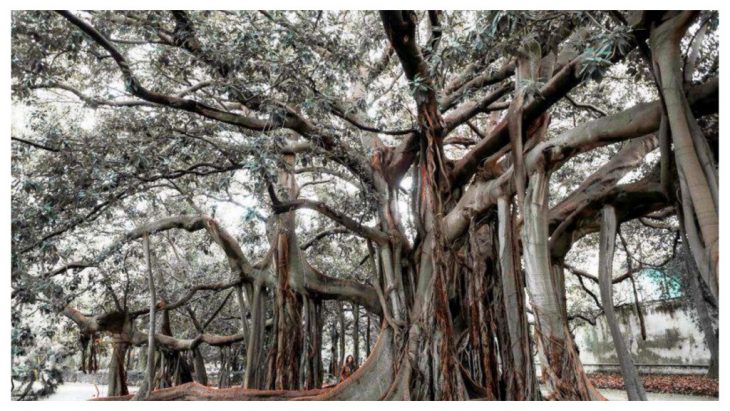

// BANYAN TREE

Banyan trees are known for having multiple roots that become indistinguishable from the primary trunk. This provides more stability for the tree to grow horizontally, with multiple points of support.

// BANYAN HOUSE

This tree names our project – it’s a house without walls, located in tropical Asia, where buildings are typically light and open and very integrated to nature, we start questioning how to make clay buildings less solid and heavy. How can we make them light and ventilated, while also providing protection from the heat?

// CLIMATE – HOT AND HUMID

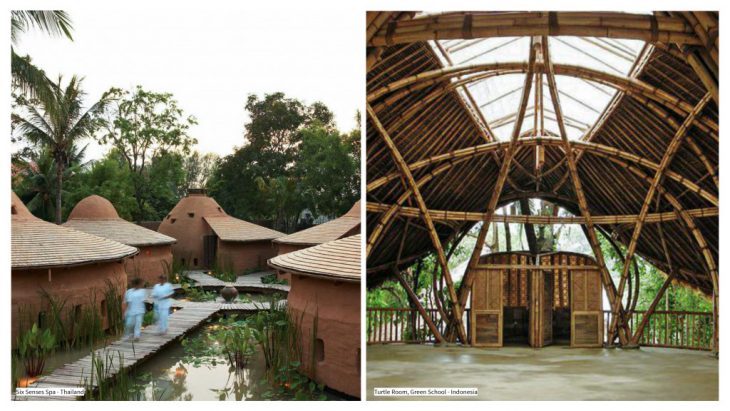

Earthen architecture brings constraints that make this lightness of bamboo buildings quite hard to achieve. In this context, 3D printing can bring solutions that reduce the constraints of building with clay.

We are designing for local Thai people who want to live close to the woods and the sea. We explore locally sourced materials like bamboo, since it’s so abundant and readily available in Thailand. And, along with 3d printing, construction techniques that are mastered by the locals.

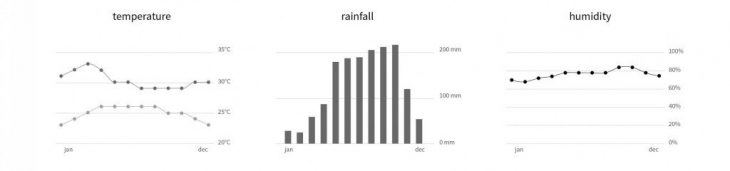

CLIMATIC CHALLENGES

The climate we are working with is hot and humid and brings us three main challenges: protection from the heat, humidity and rainfall, which are all intense throughout the year.

CLIMATIC SOLUTIONS

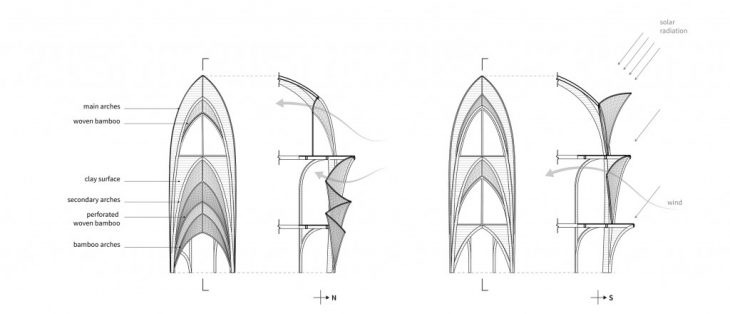

To deal with these challenges we explore some design strategies to ensure permanent natural ventilation, structure being elevated to avoid contact with the soil to protect from its humidity, and increase the surface area of the outer surfaces in order to reduce the temperature gain. different shaded openings and permanent ventilation strategies for each orientation. Taking advantage of slope ventilation which follows the stack ventilation within the structure.

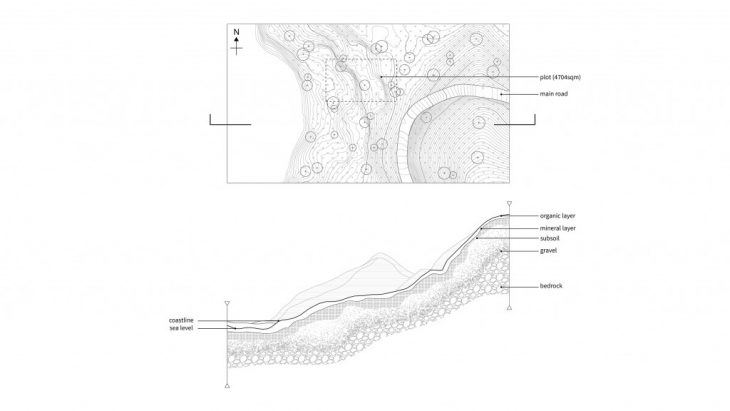

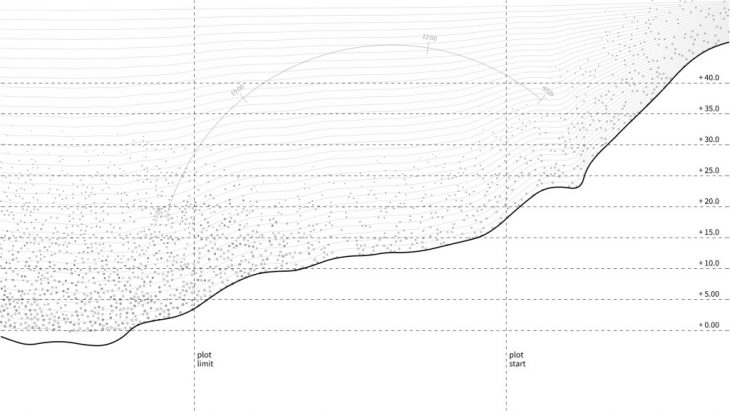

// SITE – THAILAND

The site is located in Thailand, on a slope by the ocean. The natural conditions of the site favors ventilation, since the sloped topography naturally creates some air circulation dynamics that can be explored in design. It is well connected to the woods and the water, and the access to the site is through a local road.

CLIMATIC SECTION

We study the ventilation and humidity dynamics on our site and feed that data into our design. The wind naturally speeds up towards the top of the hill, and during the day the cold wind comes from the water, reversing at night.

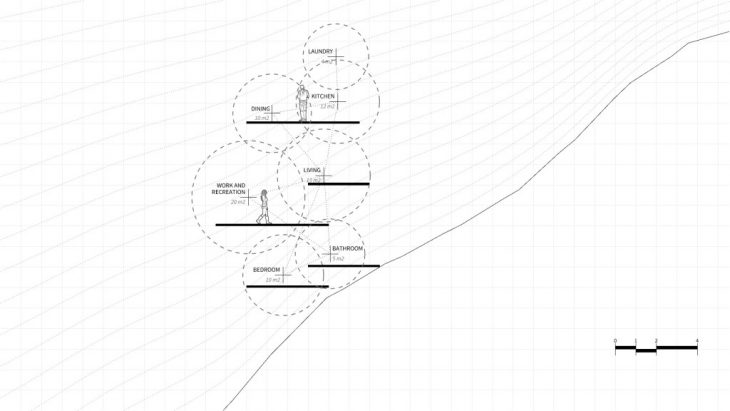

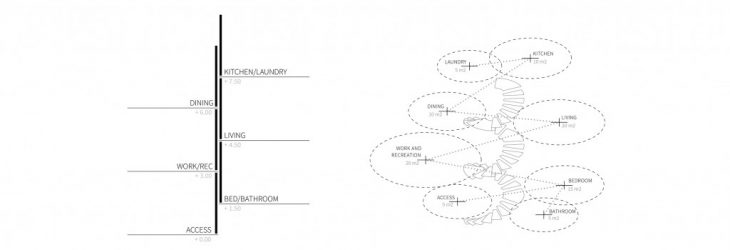

PROGRAM DISTRIBUTION

The program distribution is based on those environmental factors, with vertical and sloped distributions keeping the common areas in the most ventilated spaces, and the humid areas on top to avoid bringing their humidity into the building

The ideal distribution centralizes the vertical circulation to act as a ventilation shaft, distributing the rooms around it.

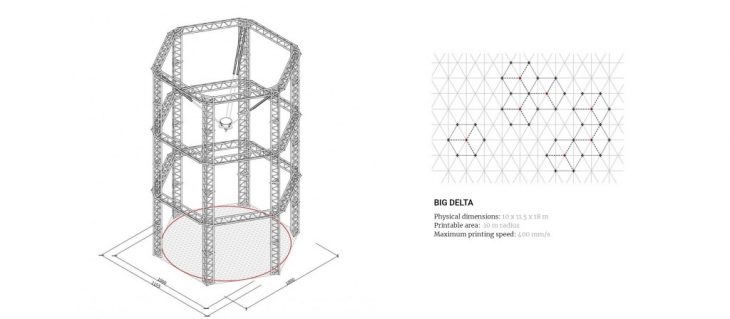

ROBOTIC SYSTEM – WASP BIG DELTA

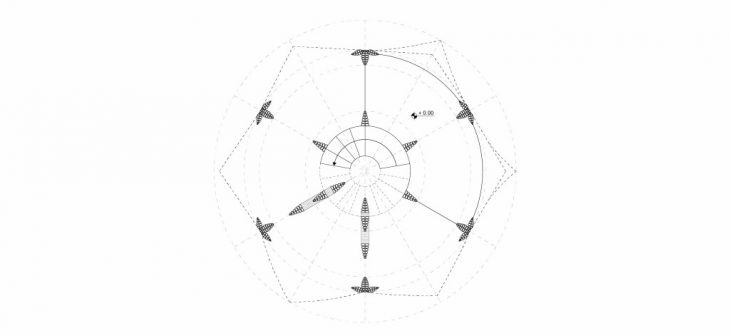

The ideal robotic system for our context needed to be stable and adaptable to slopes, so the best solution is a cable robot. Based on the WASP Big Delta, which can be built without any scaffolding, we propose new dimensions and the extension of its supports in order to adapt to the topography. The printable area has a radius of 5 meters.

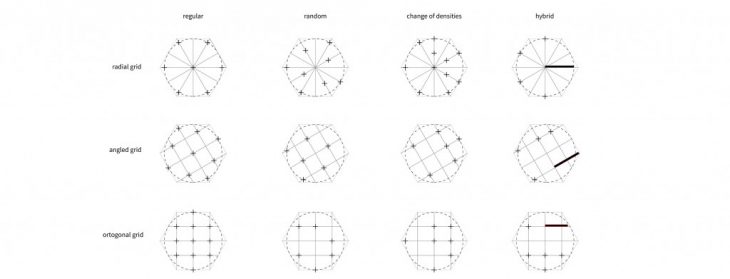

STRUCTURAL GRID STUDIES

From the robotic system chosen we study several structural grid strategies, based on a radial, an orthogonal and an angled grids. A regular radial grid is ideal for our system, making it possible to centralize columns where the arches branch out from.

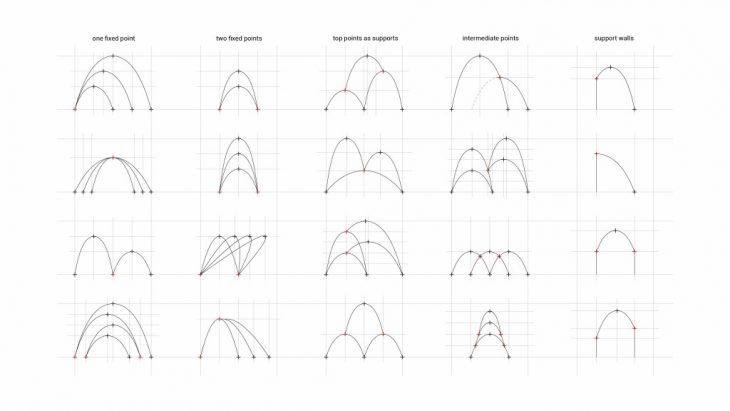

Our structure is defined by variations and associations of arches, of different shapes and heights. Such a structural system enables vertical and horizontal connections in various points of the arches, in multiple directions. These 2D studies orient the structural design.

//RESIDENTIAL UNIT

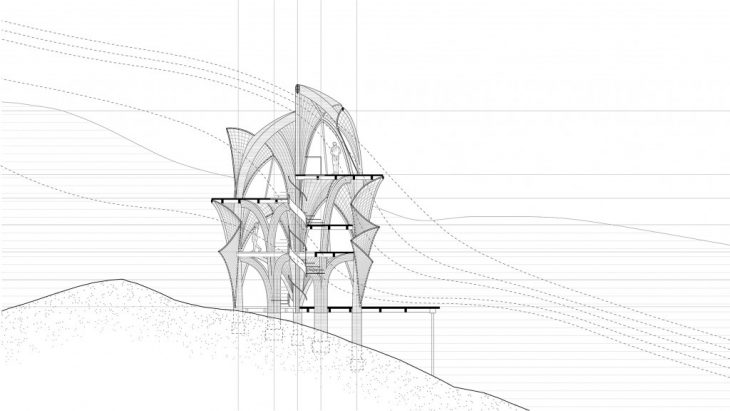

AXONOMETRIC SECTION

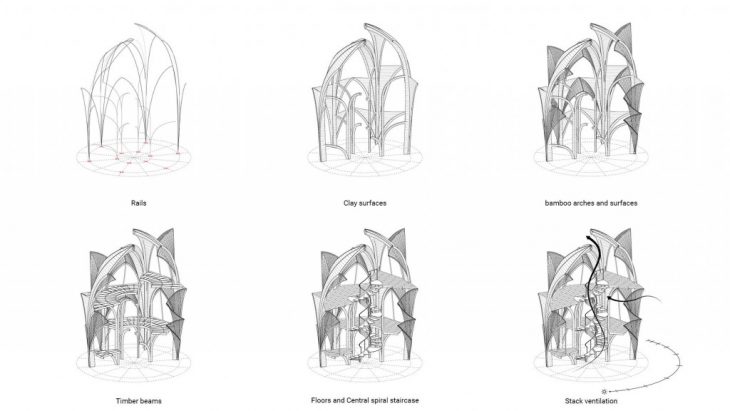

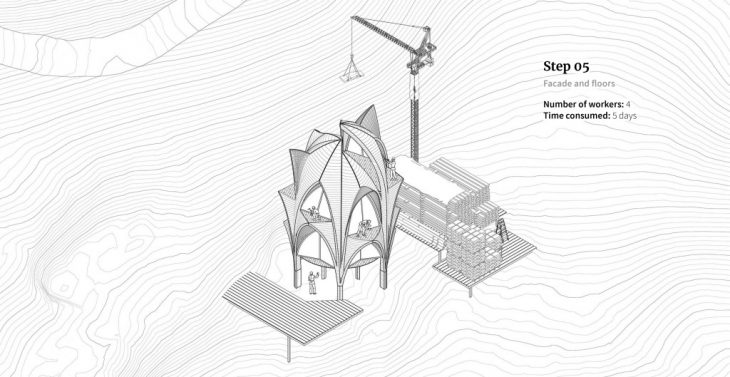

The building is shaped by rail curves that define the arches. They shape the primary structure of 3d printed clay. Then, angled bamboo arches and surfaces shape the facade and provide shading. Timber beams are connected to the arches to support the floors, and a central spiral staircase unites them. We take advantage of stack ventilation, bringing the cold air in through the woven bamboo and out through the staircase and the top openings.

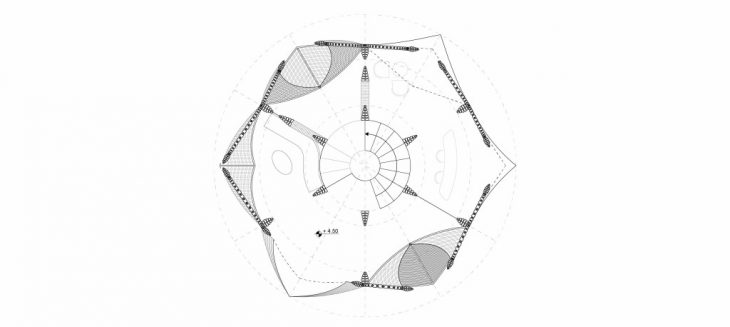

PLANS

1. Entrance

In the first floor the arches are used to elevate the building from the terrain, protecting from the humidity. On the ground level there is a platform for access to the building. 2. Bedroom and Bathroom

2. Bedroom and Bathroom

The units are designed for two people who enjoy living close to nature. On the next level, there’s a bedroom integrated to the bathroom. These are the only rooms with walls, since they require some privacy. They face north-west, requiring a lot of shading but also getting most of the ventilation.

3. Work and Recreational area

3. Work and Recreational area

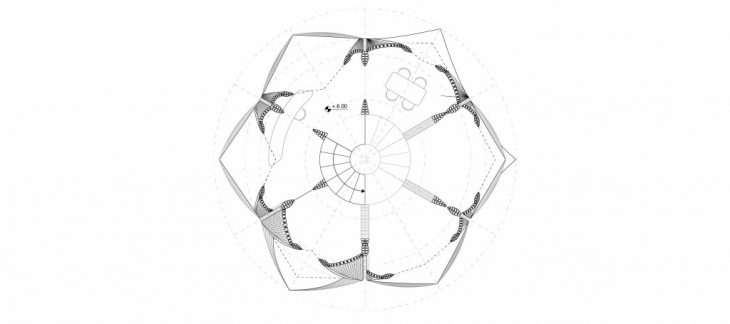

we have common areas – work, living and dining area in the most ventilated area in the middle with more shaded openings facing the vegetations and ocean. 4. Living area

4. Living area 5. Dining area

5. Dining area 6. Kitchen and Laundry

6. Kitchen and Laundry

kitchen and laundry which are the most humid areas are placed on the top to avoid bringing the humidity inside the building. The visibility and ventilation between floors is unobstructed. The goal was minimizing the solid walls in the building and making it as light as possible, bringing views of the vegetation and the ocean into every room. The clay walls have increased rugosity and air pockets, in order to increase the outer surface and the insulation, reducing heat gain.

The goal was minimizing the solid walls in the building and making it as light as possible, bringing views of the vegetation and the ocean into every room. The clay walls have increased rugosity and air pockets, in order to increase the outer surface and the insulation, reducing heat gain.

SECTION

We study each facade according to their orientation, in order to maximize the natural ventilation and protect from solar radiation.

FACADE STRATEGIES

The north facade doesn’t need as much shading, so it is more open while still having some woven bamboo for permanent ventilation. The south and west facades have longer overhangs for solar protection. The bamboo arches that are angled inwards have a loose woven bamboo surface for permanent ventilation.

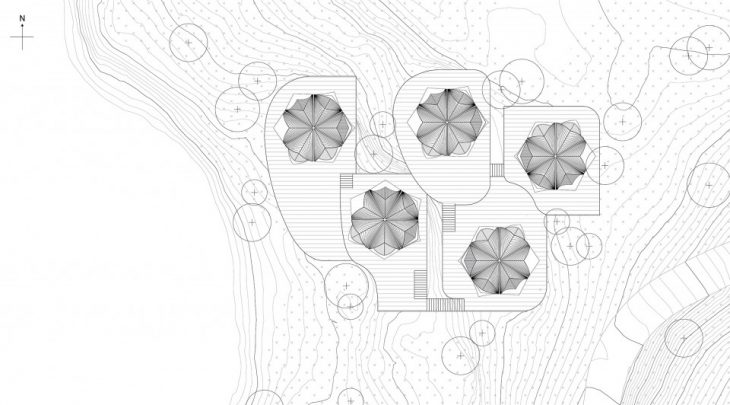

//SITE PLAN

Multiple units are distributed on our site creating platforms in between them that connect all of the buildings to the water. Their distribution is studied in order to ensure that the ventilation remains uninterrupted. The decks between units become common spaces near the beach.

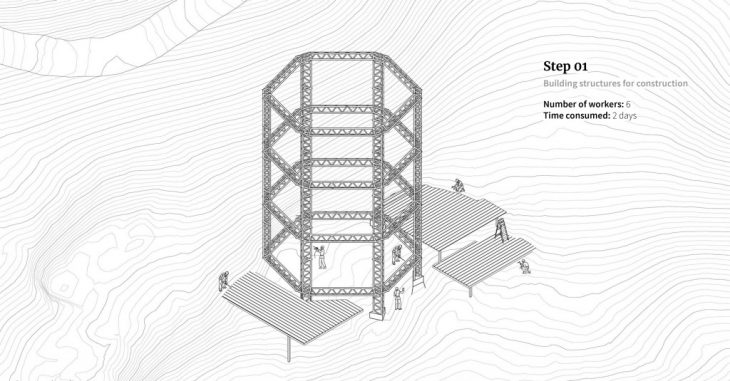

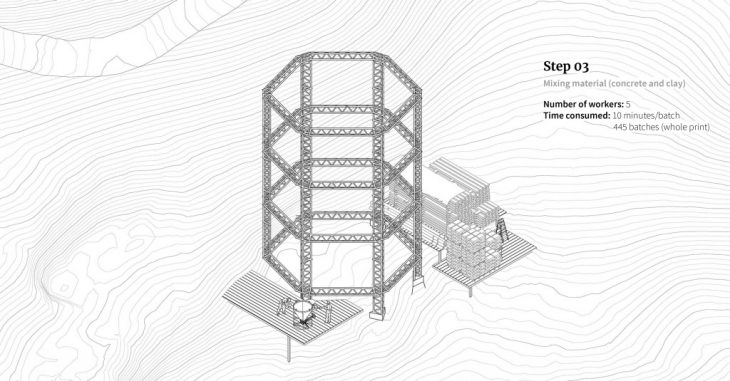

CONSTRUCTION

The construction process starts with setting up the structure of the printer and the material storage decks. Then, the materials should be brought to the site and safely stored, taking advantage of the availability of locally sourced timber and bamboo. 89 cubic meters of clay are needed for the production.

Then, the materials should be brought to the site and safely stored, taking advantage of the availability of locally sourced timber and bamboo. 89 cubic meters of clay are needed for the production.

In production, the first step is printing the clay arches and walls. The printing process lasts around 12 days, demanding pauses for drying between every floor.

In production, the first step is printing the clay arches and walls. The printing process lasts around 12 days, demanding pauses for drying between every floor. After drying for another week, the bamboo facades and timber floors can be installed.

After drying for another week, the bamboo facades and timber floors can be installed.

//RESIDENTIAL UNIT VARIATIONS

Using the same structural logic this system can grow by associating multiple printers. These units can grow, multiply, connect and adapt to different demands and numbers of users, with the potential of housing bigger families or becoming shared living spaces.

Banyan House is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in Open Thesis Fabrication 2020/21 by Students: Brenda Freitas and Nitha Shivapuram, Faculty: Edouard Cabay, Alexandre Dubor, Kunaljit Chadha, Ashkan Foroughi Dehnavi