Introduce: Mountain Dwellings

Mountain Dwellings is a residential compound that consists of ? Housing (80), and ? Parking (for residents of the building and the neighbouring residential compound).

The building is designed in cascading form of 11 floors (34 m height) and total area of 33,000 m².

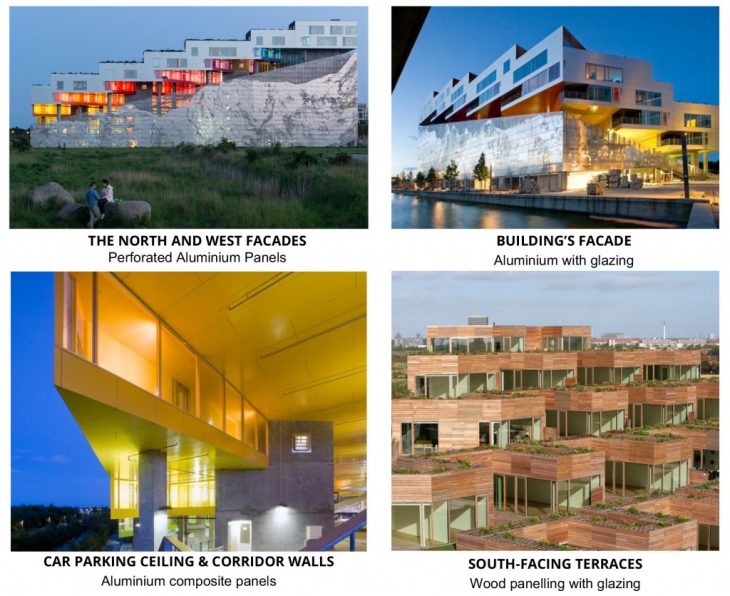

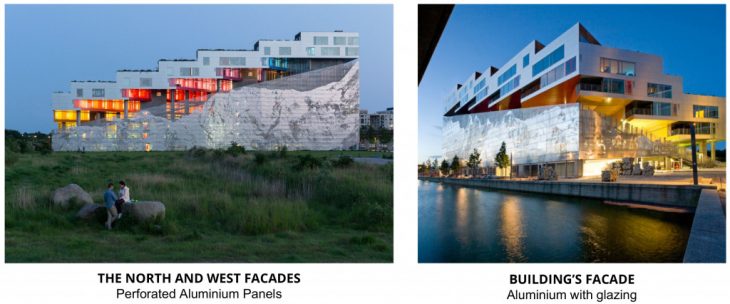

Photo of Mountain Dwellings

Case Study

Existing Elements

Material Table

Chosen Elements

Materials Research

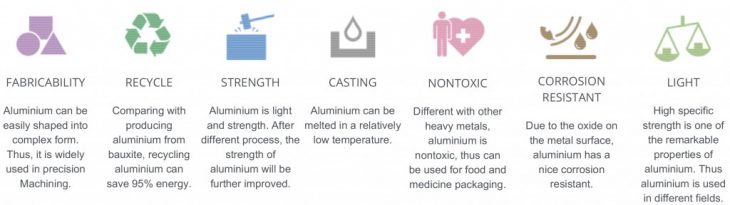

Aluminium is a circular material, capable of being recycled multiple times without losing its original properties. The energy needed to recycle aluminium is as low as 5% of primary production, there are obvious financial and ecological benefits.

Advantages and Properties of Aluminium

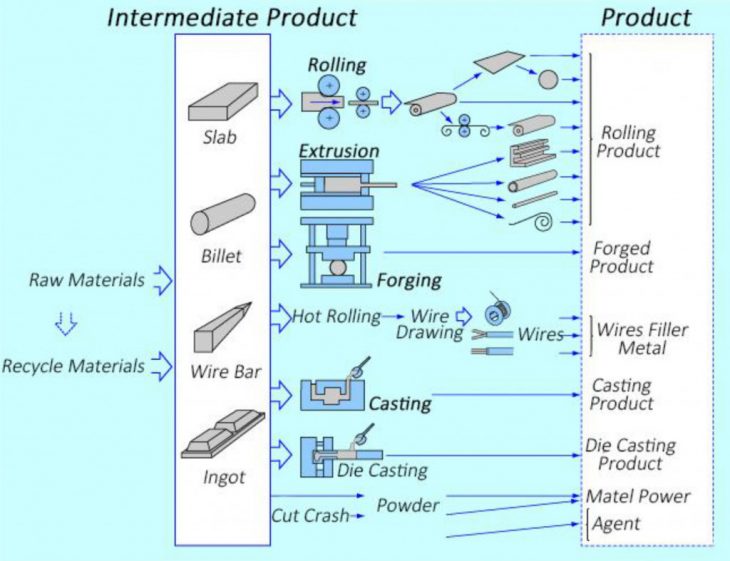

From raw materials and recycle materials, various aluminium products can be fabricated. There are four different main fabrication methods: rolling, extrusion, forging and casting. Different final products correspond to different fabrication methods.

Aluminium Fabrication Method

Element Research

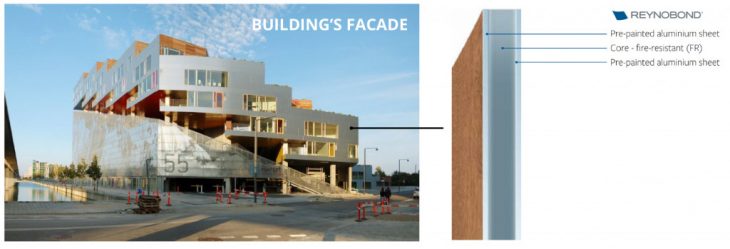

1. Composite Panels by Reynobond®

USE:

- Exterior cladding

FEATURES:

- 2 coilcoated aluminum sheets that are laminated to both sides of a fireresistant , extruded thermoplastic core.

- The threecoat finishes typically consisting of: 1. 0.2 mil primer; 2. 0.8 mil color coat; 3. 0.5 mil clear top coat.

- Reynobond® Composite Panels are only sold with fire resistance core.

Element Details

ASSEMBLY:

Design for Assembly

- Metal framing for panels

- Panel interlocked with the next panel

- Panel to frame joinery: Head fasteners with washer to metal plate

CRADLE 2 CRADLE CERTIFIED KINGSPAN PANLES?

Cradle

2. Perforated Aluminium Panels by Netto Perforering

USE:

- To control sunlight

- Air circulation

- Aesthetics

FEATURES:

- Covered in corrosion preventive oil

- PVC foil panels to reduce surface scratches

- Hotdip galvanized (post production)

The range of hues was matched with six different perforation sizes of the lasercutting machine, which then perforated the thin aluminium materials.

Element Details

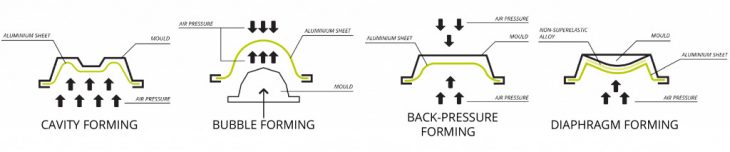

REFABRICATION TECHNOLOGY:

Superforming is a hot metal forming process where a sheet of material is heated and forced onto a male or female form using air pressure. The benefits include short lead times, low tooling costs, no springback in parts and good repeatability.

Fabrication Technology

- Cavity Forming: In the cavity method, air pressure forces the sheet up into the tool.

- Bubble Forming: Air pressure blows the sheet into a bubble. A mould is then pushed up into the bubble and air pressure is applied from the top, forcing the material to conform to the shape of the mould.

- Back-Pressure Forming: In back-pressure forming, pressure is employed from both the top and the bottom surface of the mould.

- Diaphragm Forming: Air pressure forces the heated superelastic aluminium onto a heated non-superelastic alloy which is then formed over the mould.

REUSE OF PERFORATED ALUMINIUM PANELS:

Perforated aluminium panels from the facade can be reused to make furniture.Furniture is public spaces are generally made out of perforated metal for hygiene purposes.Perforated Sheets can be used for the seating. Framework of the panels can be melted and used to create new framework for the furniture.

Reuse of Materials

Another possible reuse is to take the structural grid and the perforated aluminium panel to make a living green wall system like the one use in San Telmo Museum extension.

Reuse of Materials

CRADLE 2 CRADLE CERTIFIED LIVING WALL?

SemperGreenwall is a living green wall manufacturer that holds a Bronze Cradle 2 Cradle certification which can be integrated with the reused perforated aluminium panels and its structural grid, along with the other elements of SemperGreenwall’s living green wall.

Cradle

Mountain Dwellings // Design For The Circular Economy is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2020/21 by Students: Elena Petruzzi, Hairati Tupe, Jihad Al Ojaili & Liang Mayuqi, and Faculty: Ignasi Cubiñá, Ariane Lima, Sofía Battistino & María Colantoni