The high consuming, disposable culture brought on by the Industrial Revolution has led to the fast production of non-renewable composite materials such as plastics, which are now a significant part of landfills and oceans. Even materials with a combination of both natural and synthetic compounds have very few end-of-life options, as often this process is irreversible and they cannot be separated, making it hard for them to biodegrade.

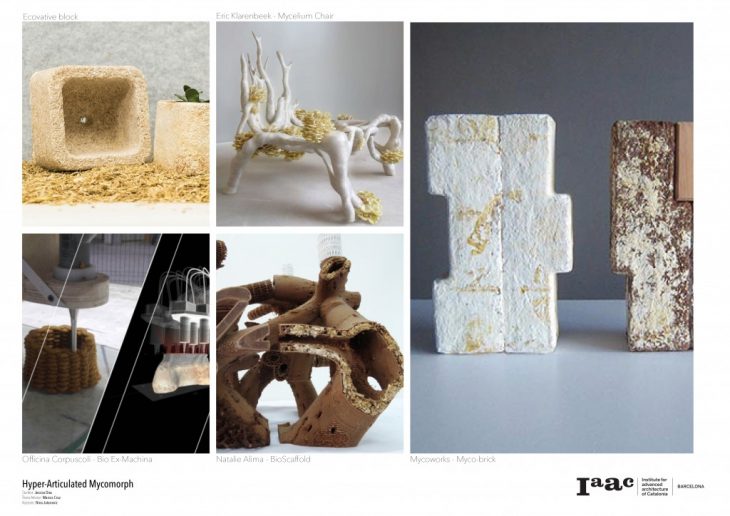

As a result, interest in biomaterials for industrial applications is growing fast. Mycelium, which is the vegetative part of the mushroom consisting of branching hyphae, performs as a natural binder when provided with the appropriate nutrients and environmental conditions. With these principles in mind, it is possible to cultivate the living organism to be used in design applications.

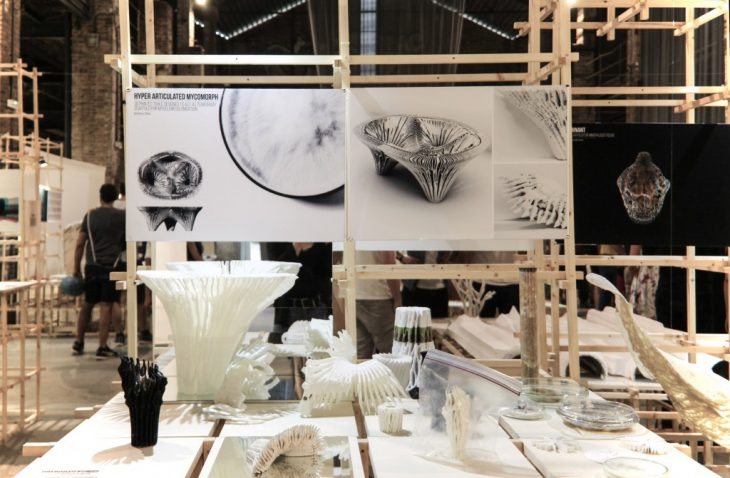

Myco-composite materials, in particular, have been extensively researched; they are low density, competitive in strength and have high performance under both tension and compression, they also biodegrade easily, therefore, adhering to Nature’s nutrient cycle. The low cost, low energy manufacturing process makes them a competitive rival to traditional composites, their current designs, however, lack a level of aesthetic sophistication.

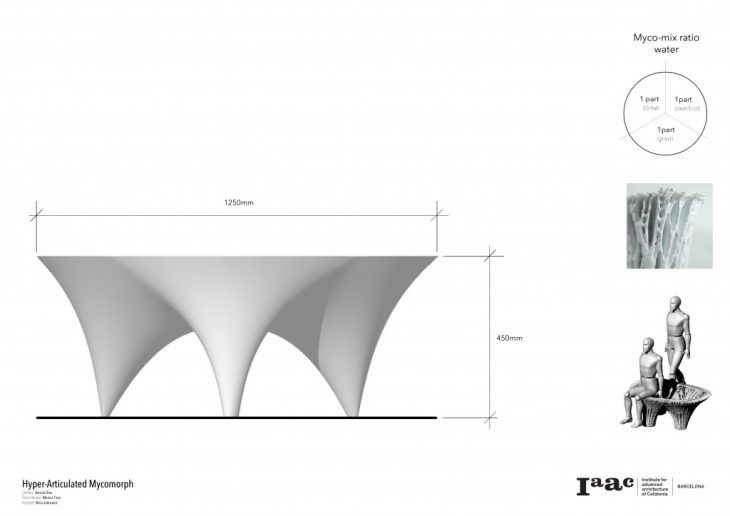

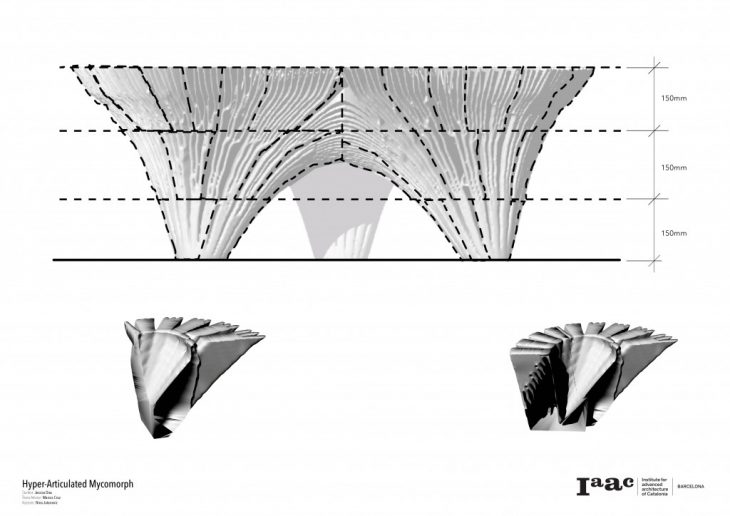

In this research, a digitally fabricated table prototype using 3D printed biodegradable PLA acts as a temporary scaffold for mycelium growth.

The objective is to generate new and sophisticated aesthetic possibilities for myco-composite objects, by observing and simulating the behaviour of mycelium in various substrates and controlling the environmental growth conditions.

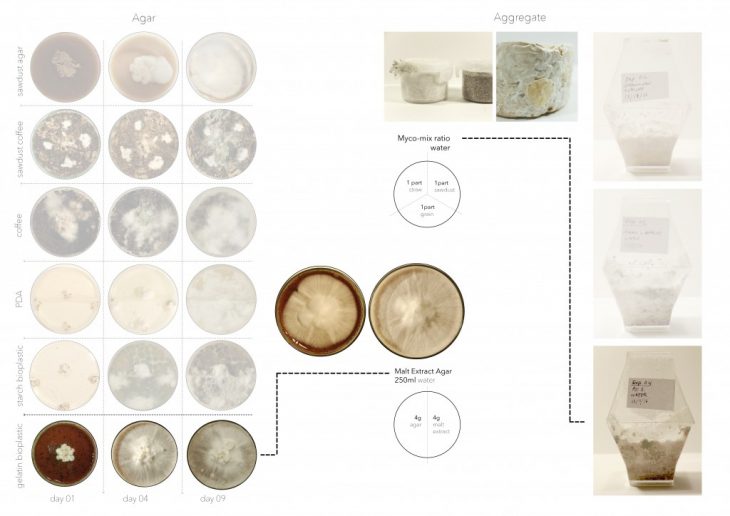

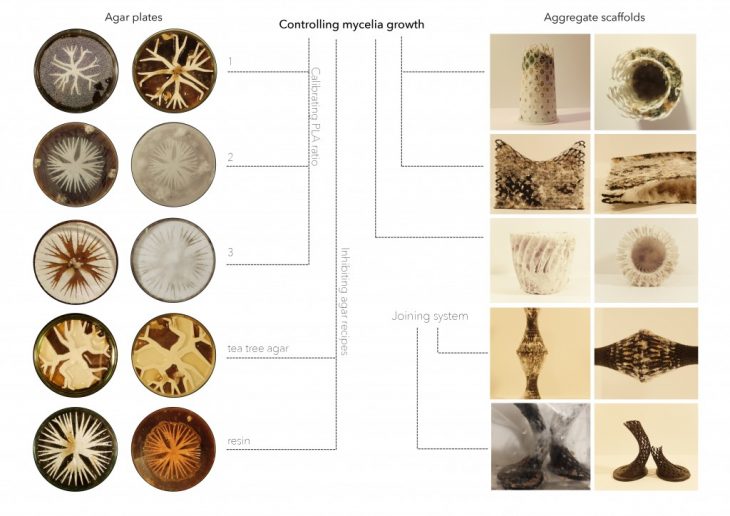

Initial testing was conducted to determine the most successful recipes in both agar and aggregate substrates. The objective of the research is to achieve full mycelium colonisation of a substrate, that has a combination of bulk, fibres and nutrients for optimal strength and binding. In this case, a mixture of sawdust, grain and straw was used.

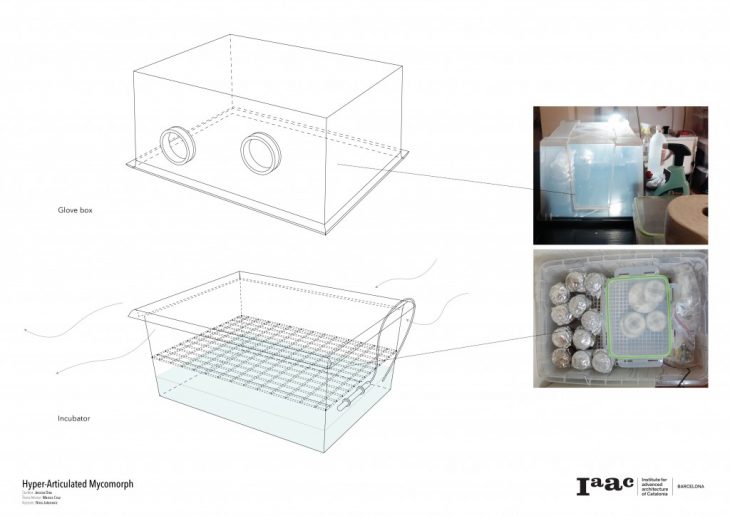

The initial cultivation techniques led to interesting yet undesirable results, where contamination of the substrates became a major concern because it prevents mycelium growth and potentially weakens the substrate. Appropriate apparatus was fabricated to prevent further contamination in future testing, and to monitor the growth conditions.

Incubator and Glove box

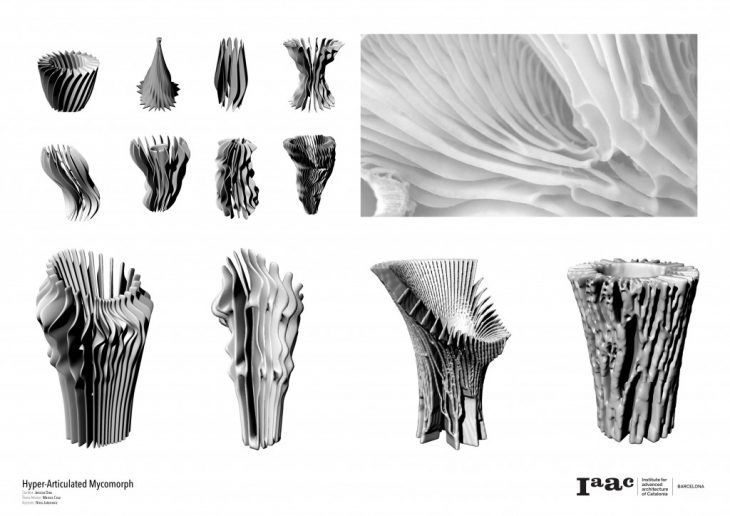

Scaffold design development

Tests using 3D printed PLA in Petri dishes and as a scaffold for the aggregate recipe attempt to control the growth of mycelium through the exploration of material ratio. Inhibiting additives such as tea tree and resin were also used to prevent growth, however, did not show much success.

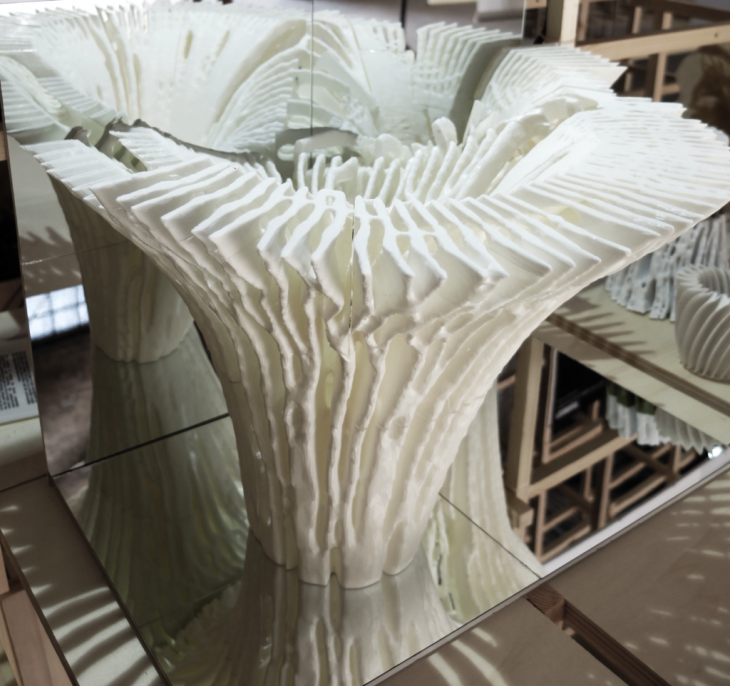

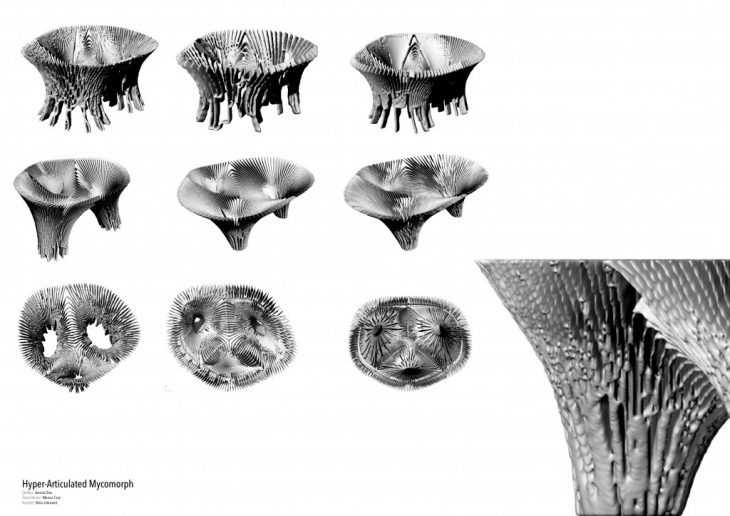

Morphogenic explorations were informed by the mycelium behaviour in a series of scaffold designs. The most successful design language provided a range of PLA densities through branching lamellae and opportunities to both blur and expose the mycelium growth.

From small scale prints to a medium furniture scale object.

With the material mix and the design language established, further parameters were determined.

With the parameters set out, I began adjusting the sizes of the legs, and a number of lamellas. A lighter and thinner feel for the lamellas at the top of the table to expose more growth and also allow the mycelium to be performative – here the mycelium can use its binding properties and strengthen the top of the table.

Depositing the mix into the scaffold and allowing it to colonise.

Colonised and dehydrated prototype.

Printing large scale with a desktop printer.

Once the pieces are printed and assembled, it’s time to sterilise and inoculate the scaffold. This should be done step my step within a sterile environment, so to deal with a larger scaled prototype I needed to upgrade my apparatus, and so I hacked a greenhouse and created a multifunctional lab space.

Here I am able to sterilise, inoculate, incubate, allow for fruiting, and then dehydrate, then easily remove the lab and the table is ready!

This project is a work in progress and is due for completion in September.

Hyper Articulated Mycomorph is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture, MAA02 in 2016/17 by:

Student: Jessica Dias

Tutor: Marcos Cruz

Assistant: Nina Jotanovic

Biology Support: Nuria Conde Pueyo

Computational Support: Rodrigo Aguirre

Fabrication Support: Anya Popova