Introduction

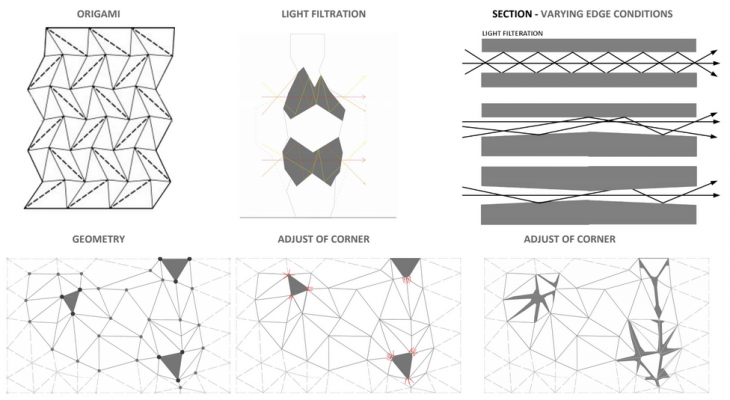

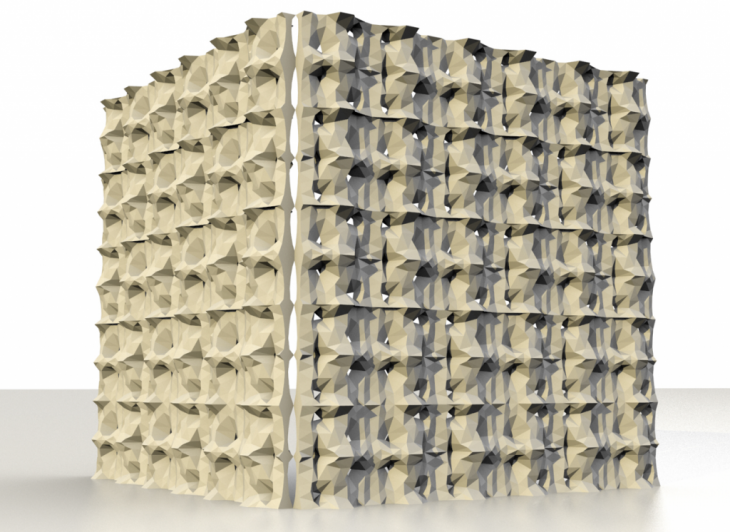

The design for this prismatic shaped brick was inspired by origami. The faces of the bricks have a multi-faceted triangulated geometry which allows the light falling on it to reflect in a dynamic way.

A triangular grid was first formed on the surface to divide it in multiple triangles. These triangular faces were then distorted to give the brick a 3D prismatic pattern. Then the holes in the brick were introduced to let the light pass after much diffusion and diffraction.

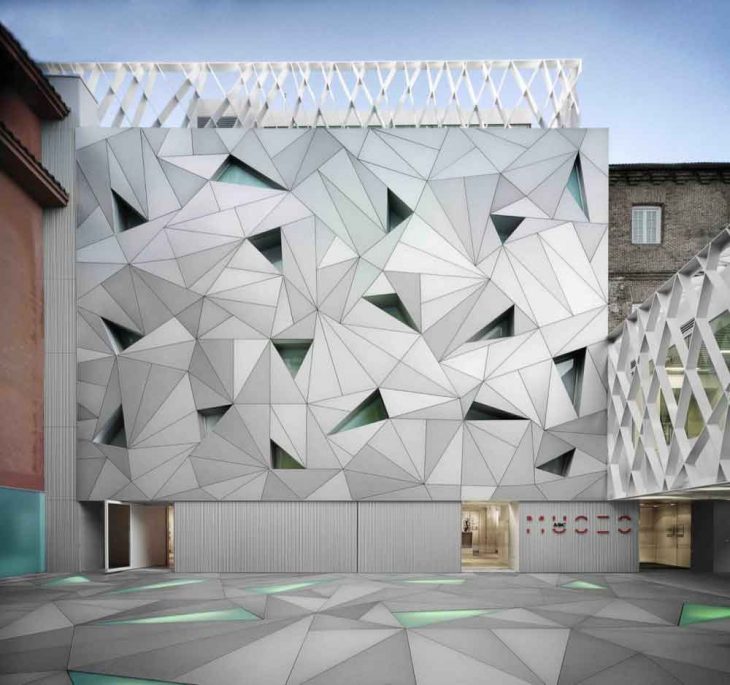

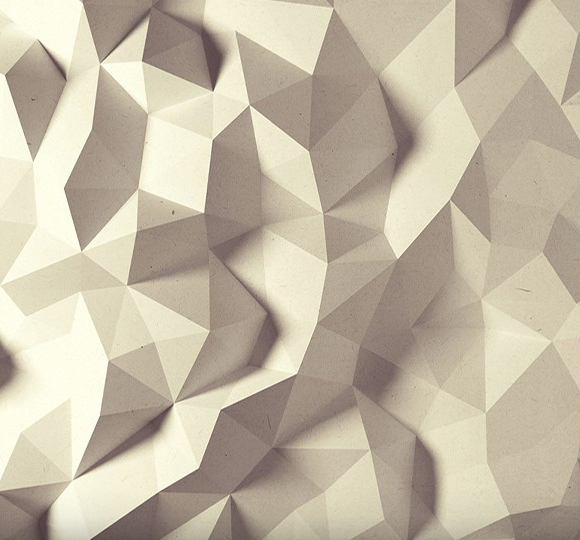

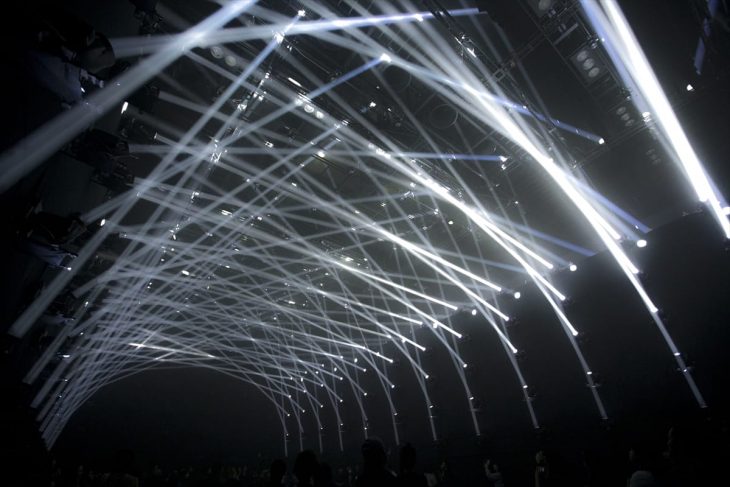

The reference images below depict the initial designs formed.

ABC Museum, Illustration and Design Center; Designed by: Aranguren & Gallegos Architects; Image Source: ArchDaily.com

Wooden Background on Vinyl Cloth; Image source: Aliexpress.com

Light Cave @ Music Festival, tem Lab Jungle :

http://musicfes.team-lab.net/osk2016/en/highlight/highlight06.html

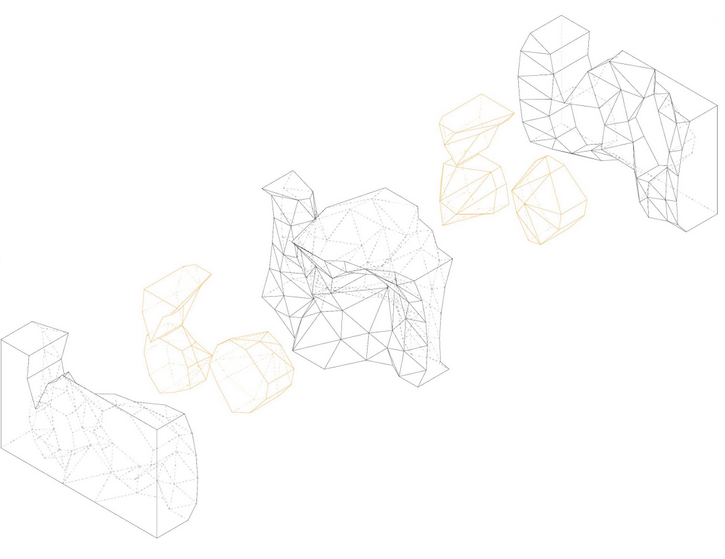

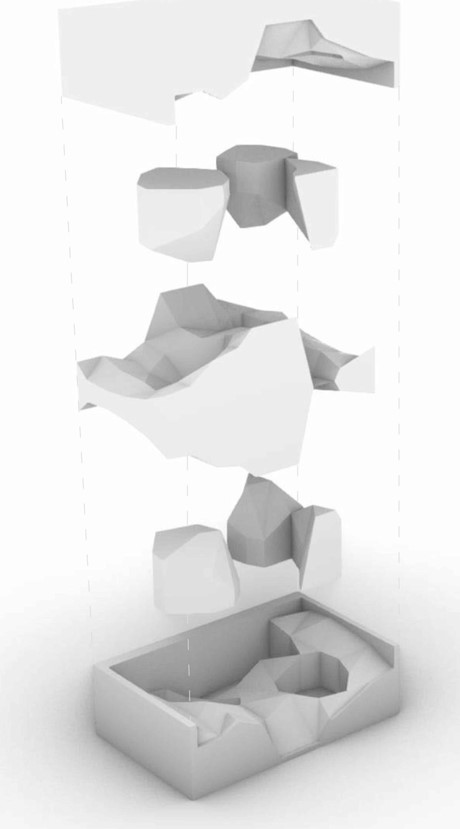

Diagrams

The diagrams below explain the development of the design from the initial concept to the final geometry.

Various factors influenced the final design of the bricks, such as the limitations/ abilities of the machines, nature of the plaster used & de-moulding process.

Production Data

Moulding Process

PARAMETERS:

Volume Percentage –

Solid – 40%

Void – 60%

MATERIALS USED:

Mould – 80MM Polyurethane Foam

Plaster – Exoduro 60%, Water 40% (+/- 3%)

Releasing Agent – Vaseline (3 coats)

TIME DATA:

Milling Time – 1hr 30min

Milling Tool bit : Horizontal Roughing – 12mm Ball Mill, Parallel Finishing – 6mm Ball Mill, Profiling- 6mm Ball Mill

Mould Preparation – 40mins

Plaster Preparation – 10mins

Casting Time – 30 mins

RESULT:

Moulds intact and brick is

casted fully.

Process Images

Moulding & Unmoulding

Fabrication of the Moulds

Casting

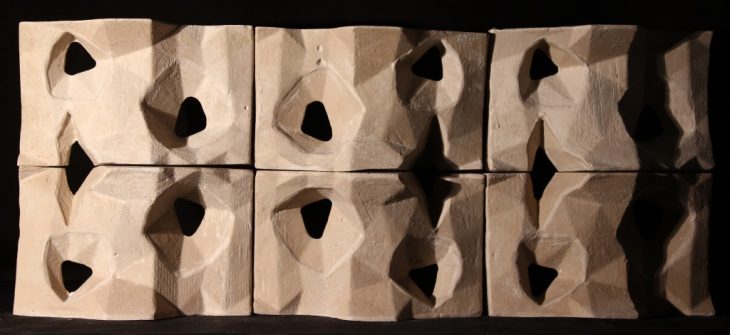

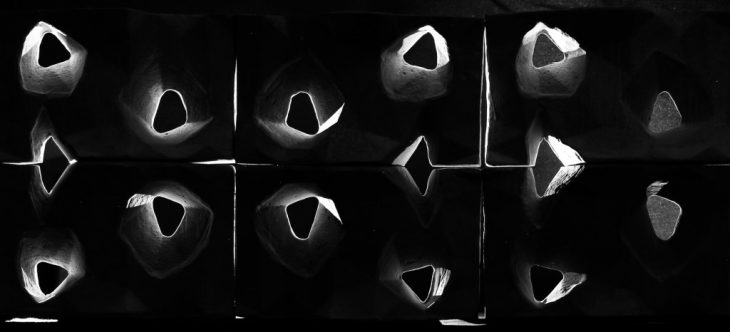

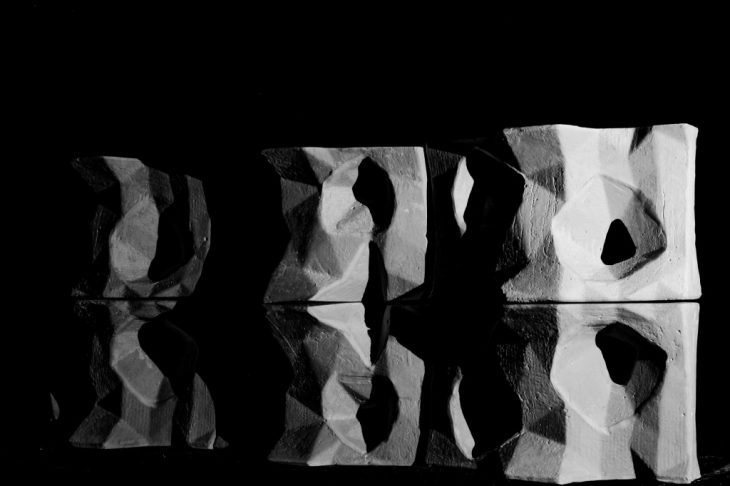

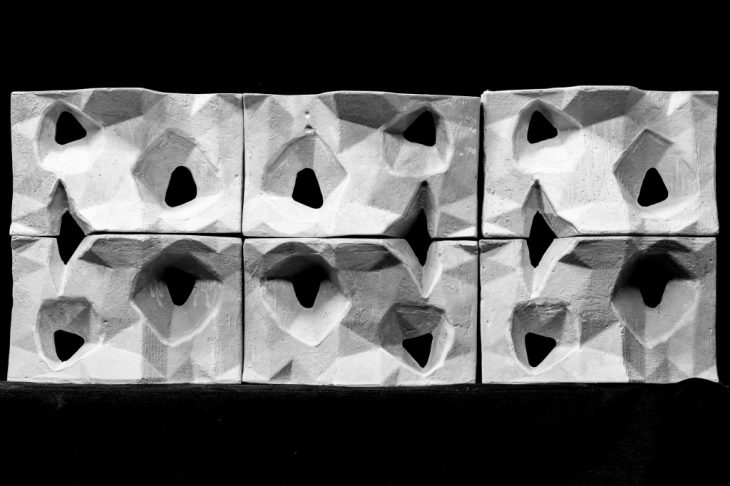

Final Photographs

Wall Render

Light Filtration and Shadow Study.

“Digital Fabrication- Team 11- Light Filtration 40%” is a project of IAAC, Institute of Advanced Architecture of Catalonia, developed as part of the Digital Fabrication course at the Master in Advanced Architecture program in 2018/19.

Student: Manan Jain, Pratik Borse, Sara Kelliane Alves Da Costa, Karisma Bhagnani

Tutors: Alexandre Dubor, Ricardo Valbuena

Support: Ricardo Mayor, Lana Awad, Sujal Kotamadanchirayil