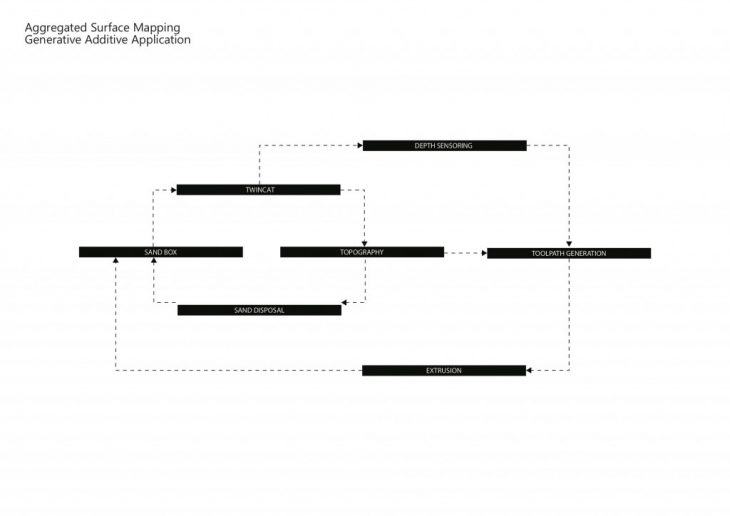

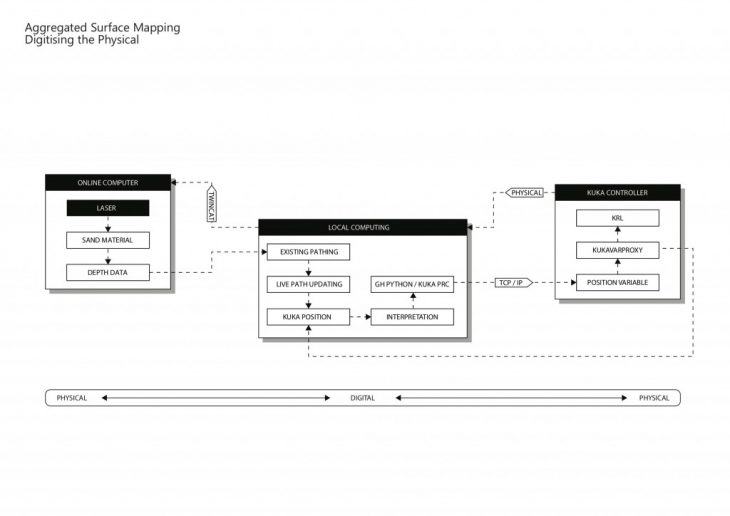

During Workshop B we were asked to explore different design and fabrication methodologies in context of local material performanc. We set out to introduce live data via a laser that communicated with a local computer utilising bespoke programmable logic controller provided by Wes McGee.

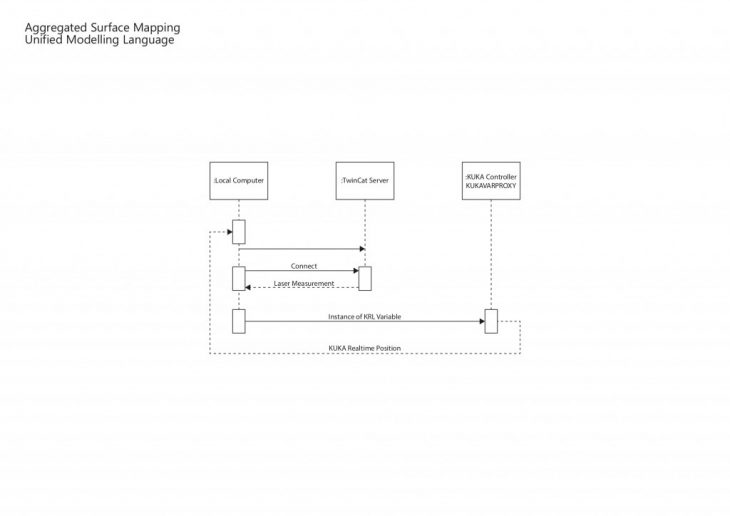

A secondary computer was setup to act as a TwinCAT server that pushed a live data stream to Grasshopper which allowed us to gain remote data feed paired with the current location of the industrial robot arm.

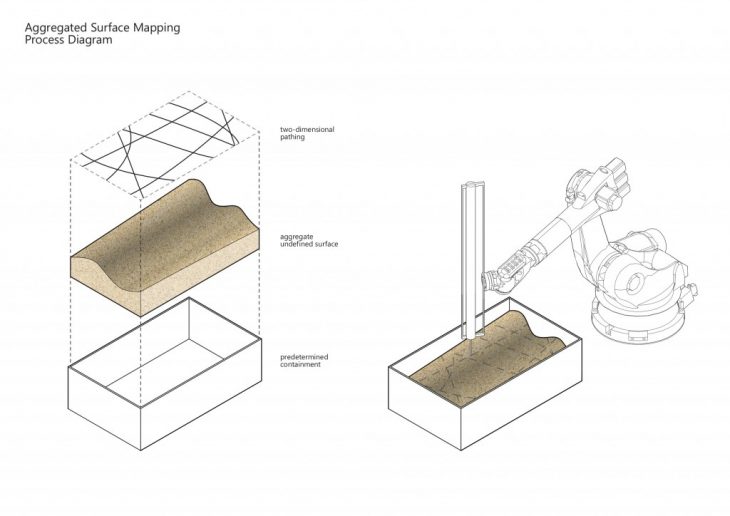

We successfully setup a system that allowed the industrial arm to navigate an unknown surface with a predetermined offset in the z-access. This envisioned process allows for the potential of new additive manufacturing techniques without the need of a predetermined and designed subsurface.

Students: Riccardo Mura, Ardeshir Talaei, Hazal Yilmaz

Faculty: Wes McGee