ABSTRACT

For the hardware seminar we had the chance to develop an endeffector for the robot with the use of eclectronic devices like Arduino or Rasperry Pi. With the help of sensors, switches, controllers and many more electronic parts and the ability to use digital fabrication tools like the CNC-milling machine, lasercutters and 3D-printers, every kind of endeffector should be possibly to build prototypical. The robot control has different digital inputs and outputs to communicate with the endeffector, so that both can react on each other .

INPUT

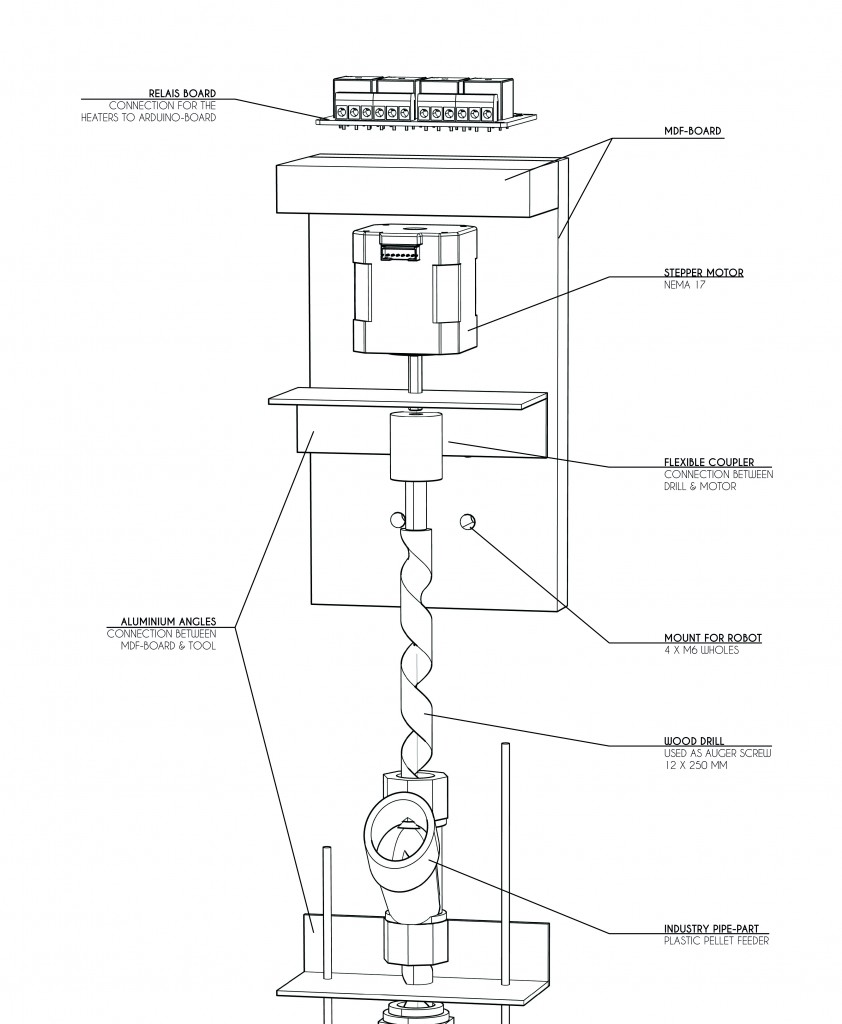

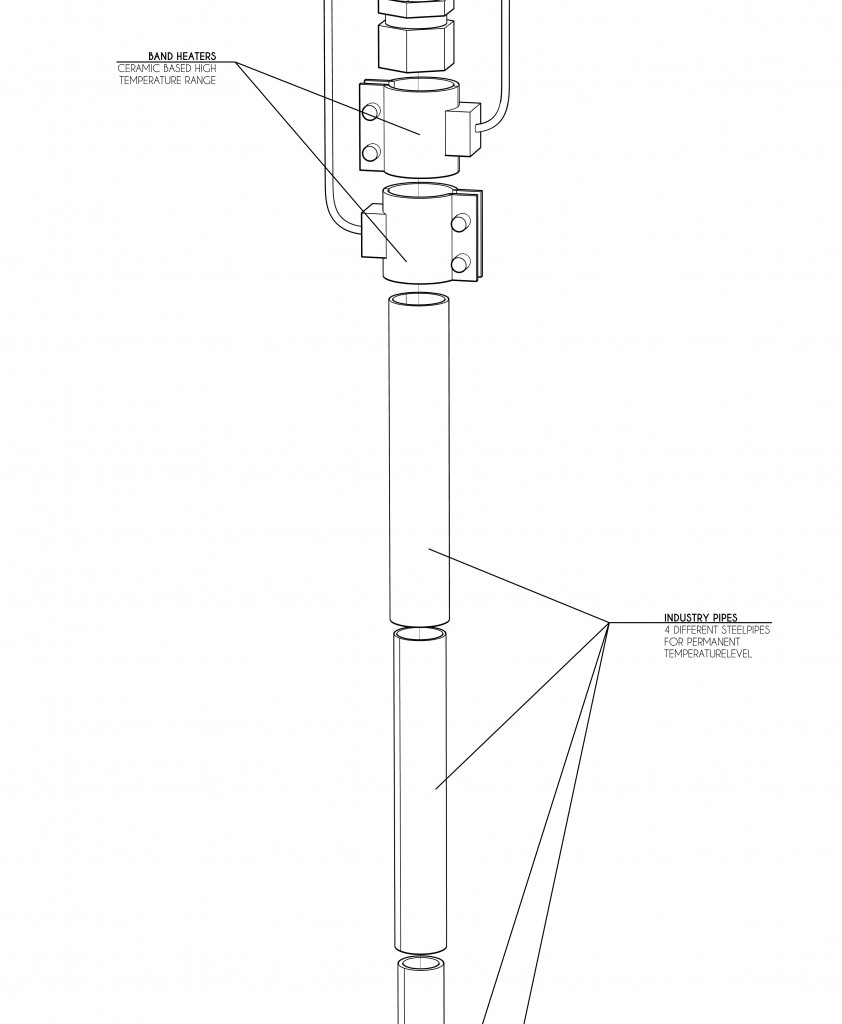

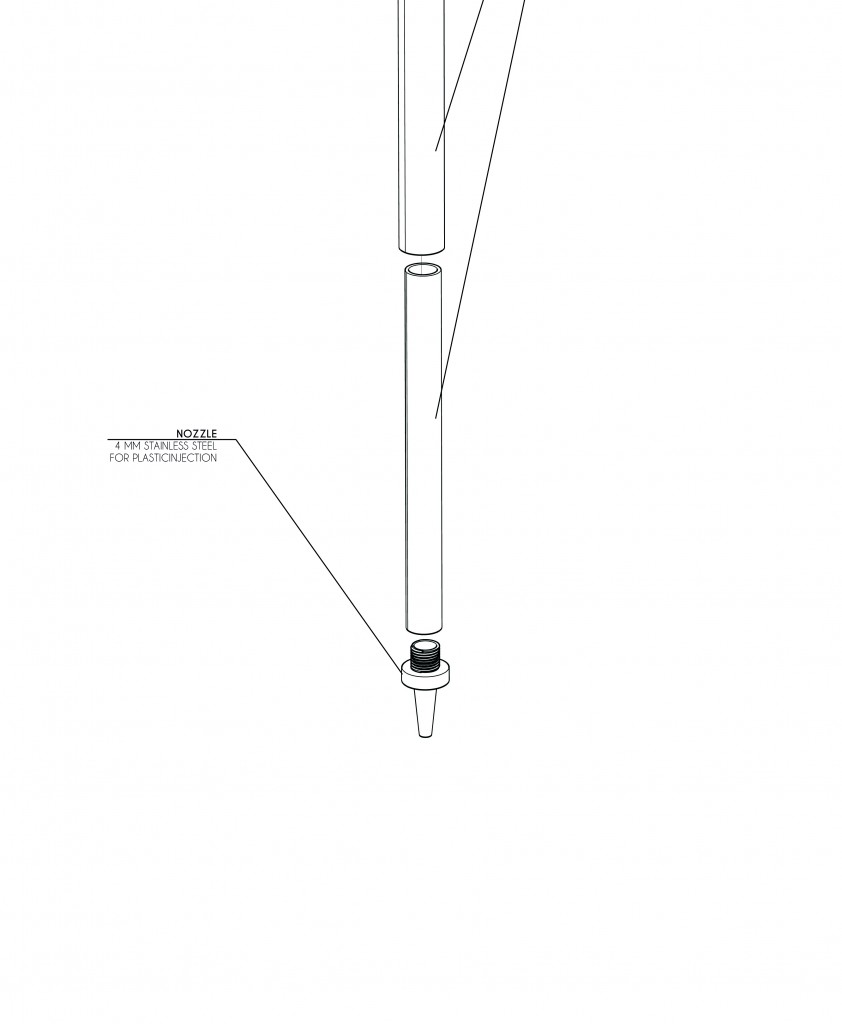

We decided to combine our hardware seminar with our studioproject – “Injected Joinery” in which we try to develop a novel kind of connection between timber elements with a hidden injected joint. So the decision was oviously to build an injection tool. For this challenge we decided to build a pelletextruder for thermoplasts. A pelletextruder in this kind, it is very close to an industrial injection molding machine . In this, pellets are heated up and transported under pressure to the front of the machine through an auger screw, till they reach a liquid aggregar state. Afterwards this liquid plastic can be injected very fast in a mold in the front of the nozzle of the injection machine by pushing the auger screw inside the pipe in direction of the mold.

OUTPUT

In the first testsetup we tried to build a pelletextruder with a 4 mm -Nozzle and a wooddrill as augerscrew with common materials from companys in Barcelona.

EXPLOSION DRAWING

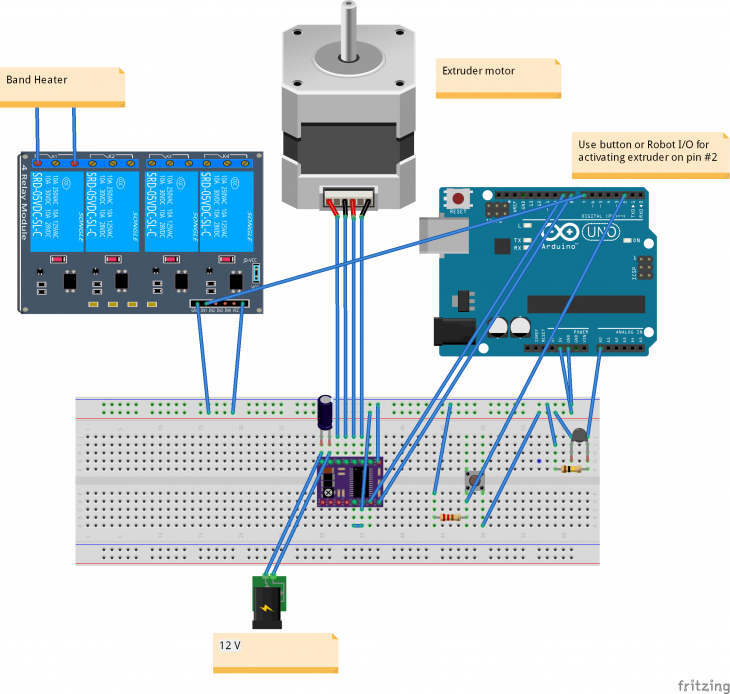

ELECTRONICAL SETUP

CONCLUSION

While we are still in process of testing , the first setup seems promising.

Any update of the project will be attached here in the blogpost.

INJECTION TOOL is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

STUDENTS

Luigi Pacheco, Omar Geneidy, Sebastian Voigt, Stefano Meloni

FACULTY

Angel Munoz