PROJECT BRIEF:

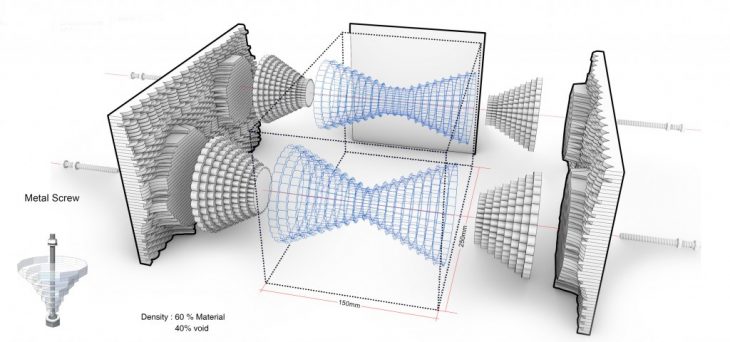

The aim of this project was to deepen the understanding and explore the capabilities and limitations of the laser cutting process. Our team was tasked with developing six modular elements that were to be cast, stacked and assembled at the scale of a 1:1 wall. The density of our bricks (solid to void ratio) were to be 60-40% and hence the concept to be privacy.

REFERENCES

“Night Garden” by Rael San Fratello Architects

Plaster-Cast from-Laser-Cut-Mold

South Asian Human Rights Documentation Centre (SAHRDC), New Delhi, India

CONCEPT:

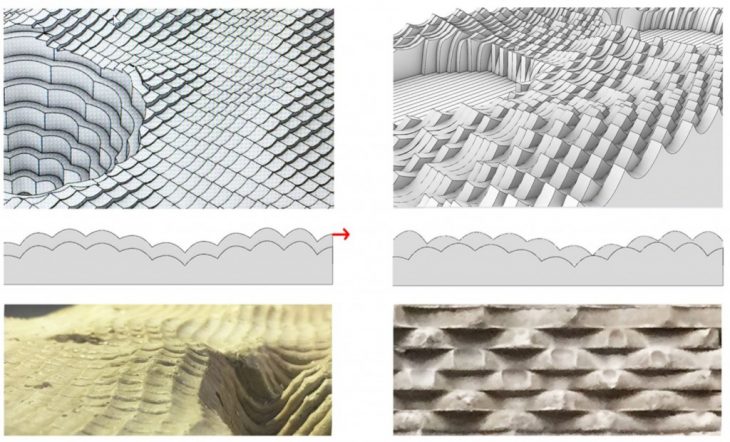

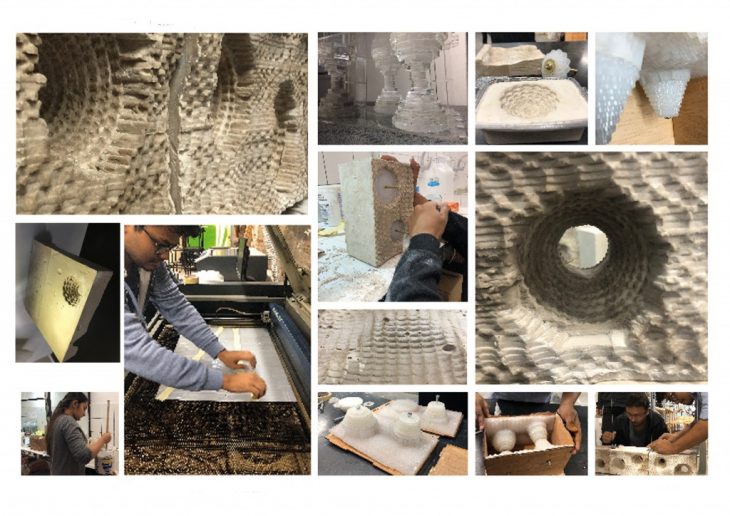

The idea was to create an interesting intricate micro-texture on the brick surface with the holes as interest points, also carrying the texture into them. The texture for the holes was created my vertically stacking similarly shaped staggered pieces of gradually reducing scale. This texture makes for an interesting visual path for the viewer looking through the holes.

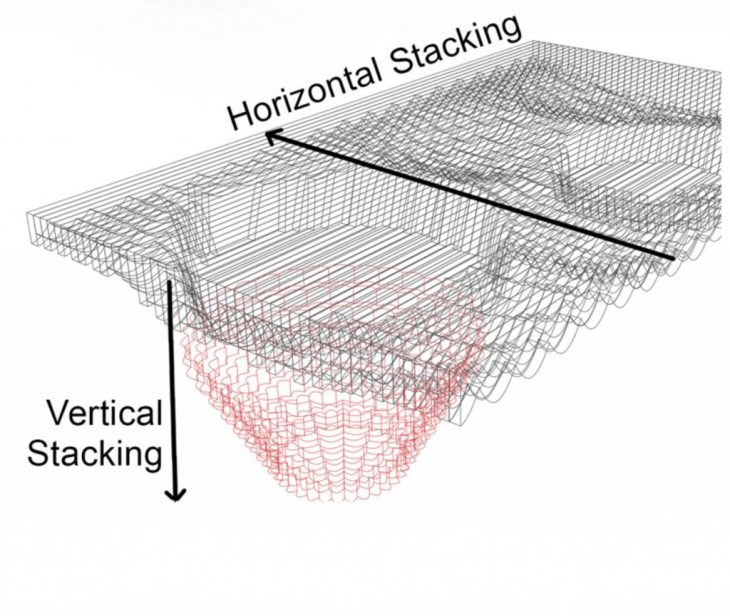

COMBINING HORIZONTAL AND VERTICAL STACKING:

The surface texture is created by horizontal stacking of laser cut pieces in a wave like, dulating pattern, while the texture of the holes is created by vertical stacking of laser cut pieces.

ASSEMBLING THE MOLD:

First the horizontal pieces are stacked to create the surface texture

The vertical pieces of the pendant are stacked and screwed onto the flat points on the horizontally stacked surface

DISASSEMBLING THE MOLD:

The horizontally stacked pieces are first removed

The vertically stacked pendants are removed by applying force from each side which pushes out the stacked pieces on the opposite face

PRODUCTION DETAILS:

MATERIALS FOR MOLD:

![]() Acrylic sheets x 3 (600mm x 500 mm, 3mm thick)

Acrylic sheets x 3 (600mm x 500 mm, 3mm thick) ![]() Plywood x 1

Plywood x 1 ![]() Screws/Bolts x 4

Screws/Bolts x 4

LASER CUTTER PARAMETERS:

Speed: 10 Power:100 Frequency: 5000

FOR CASTING:

![]() EXODURO: 4.5kg Ratio of Exaduro to Water 70:30

EXODURO: 4.5kg Ratio of Exaduro to Water 70:30

![]() Water: 300ml per kg

Water: 300ml per kg

PRODUCTION TIME:

Per Brick: 370 mins

To laser cut To prepare mix To pour/cast To pour/cast To unmold TOTAL/brick 6 bricks

20 mins 20 mins 30 mins 240 mins 60 mins 370 mins 2220 mins

PHOTOGRAPH OF THE PROCESS:

Neel Prajapati | Gayathry Mohan | Jitendra Farkade | Ricardo Lichtle