Concept

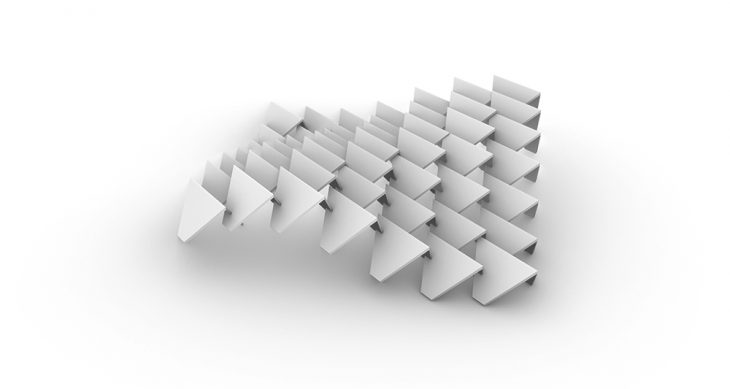

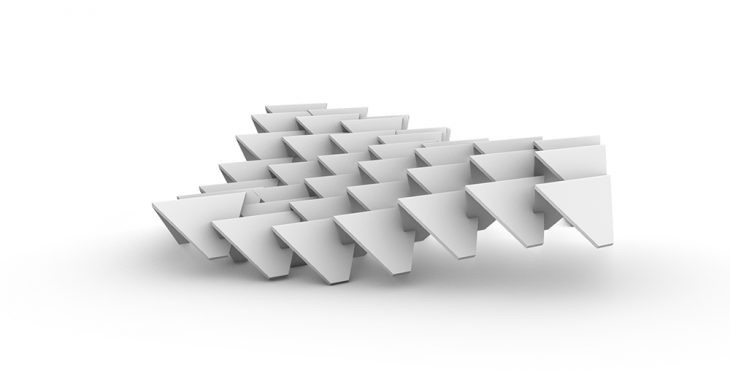

Interlocking shells were the technique of our choice in the interpretation of our two-direction curving surface. We really appreciated the system of interlocking modules because of its simplicity. Firstly, because the module is repetitive and the intersections become the unique feature. Secondly, because the form is performative as well as aesthetic. The design of our module started with the simple folding gesture of a square panel. We proceeded by testing how this would translated in the greater scheme.

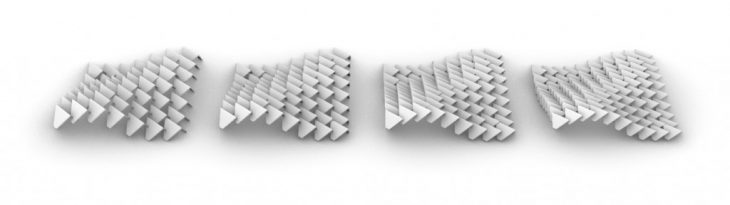

We explored different grid divisions and consequently different module sizes. Each alternative has implications on the sizes of the module, the scale of the panels and their joinery.

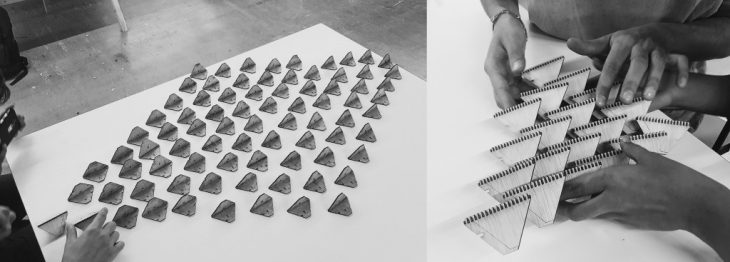

Prototypes

In parallel, we built prototypes to understand the strength of the plywood, the scale of the joinery and the required material tolerances in the design. We shifted from our initial thickness of 5mm and large-scale hexagonal joinery to a 3mm board and a minimal joinery detail.

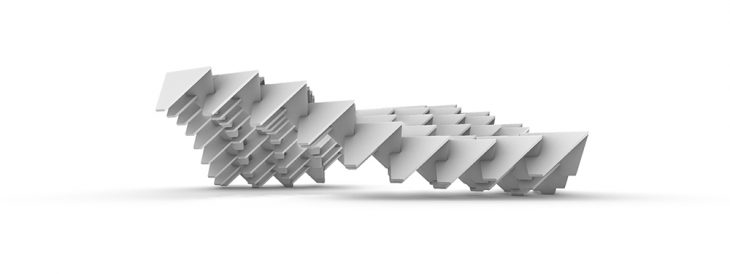

We refined the design of the module to take into account potential collisions with neighboring modules as the modules lift off the ground. The angle between the wings of the module was modified to 90 degrees to improve the fitting of the modules into each other and work with the perpendicular cutting nature of the laser-cutter. The grid was finally changed from a 7 x 7 grid to a 9 x 9 grid for a higher resolution translation of the surface.

Final panel

The final design was built within 2.5 hours and fitted with an interlocking detail into the frame at two points. The panel weighed around 1.09kg was made of a total 81 modules made from a single 60x80cm plywood board. The flock is currently mid-flight at the IAAC Atelier 59.

Digital Fabrication II – The Flock is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Master in Advanced Architecture in 2019 by:

Students: Rani Kamel, Deepika Raghu, Andrea de Stasio, Daniel Nahmias

Faculty: Lana Awad, Ricardo Mayor, Sujal Kodamadanchirayil

Assistants: Alaa Al Baroudi