SOUND ABSORPTION PANEL // CNC MILLING

// BRIEF

The project aim of the CNC Milling was to understand the architectural acoustics of a space. The loud environment of the CNC room, due to the heavy machinery and power tools, requires an intervention which thoroughly understands the absorption, reflection and manipulation of sound through varying textures and designs. Each group was required to create a 300 x 300mm panel of various depths by using the properties of chosen materials in order to either absorb or reflect sound. Each group was given a total of 4 hours of production time in order to complete their panel.

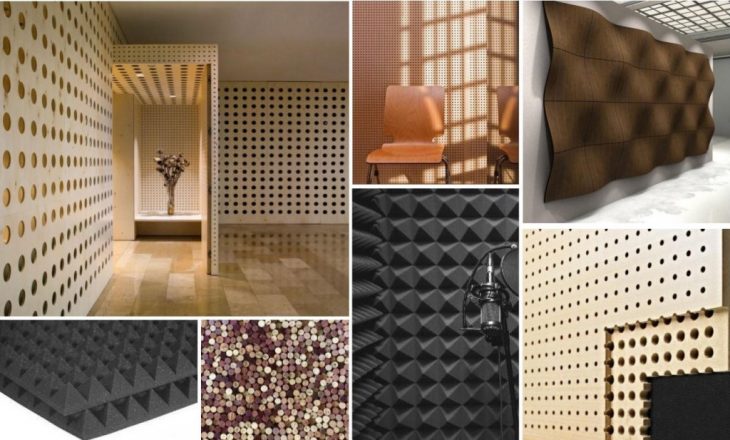

// REFERENCES

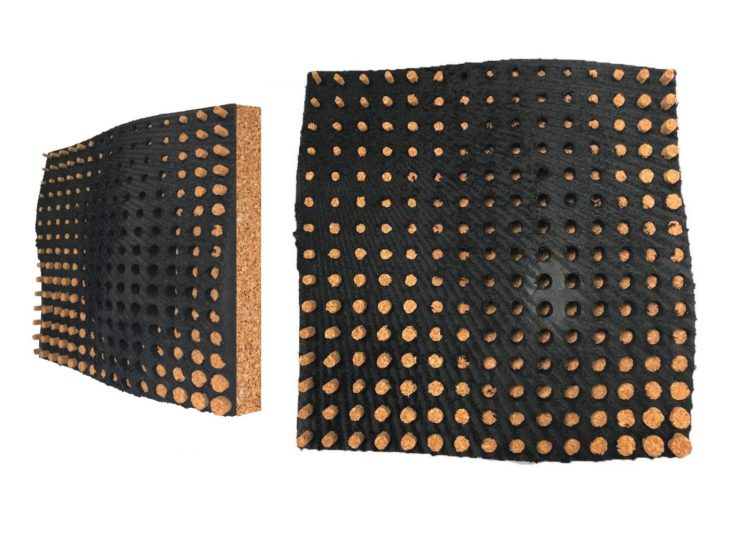

The material we were assigned for our panel was EVA foam. We decided to use cork with the EVA foam in order to get a contrast in the colour of the materials. Our main focus was to create a panel that would absorb the loud sounds of the CNC room. Our panel is positioned at the bottom of the first row of panels, close to the large CNC machine. We looked at various references with perforations and soft materials that would help to absorb the sound waves.

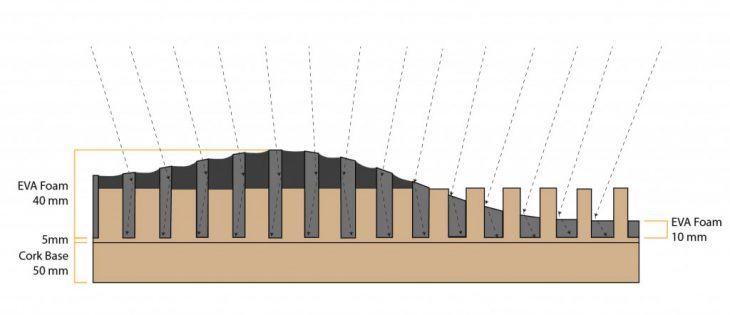

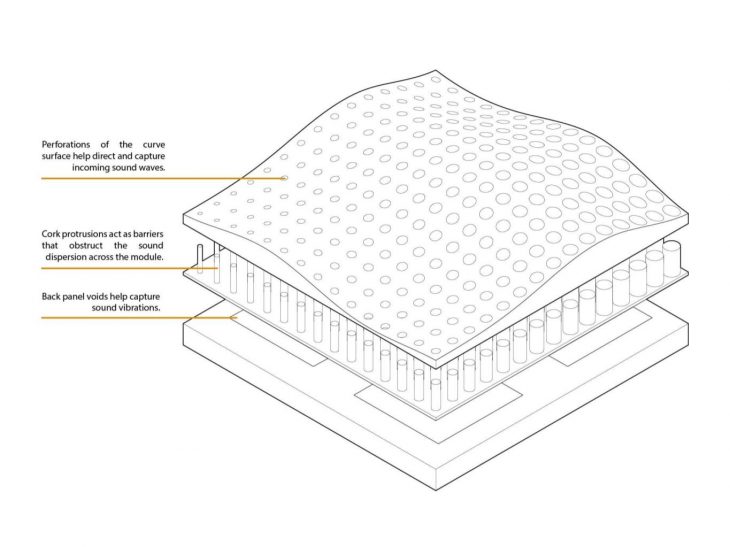

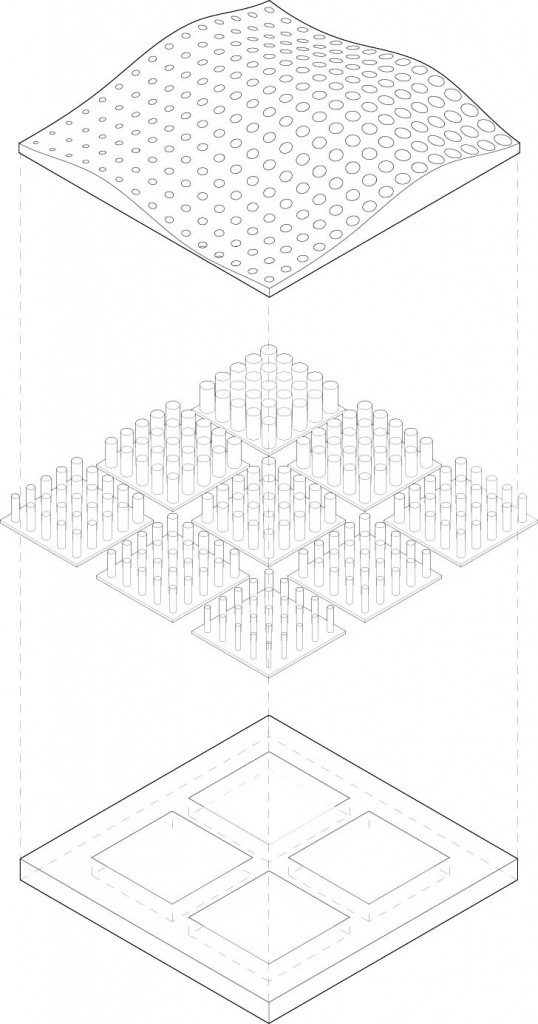

// CONCEPT

Our concept of the panel was to use the cork to create circular protrusions that varied in side but remained the same length. The protrusions would be cut on the CNC machine in 9 smaller sections, in order to make the assembly process easier. The EVA foam was then designed with identical holes in order to fit over the cork protrusions. The EVA foam was designed to be milled in a curved surface with a radial finish that would help capture incoming sound waves. The combination of the materials would show the cork protruding or intruding in certain parts to create a variation across panel. In order to create the required height of the panel, we mounted the milled surfaces onto a thick cork base.

// PROTOTYPE

Our prototyping included learning about the materials and how they would cut, trying to optimize the time and efficiency of the machine. We found that cork was very delicate and needed to be milled at a slow speed. We also looked at various shapes and sizes for the protrusions, and found that the circle was the best shape to mill at this size.

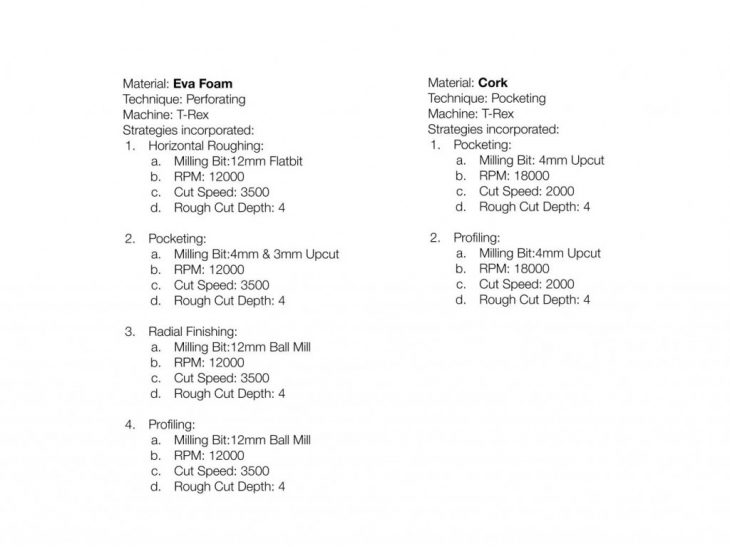

// PRODUCTION PROCESS

// FINAL PANEL

The final panel took a total of 5.5 hours to mill and an hour to assemble together.

// ARCHITECTURAL APPLICATION

Digital Fabrication II // Sound Absorption Panel is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Master in Advanced Architecture in 2019/2020 by:

Students: Jorge Mauricio Casian, Chim Meng Lim, Ilaena Mariam Napier & Zackary Bryson

Faculty: Lana Awad, Ricardo Mayor, Sujal Kodamadanchirayil

Assistants: Alaa Al Baroudi & Sara Rosenberg