Advanced Wood Tectonics

For Mass production & Fabrication

Artificial intelligence (AI) technology has made its mark in almost every industrial sector today, and architecture is no different. Algorithms now automatically process information to help architects design new buildings

AI technology can drastically reduce the amount of time it takes to design a new building, as well as help to improve design quality by offering multiple, successive, iterative designs that improve with ML at each iteration.

What AI does in Our case

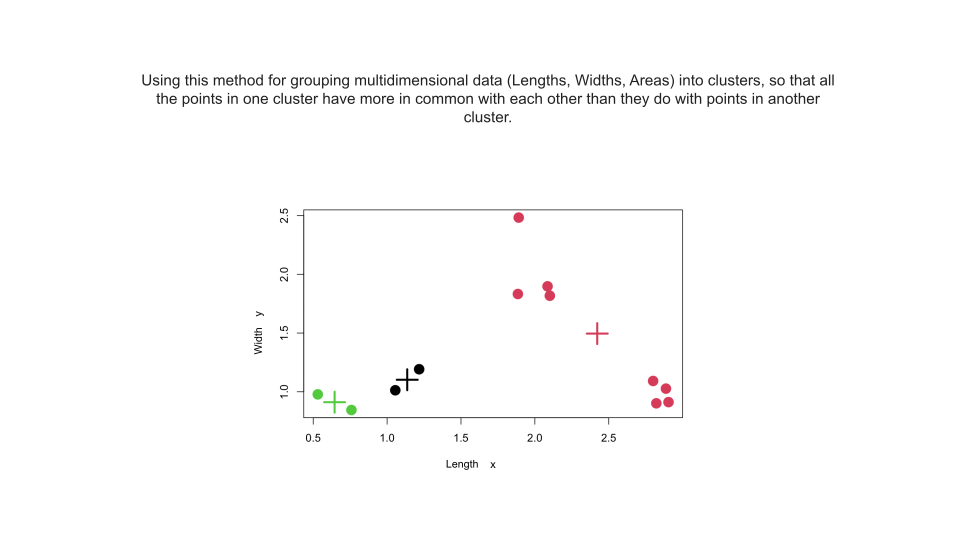

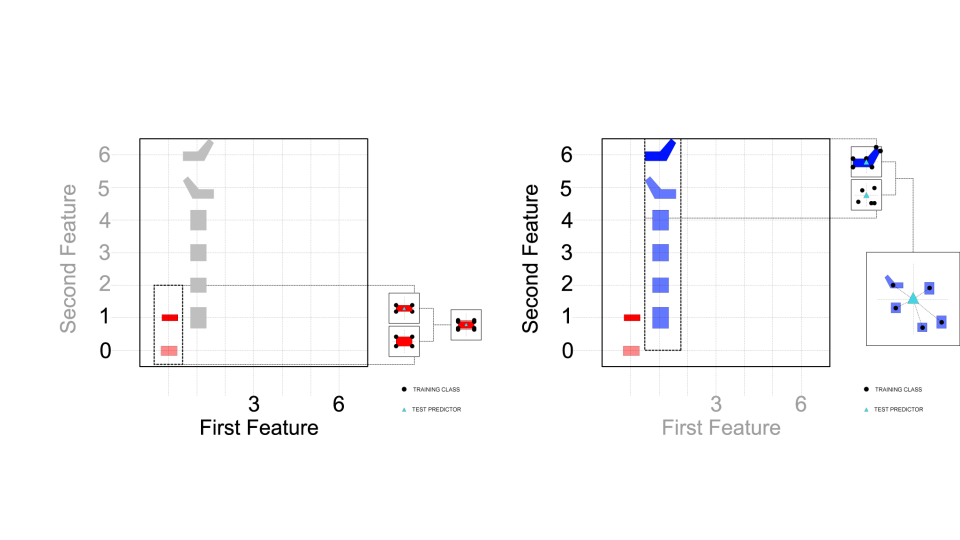

Clustering based on Lengths Clustering Based on the area

Concept

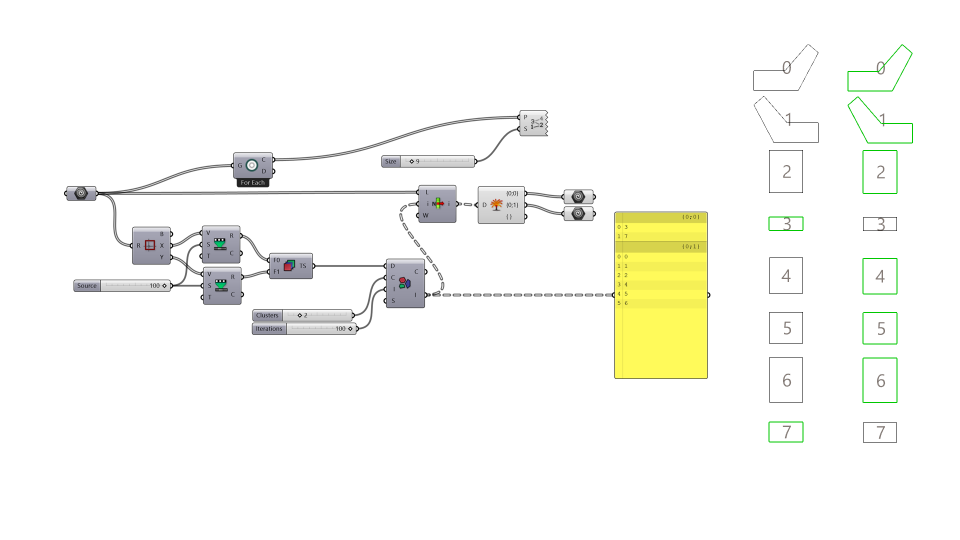

K-Means Relevance

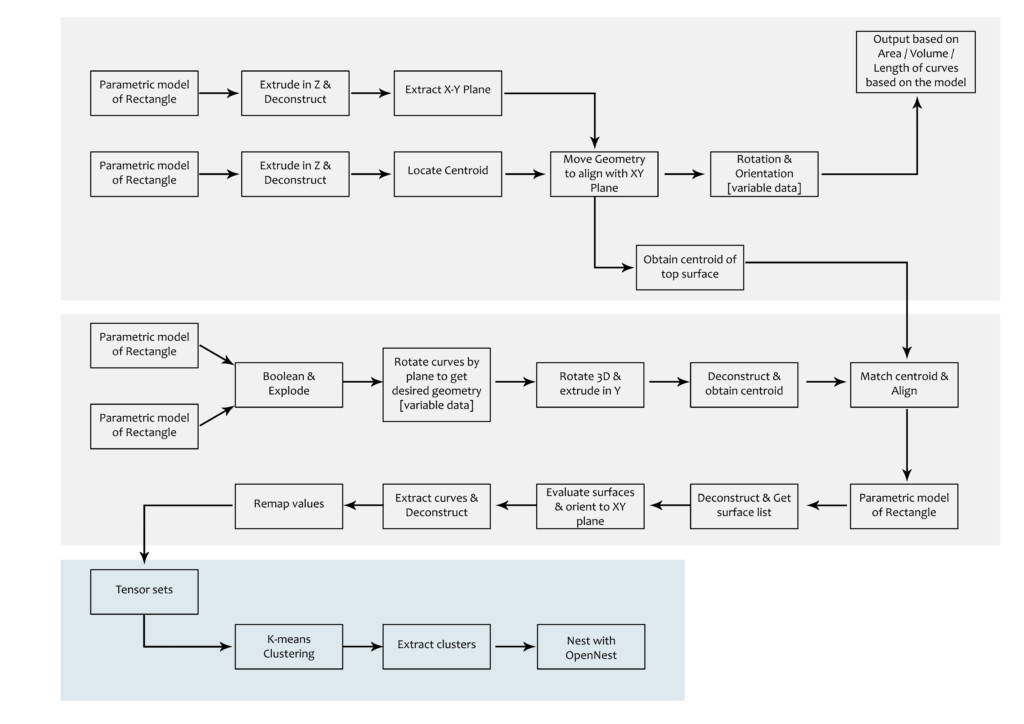

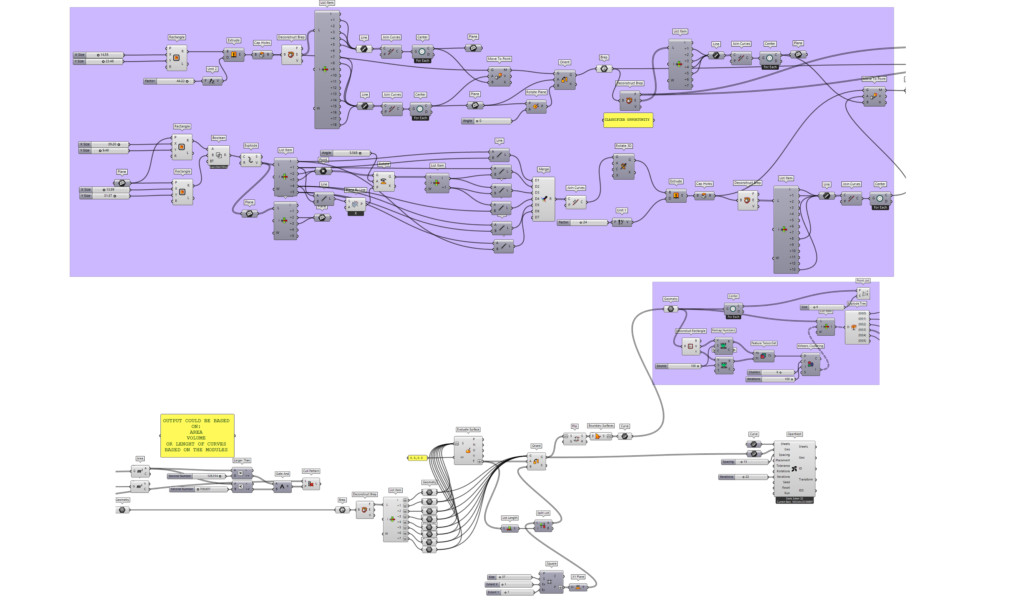

Workflow

Generating a Parametric model of the box

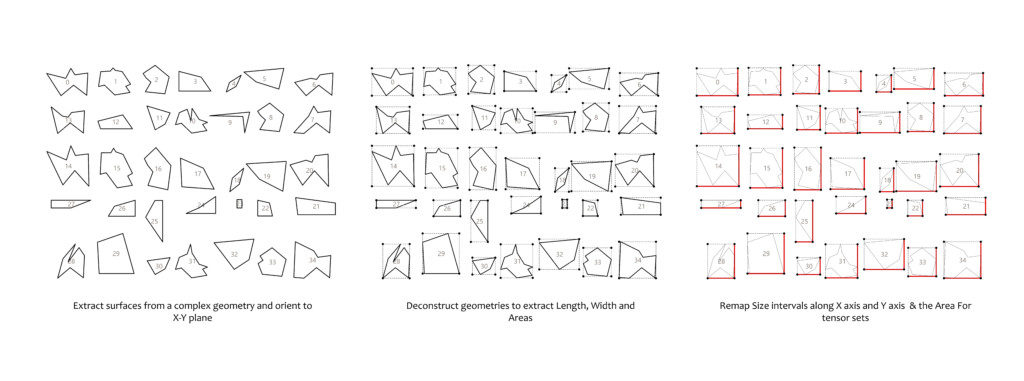

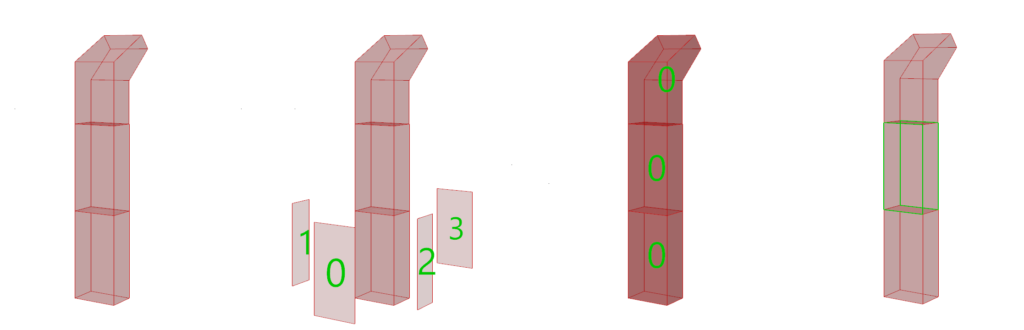

Extracting the surfaces

Evaluating the surfaces to extract lengths and areas

Clustering the curves based on lengths and areas

Finding the Average of each cluster

Replacing the parametric Box model with the average found

New box sizes with minimal variations after replacing with average

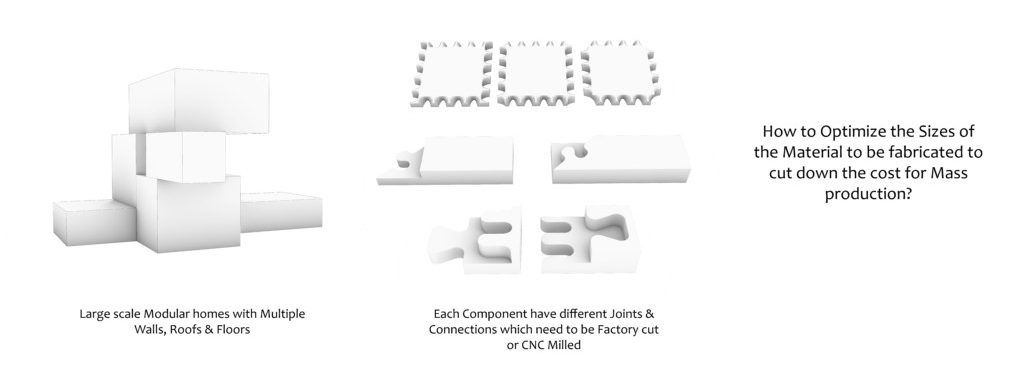

Testing for Non-rectangular shapes

Pseudo-Code

Grasshopper Code

Parameters

Width & Height Area Volume Length

Directions after Clustering

Nesting for Optimizing sheet size for Fabrication

The output data of the clusters can be written in Excel.

This data can be further used to Purchase sheets for fabricating the complex geometries.

This data range can be expanded by adding a variable of sheet thickness.

Various uneven geometries and joints can be mass fabricated optimally.

Optimising Complex Geometries based on Available sheet sizes in the market

The Average geometry for each cluster can be obtained.

The original Complex Geometries can be changed with minimal variations by replacing the faces with the newfound averages.

This way, Mass production of these geometries can reduce cost and time for manufacturing.

Advanced wood tectonics is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2021/22 in the Business Innovation Seminar by Students: Rigoberto Moreno and Prarthana Sudhindra Faculty: Mateusz Zwierzycki