Hong Kong

Waste as Resource

Exploring Dimension of Time, Over Space

To start to understand the concept of “place making” we

had to ask ourselves these four fundamental questions.

WHERE? WHY? WHAT? HOW?

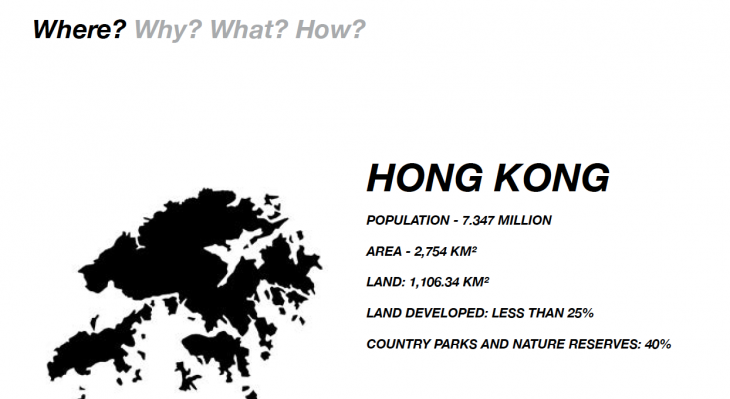

First we had to understand that not all urban fabrics are made the same.

And with Hong Kong, we had a lot to learn from the complexities of it’s urban jungle.

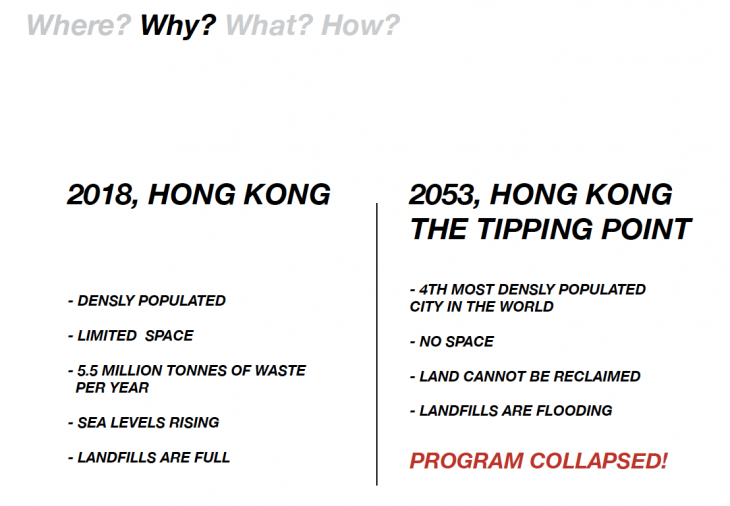

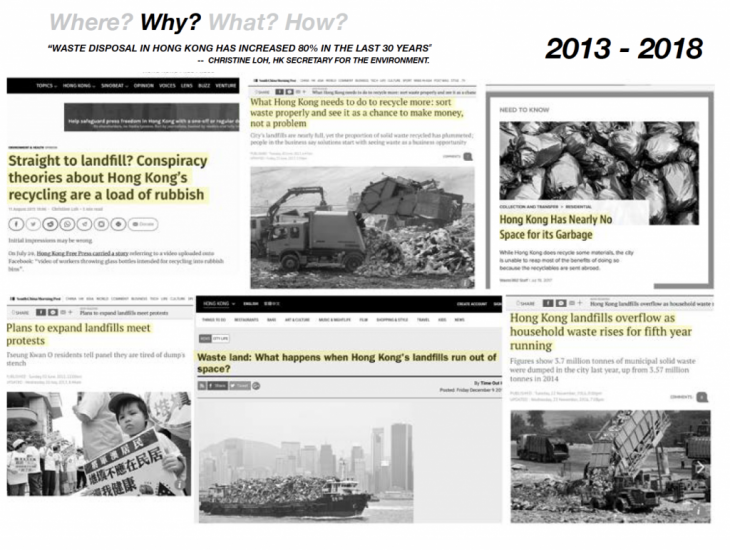

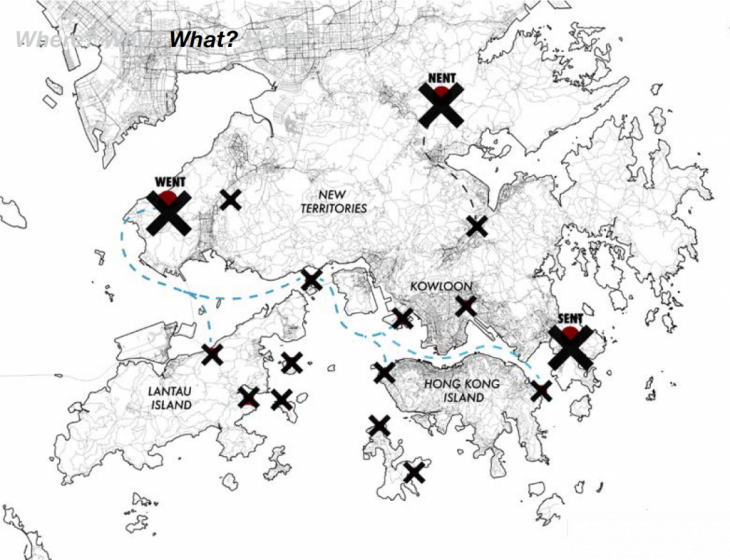

We researched into the problems that Hong Kong manages within it’s infrastructure.

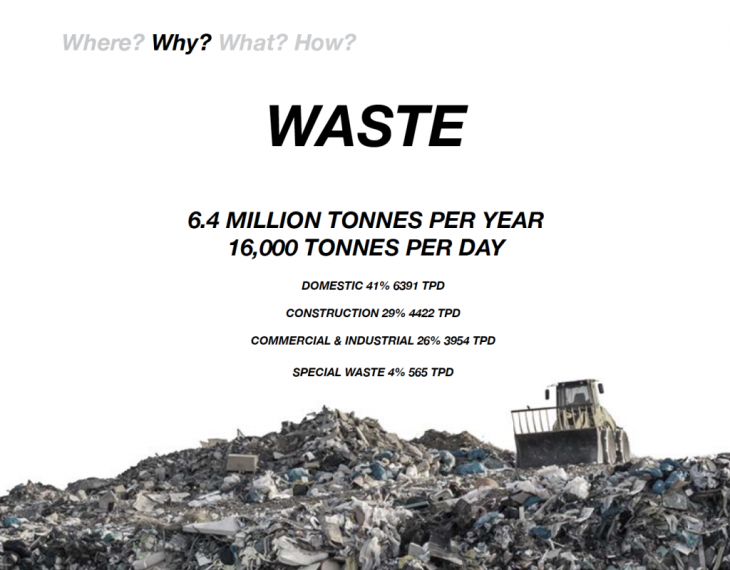

And we discovered that they have a huge waste management problem.

Each person produces 1.49 kg of waste, PER DAY.

Now, multiply that by 7.3 million people

The result:

6.4 million tonnes per year

These facts and figures easily captured our interest and quickly lead us

into a deep journey of investigation and design.

And to explore above all, the relationship between this complex waste system

and how it affects the infrastructure that hosts it.

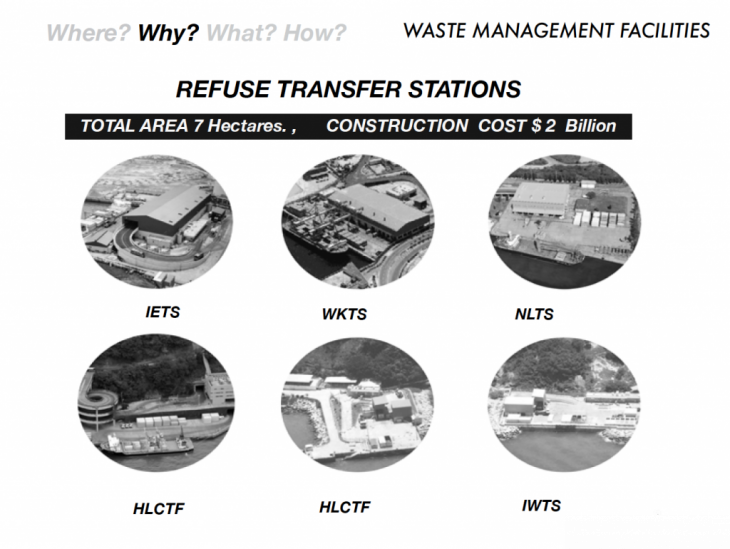

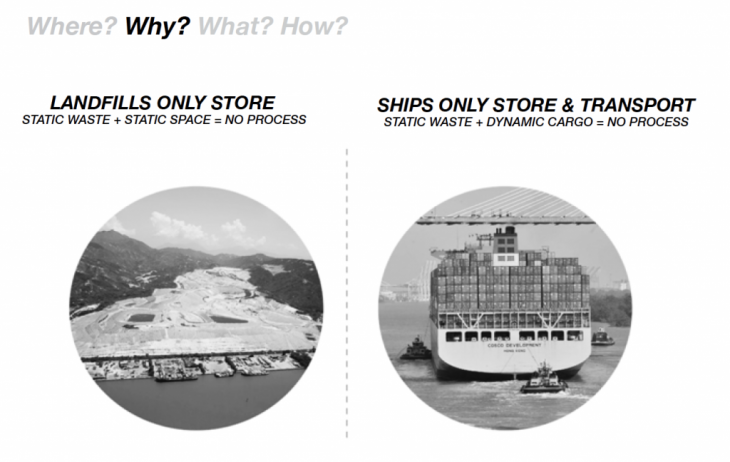

The main purpose of an RST (refuse transfer station) is to compact

the waste for easier transportation, in the case of the RST being on the

shore line, it is transported via cargo ship.

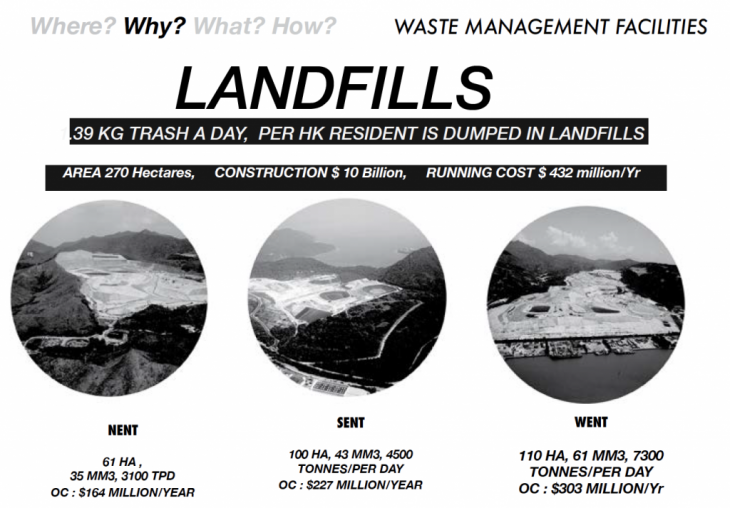

The main purpose of the landfill is to safely dispose of all

of the non-recyclable waste within a man made void in the ground.

They’re usually on the outsides of the city because of the smell

and possible toxicity it could give to the ground and water table.

In the case of Hong Kong, 98% percent of their waste is recycled abroad,

that means that the small percentage that the city recycles

is not even being done properly because it still goes to the landfill.

When we looked into the waste management cycle we realized there

were many “cracks” in the system. The main one being that the waste is

supposedly separated in categories for easier disposal. Instead of this, all

the waste is sent together to the landfills thus making the waste lose

it’s value – because as it is unique in it’s material it is also

unique in the way it’s processed

Leading us to the conclusion that we must not see the

waste as a whole but as categorized entity.

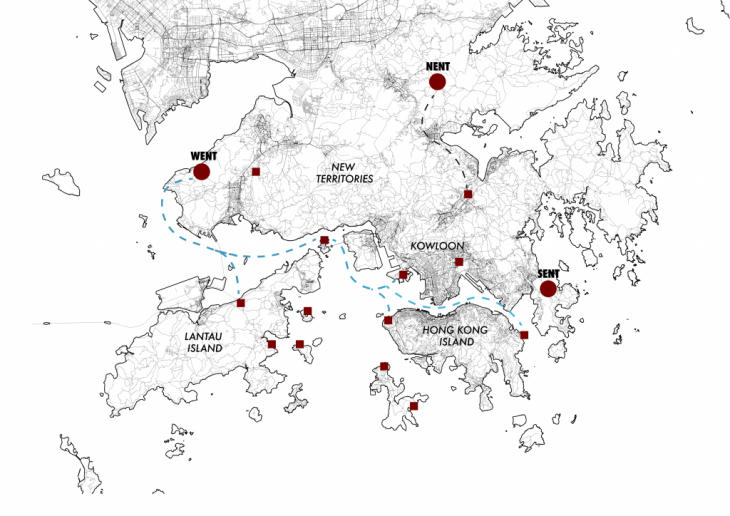

The container ship plays such an important role in Hong Kong

and it’s waste management system (being the main form of transportation

from RST to landfill). That lead us to the realization that it was necessary to hack

this failing system with an existing one, one that is in fact a prominent

element of this system that is failing.

This gives us an opportunity

The extra space that Hong Kong lacks to further develop their waste management infrastructure.

AND

To create a new urban condition where the waste cycle doesn’t betray the city, but gives it back as a

RESOURCE

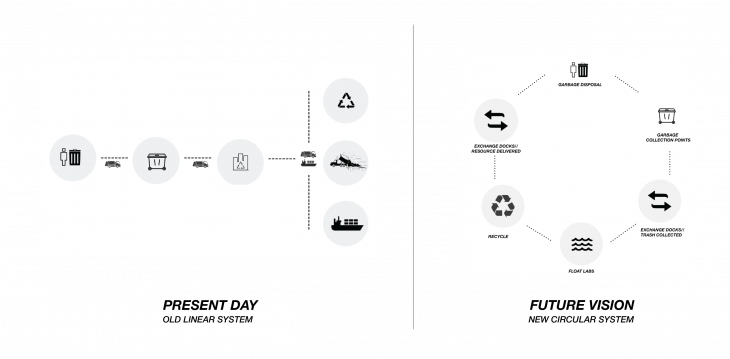

Having as a result a circular system, where the user benefits from the waste they produce and

also reduces overall waste output of the city.

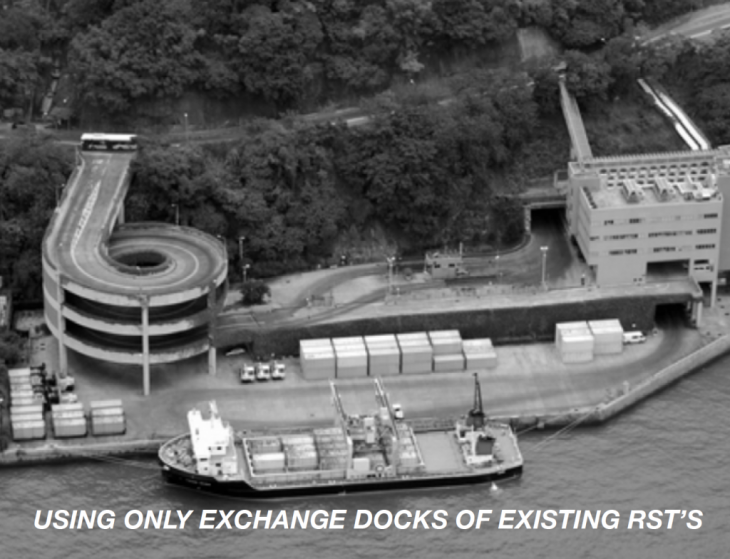

This new strategy frees up the space from the three remaining

landfills and ONLY keeps the docks from the RST’s (refuse transfer stations).

We took the old re-purposed docks from the RST’s (refuse transfer stations)

and we created them into “Exchange Docks”, where their main function is to the exchange

and load the Float Lab with waste – the Float Labs then make their cycle and provide

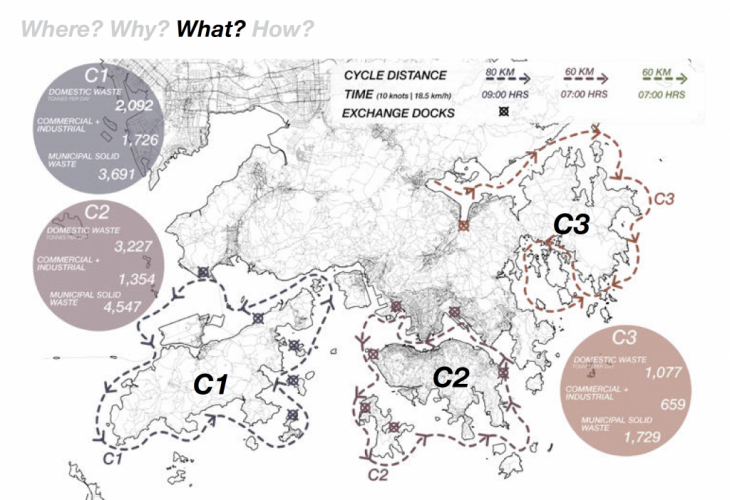

the city with the resource from waste. For this we created three new cycles for our

Float Labs where we grouped Hong Kong’s districts not only according

to their proximity, but also as a way to save energy and to not do lengthy unnecessary trips.

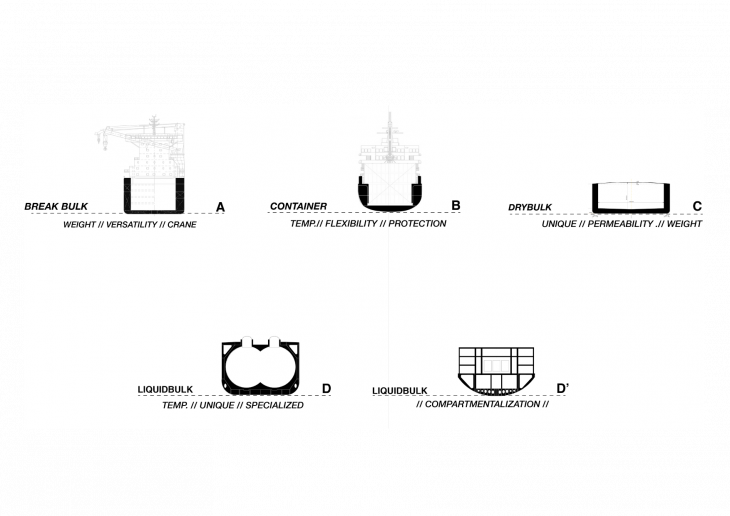

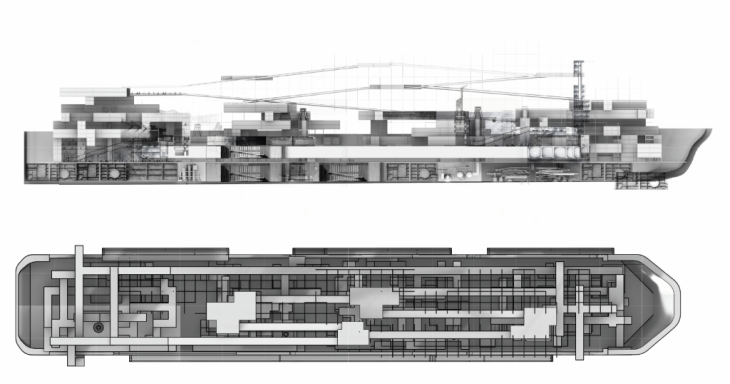

To fully understand how we would embed our vision of the new waste

management system into a container ship we had to research on how cargo ships work

and WHY they’re built the way they are – All cargo ships are not made

equal, they are all unique and respond to the necessities of what they’re meant to transport.

The Liquid Bulk cargo is meant to transport liquified natural gas, which offers not only

protection against hight temperature but a unique shape… the Dry Bulk containeron the other hand, is

meant to move freight carriage like coal, sand or wheat; it offers impermeability as well as the

ability to handle very heavy loads of material.

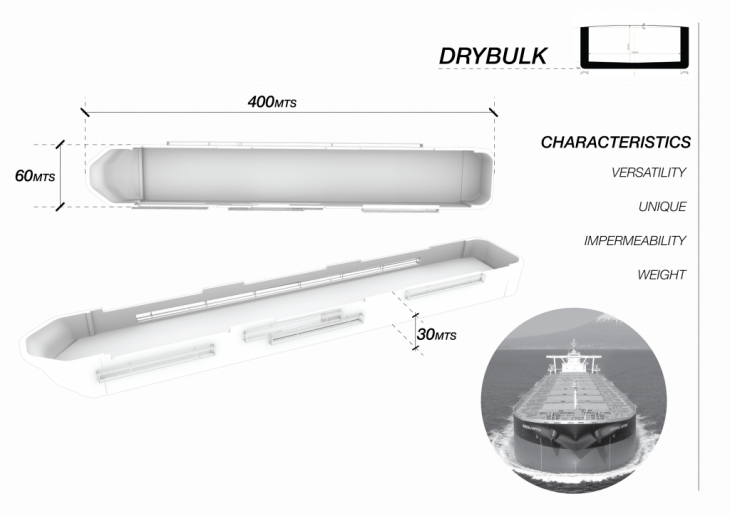

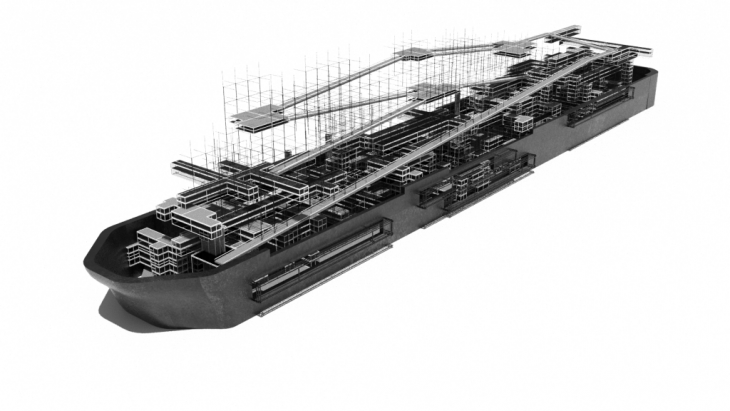

The most convenient specimen for our case study was de Dry Bulk container ship.

Not only does it come in many sizes (being the largest 400 X 60 meters) , but it’s shape

offers more regular inner space where we could embed our new system to.

An important factor we had to take into account is the SCALE; container ships

are immense and as it was mentioned before, the largest cargo is approximately 400 x 60 meters.

To understand it fully, we lay it on Barcelona’s Eixample district, and it takes up three building blocks;

when it’s laid on Hong Kong’s dense central district, it takes up 30 high rise buildings.

Having our project set in such a compacted city, we understood that our waste system must be embedded into an dense

urban setting as well- after all ,we cannot handle the waste alone without taking into account the city it is embedded to.

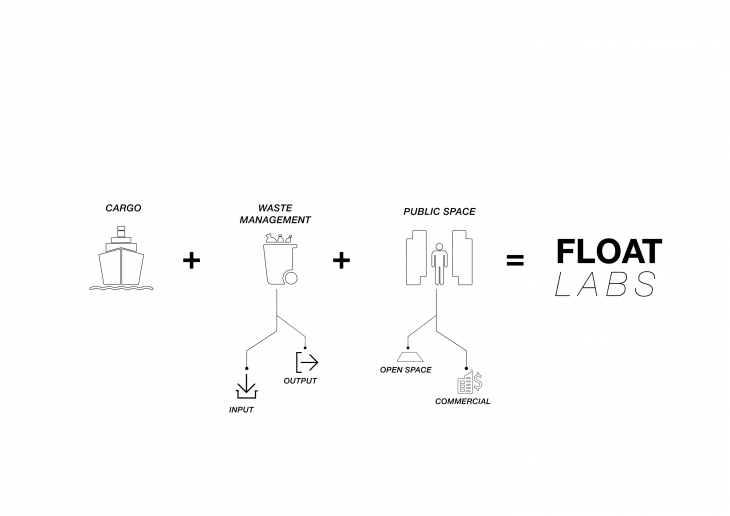

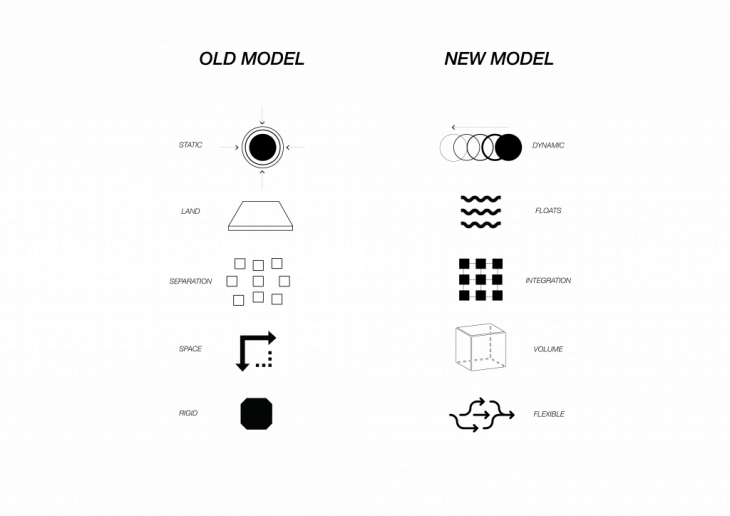

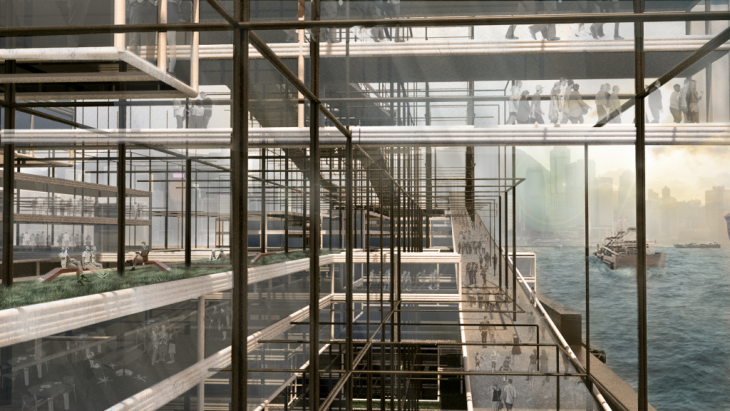

This type of new urban model or infrastructure depends on different factors

a normal city would usually rely on- such as that our Float Lab REQUIERES dynamicity for

its functionality, it processes the waste while it collects it on the exchanges docks.

It is not dependent on land anymore, but provides space on the water where it floats.

It works in an integrated systems between waste management, fablabs, reasearch

and other programatic functions. It no longer bases it’s space limits on area but on volume.

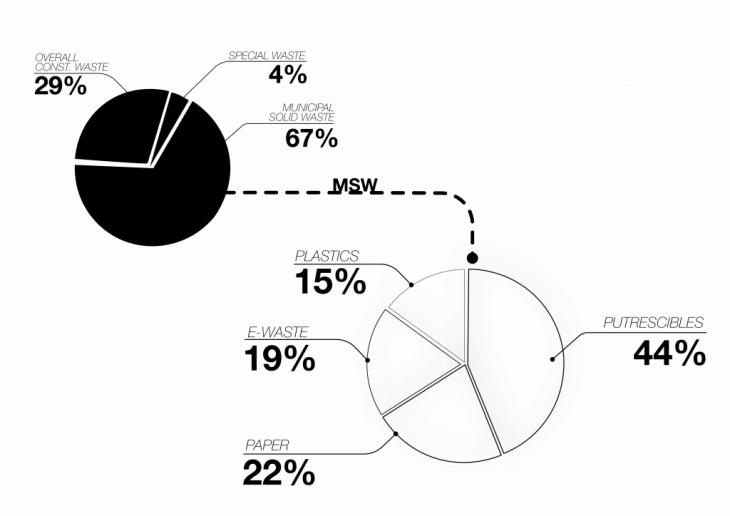

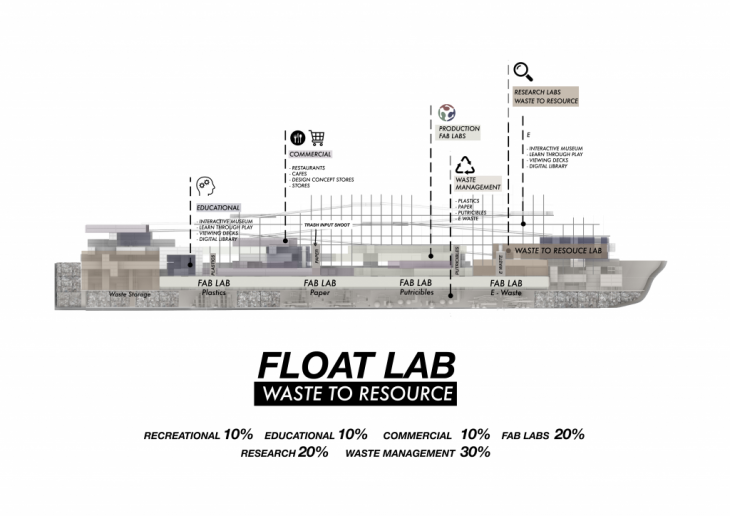

We decided to categorize our waste management facilities according to the waste output

percentage – Municipal solid waste accounts for more than half of Hong Kong’s waste output,

and MSW is divided in four main categories (listed above).

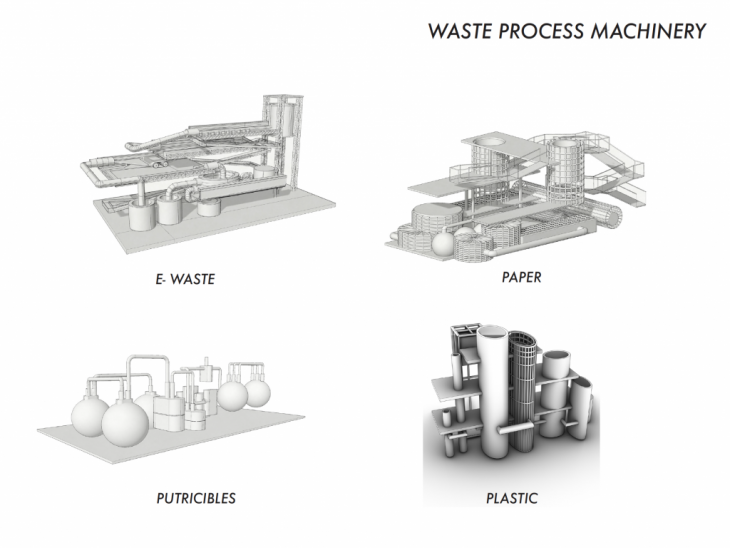

We looked into the machinery that was currently being used to recycle these four specific categories

of waste, and we started to speculate on how these machines would evolve in the near future to be adapted to this

new urban system within our Float Labs. We put a lot of importance into putrescibles (since they have a waste

output of 44%), because we would get our energy from the methane that is produced from organic waste when it putrefies – In fact,

many landfills harness the methane that they produce to locally power the facilities near the landfill, not to mention that

they MUST utilize it somehow because it’s a much more potent greenhouse gas than CO2, so they either flare it or harness it as energy.

We took this principal and decided to utilize for the advantage of our Float Labs.

Just as Hong Kong holds part of its infrastructure beneath it’s buildings, so do our Float labs, machinery

functions on the bottom level where through a number of chutes it connects to the assigned waste Fablab, where the processed waste

is taken to the the lab where it is then transformed into a resource for the city of Hong Kong. The following level is research, where new

ways of utilizing the waste can be explored and studied. The rest of the levels build up on other programatic functions a city would have

such as restaurants, cafes, shops etc

Additional educational sectors were added since the root of the waste problem is indeed the citizen of

Hong Kong, as it was mentioned before, recycling doesn’t happen much in the city, and it’s because it’s not separated properly

at the source – the main purpose of the Float Labs is not only to reduce waste output, but to educate people on the importance of

up-cycling and the tremendous potential waste has to be turned into a resource; once you see what this resource can be turned

into, you start becoming more conscious of how much you produce and the impact you have on the environment.

X-Urban Design Studio /// MAA01 2017/2018.

Project developed by Andrea Champion, Tal Dotan & Hira Zuberi

Faculty: Willy Müller

Professor Assistant: Jordi Vivaldi Piera