BENDY! Is a table which incorporates bending plywood using “kerfing” techniques. It essentially serves as a desk which is an amalgamation of various digital fabrication techniques; the CNC and the 3D printer. It showcases various joineries and bracing methods alongside kerfing.

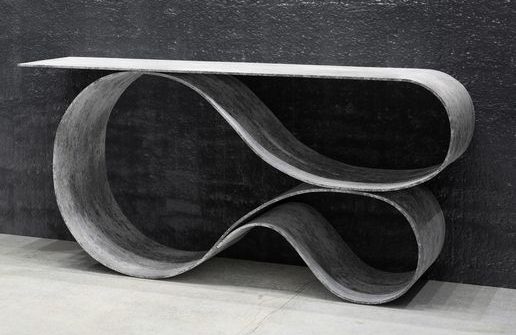

INSPIRATION

The inspiration for the design originated from our fascination with bent metal sheets, we wanted to try and mimic the same using plywood.

PROTOTYPING

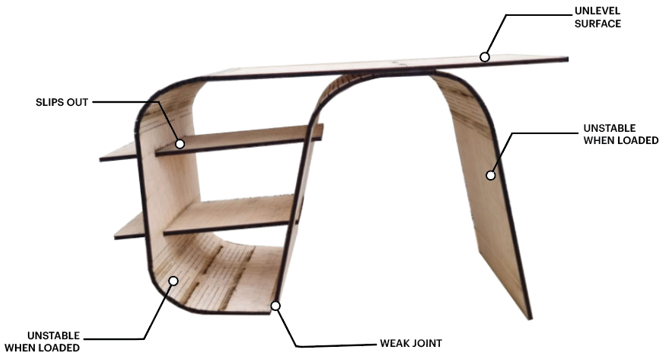

TRIAL 1 & PROBLEMS

TABLE LOADING VIDEO:

The 1st prototype was done in 1:3 scale using the laser cutting machine. It was very unstable due to too many bends in the table.

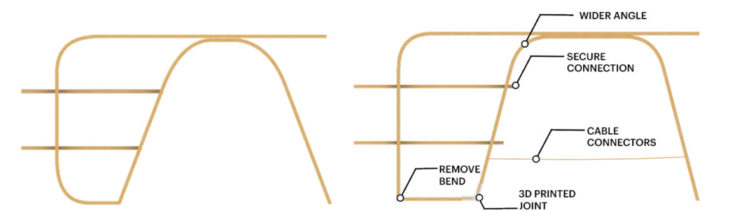

CHANGES IN DESIGN

Therefore, in the 2nd prototype, we reduced the number of bends, but this led to an increased number in the variety of joineries hence making the solution more stable yet more complicated.

TRIAL 2 & PROBLEMS

TABLE LOADING VIDEO:

As per the problems faced with the 2nd prototype, final changes were made and the sizes were adjusted before the fabrication.

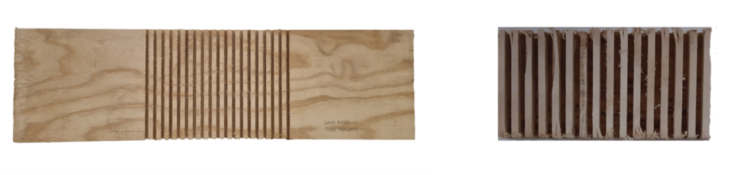

KERFING TRIALS

Moving on to the kerfing! The most challenging part of this design solution was the actual bending of wood, using a pattern unique to the CNC. We tested various types of kerfing techniques using CNC, Polyurethane glue, steam bending, with and without supports.

ONE WHOLE BOARD USED TO TEST VARIOUS TYPES OF KERFING TECHNIQUES

KERF 1 – 25MM SPACING/6MM ENGRAVING/ 13 MM CUT DEPTH, BENDS BUT WITH CRACKS

KERF 2 –9MM SPACING/3MM ENGRAVING/13MM CUT DEPTH, ROUGH EDGES & VERY BRITTLE

KERF AFTER CUT-NEATER EDGES CUT AFTER KERF- ROUGHER EDGES

The kerf cuts tended to have rougher edges if the kerfing pattern was done before cutting, so we tried a changed strategy for the CNC, i.e., Kerfing after Cutting.

KERF 3 –12MM SPACING/6MM ENGRAVING/10.5MM CUT DEPTH, TRIAL WITH POLYURETHANE. VERY MESSY AND DOES NOT HOLD THE SHAPE

KERF 4 –THROUGH AND THROUGH PATTERNED CUTS 6MM ENGRAVING, TOO FLEXIBLE, NO STRUCTURAL STRENGTH

KERF 5 –THROUGH AND THROUGH PATTERNED CUTS 3MM ENGRAVING, TOO STIFF, DOES NOT BEND

TRIAL WITH KERF+STEAM BENDING:

After failing to achieve the desirable outcome, we decided to change strategies. Steaming the ply after kerfing was the solution of the hour.

DOES NOT HOLD THE SHAPE, THEREFORE SUPPORTS ARE REQUIRED

We decided on the patterned kerfing of 10.5mm depth and 6mm engraving, with supports to hold the shape.

FABRICATION

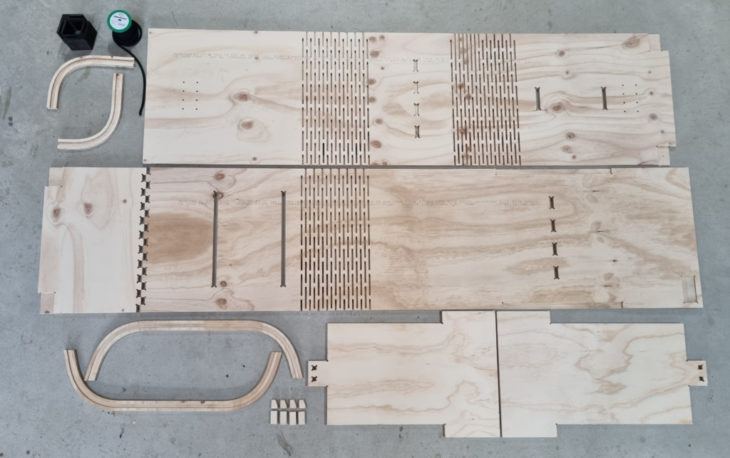

PRE-ASSEMBLY

TABLE ASSEMBLY VIDEO:

Various techniques and joineries used:

- Kerfing the ply

- Strings to hold the Kerf

- Additional supports for the kerf

- Finger Joints

- 3-D printed joints

- Dowel for the shelves

- Table top joint

POST-ASSEMBLY

“BENDY” is a project of IAAC, Institute for Advanced Architecture of Catalonia, developed at Masters in Advanced Ecological Buildings and Biocities in 2021-22 by:

Students: Zani Gichuki & Shagun Modi

Faculty: Bruno Ganem