Research Background

CO2 emission from construction

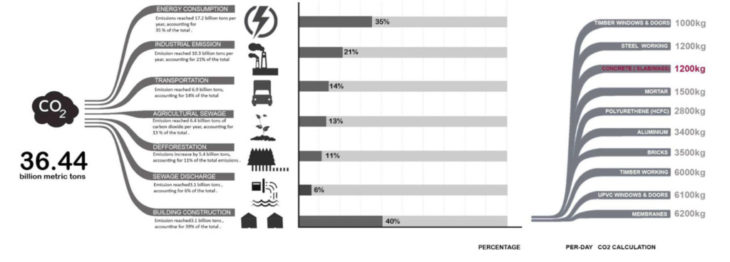

The CO2 emission result by construction industry is huge each year: 36.44 billion tons carbon dioxide is released in total per year. In which, 40% of CO2 emission is resulted by building construction. And 1200kg CO2 is produced by concrete fabrication per day.

Ways to reduce cement usage

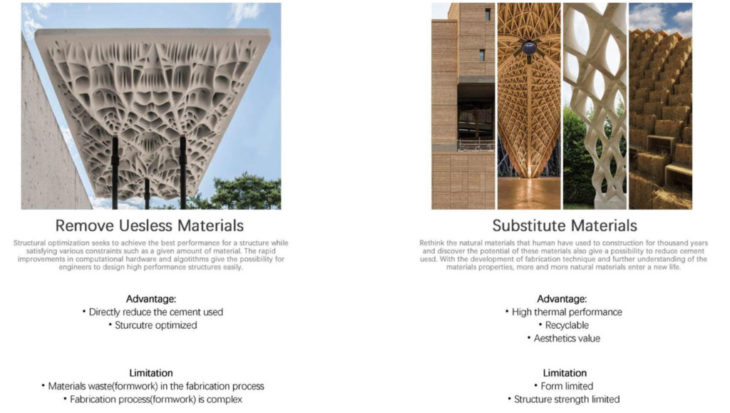

In order to reduce the usage of cement, different methods are tired. The first one is to use the algorithm to find out and remove the performance less materials inside the structure. The second one is use other materials to replace cement. However, cement is such an amazing material that has a lot of benefits especially in structural performance. So currently, it is still widely used in construction. Furthermore, another problem of the first method is that in order to fabricate such a complex form geometry, it will cost much more materials to fabricate the formwork than the materials used for the formwork for standard geometry.

Cost of formwork

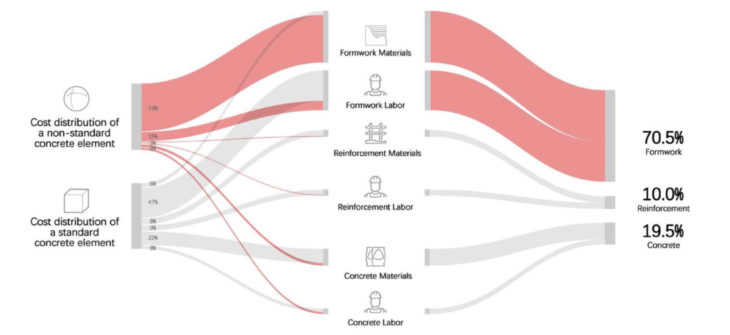

Once we zone in the cost of concrete casting industry, a truth about formwork cost is that no matter for standard elements or non-standard elements, formwork respond to 70% of the total cost. So, we need solve the problem bring by formwork for both economic and environmental reason.

Systey Mapping

System mapping

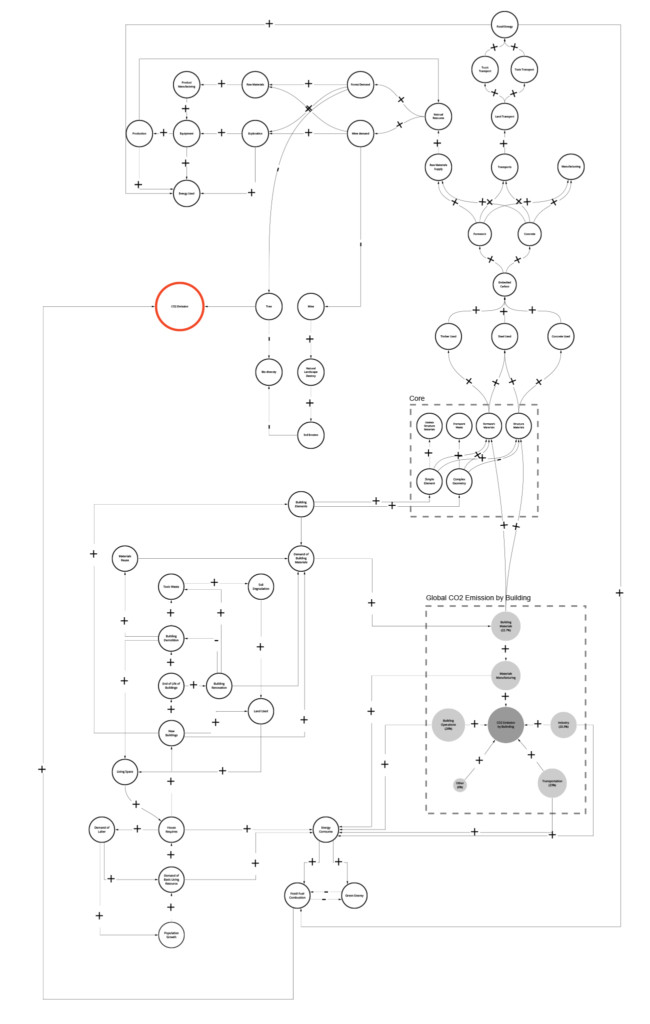

To understand how we can solve the problem, we start from the system mapping how each cell is linking to others inside the whole picture of concrete industry.

The mapping is developed based on three main parts: the reason why people need to use concrete, the source of CO2 emission of building construction and what the life cycle of the materials used for concrete industry looks like.

Feedback Loops

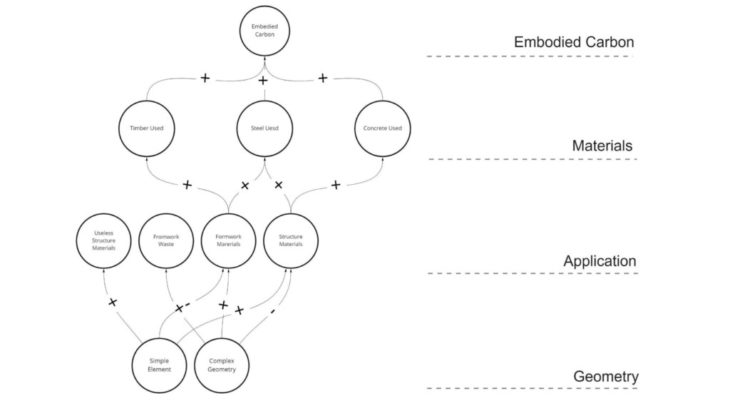

Geometry system

The first sub system inside the mapping is the relationship of materials usage and the complexity of the geometry.

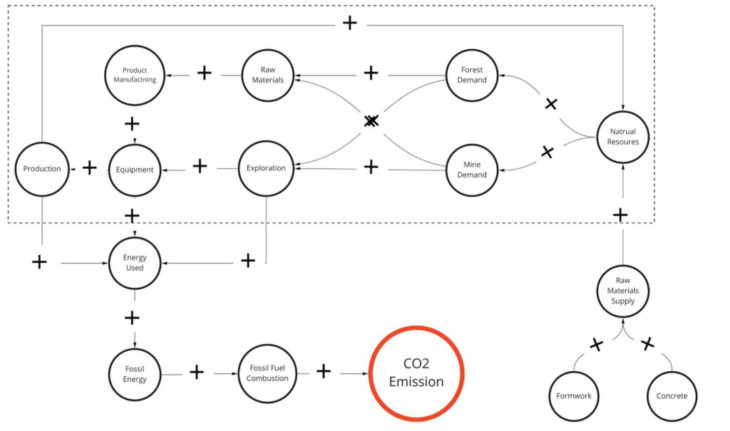

Feedback loop of energy

The second sub system is how different materiasl will contribute to the CO2 emission.

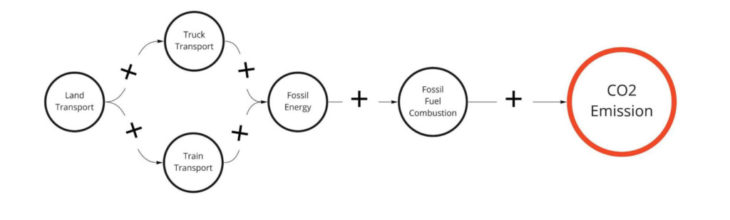

Feedback loop of transport

The last sub system is how transport will contribute to the CO2 emission.

Vision

Main goal

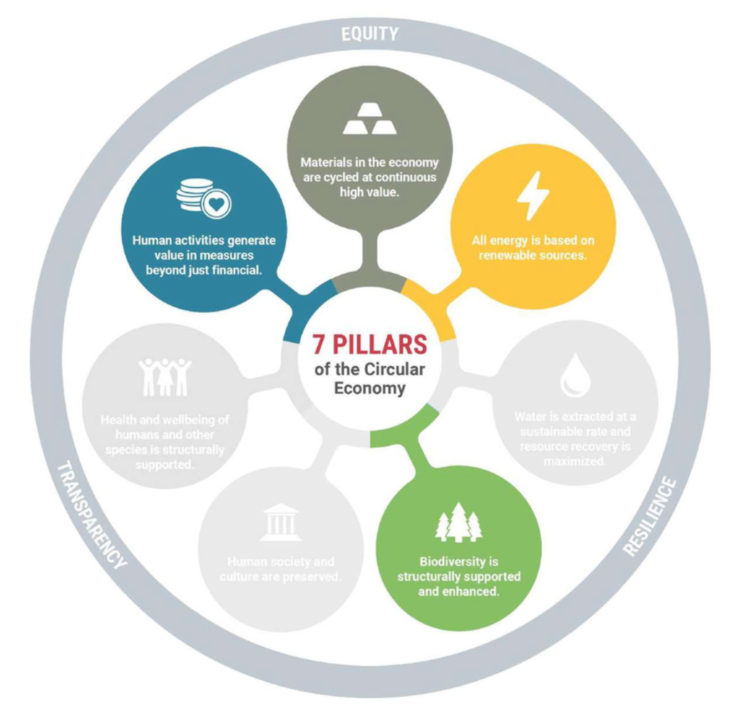

The main goal of the research is to achieve the 4E. In detailed, is environmentally friendly, economic sustainability, ecological recycled and easily access. To understand how those could be achieved, we first look at the current research how people trying to cast complex geometry with less materials waste for formwork.

Current development

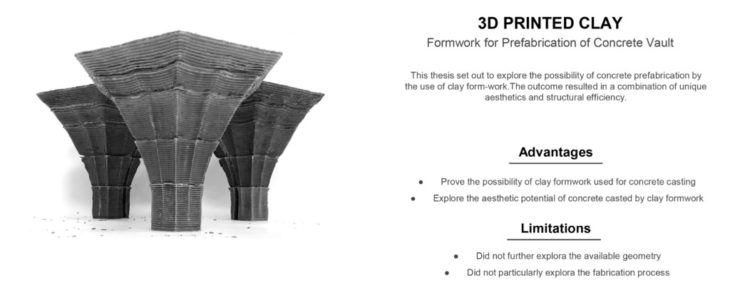

Current development2

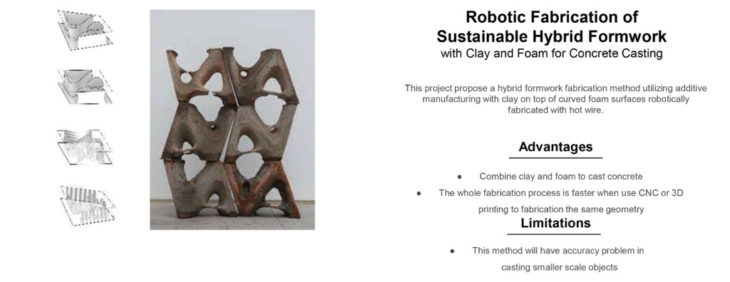

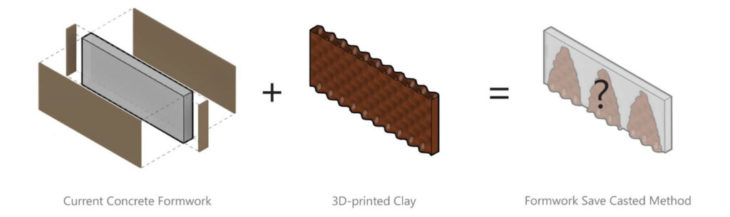

Two projects propuse a solution that use clay to replace plywood as the formwork materials.

Vision

From those reaserch, a question is raised,

Can we use 3D-printed clay formwork cooperate with regular formwork to fabricate complex form castable materials structural elements?

Seven Pillars

Stakeholder Analysis

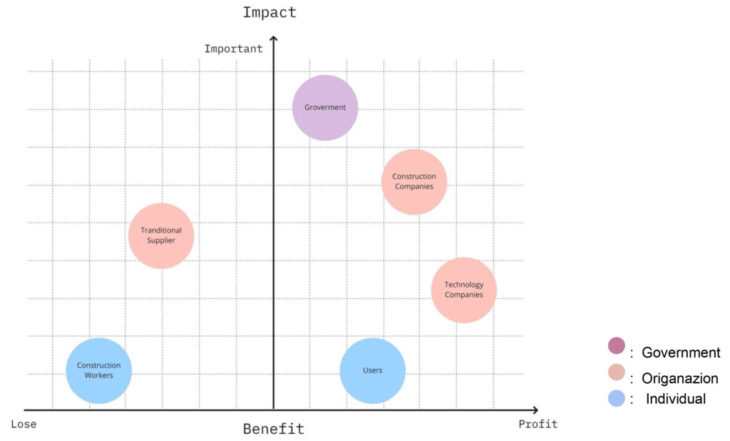

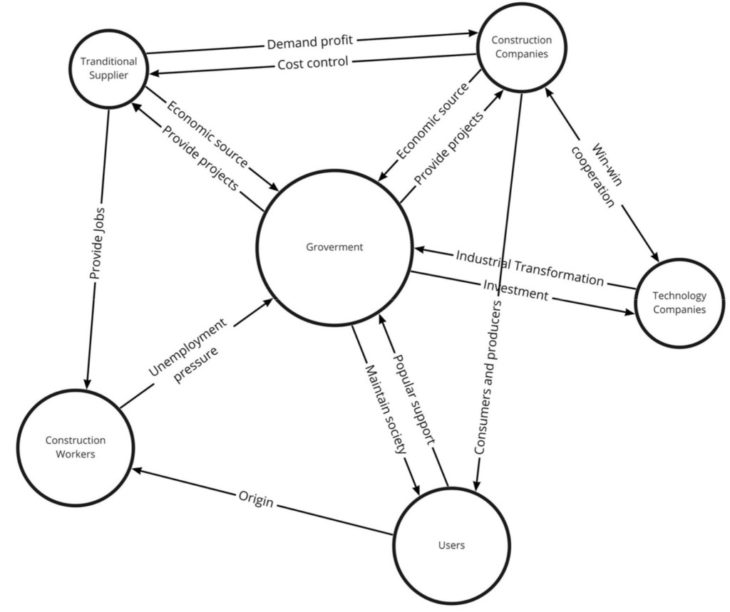

Stakeholders mapping

Stakeholders relationship

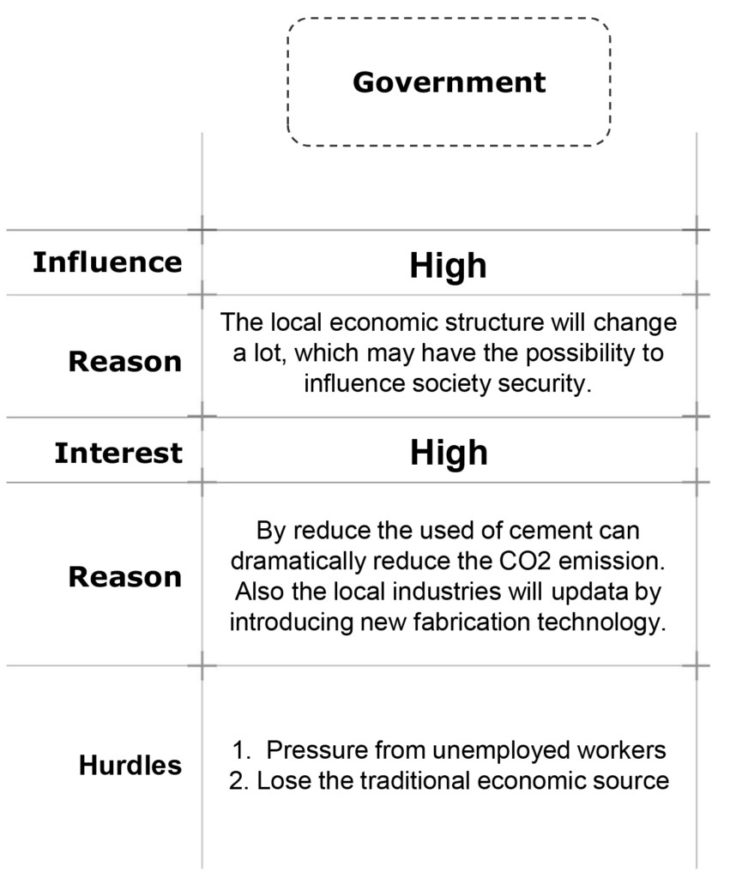

Stakeholders impact

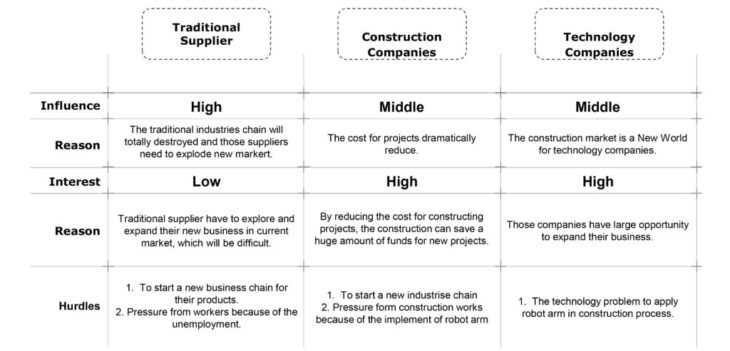

Stakeholders impact

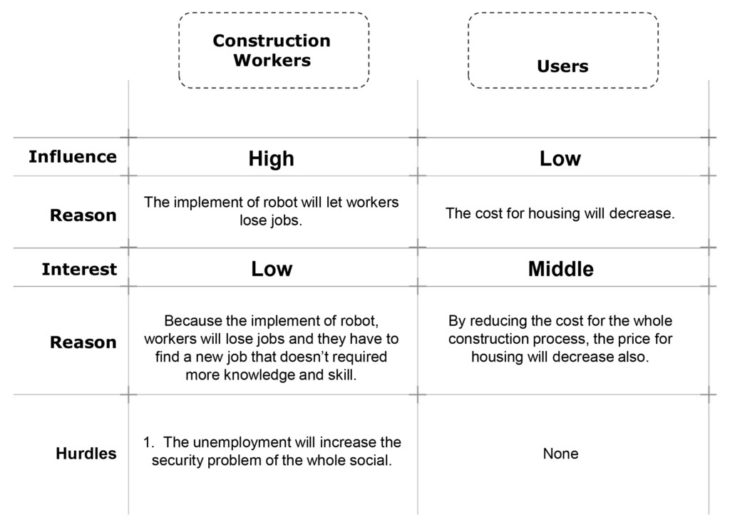

Stakeholders impact

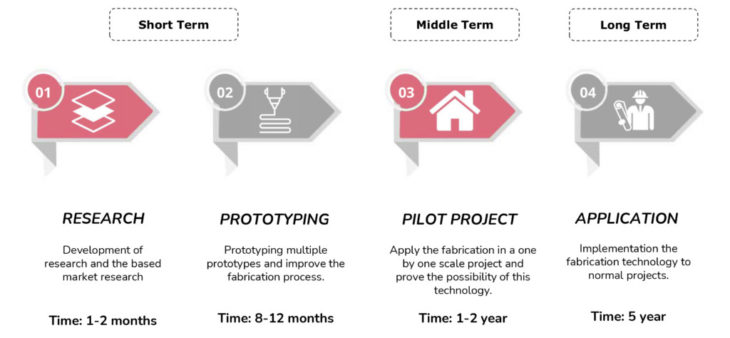

Intervention Timeline

Intervention Timeline

Cast Green is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the second year of the Master in Advanced Architecture in the Circular Economy Seminar in 2021/22 by Student: Liang Mayuqi and Faculty: Nico Schouten