A Conversation on the Re-naturalisation of Plywood

Digital Fabrication | Fall 2021

MAEBB | Prachi Agrawal | Iletutu Awosika | Lillian Beauttah

The arguably over-processed nature of plywood, render it a cheap substitute to raw wood as a furniture building material. For this very reason, we set out in concept to ‘re-naturalize plywood’. The method we employed to achieve this, dubbed ‘green parametricism’, revolved around developing alternative ways for furniture to harken nature.

Why?

The average piece of furniture generates 47 kilograms of carbon dioxide equivalents, equal to burning 20 litres of petrol and therefore our first task was to develop a manner in which a piece of furniture would be able to offset its own carbon emissions by being built , in addition to serving a specific function, to bring forth plant life. Parametricism in our design was subsequently called upon to ‘emulate natural systems by employing fluidity and complexity’. Thus answers the ‘Why?’ in the ‘Why , What and Where’ triad of furniture design.

What and Where?

Our ‘Where’ was answered towards the end of our fabrication process.

”Intended Bench Location”

With the exception of perching oneself on the walls or on the stone blocks as shown above, the area to the right of the entrance courtyard of the Valldaura property, offers limited seating options and in general none that particularly encourage privacy.

‘ ‘Location optimal for privacy but lacks appropriate seating to encourage use.”

The bench we had begun developing, would definitely reach its full potential if placed in this location.

How?

The beauty of hands-on fabrication is that it allows one the opportunity to guide the little less experienced aspect of furniture design, the, ‘How?’

Step 1:

Curve development

Step 2:

Form development

Form development had to consider the limits of material availability. Having being provided with 3 pieces of 15mm thick plywood, totaling up to an area of 8.9m2, the dimensions of every piece had to be optimized to both meet the area requirements and also hit the appropriate ergonomic and comfort levels.

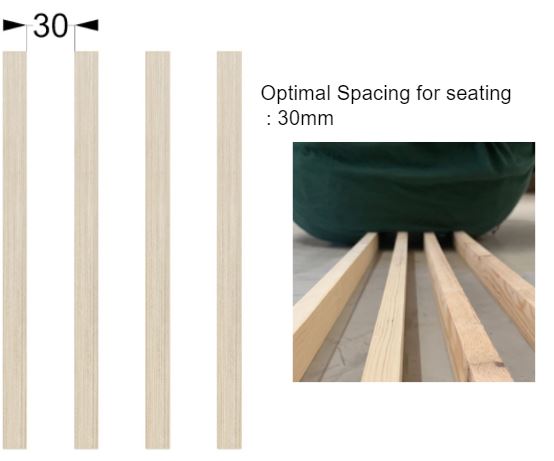

To do this we performed a quick study as to the most comfortable maximum spacing distance.

” Optimal Spacing Test”

The maximum spacing was determined as 30mm in between individual pieces. The rest of the benches dimensions were established as below .

”Bench Dimensions”

Step 3: Fabrication

3 hours of ‘CNC-ing’ later we had our 21 cut outs that were later coated in a UV and waterproofing sealant.

”Cut-Outs”

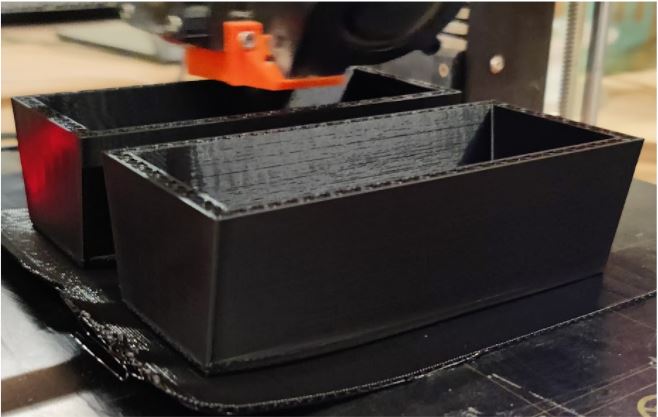

Planter boxes inserted into the bench were 3D -Printed out of black PLA (Polylactic Acid) filament.

”3D – Printed Planter Boxes”

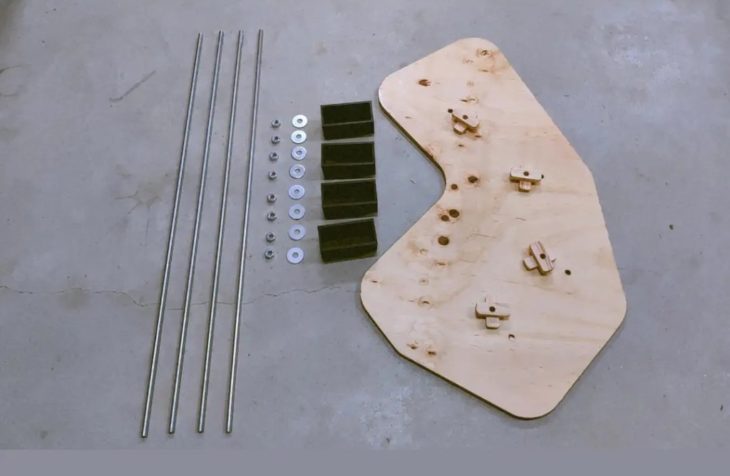

Spacers that went in-between the pieces of plywood were fabricated from waste wood, each 70mm long and 12.5mm thick. These were adhered together using wood glue in an X formation and drilled through forming 12.5mm dia holes that would allow threading using 12 mm dia , 1m long zinc alloy rods.

Step 4 : Assembly

”Bench Pieces”

What ?

Our hope is that the bench eventually does serve to elevate the use of the space, even further highlighting the magnificent views that Valldaura has to offer.

” Bench in Use”

”green parametricism”

Credits:

Models: Kshitij Sarote, Anton Hofstadt & Prachi Agrawal

” green parametricism” is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Ecological Buildings and Biocities in 2021/2022 by:

Students: Prachi Agrawal | Iletutu Awosika | Lillian Beauttah

Faculty: Bruno Ganem Coutinho