Initial Inspiration

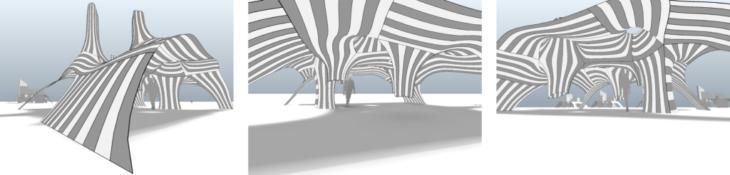

Leveraging the use of mesh relaxation and smoothing to create developable surfaces, this study set out to explore the geometrical possibilities in form finding and creation of developable strips within rhino and grasshopper, and derive a framework from which a min. 3x3x3m – max. 6x6x6m pavilion could be constructed. Focus was given especially to the geometry around openings and the ability to drive the overall shape and mesh topology at these openings.

Although the geometry wasn’t necessarily derived from the same form-finding, the initial spring-board for this study came from the Kunsthaus Graz.

Kunsthaus Graz (image: Peter Cook via archdaily.com)

Kunsthaus Graz (image: Peter Cook via archdaily.com)

Catmull-Clark Subdivision & Mesh Relaxation

The oculi were first studied with 1x1m mesh cubes and were only manipulated via subdivision and smoothing. By reducing the mesh to the opening itself, the resulting geometry around the opening – especially in regards to triangular and quadrilateral mesh faces could be analyzed.

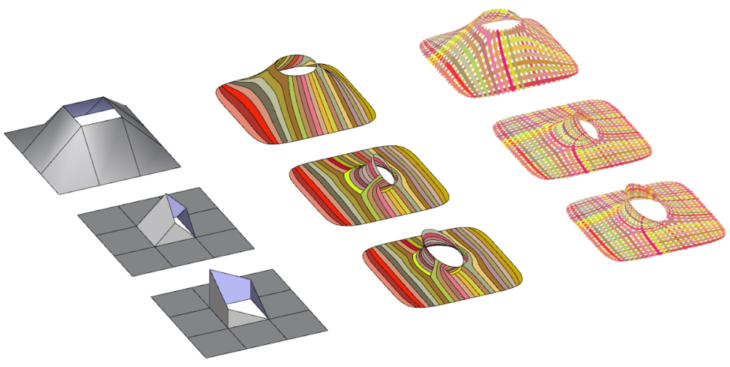

Initial iterations depicting mesh smoothing of cubes with a single opening (from left to right: initial mesh geometry, smoothed mesh strips (single directions), smoothed mesh strips (warp and weft))

Initial iterations depicting mesh smoothing of cubes with a single opening (from left to right: initial mesh geometry, smoothed mesh strips (single directions), smoothed mesh strips (warp and weft))

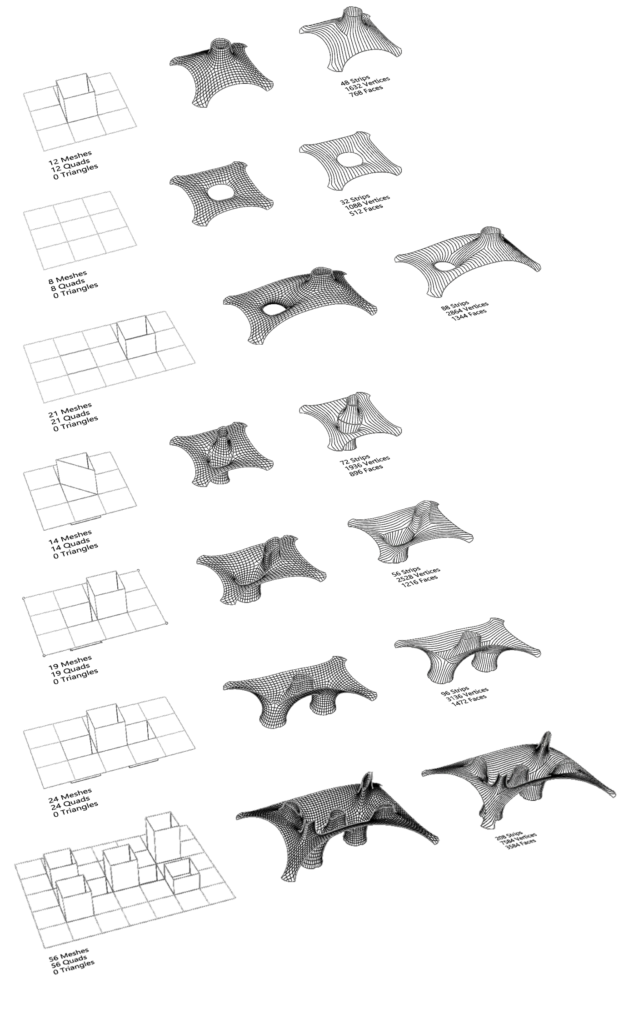

Working up in scale, the openings were then set into a 3x3m grid of surrounding flat geometry. This helped in gaining an understanding of how these openings were interacting and informed by this adjacent geometry.

Iterations depicting mesh smoothing 3x3m grid with variations in the middle opening

(from left to right: initial mesh geometry, smoothed mesh strips (single directions), smoothed mesh strips (warp and weft))

(from top to bottom: hole is translated in the z-axis and distorts neighboring geometry into non-planar meshes, hole is translated in z-axis and rotated to meet at one vertex of flat mesh, hole is translated in z-axis and opposite points of opening are dragged up and down to increase the opening’s height and meet at the flat mesh, respectively)

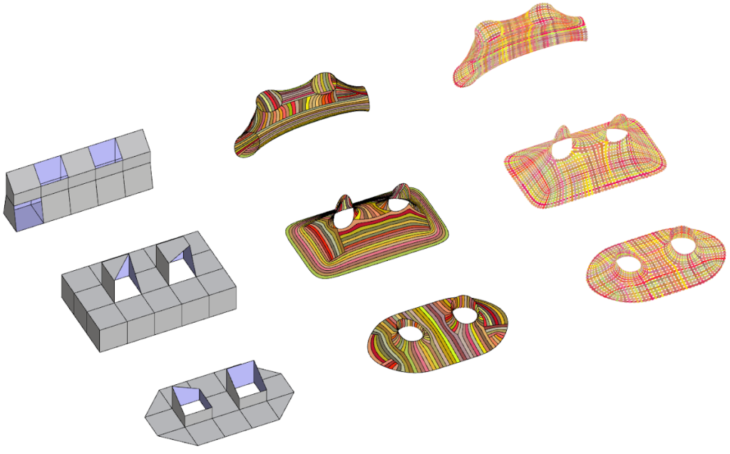

Overall initial form was then investigated to see how the strip directions interact when wrapping around two corners and edges, as well the interaction between multiple openings.

Iterations depicting mesh smoothing 3x3m grid with variations in the middle opening

(from left to right: initial mesh geometry, smoothed mesh strips (single directions), smoothed mesh strips (warp and weft))

(from top to bottom: 1x5x2m grid with the row scaled and two faces removed to create openings as well as two openings on either end; 3x5x1 grid with two openings popped up – one with a triangular top-face and one a trapezoidal; 3×5 grid with two openings – one non-planar quad that was removed, and the other a planar but rotated quad that had been removed)

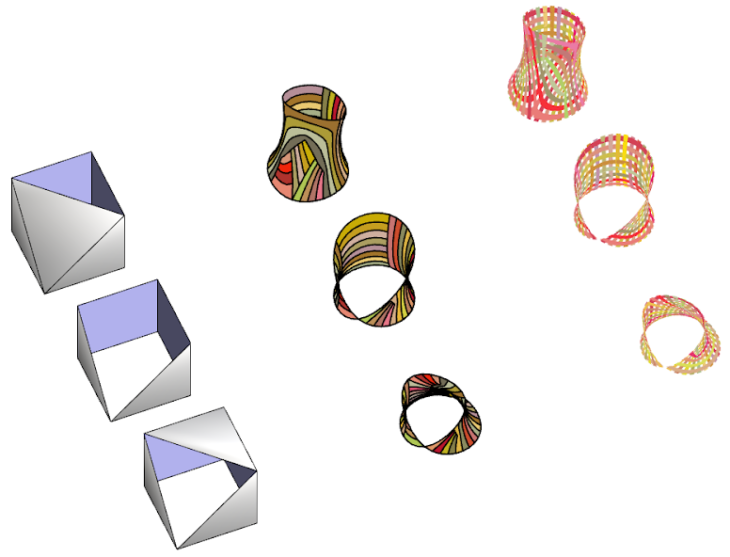

Mesh Relaxation

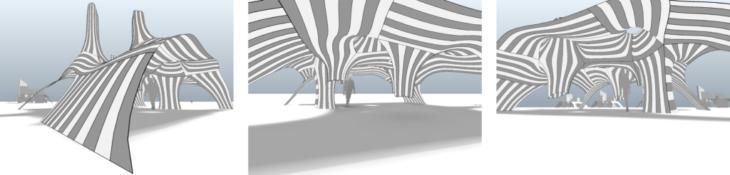

In the following iterations, mesh relaxation via Kangaroo was introduced into the study. The goal of the study shifted to include a vaulted form that would interact with these openings. By anchoring the corners and some of the holes whilst relaxing the remaining mesh, the form was allowed to open up and create a space beneath the surface, thus moving closer to an inhabitable architectural space.

The openings and their proximity to one another were also investigated. When the openings shared faces, this began to distort the shape of the openings in a visually noticeable way.

The openings and their proximity to one another were also investigated. When the openings shared faces, this began to distort the shape of the openings in a visually noticeable way.

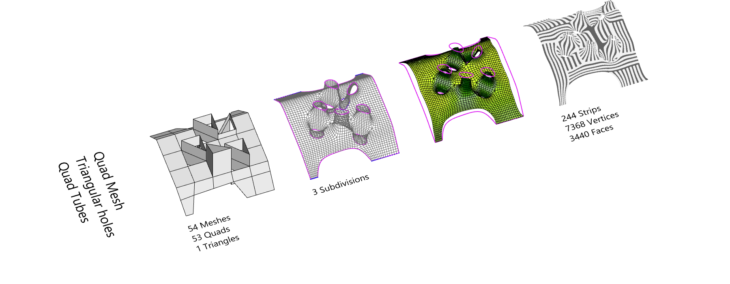

After a final overall form was decided upon, and the focus was set on deriving the final striping, it became increasingly apparent at this point that the stripes’ directionality would be a difficult hurdle to navigate, as they would not necessarily follow the bounding geometry and begin intersecting in places where this was not desired. This occurs especially around the openings and along the arched edges. The initial intent was to achieve a geometry that is able to follow both the arches and the holes.

The possibility of utilizing triangulation in various directions and at various intersections was explored, but ultimately it was found that in order to achieve this the overall form would need to be manipulated.

Final Form

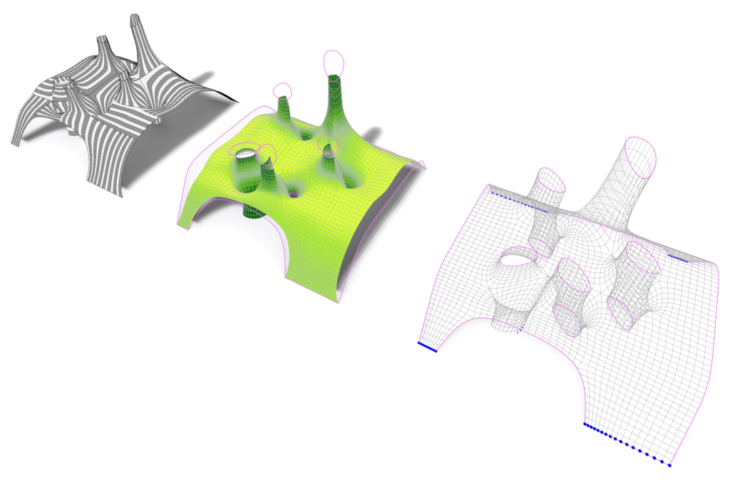

The final form and stripping was chosen based the intersection at the various openings with the strips coming from the edges, in addition to the lengths of the strips and overall aesthetic balance.

Final chosen geometry

Final chosen geometry

Fabrication

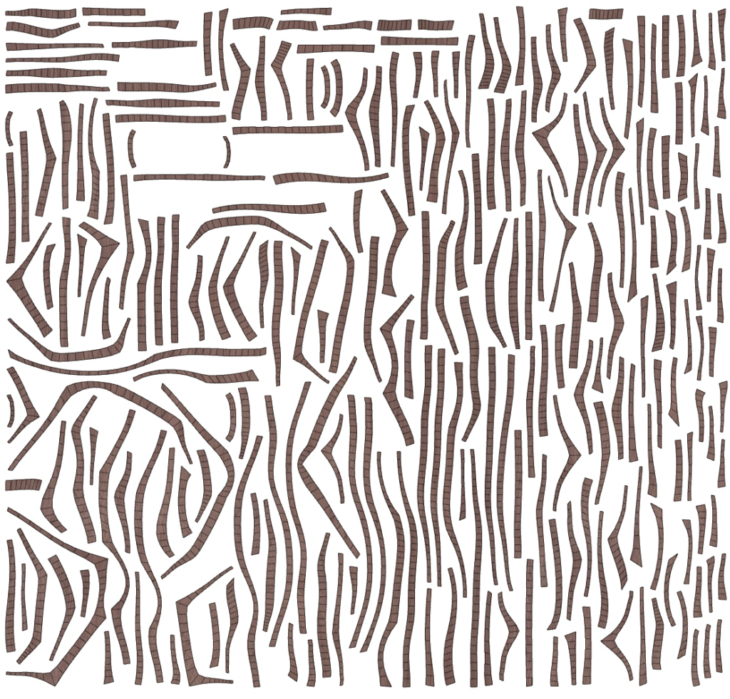

For fabrication the thought was to use strips of wood veneer. By using veneer stitching, these strips could be glued together at their common edges. Also needing consideration is the length of these strips and the extent to which the wood grain could continue in the same direction for the geometry of the strip would begin turning too much. The approach taken would have the strips broken up into smaller segments that would then be stitched into the longer complete strips.

Strips are unrolled and segmented at vertices

Strips are unrolled and segmented at vertices

Like sewing strips of wood, veneer stitching uses a zig-zag bead of glue to adhere adjacent strips

Like sewing strips of wood, veneer stitching uses a zig-zag bead of glue to adhere adjacent strips

Credits

Innies & Outies: Exploration in Oculi and Mesh Topologies // S.1 Studio is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2021/22 by:

Students: Tomás Quijano, Robert Michael Blackburn

Faculty: Andrea Graziano

Faculty Assistant: Eugenio Bettucchi