Introduction

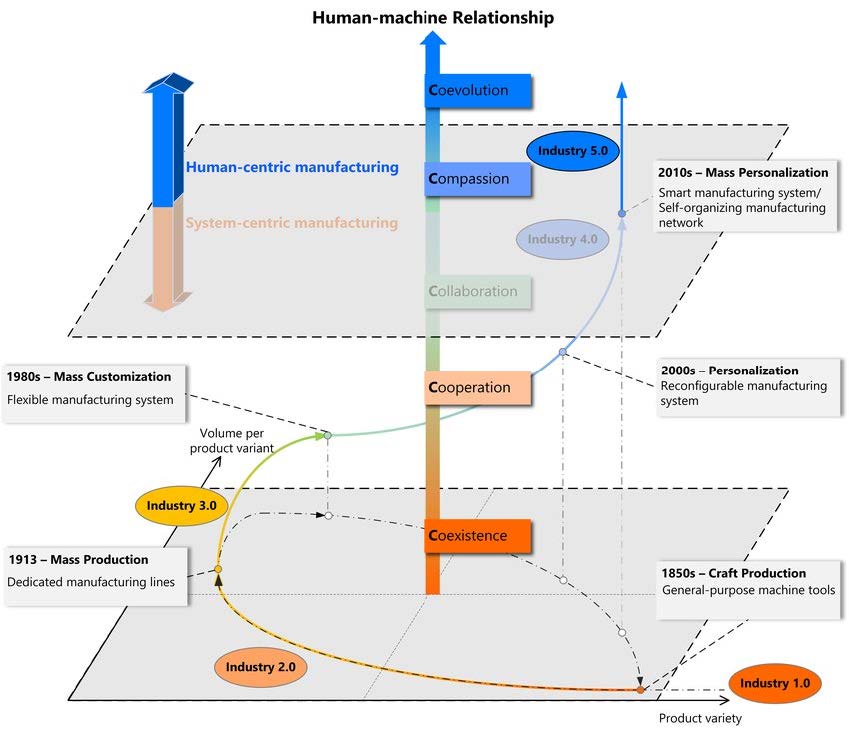

This research explores the generational shift from the mass production (Industry 4.0 and olders) to the mass customization in the industry (5.0) and its effect on the relationship in human-robot interaction. During the course of this research we are addressing the shift from technology to human centric approach in the industry and so the new human-machine symbiosis, the dawn of the Augmented Age [Lancaster, 2018].

The core of the work will study the digital shift in technology and construction industries, the evolution of hardware, software and languages in the field, as well as the digital user experience in other sectors and the human-robot interaction processes. This part will conclude with the analysis of 3 case studies where we evaluate the control, collaboration and degree of human factor in their interaction.

Outcome includes a speculative prediction of digital and human connections in 20 years time. Despite the fact of having a numerous quantity of technologies in their own current exponential development (material research, connectivity, machine learning, bioengineering, etc), this can give us endless directions on the interaction between digital and human actors in the industry.

1. Conceptual Framework

We are currently living in a time of transition between industrial movements where essential and critical changes are taking place. The so-called Industry 4.0, started its settlement and growth in the beginning of this century fulfilling the previous industrial goals, such as optimization and standardization of products, covering a homogeneous global market, connectivity and machine communication systems (IoT). With the help of

digitalization and AI-driven technologies, this industry focuses on increasing the efficiency and flexibility of production over social fairness and sustainability.

Moreover, the technological progress linked to the numerous social-humanitarian crisis is shifting the key agent on its core structure of the industry: from a technology centric to a human centric approach. This new industry (5.0) highlights the importance of research and innovation to support the industry in its long-term service to humanity within planetary boundaries [Breque et. al, 2021]. Other important changes are related to customization over production priority. Hence, providing a flexible, heterogeneous market with low cost and efficient process.

This leads to the Age of Augmentation, a concept that introduces human-machine symbiosis. A relationship between two very distant environments where collaboration, feedback and consciousness take a new important role in the industry.

2. Digital Shift

Digital shift is evident in all walks of life from the way we use the infrastructure to navigate the world to the way we communicate with the objects around us. As we move towards an ever more connected, digital society, it is important for us to understand its trajectory to anticipate the future.

In this section of the essay we look at the digital shift in construction in parallel with evolution of technology and digital language in general.

Construction

Architectural design, an important part of the construction industry, was one of the disciplines of design that foregrounded the use of digital tools and techniques ahead of every other design field.1 On the contrary the construction industry is still in the primitive stages of digital transformation second only to hunting.2

In the recent past there has been a significant advancement in research and development to develop novel techniques to bridge this disparity between design and construction. In the essay, The Digital in Architecture: Then, Now and in the Future,3the descriptive illustration provides an insight into the past and helps anticipate the future of architecture and construction. Some of the important movements that are significant to this essay are stitched below.

Proto Parametricism

The development of a series of works that could be argued as ‘proto-parametricist’, or using analogue means to compute form using parameters.

An example of this is sagrada familia designed by Antonio Gaudi.

Early Digital Explorations

The shift where the buildings were translated from a physical model to digital model. In the case of Guggenheim Bilbao, Frank Ghery worked with the software Catia to realize the project.

Guggenheim Bilbao, Frank Ghery

Parametric Explosion

Grasshopper, a plugin for Rhino 3d, empowered architects to develop designs digitally based on certain parameters.

Kartal Pendik Masterplan, Zaha Hadid Architects

Robotics

Introduction of robotics into the design and fabrication workflow has given rise to novel technologies that could not be envisioned previously.

BUGA Fiber pavilion, ICD & ITKE

Collaborative Robotics

Handful of researchers are pushing the envelope of fabrication by bringing human cognition and robotic control together to build workflows that are efficient and use minimal resources.

MoRFES_01, Milan, Maria Yablonina

Collaborative Robotic Systems

At the cutting edge of fabrication and construction is the collaborative robotics systems that integrate multiple devices and sensors into the workflow to bridge the gap between design and execution.

Augmented Brick Laying, Gramazio Kohler Research, ETH

Technology

As we notice the evolution of the fabrication and construction industry towards collaborative systems, we notice a similar trend with technology in general.

The first major shift took place during the industrial revolution. The sole focus of this shift was mass production to cater to the world’s demand. Most of the systems of this generation were analog. The shift to digital systems in industries was facilitated by the advent of programming languages that could improve the efficiency of machines and with minimum labor for mass production.

As hardware and software systems got complex over time for the general public to use, personal computers and operating systems such as Windows and MacOS acted as bridge between analogous machines and humans. This shift signifies the swing in technology to incorporate humans into the digital industrial workflow.

The invention of mobile devices gave rise to a whole new field called UI/UX where human experience formed the core of the device’ design. Another important aspect of modern society is communication. The technological industry for a short while shifted its focus to interconnection of devices for industry 4.0 coining the term Internet of Things.

Governments such as the European commission are already pushing for Industry 5.0 to provide a vision of industry that aims beyond efficiency and productivity as the sole goals, and reinforces the role and the contribution of industry to society.

It places the wellbeing of the worker at the center of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.

It complements the existing “Industry 4.0” approach by specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient industry.4

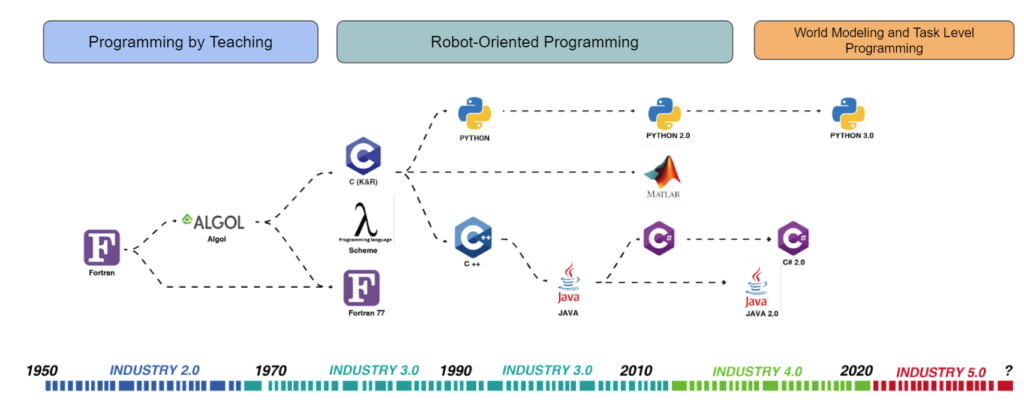

It is clear from our studies that the industry is moving towards human centric design and it is of importance to develop efficient human robotic communication channels. To understand what it takes to facilitate this communication we dwell into the evolution of language in the digital world.

The graph above shows the evolution of robotic programming languages. To find the first real programming language, we have to jump back to around 1945 when robots used a very low level of programming language. The programming method for robots was purely mechanical, most of them had only one program. To reprogram would mean redesigning the whole machine.

The second generation languages were developed throughout the 1980s. They featured more advanced motion control, sensor interface capabilities, inter-robot communication and even some limited artificial intelligence.

Industrial robotics currently has more or less stayed around the level of the second generation of languages. This is maybe because robots are traditionally still used for repetitive tasks. However the third generation of robot programming languages is foreseeable in industrial 5.0. It is no longer about specific languages. It’s probably more realistic to call it an ever-developing set of programming ideas, as it has become almost irrelevant which language you choose to program with, which features include automatic 3D world models, task level programming (e.g. “move that box over here”) and a dynamic understanding of the environment.

In modern smart factories humans and robots have to coexist in a common workplace: robots can complement the humans’ sensory, physical and cognitive characteristics, while humans can take care of the more delicate and cognitive tasks. Moreover, robots should be designed to properly assist human workers in performing a certain task in order to obtain greater efficiency and effectiveness by using different sensors and a set of UX techniques.

Experience Is Everything – The Ultimate UX Guide

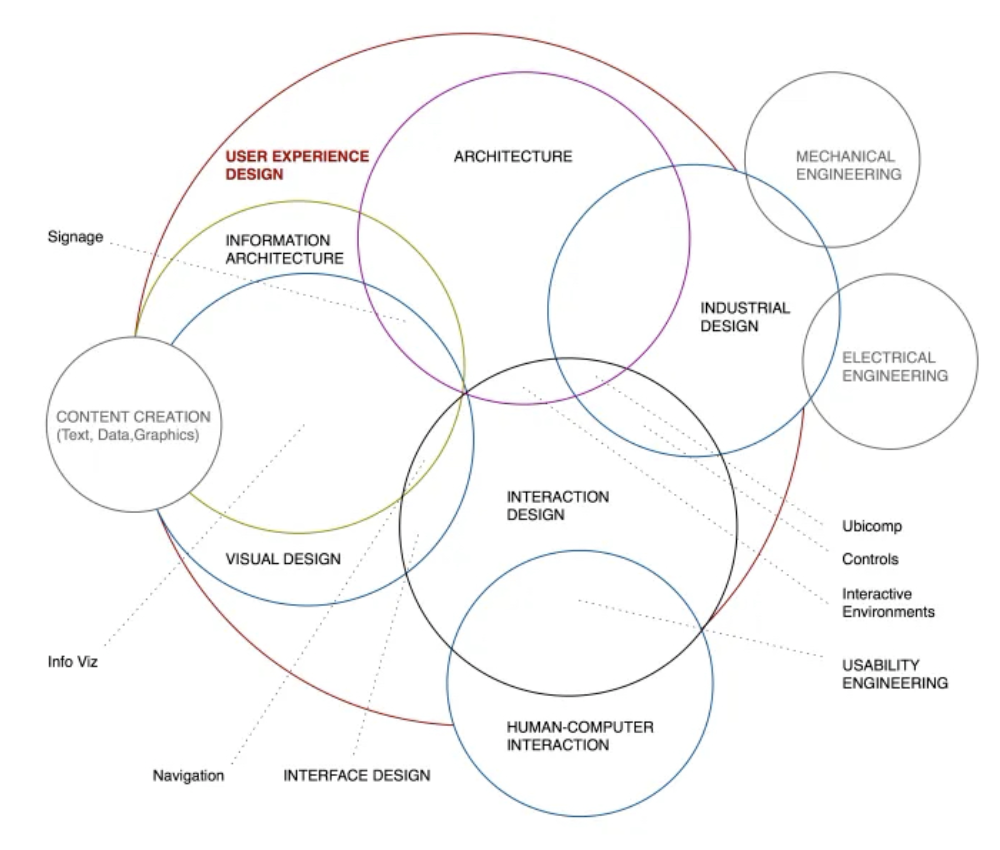

From the graphic above we can infer that user experience has completely encapsulated architecture, visual design, etc. But, Human-Computer interaction is still far off from being completely inducted. From our interview with Dr. Madeline Gannon where she quotes, “Maybe we are still in the phase where there is a continuous hardware exploration therefore it is difficult to develop general UX UI.” We know that the technology is not there yet, but, this is also an opportunity to nudge emerging technologies to integrate human robot communication channels within their systems.

The below infographic summarizes how human robot communication is evolving with respect to work environments and its respective interfaces. It is interesting to see that as the ellipse expands and the proximity of human and robot decreases, the communication means is more inline with the natural human senses than through an electronic device.

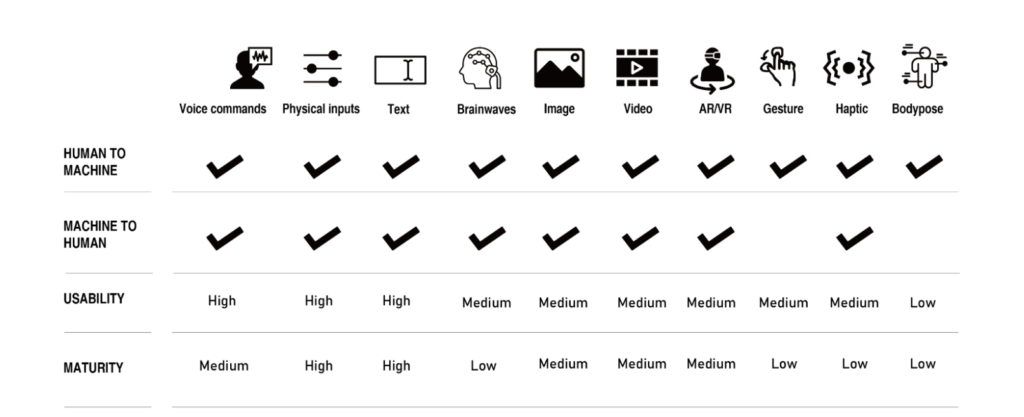

Speaking of human senses as a communication channel with robots, an interesting communication matrix was illustrated in the research paper “Outlook on human-centric manufacturing towards industry 5.0” which illustrated maturity and usability of inputs from humans to machines and vice versa.

Outlook on human-centric manufacturing towards Industry 5.0

There are few technologies in the matrix such as bodypose, brainwaves, haptic, etc, that are still low in maturity but have the potential to play an important role in human robotic communication. Pushing for the maturity of these technologies could open up new possibilities of interaction bypassing the usual tedious methods.

3. CASE STUDIES

Robot see Robot Do Workshop3.1, IAAC

Robot see robot do is a project of human-robot collaboration for the in-place assembly of complex building structures using a custom-made and object-aware mobile AR interface. Humans and robots share a digital-physical workspace, in which humans are informed by digital spatial data, and robots are informed vice versa by the information of tracked physical objects for cooperative assembly routines. In this project, one modular element is formed by two sticks held together by robots while the other one is fixed by humans. To explore a more efficient assembly method, the operator helps the robot moving robot joints to an approximate position then the robot reaches the exact point. As a matter of fact, this strategy breaks down the automation when the computational process goes wrong, human intervention replaces complicated simulation by a collaborative process.

Other natures Madeline Gannon

ther natures is a performance or artistic event hosted by the multidisciplinary designer Madeline Gannon. In this work, she interacts with 4 hanging industrial robots by gestures captured by depth sensors on their TCPs. There is a physical and a digital environment that merges when both agents interact. The role of the human interfering in the behavior of the robot by moving around their territory or approaching her hands to them, becomes strongly mesmerizing.

There are simply 2 digital points (one relative to the robot sensor and another one to the hand of the person) that will define the resulting action according to their relative position (distance) and orientation. Therefore, the nature of the industrial robot becomes anything similar to a wild animal, with apparent affectivity or feelings not typical of machines, being able to communicate and send operational feedback in a collaborative and a humanized task.

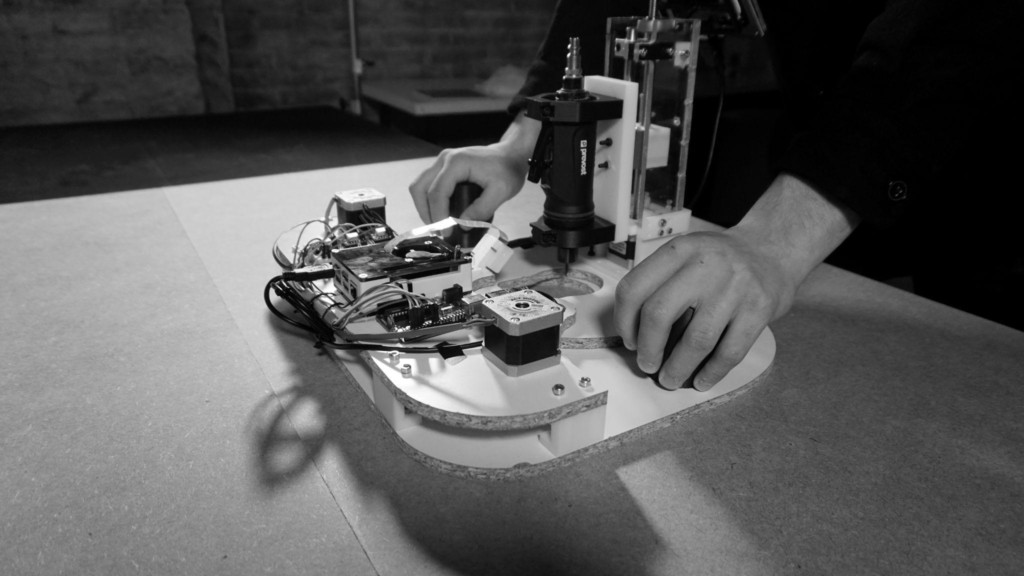

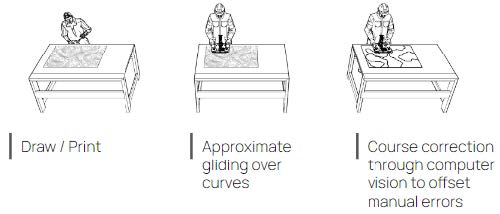

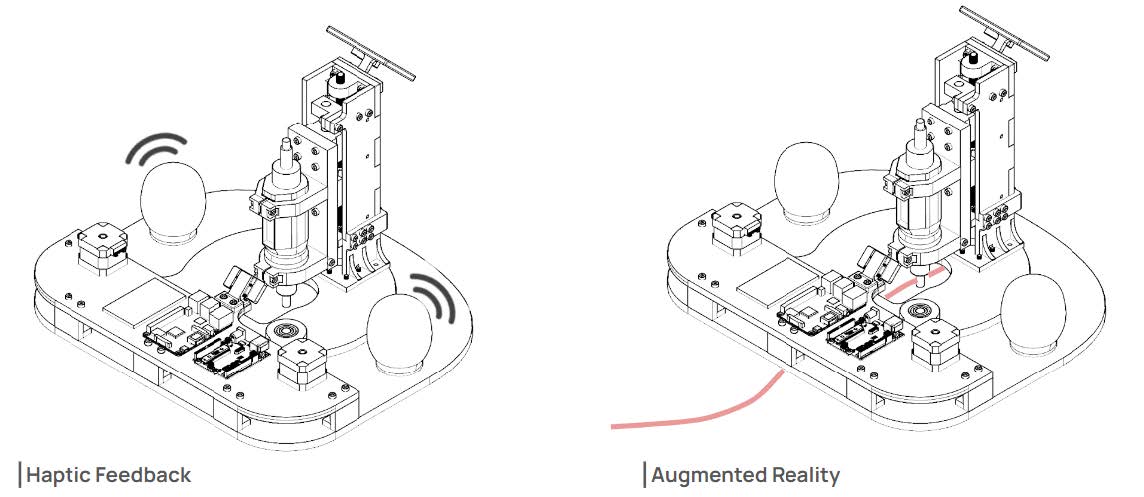

Frebujar : Handheld CNC

Frebujar is a project that was conceptualized in the second term. The project aim is to develop a handheld CNC router which could be used for milling and inscribing onto planar sheets of material. The router will be hand-guided by the user while motors which control the position of the end mill will activate to correct for the error made by the user between the two positions of the bit

The prototype is designed with the intelligence to neutralize the irregular movement of the hand by using computer vision to keep the end mill on track.

Although the prototype has a good balance of cognition and control, it can get better with human feedback by incorporating haptic sensors on the handles to inform users if they are going off track. Augmented reality is another feature that can completely digitize the prototype.

4. Conclusions

Human-machine Relationship –link

In the Age of Augmentation when Human-Robot Collaboration (HRC) has become a strategic research field, considering the emergent need for common collaborative execution of mass customization tasks, a new automation mode should be reshaped in the following 20 years. In industry 4.0, intelligent machines shared the same workspace with humans, with the definition objective to accomplish tasks via synchronized interactive joint activities between all the parties under a shared team identity. Our study cases above can describe an experimental proposal in human process and robotic automation. In an ideal scenario, human–robot collaboration should feel the same as human–human collaboration, however human workers still surpass their robotic partners with their cognitive, adaptation and problem-solving abilities. When it comes to the field of mass customization, the main oversight of the explored communication

systems is the skill acquisition interfaces. Such interfaces would enable a more intuitive definition and teaching of tasks to the robots and allow humans to transfer their domain knowledge and cognitive abilities to them. The self-cognitive robots can observe the environment and communicate with operators in human senses and complete simple tasks automatically.

If current exponential rates of technological progress continue, in 20 years we could have computing capabilities anywhere from 500 to 10,000 times more powerful than we have today. This could be replicated across every domain of information technology, encompassing fields such as artificial intelligence (AI), machine learning, robotics, drones, big data stores, quantum computing, hyperconnectivity, cloud computing, sensor devices, the Internet of Things (IoT), 3D/4D printing, and augmented and virtual reality.

Some hope that we will see exponential advances on the already impressive current progress in brain computer interfaces and wireless brain-to-brain communication. Almost certainly, voice and gesture will have eliminated the bulk of interactions with everything from our refrigerator and vacuum cleaner to whatever replaces the computer and smartphone in 20 years’ time.

No one can accurately predict where the future of work will take us in the next few decades, but the developments taking place today and the ideas emerging from research labs creating the next waves of technology give us some pointers around what our systems might do. The technology may allow us to operate seamlessly around the globe, provide genuinely consistent levels of service 24/7/365, and become far better at predicting issues and solving problems. One thing is certain: we will be learning constantly, and smart systems will be a key resource. In parallel we need to be focusing our efforts on enhancing human capabilities to help us perform in whatever jobs and roles we might be undertaking. From raising digital literacy to enhancing our communication and collaboration skills, continuous learning will be the essential lifeforce for individuals and organizations alike.

Citations

- Carpo, Mario, The Second Digital Turn: Design Beyond Intelligence, MIT Press, 2017

- “Reinventing Construction: A Route to Higher Productivity”, McKinsey Global Institute, McKinsey & Company, February 2017.

- “The Digital in Architecture: Then, Now and in the Future”, Mollie Claypool, Pentagram, SPACE10.

- “Industry 5.0”, European Commision

- Frebujar – Handheld CNC, Hardware Seminar II, IAAC.

- R.D. Cowan et al., “Software Engineering TechnologyWatch,” IEEE Software, vol. 19, no. 4, 2002, pp. 123–130.

- Y. Chen, “Programming Language Trends: An Empiri-cal Study,” doctoral dissertation, New Jersey Inst. ofTechnology, 2003

- Humans and Work in the Digital Era – The Next 20 Years

Interactions between physical and digital environments in mass customization industry s a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2022 by:

Students: Huanyu Li, Shamanth Thenkan, Alberto Martínez

Faculty: Mathilde Marengo