CONCRETE WEAVING

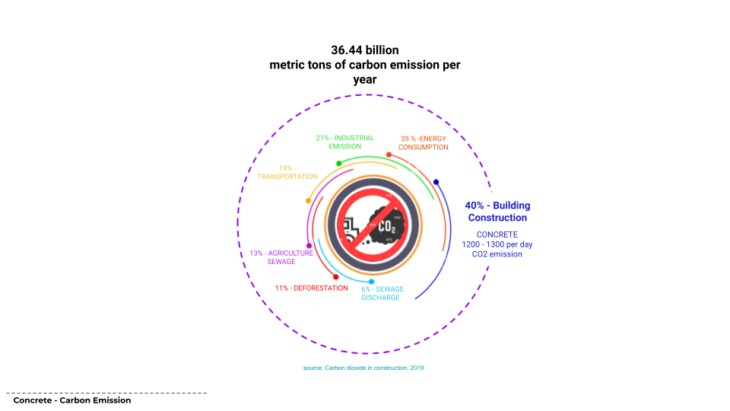

Everyone is aware of Concrete and its use, but its production is one reason for carbon emissions. Concrete it is still widely used because of its availability , easy to fabricate, durability & etc.

FRAMEWORK

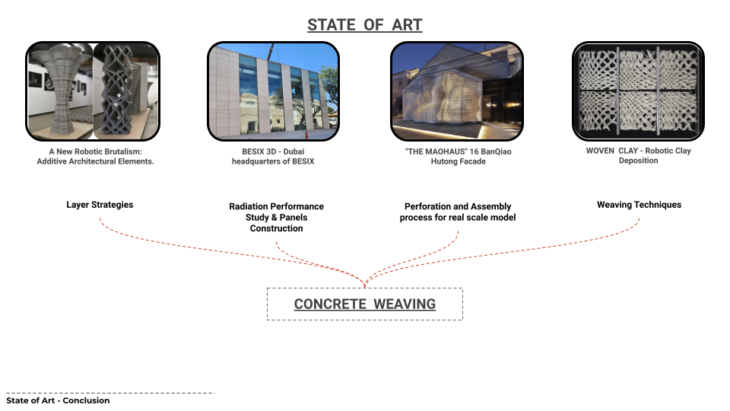

One of the way contributing to the efficiency progress for construction industry is 3D printed concrete (3DPC) which has attracted more and more attention in recent years. The utilization of 3DPC accelerate the construction speed, save the labor and raw materials, as well as improve the design freedom of construction without formworks.

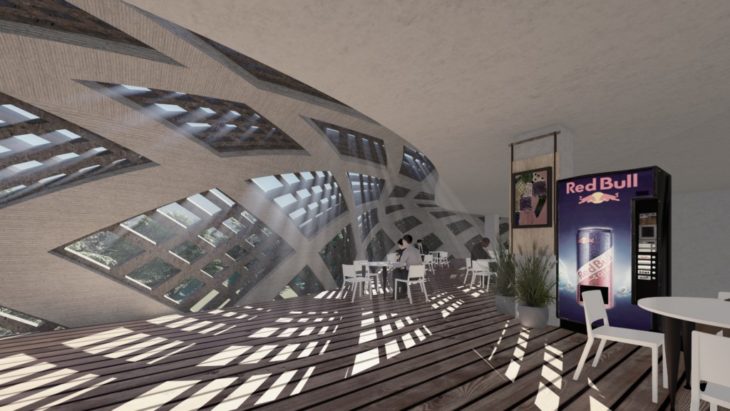

Concrete 3D printing have been explored in many categories. As concrete 3d printing is not yet develop to print large structure, but it can print small elements that can help to enhance the structure performance. The main focus of my thesis is to look mainly in façade construction by concrete 3D printing and its future opportunities.

RESEARCH QUESTION

How can we use Concrete 3d printed panels to create a performative façade system for structures?

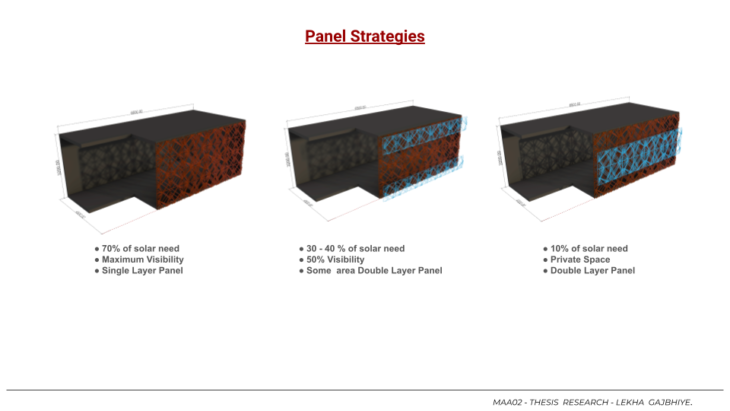

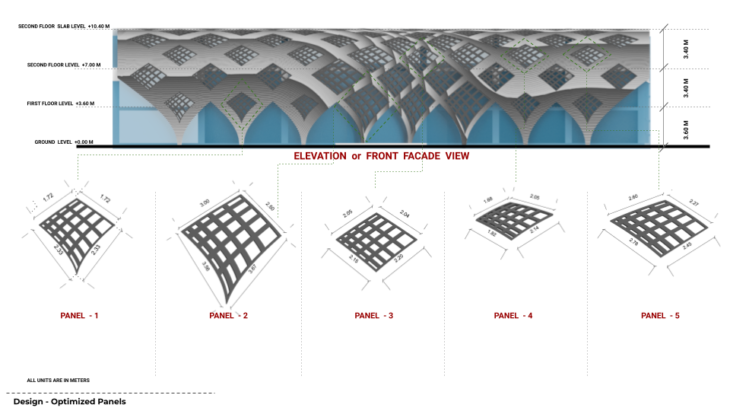

After having a brief understanding of on going project in concrete 3d printing in a small scale and with sustainable concept, I would like to work on concrete paneling system which will evaluate on solar & radiation analysis and printed with weaving technique.

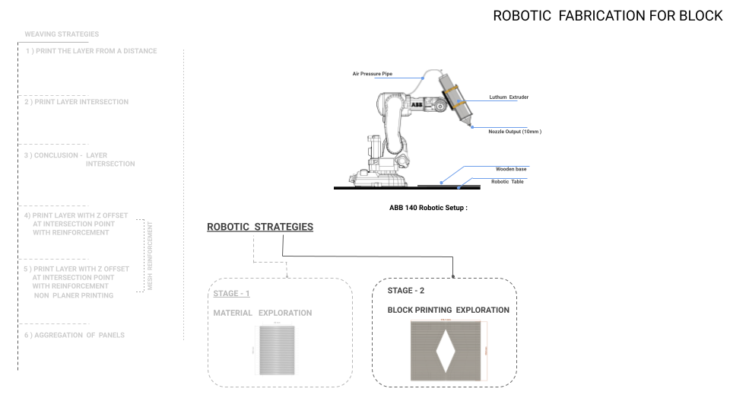

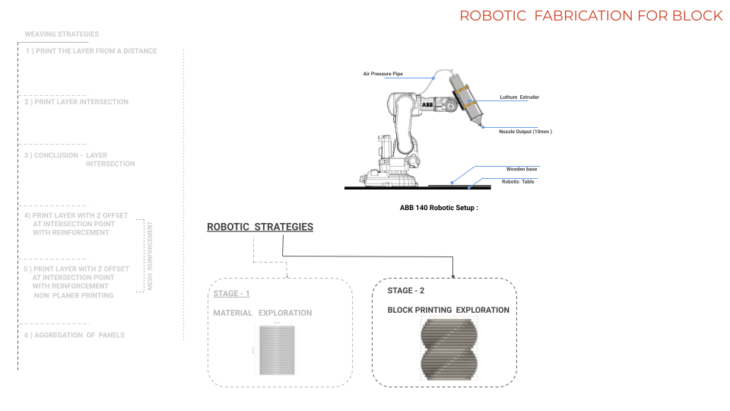

FABRICATION PROCESS.

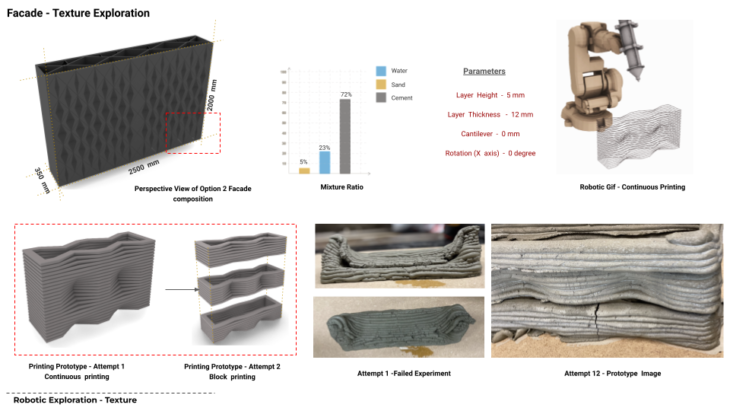

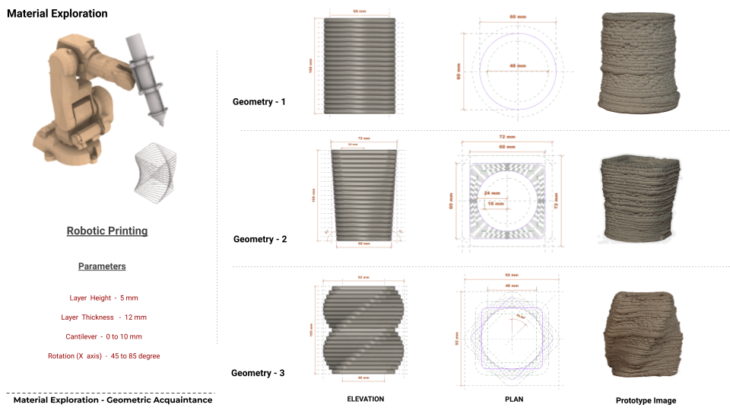

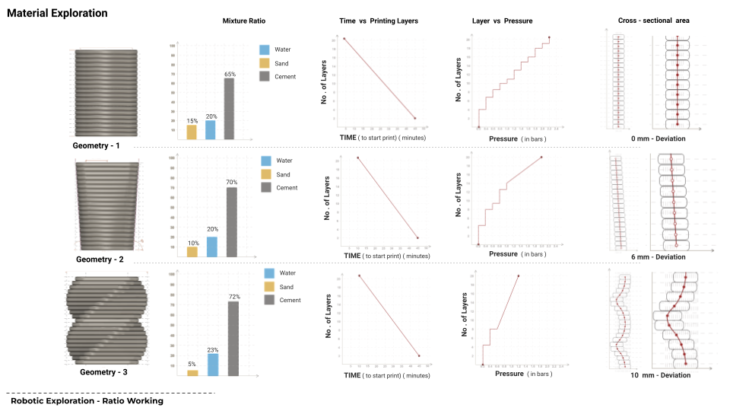

Before going into panel printing here are some basic exploration of concrete 3d printing with pressure base extruder.

Step – 1 – Basic Geometry

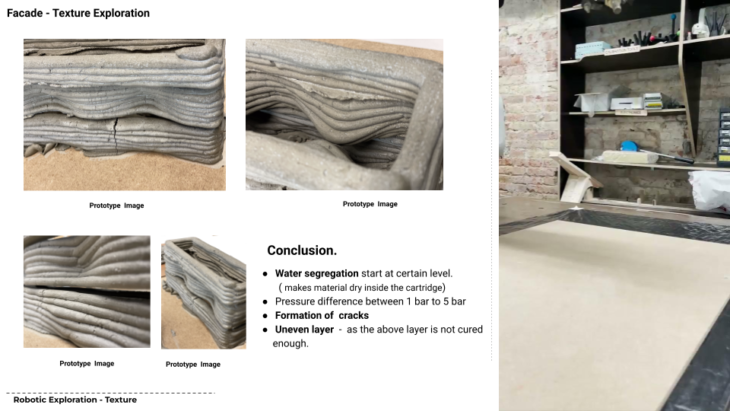

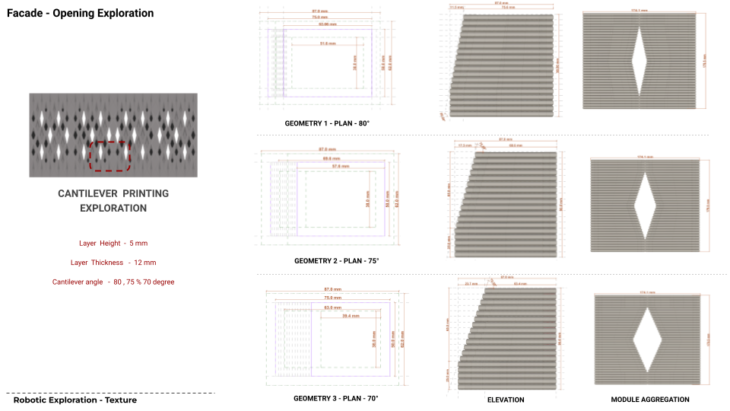

Step – 2 – Texture Wall Exploration

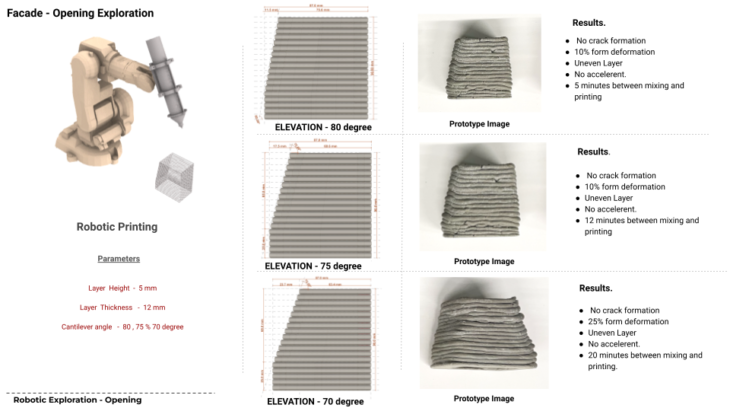

Step – 3 – Block Wall Exploration

Printing cantilever with block printing, where explored angles are 80 degree, 75 degree & 70 degree.

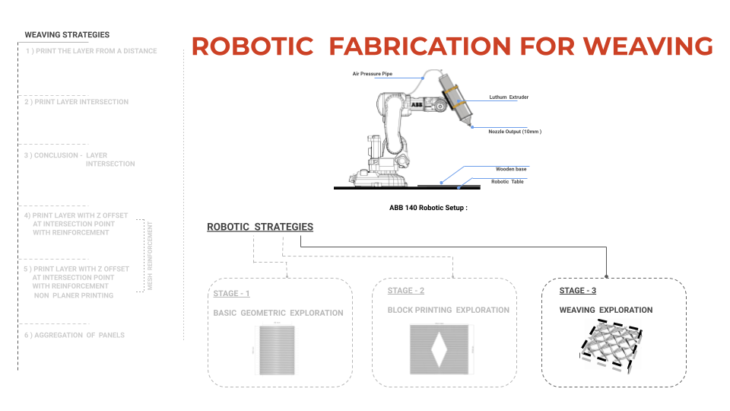

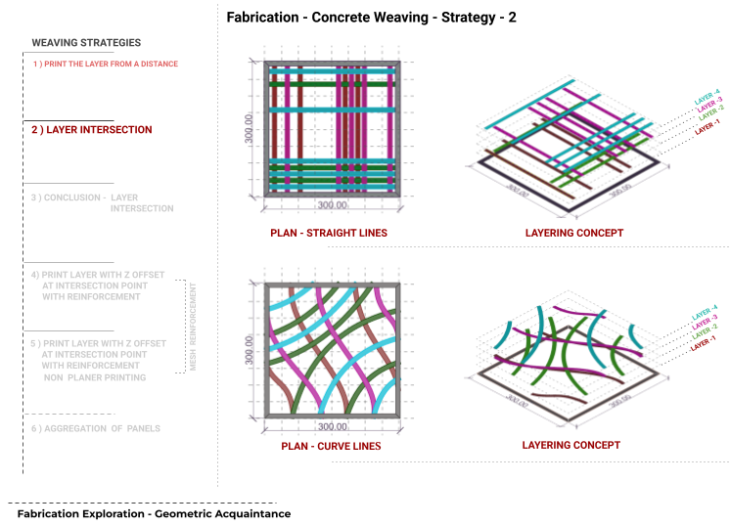

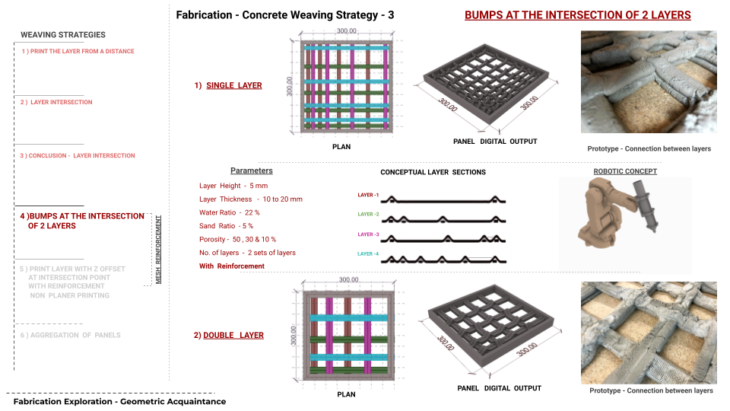

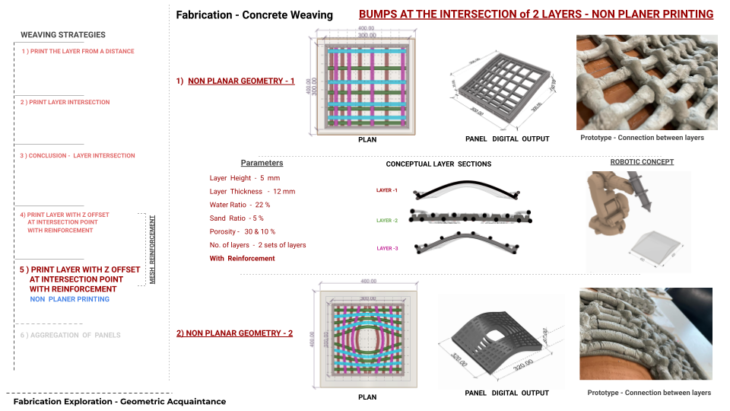

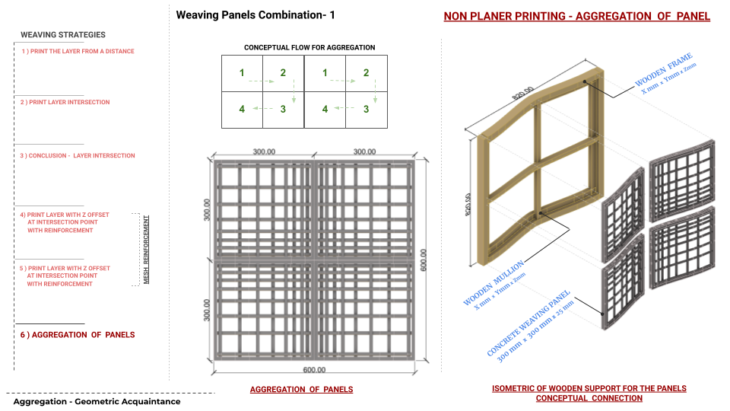

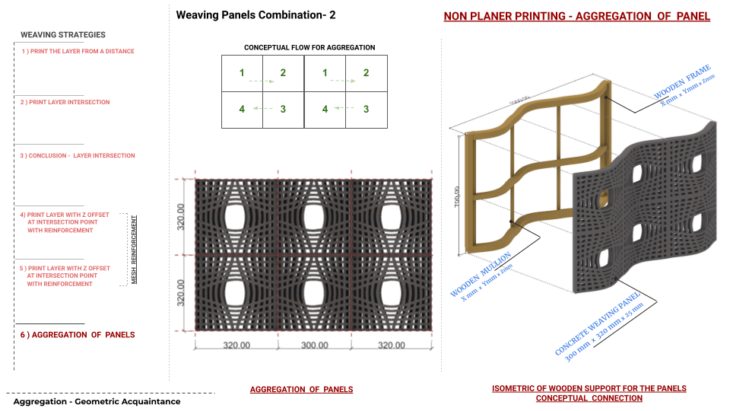

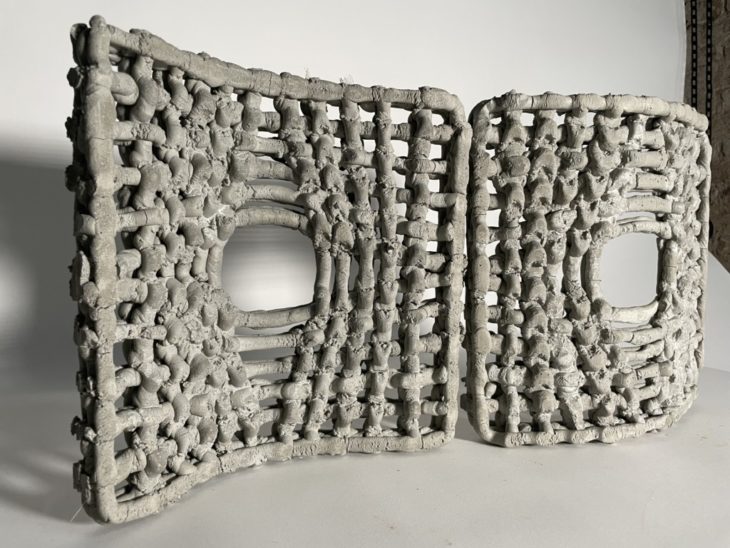

Step – 4 – Weaving Panels Exploration

LAYER PRINTING CONCPET

Step – 5 – Variation in Weaving Panels Exploration

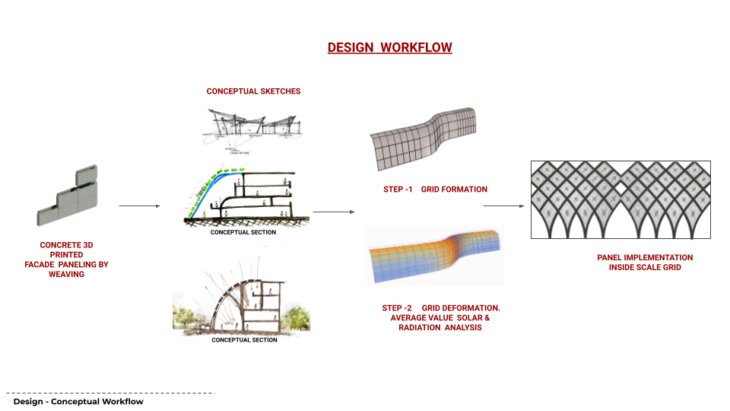

DESIGN PROCESS.

Weaving Facade Design Process.

WEAVING FACADE DESIGN EVALUATION

CONCRETE 3d PRINTED WEAVED PANELs FACADE DESIGN on the basis of solar and radiation analysis.