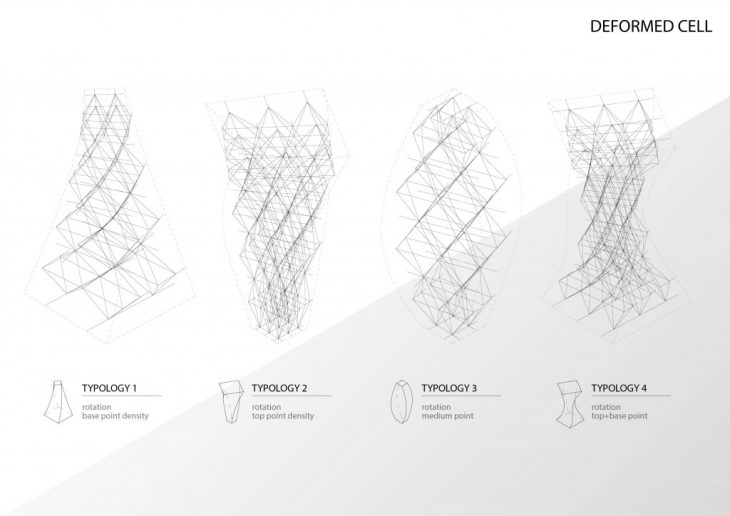

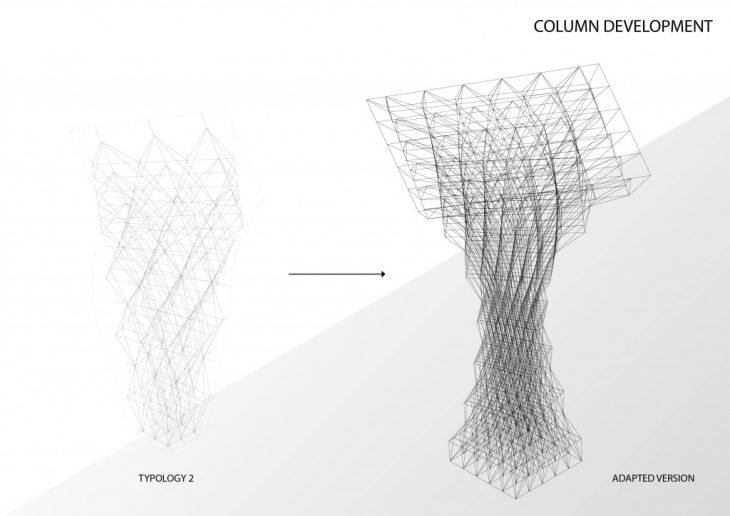

The process began by defining a module in a primitive box. With the goal of creating a column, the module derived from drawing connections from the strong corner points of a cube and the symmetrical midpoints of the opposite line. The line work formed a structurally stable multifaceted triangulated module. The multiple points of connection allow for a three-dimensional propagation of the structure which could possibly turn into a holistic structure.

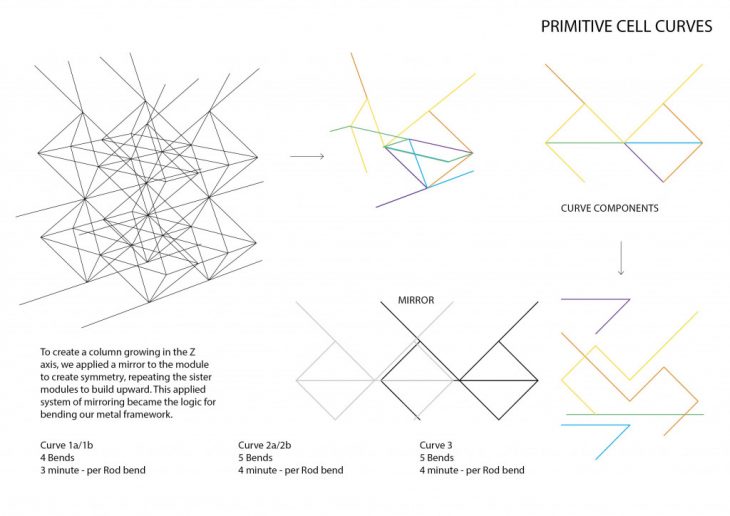

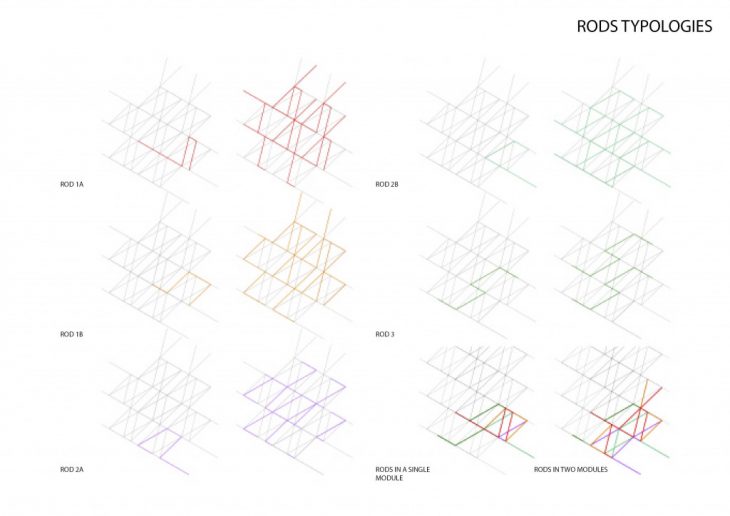

This applied system of rod bending uses a total of 3 different curves and two mirrored variations which makes the production time fast and efficient. The bending of a column base, comprised of 8 modules, takes 45 minutes and the assembly around 20 minutes, following a mirrored-symmetry based assembly technique.

Institute for Advanced Architecture of Catalunya, IAAC.