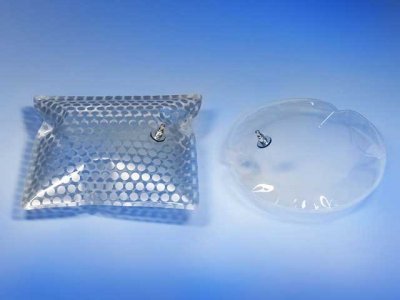

source: grimshaw architects, eden project, England ETFE foil is fast becoming one of the most exciting materials in today´s design industry and has set the construction world alight with the potential it offers. Originally invented by DuPont as an insulation material for the aeronautics industry, ETFE was not initially considered as a mainstream building material. Its principal use was as an upgrade for the polythene sheet commonly used for greenhouse polytunnels. The advantages of its extraordinary tear resistance, long life, and transparency to ultraviolet light offset the higher initial costs, and over 20 years later, it is still working well. The Eden Project in the UK and the Beijing Olympic Aquatics Centre has brought the material into public discussion. ETFE is increasingly being specified on a wide range of new projects, from schools and offices, to government buildings and sports facilities. ETFE is under the spotlight and intends to shine. ETFE foil is essentially a plastic polymer related to Teflon and is created by taking the polymer resin and extruding it into a thin film. It is largely used as a replacement for glazing, due to its high light transmission properties. Transparent windows are created either by inflating to or more layers of foil to form cushions or tensioning into a single-skin membrane. Weighing approximately 1% the weight of glass, simple-ply ETFE membranes and ETFE cushions are both extremely light-weight. This enables a reduction of structural framework and imposes significantly less dead load on the supporting structure. Another major benefit of ETFE is its high translucency. Transmitting up to 95% of light, it is easy to see why it was chosen to construct Eden Project. When high levels of light and UV transmission are not required, ETFE also has the ability to be printed or fritted with a range of patterns. This fritting can be used to reduce solar gain while retaining transparency or it can incorporate a white body tint to render the foil translucent. ETFE cushions can be lit internally with LED lightning to make them glow or may be projected onto externally like a giant cinema screen, creating dramatic results. Unaffected by UV light, atmospheric pollution and other forms of environmental weathering, ETFE foil is an extremely durable material. While no ETFE structure has been in place for longer than 25 years, extensive laboratory and field research have suggested that the material has a lifespan in excess of 40 years. The benefits of this material are extensive and have yet to be put to use in many areas.

source: grimshaw architects, eden project, England ETFE foil is fast becoming one of the most exciting materials in today´s design industry and has set the construction world alight with the potential it offers. Originally invented by DuPont as an insulation material for the aeronautics industry, ETFE was not initially considered as a mainstream building material. Its principal use was as an upgrade for the polythene sheet commonly used for greenhouse polytunnels. The advantages of its extraordinary tear resistance, long life, and transparency to ultraviolet light offset the higher initial costs, and over 20 years later, it is still working well. The Eden Project in the UK and the Beijing Olympic Aquatics Centre has brought the material into public discussion. ETFE is increasingly being specified on a wide range of new projects, from schools and offices, to government buildings and sports facilities. ETFE is under the spotlight and intends to shine. ETFE foil is essentially a plastic polymer related to Teflon and is created by taking the polymer resin and extruding it into a thin film. It is largely used as a replacement for glazing, due to its high light transmission properties. Transparent windows are created either by inflating to or more layers of foil to form cushions or tensioning into a single-skin membrane. Weighing approximately 1% the weight of glass, simple-ply ETFE membranes and ETFE cushions are both extremely light-weight. This enables a reduction of structural framework and imposes significantly less dead load on the supporting structure. Another major benefit of ETFE is its high translucency. Transmitting up to 95% of light, it is easy to see why it was chosen to construct Eden Project. When high levels of light and UV transmission are not required, ETFE also has the ability to be printed or fritted with a range of patterns. This fritting can be used to reduce solar gain while retaining transparency or it can incorporate a white body tint to render the foil translucent. ETFE cushions can be lit internally with LED lightning to make them glow or may be projected onto externally like a giant cinema screen, creating dramatic results. Unaffected by UV light, atmospheric pollution and other forms of environmental weathering, ETFE foil is an extremely durable material. While no ETFE structure has been in place for longer than 25 years, extensive laboratory and field research have suggested that the material has a lifespan in excess of 40 years. The benefits of this material are extensive and have yet to be put to use in many areas.  Bibliography: WILSON Amy, 2009, ETFE: The new Fabric Roof

Bibliography: WILSON Amy, 2009, ETFE: The new Fabric Roof