The digital fabrication exercise demanded designs for three different performances: a tile of a lamp for 3D Printing, a tile for an acoustic panel in CNC Milling, and a tile of a partition to manipulate privacy in Laser Cutting.

3D PRINTING

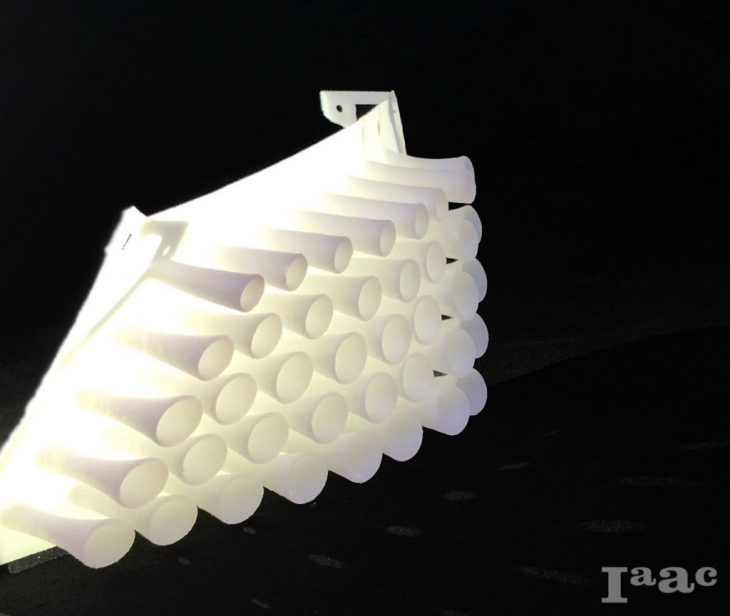

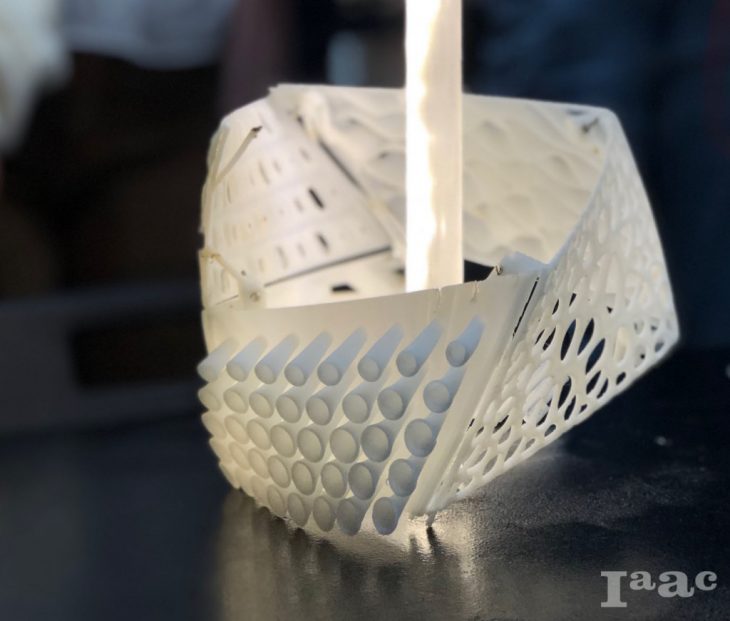

The lamp tile design was conceived as tentacles that guide the light from its source, designing the play of shadow as a contrast. 3D Printing technology allows a controlled orientation and intensity of light defined by the variable size of the openings and the dynamic form of the tentacles.

Image 1. Final tile printed

Image 2. Final tile installed on lamp

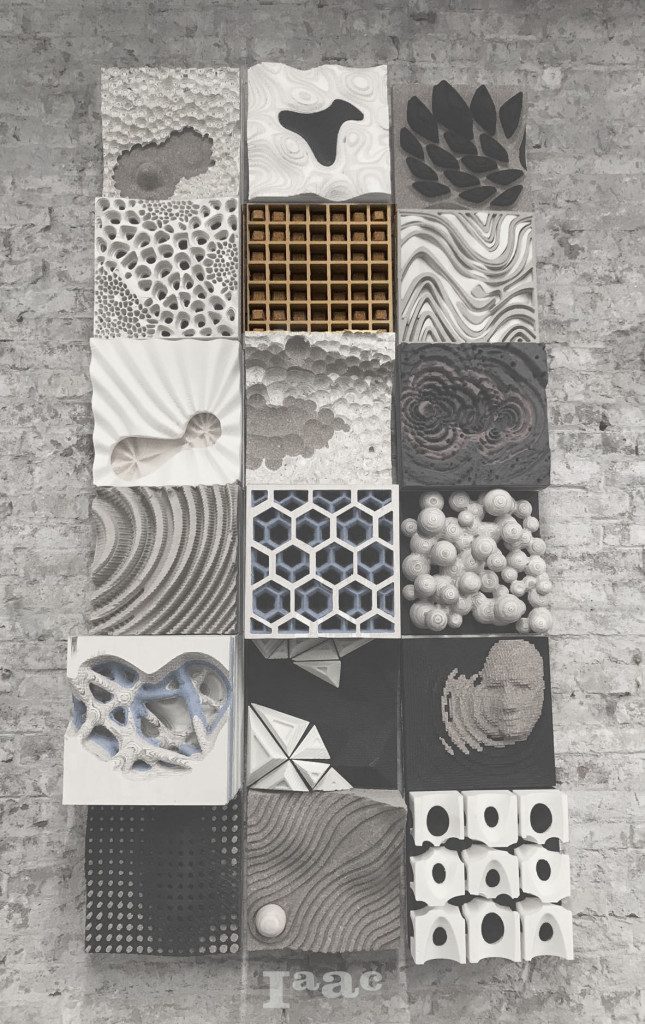

CNC MILLING

The design for the acoustic panel is conceived as a waffle made of two different materials: one that diffuses sound (MDF board) and another one that absorbs it (cork). The hidden quality of this design is the way cork sits inside the square grid of MDF. Inside each puncture is a cork in a pyramidal shape with variable heights carefully playing with the void generated, affecting sound absorption as a resultant.

Image 3. Final panel installed on wall.

LASER CUTTING

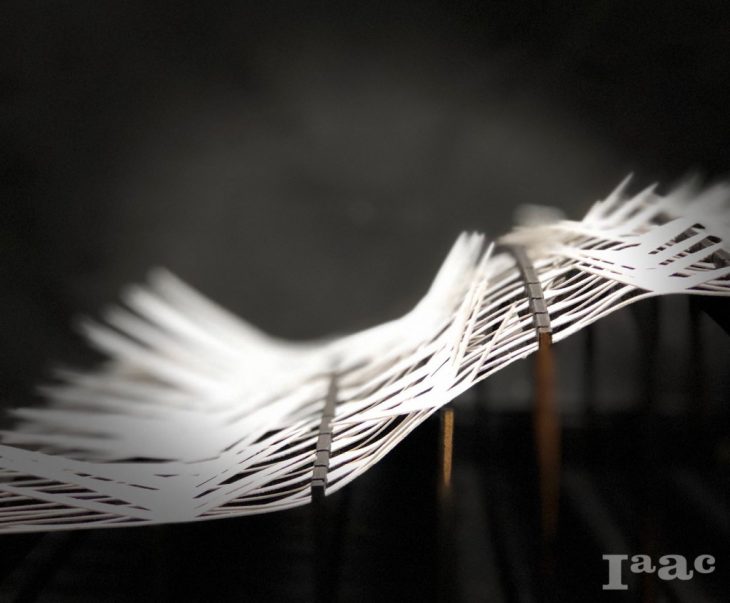

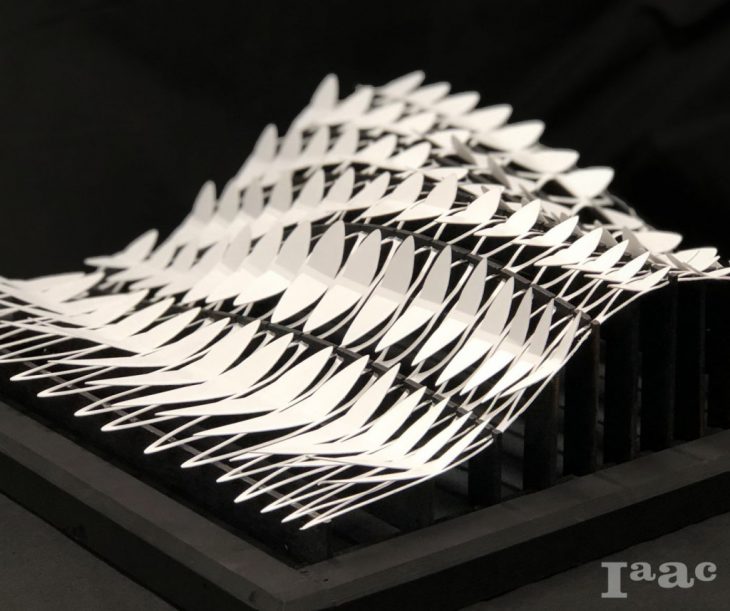

For the laser cutting exercise, the partition was defined as an element for visual obstruction. The laser-cut and braided panel is designed to create curiosity and mamipulate privacy through its openings. The design pattern not only creates beautiful joinery detail for the braiding technique but also an intricate play of light and shadow on its surface.

Image 4. Final braided structure is able to hold its shape without a frame.

Image 5. With the frame in place, the panel was ready to be hung as a partition element for privacy.