This special concrete tile allows light to pass through. The tile contains optical fibers that make up about 5% of its surface area. The fibers are distributed uniformly throughout the surface to allow an outline to be clearly visible on the other side. The tiles have the unique combination of being nearly unbreakable and translucent. The material is made with a combination of optical fibers and fine concrete. It can be produced as prefabricated building blocks. Due to the small size of the fibers, they blend into concrete and become a component of the material like small pieces of aggregate. The result is a new material, which is homogeneous in both its inner structure and its surfaces. The material is manufactured by alternating layers of concrete and fibers. The concrete sets and the material is cut into tiles. The pattern of the fibers can be uniform, or can be designed to a specification such as artificial wood grain.  The idea for Flexicomb grew out of a research project on structural honeycombs at the Yale School of Architecture. Thousands of closely packed polypropylene tubes form the flexible honeycomb matrix, which bends in the convex direction while remaining rigid in the concave. This translucent material is a re-valuation of a disposable everyday product—plastic drinking straws. Flexicomb can be bent, sprung, and compressed to form sculptural installations.

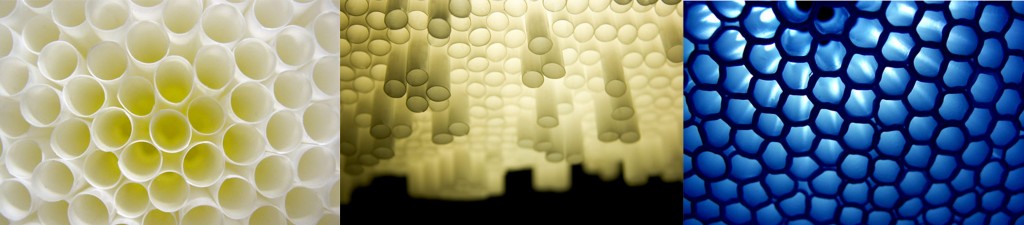

The idea for Flexicomb grew out of a research project on structural honeycombs at the Yale School of Architecture. Thousands of closely packed polypropylene tubes form the flexible honeycomb matrix, which bends in the convex direction while remaining rigid in the concave. This translucent material is a re-valuation of a disposable everyday product—plastic drinking straws. Flexicomb can be bent, sprung, and compressed to form sculptural installations.

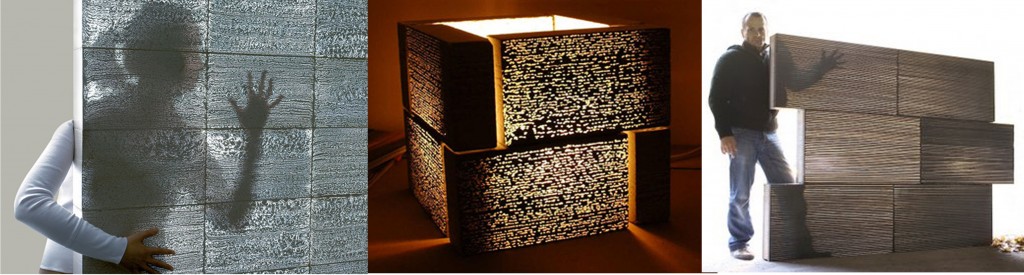

This special concrete tile allows light to pass through. The tile contains optical fibers that make up about 5% of its surface area. The fibers are distributed uniformly throughout the surface to allow an outline to be clearly visible on the other side. The tiles have the unique combination of being nearly unbreakable and translucent.

The material is made with a combination of optical fibers and fine concrete. It can be produced as prefabricated building blocks. Due to the small size of the fibers, they blend into concrete and become a component of the material like small pieces of aggregate. The result is a new material, which is homogeneous in both its inner structure and its surfaces.

The material is manufactured by alternating layers of concrete and fibers. The concrete sets and the material is cut into tiles. The pattern of the fibers can be uniform, or can be designed to a specification such as artificial wood grain.