In this project, we aim to explore the possibilities of a scalable waste material to design workflow and how irregularities in waste material could be intelligently used as an advantage in the design process by using adaptive algorithmic workflows. We propose a system for planar wood reuse where each recovered wooden plank is scanned using an RGB camera and rated based on its visual defects and then graded by a pre-trained neural network. After generating an algorithm to use each piece of wood in the most efficient manner in our design, we use a Kuka irb150 to cut each piece with a circular saw at a precise angle and place it into optimized triangular units which are then assembled to create our desired design.

</p>

Wood Waste

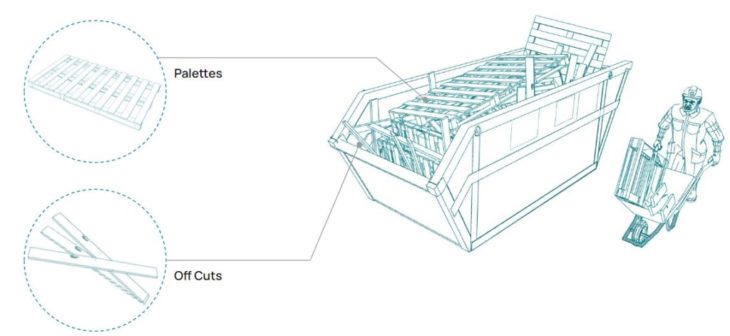

According to environment protection agency, wood forms 8.2% of the solid waste that ends up in landfills, which accounted to 12.2 Million tons in 2018. Of that wood waste, a vast majority comes from planarized wood, such as offcuts, packaging and pallet wood. This is material which has had a considerable amount of useful energy put into it in order to dry, clean and planarize it, which is then wasted as these offcuts are then discarded back into landfulls.

The major reason why wood waste is generated is because of the irregularities in its shape, properties and defects. Therefore a standard recycling plan can not be put in place to accomodate for this diversity of properties. Therefore there is a need to build robust systems which can accommodate irregularities in the workflow to add value to the waste.

State of the Art

We can see that the recycled wood is used in many ways from creating partitions to building shelters. But these are all one off projects which are labour intensive and difficult to scale.

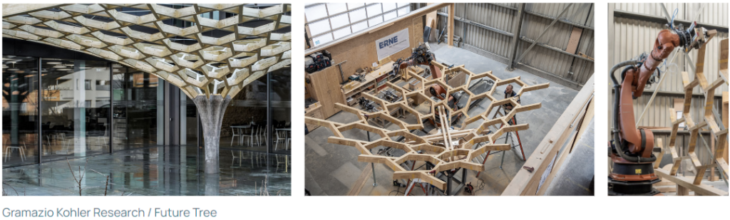

One similar project was ‘Future Tree’ from Gramazio Kohler Research, where they customise every cut to suit the desired geometry but the difference here is that they use engineered wood with defined and precise dimensions and properties.

We inferred the following:

- Existing recycled pallet wood projects are labour intensive, hence, difficult to scale.

- Current fabrication processes struggle to accommodate irregularities in material.

Value Proposition

Project Vision

The project vision is to source the material, scan it and classify the wood using machine learning. We incorporate robotic processes to help us scale and also customising for design and assembly.

Project Goals

We wanted to create a process that relied on simple ubiquitous tools backed up by intelligent software which could easily be deployed at a global level.

Material

We sourced material from different dumpsters from around barcelona and dissassembled them in order to obtain the individual flat planks.

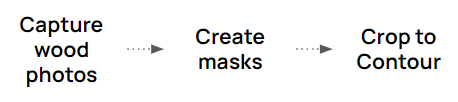

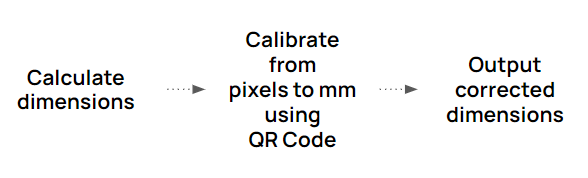

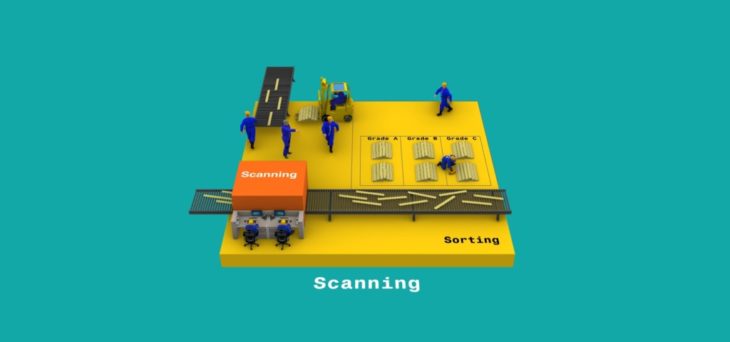

Scanning

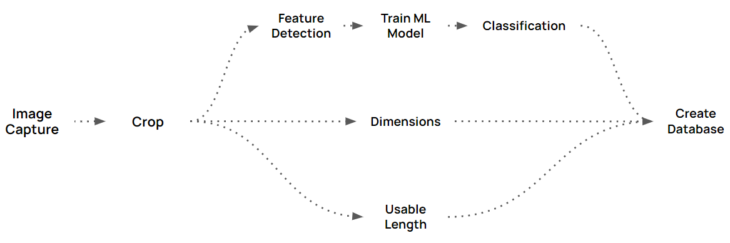

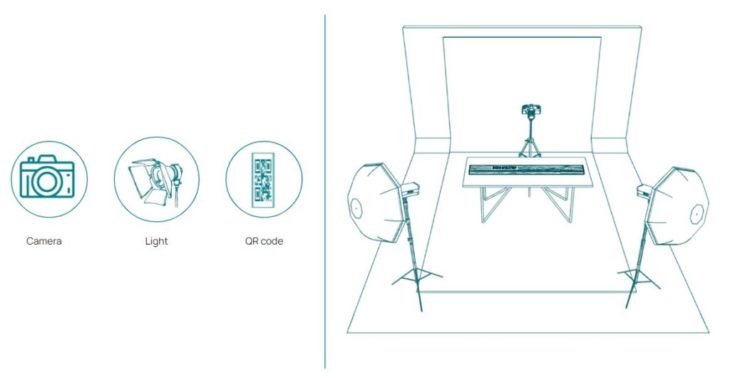

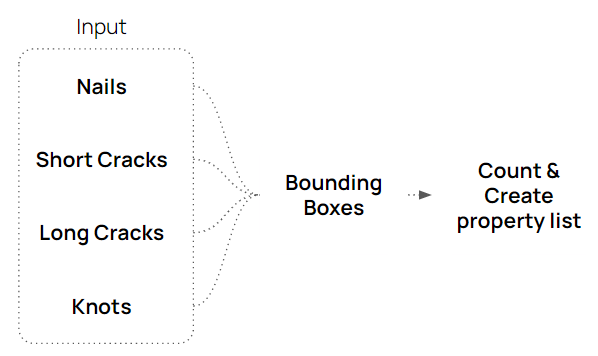

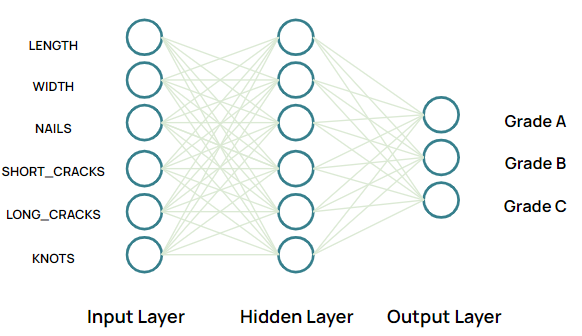

We propose a scanning setup using a simple RGB image taken with a camera and use computer vision algorithms to detect features and irregularities on the wood surface. These features are identified, counted and indexed and are fed into a simple neural network which is trained to identify each plank as Grade A, B or C determining it’s quality. In parralel from that image, we extract the plank dimensions and create a database of our wood which will then be used to guide our design.

Setup

Cropping

Dimensions

Feature Detection

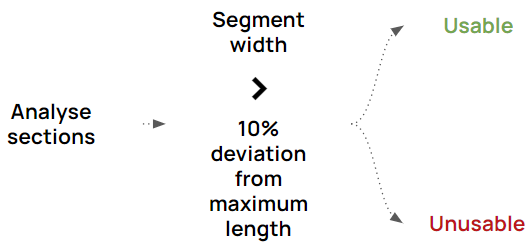

Usable Length

Classification

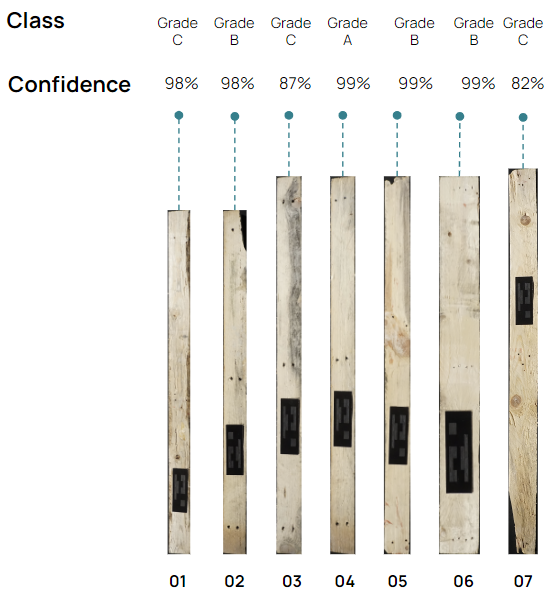

We then manually rated each of these planks as Grade A,B or C and trained a neural network on that data. After training it on a set of 100 planks, we then fed it 50 more planks for testing and were able to recognize whether each piece of wood should be used in our structure.

After testing our neural network on our planks, we grade them into 3 categories

- Training Set: 100 planks

- Testing Set: 50 planks

This process is still kind of incomplete as the quality of wood doesn’t depend solely on the visual factors, but also on moisture content, rotting, and several other factors which could be scanned with other apparatuses in the future.

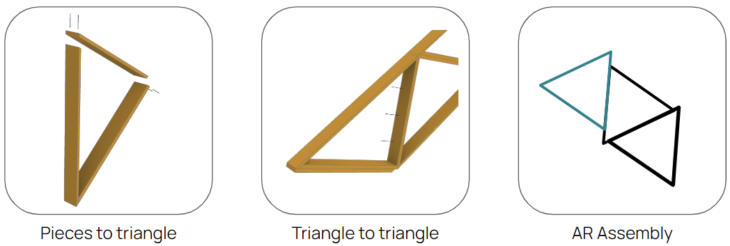

Triangles

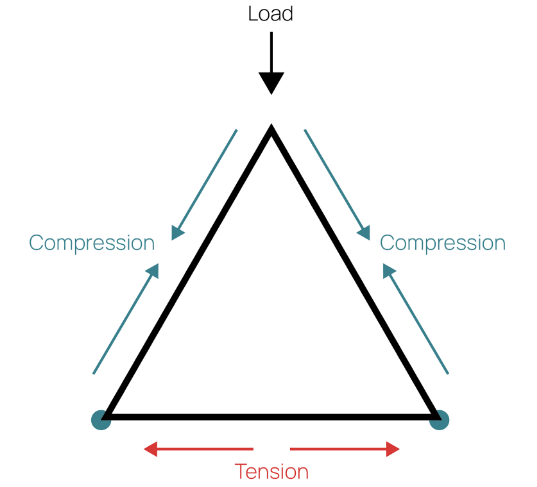

We wanted to arrange our wood database into repeatable and manufacturable units. We chose triangles for the following reasons:

1. Structural

- Triangles distribute loads efficiently throughout their members

- Traditionally used in structural or self-standing systems

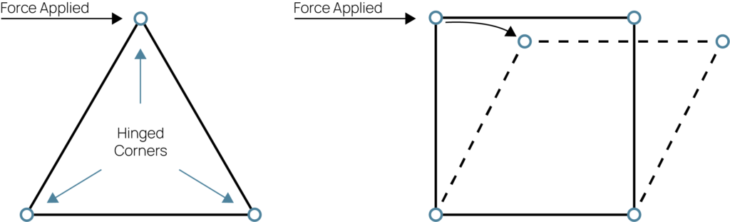

2. Deterministic

- Hinged corners mean no relative motion between any two pin-jointed links of a triangle

- Degree of Freedom = 0

3. Stackable

- Triangles can be easily stacked in any direction

- Most surfaces can be approximated as triangles (Meshing)

4. Flexible

- Triangles allow us to have an adaptive and reactive system which can accommodate the varied dimensions of each beam.

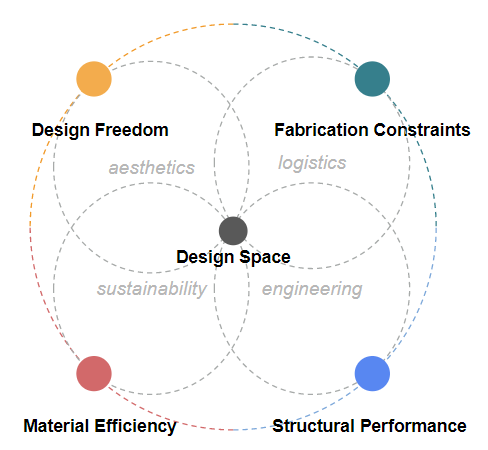

Case Study

We wanted to design an intelligent system which could satisfy design, fabrication, material and structural constraints. We wanted to balance our aesthetic instinct as designers with algorithmic and structural modelling in order to create an optimized system.

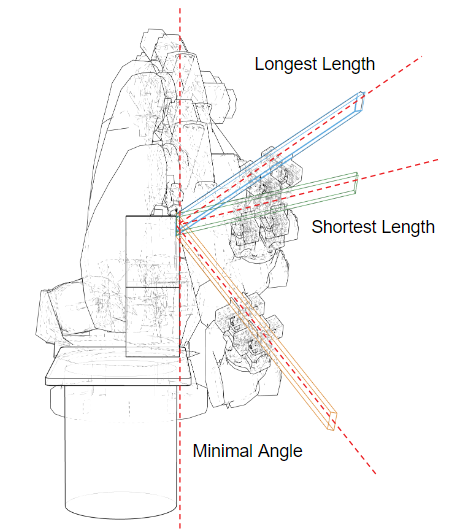

Fabrication Constraints

From our robotic setup including a pnuematic gripper to hold the wood planks, and a circular saw installed in front of the robot we extract our fabrication constraints which emerge after analysing the robot reach and collison objects

- Maximum Angle: 65°

- Shortest Length: 700mm

- Longest Length: 1400mm

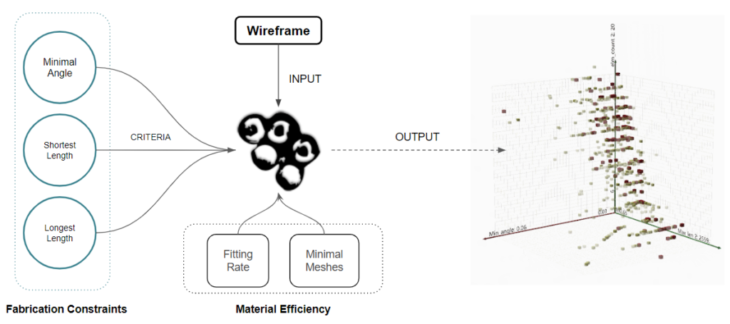

We then input these constraints into the octopus plugin in Grasshopper in order to obtain a design which we would be able to fabricate with our current setup.

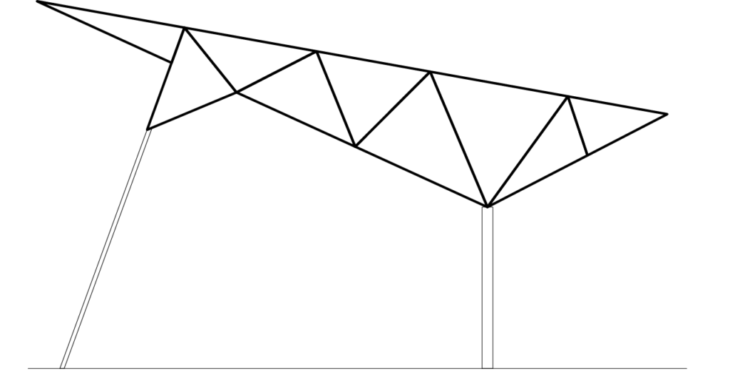

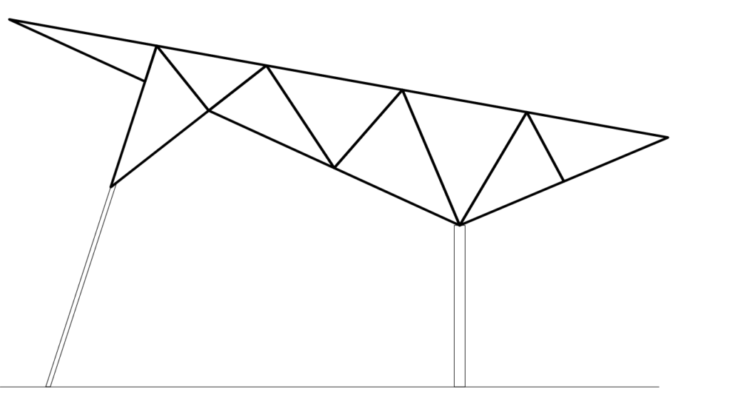

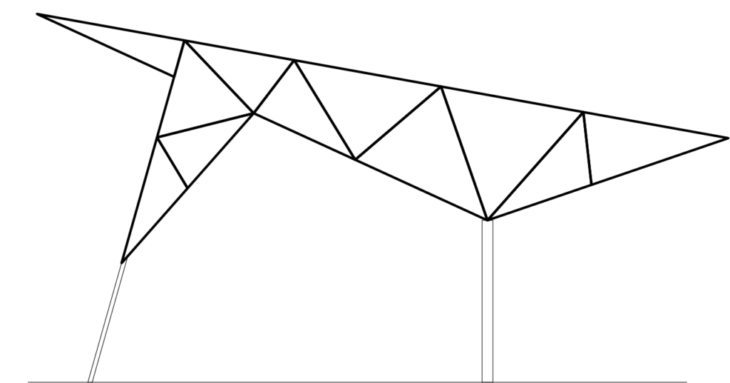

From the multi-objective generative algorithm we output several obtions that could satisfy our constraints. We then use our design intuition as designers to choose the trusees which satisfy our aesthetic judgment.

Structural Analysis

We use Karamba structural analysis to test the structural stability of our truss in order to validate our design.

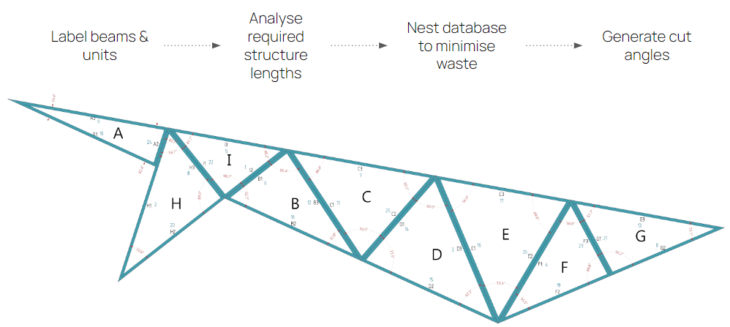

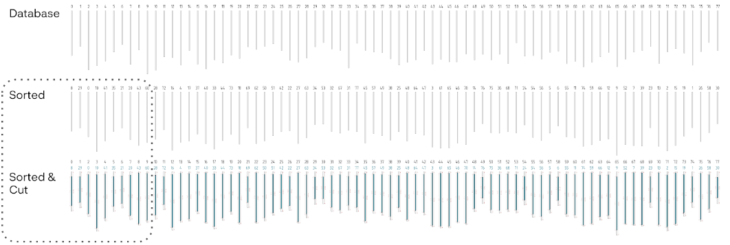

Wood Sorting

After we get our design, we analyse what structure lengths are needed and compare them against our database in order to minimise waste and use our wood in the most efficient way and generate the needed cutting angles.

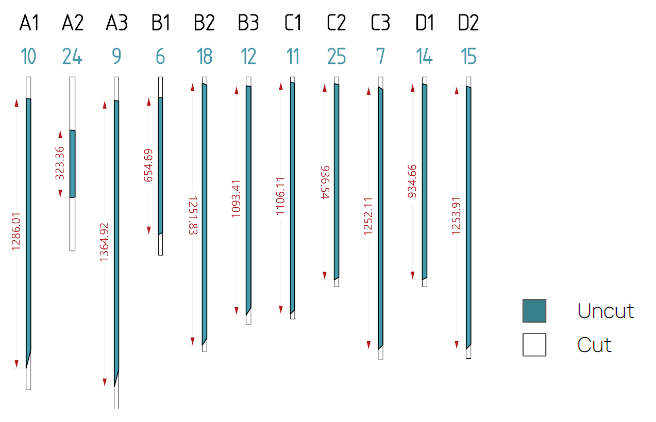

We sort and label each plank in order to prepare it for fabrication.

Zooming in we can observe the used area of each plank

The numbers:

- Usable planks: 97

- Max length: 1590mm

- Min Length: 798mm

- 86.3% recovered material

- 86 beams cut

- 26 triangle units built

- 3 trusses built

Prototype

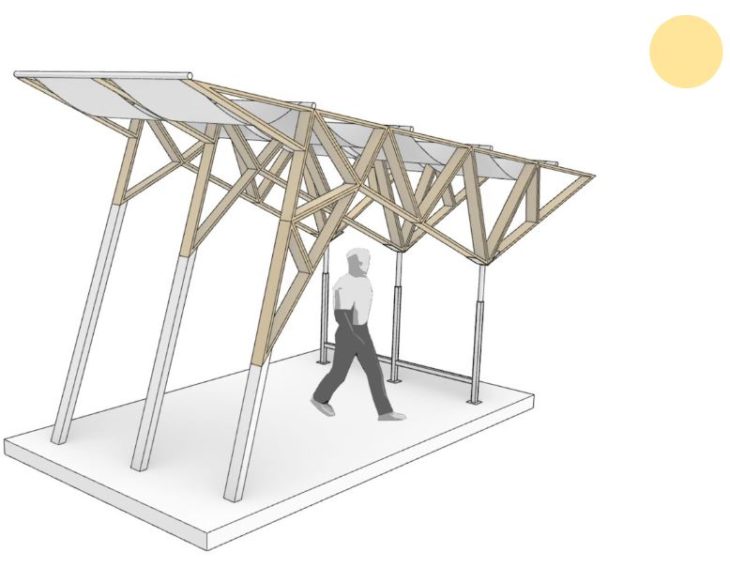

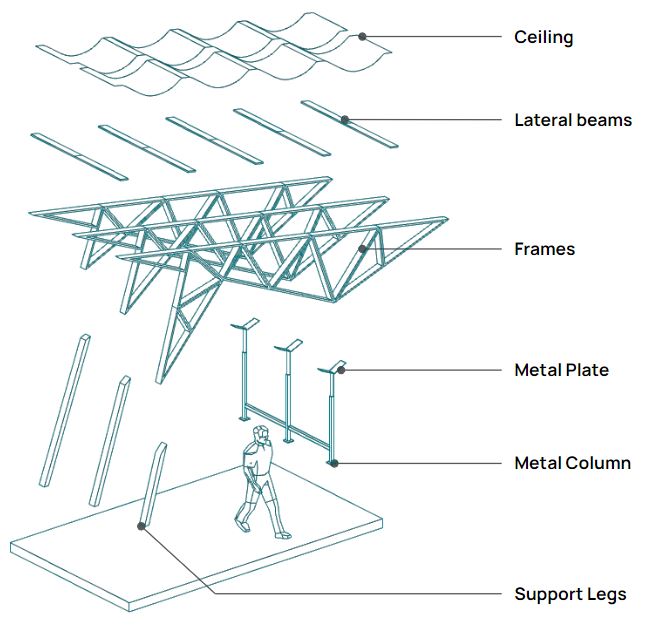

We set out to demonstrate our system by developing 3 trusses for a self-standing roof structure which could be used for small to medium-scale roofing or shading.

Exploded view

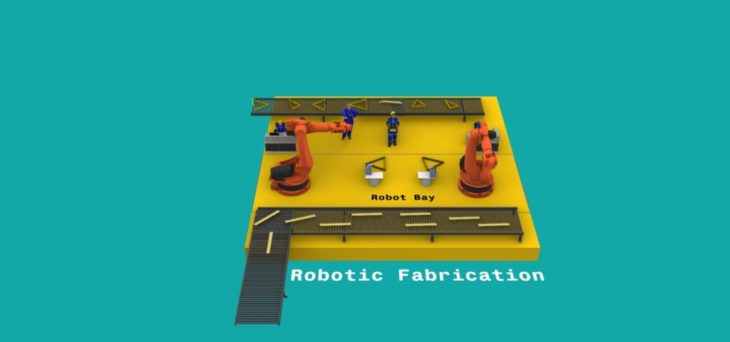

Robotic Fabrication

</p>

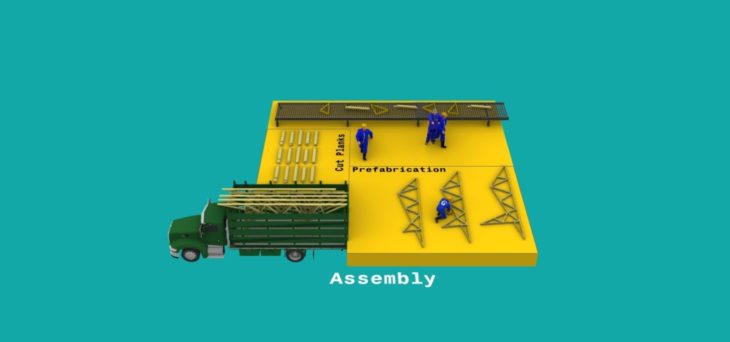

Assembly

Using the fologram plugin we develop an AR assisted assembly method to guide us with placing each labeled unit in it’s place.

Future Proposition

Microfactory

Decoded Disorder is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Masters in Robotics and Advanced Construction, in 2021/2022

by:

Students: Alfred Bowles, Huanyu Li, Shamanth Thenkan, Vincent Verster

Faculty: Alexandre Dubor, Marielena Papandreu

Assistant faculty: Cecilia De Marinis