BIO-ACTIVATED SKIN MEMBRANE

Bio-Activated Skin Membrane operates at the intersection between biology and design. The project focuses on developing an experimental methodology that uses computational tools and bio-material progressions in order to propose a dynamic and responsive geometrical system that is stimulated by the environment through a set of bio-inputs.

[ GEOMETRICAL ITERATIONS ]

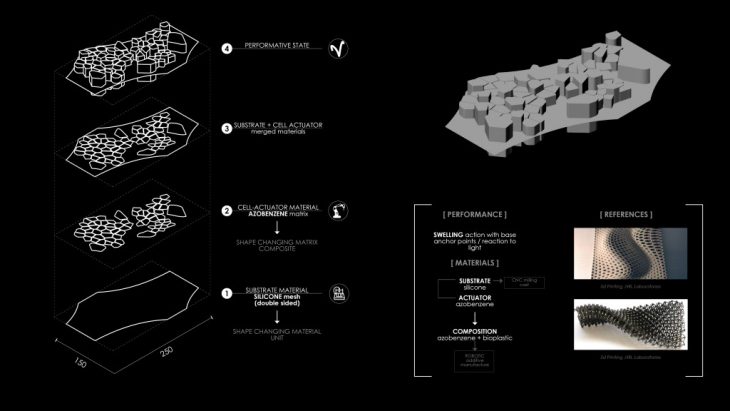

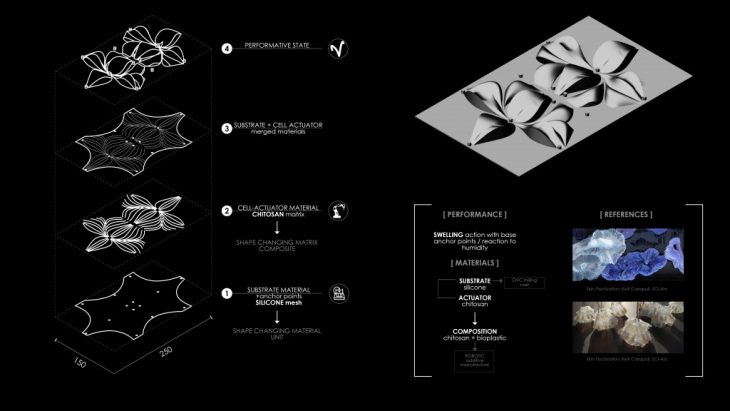

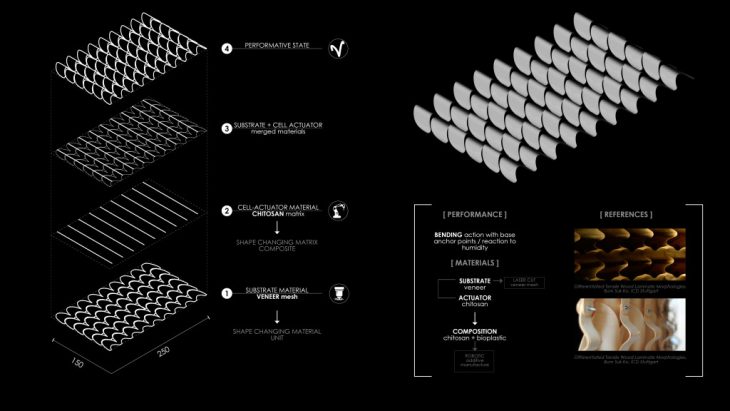

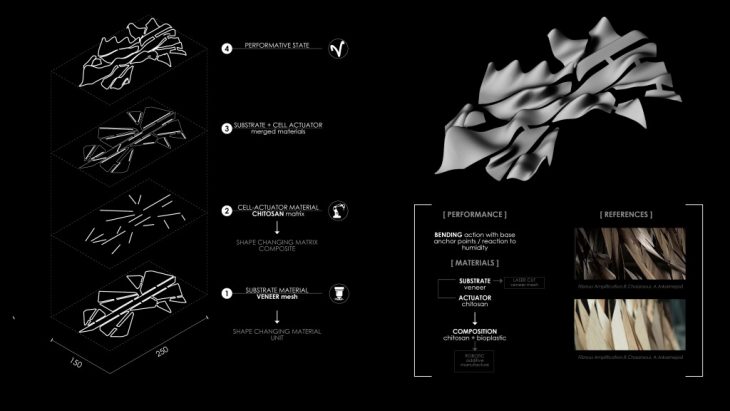

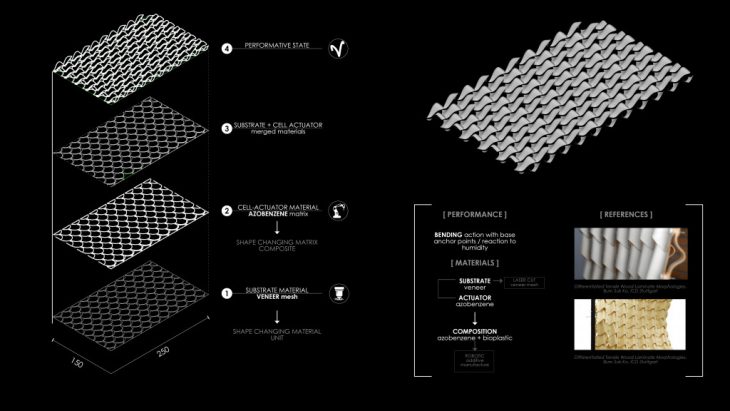

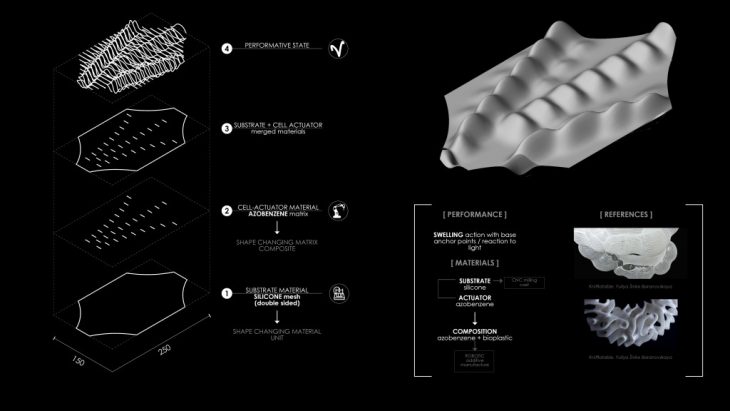

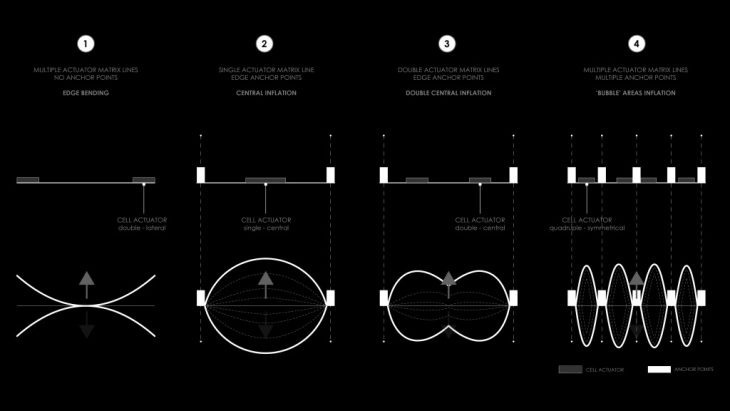

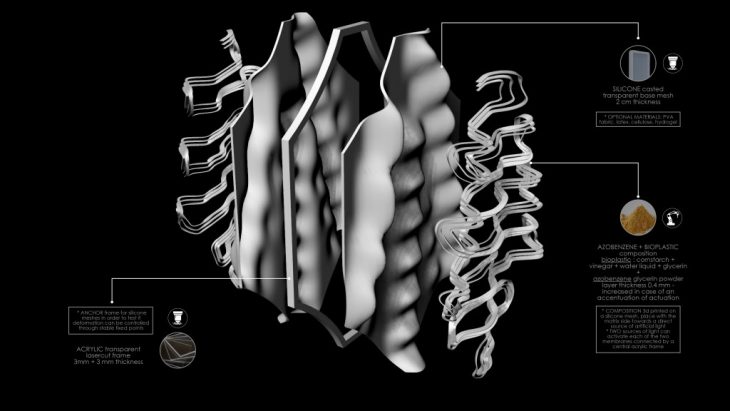

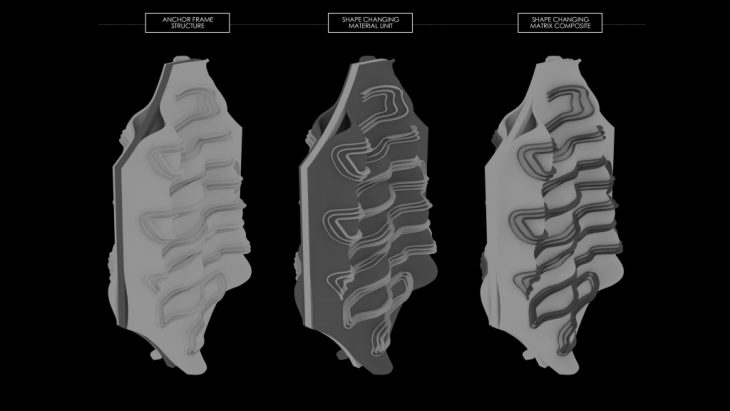

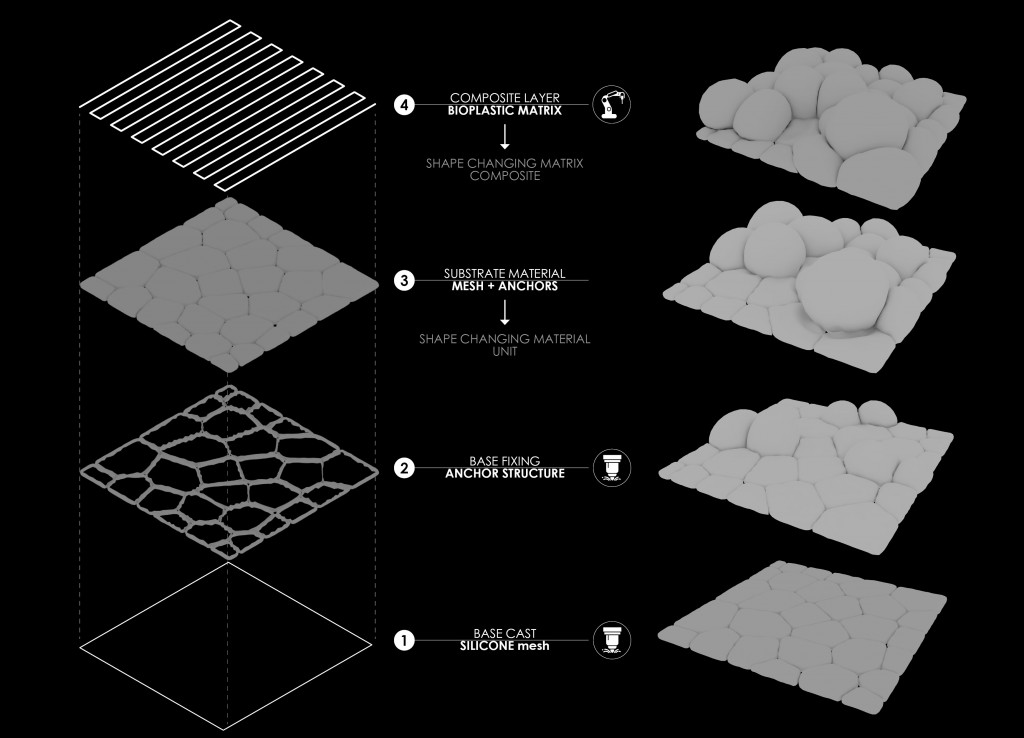

Phase 1 of the project starts with the development of geometrical variations that consist of two main layers: the shape changing material unit and the shape activation matrix composite. With this, each geometrical iterations aims to mimic a series of behaviors and shape-changing mechanisms that occur in nature, such as swelling and bending.

[ OPTIMIZATION AND FABRICATION ]

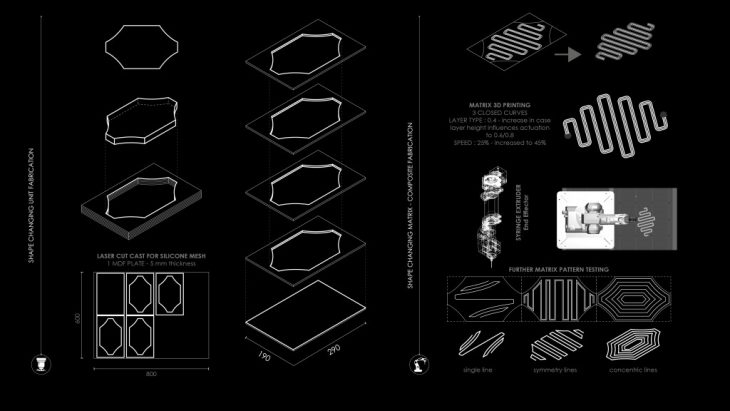

The optimization process looks at simulating the swelling reaction through using a flexible base material (latex,silicone) achieved through mold casting by CNC milling and an activation matrix composed of a bioplastic + chitosan mix, that will be 3d printed with a robotic arm using an End Effector Syringe extruder. The bio-matrix would react to humidity and therefore will produce movement and bending to the base unit, creating a series of dynamic shapes and deformations.

[ BIO-MATERIAL EXPERIMENTATION ]

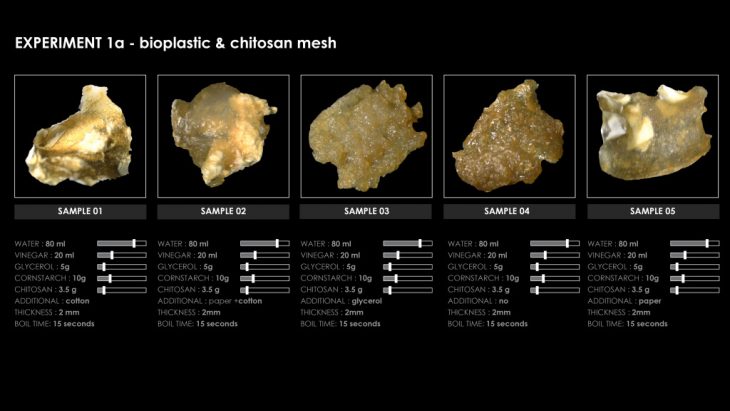

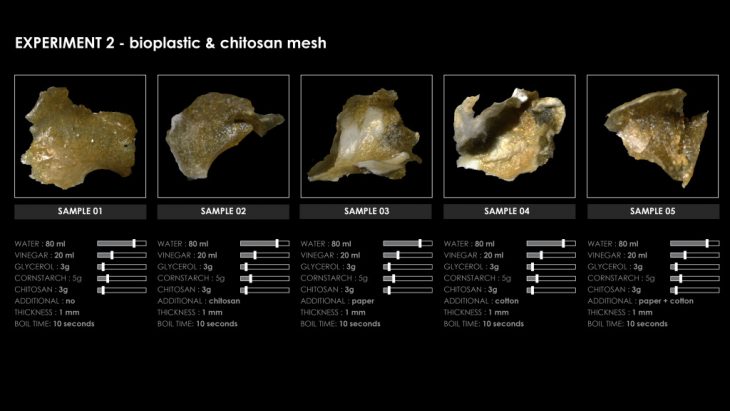

Phase 2 of the project focuses on developing the biological formula that would allow for experimentation with bioplastics and chitosan in order to achieve a shape changing material. In this case, 2 recipes are tested, both including the same components, but with different quantities. The formulas consist of: water, vinegar, glycol, cornstarch (for bioplastics) and an addition of chitosan for response to different levels of humidity. After creating a set of 10 different bioplastic meshes, the experiment tests how the recipe would work if applied as a matrix to a base material. As a result, the matrix becomes successful only if applied to thin bases and with higher layer height.

[ DIGITAL SIMULATIONS AND FINAL GEOMETRY ]

For a further understanding of the shape-changing output, a series of digital simulations were developed, based on swelling movement. The simulations were developed using Houdini. The fabrication process was also simulated, showing the process of robotic 3d printing.

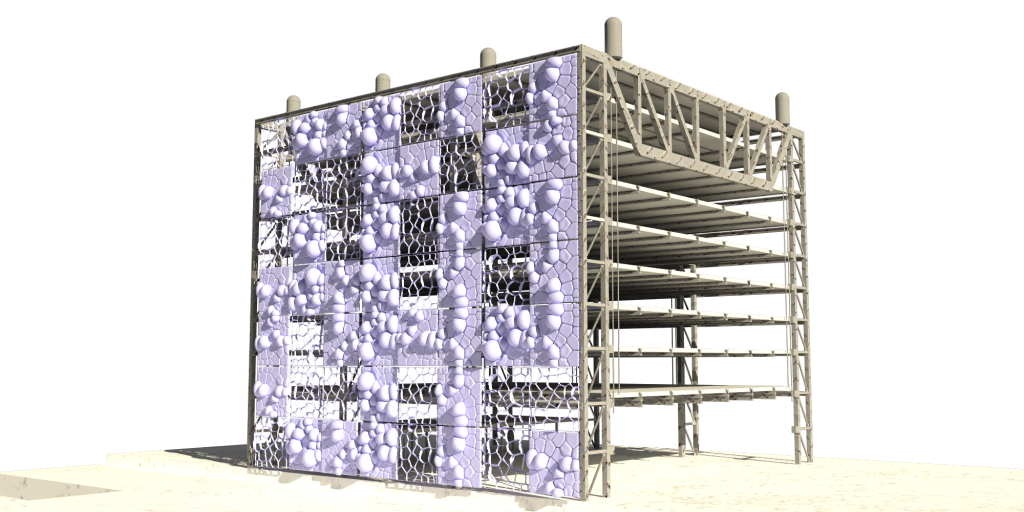

The final proposal focuses on a shift in materiality: a base unit of bioplastic and a 3d printed activation matrix composed of bioplastic+chitosan. The final shape proposal is based on simulating an inflation behavior, which in this case can become a performative architectural component, that inflates and bends in accordance with humidity fluctuations.

BIO-ACTIVATED SKIN MEMBRANE is a project developed at IaaC, Institute for Advanced Architecture of Catalonia, developed at Master in Advanced Architecture 2019/20 by:

Student: Daria Ciobanu-Enescu

Faculty: Ricardo Mayor & Nuria Conde Pueyo