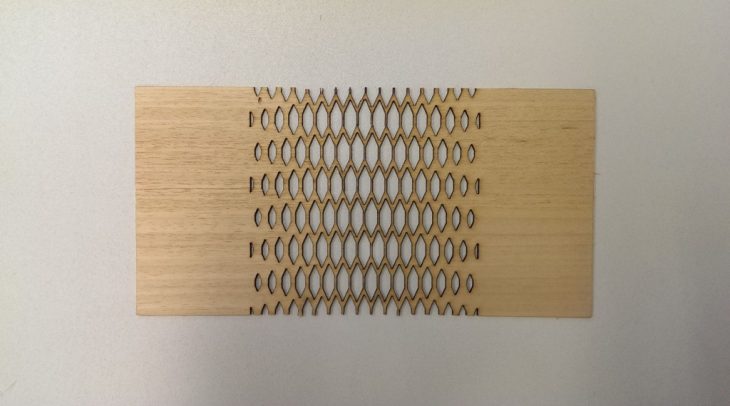

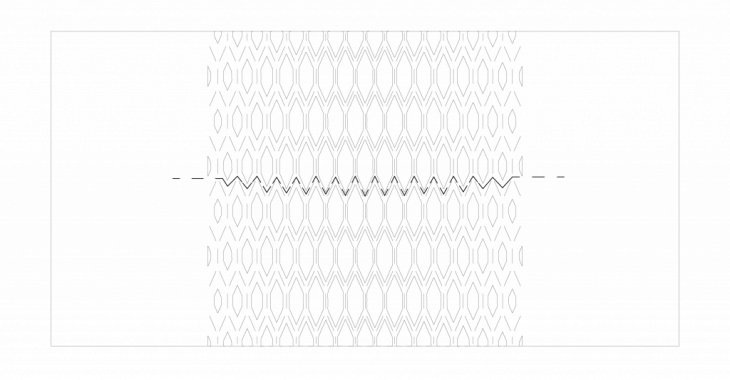

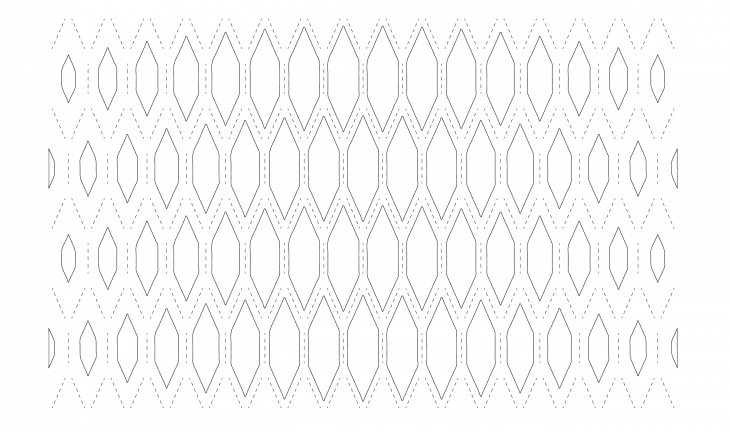

HEXAGONAL KERF SCHEME Material: Wood Technique: Laser Cutting

The idea behind the proposal is to achieve the kerfing movement of a wooden panel with an hexagonal pattern: heterogeneously scaled and weakened by additional cuts to make it even more flexible. In order to increase the lenght of the material’s path from the left side of the panel to the right (and vice versa), I designed the hexagonal grid on grasshopper with the help of the LunchBox plugin. Consequently, I scaled with an attractor the shape of the grid and a gradient of holes started to appear. In conclusion additional cuts following the first hexagonal schemes were added so to weaken the wooden panel and make the system more pliable.

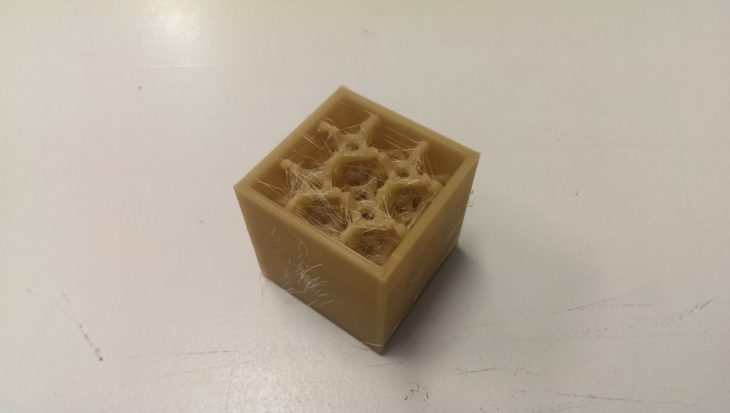

WEAKENING THE VORONOI Material: Foam Technique: CNC Milling

The concept of the second exercise was to mill a surface with CNC in order to obtain a mould for tiles. Aim of the project was to create a stone-like effect on the defined shape and consequently trace a weaving texture. In order to reach the desired form, a Grasshopper 3D code was created. The code is structured in three steps. First step was the generation of a 3D population of points that worked as a base for a voronoi 3D construction. Between the resulting cells, the second step separated a group of them based on the Z dimension. After a Boolean union, a Mesh Weak analysis was done to extrapolate a texture between the center points of each face of the resulting surface. Finally some of the lines were eliminated due to the distance to two attractor points.

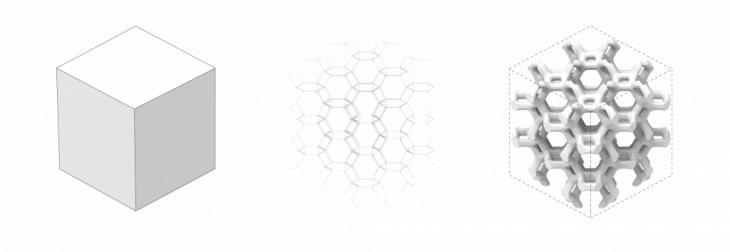

VINTILES LATTICE BOX Material: PVA & Resin Casting Technique: 3D printing

The concept of the proposal is to 3D print a cube that contains a model which is going to be used as negative for the casting of resin inside the cube itself. This project has been the chance for me, to test and exploit the potentials of the Intralattice (from McGill’s Additive Design & Manufacturing Laboratory (ADML)) and the Cocoon plug in ( from David Stasiuk) in Grasshopper 3D. The resulted algorithm, Vintiles Lattice Box, generates a vintiles-like struts inside the defined box and allows me to control: density, thickness and dimension of the cells. Starting from the box, first step was to create the cells with the UniformDs and the PresetCell component. Once decided the dimension and the plan of construction, the vintiles structure was thickened with the help of the Curve Group Charge in Cocoon and the Cocoon component itself before getting trimmed and placed in the original Box.

INTRODUCTION TO DIGITAL FABRICATION is a seminar of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in City and Technology, in 2016 by:

Student: Iacopo Neri

Tutors: Djordje Stanojevic