Kerfing Lamp

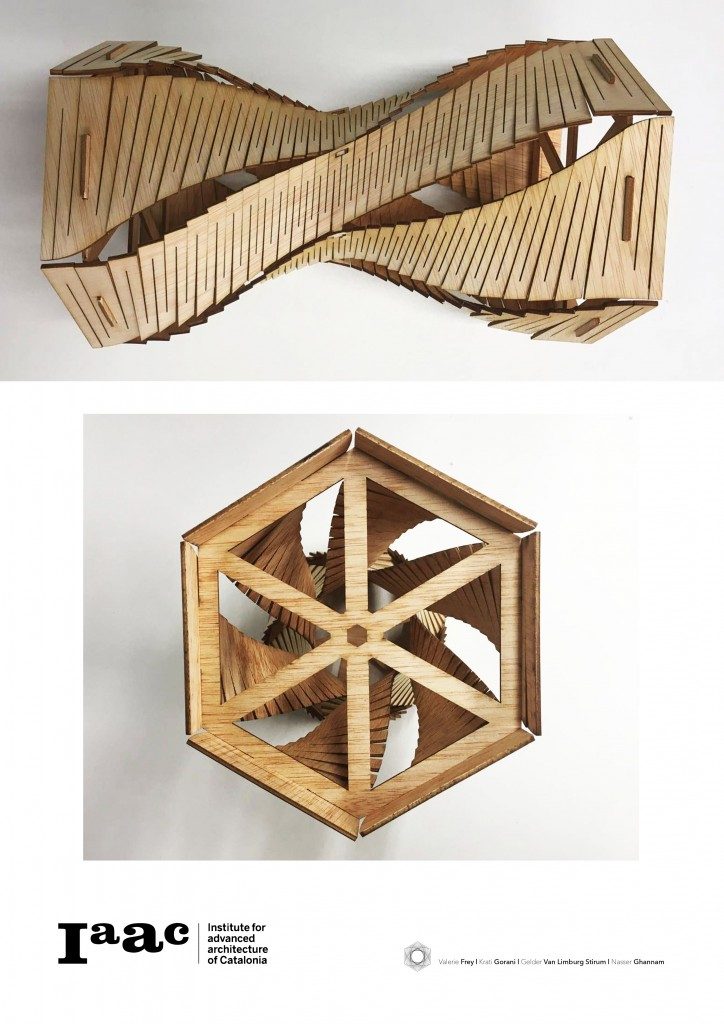

For the Digital Fabrication Module we used kerfing to establish the final shape of the lamp. We started of with a twisting shape with a hexagon on the top and the bottom of the lamp. After testing the first try-outs we found out that the wood strips were to thin and that the kerfing pattern we used didn’t perform as we had expected. Then we further developed the 3-D model together with the pattern to achieve what we had in mind.

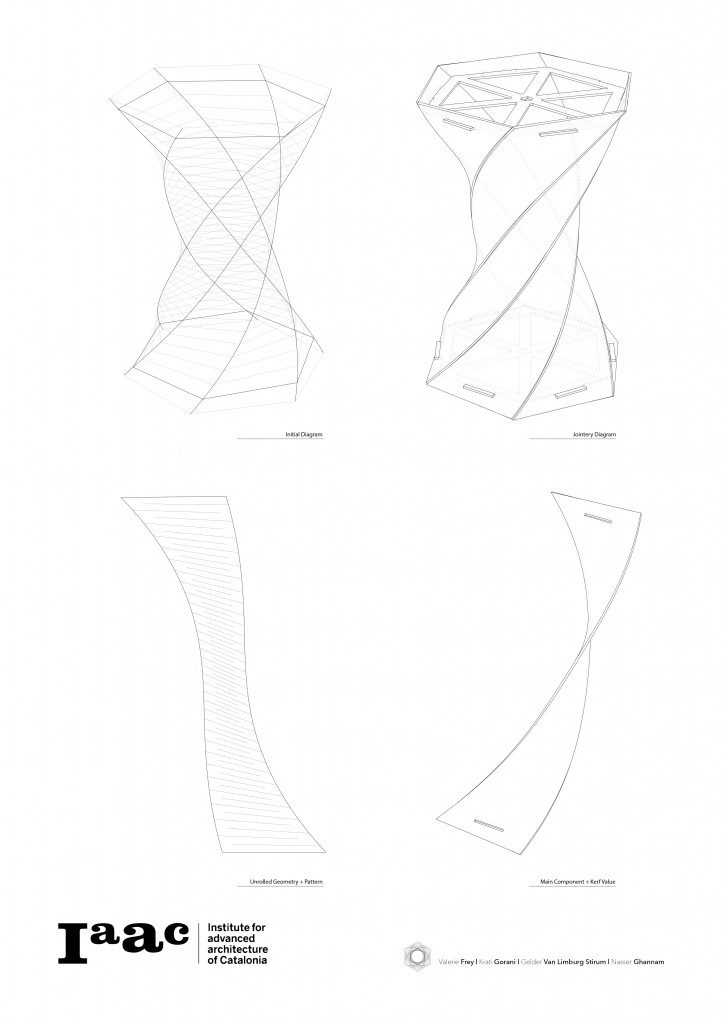

We aimed for the strokes of wood to twist in two axes (as can be seen in the diagram below). The next step was to merge the strokes with the top and the bottom parts. We did this by using relatively simple joinery, which is strong enough to keep the twisting wood in place, since the top hexagon piece is twisted 180 degrees in relation to the bottom piece. The challenging bit was to keep the shape of the lamp intact. We managed to do this by incorporating joinery in the middle of the lamp as well. Here we used the same type of joints as mentioned before. We placed the light bulb in the middle of the lamp to capture the most optimal light pattern.