DATA

Material: wood

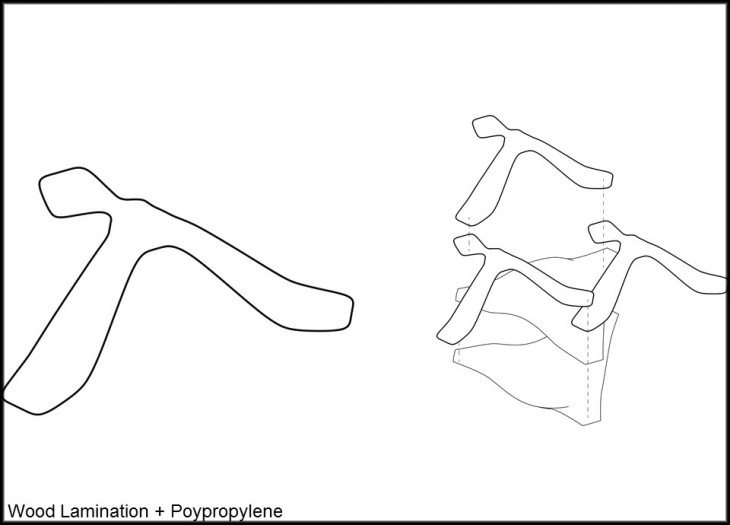

Technique: Laminating

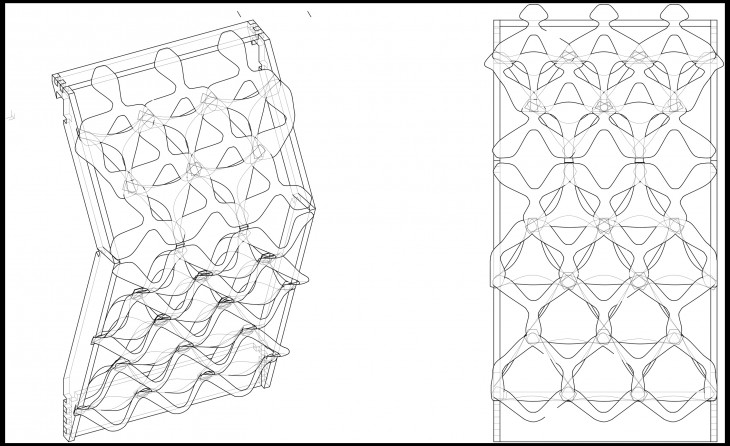

Percentage: 55

Translucent material: Polypropylene

Percentage: 45

CONCEPT

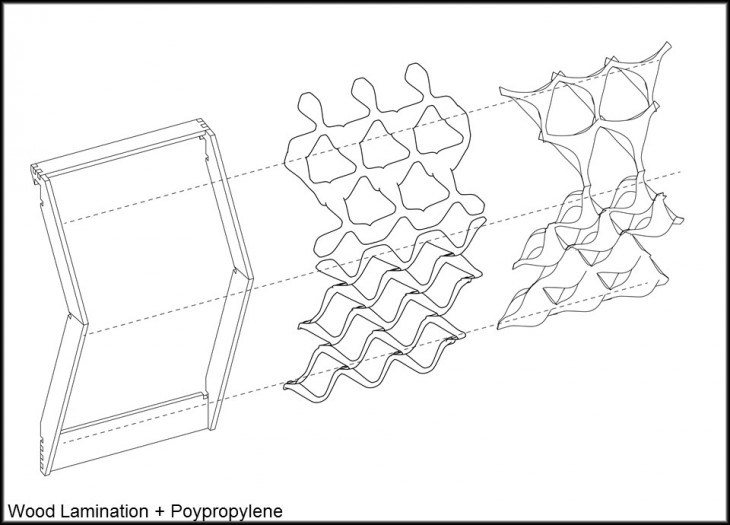

The 3 dimensional hexagrid serves as a supporting structure for the soft material, on the other hand pretensioning the polypropylene had increased the overall stiffness of the structure. With slight variation in each component, the system can create various gradients. The higher density of wood on the top of the façade protects the interior from overheating (South- West orientation in Barcelona) and rain. Ventilation is achieved through the openings between the two materials used. The lower density of wood at the bottom of the façade lets natural light come into the interior thus creating a bright indoor space.

METHOD

The main method we used for our façade was lamination. After deciding on the design, we created 12 foam molds in the milling machine. In the meantime, we laser cut the wooden shapes that had to be later laminated. After having the two components (molds and wood shapes) ready we used epoxy to glue four layers of wood together, place them on the molds and vacuum for 24 hours (the time needed for the epoxy to dry). We used the molds twice in order to finally have 27 wood components for the façade (with some spare ones).

We cut the polypropylene in the laser cutter, while joining together the wooden components with screws and attaching them to the frame. After, we had the translucent components of the façade ready, we joined them with the wood using the same screws so we have a minimum joinery.

Mold milling ( using CNC milling machine )

Wood on top of mold ready to go into the vacuum machine .

Assembling the laminated wood component with polypropylene using screws

Hexagrid façade is a project of IaaC , Institute for advanced architecture of Catalonia developed at Master in advanced architecture in 2015-2016 by :

Students :

Carlos Daniel Gomez Onate

Jakub Havlik

Michel al Azzi

Monika Koeva

Faculty :

Alexandre Dubor

Djordje Stanojevic