Introduction

The course required groups to explore three different digital fabrication methods; 3D Printing, CNC Milling and Laser Cutting. The capabilities and limitations of each of these fabrication methods were explored by¨ learning by doing¨ through developing modular recursive geometries which could be stacked, put together and aggregated. The process helped to understand more about how to transition between a digital model and to produce physical results through these different fabrication methods. As a result, the stages to completing this introductory course gave us the opportunity, knowledge and experience to be able to decide what fabrication method is most applicable for future projects.

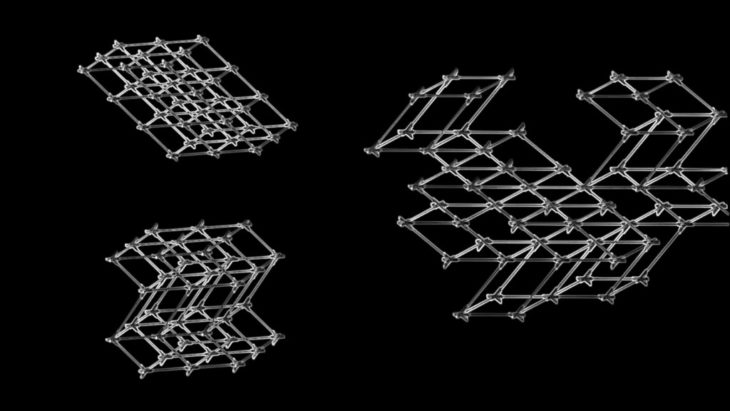

3D Printing

Two node variations were designed and fabricated to form a recursive rhomboid geometry. The process introduces these two nodes to create multiple aggregated iterations. When connected, these forms build a truss like structure that can be infinitely customized for its application.

// Technical

Material type: Z-ABS

Machine specifications: M200 plus

Layer thickness: 0,19 mm

Support type, angles and specifications: Automatic, 20°

Supports required: none

Infill type, percentage, & pattern: Normal, 50%, Pattern 0

Seam: Normal

Total number of nodes: 24 (2 node variations)

Total print time: 3hr 9m

Total material quantity: 6.36 (15g)

// Digital Exploration of Recursive Growth

// Final Recursive Geometry

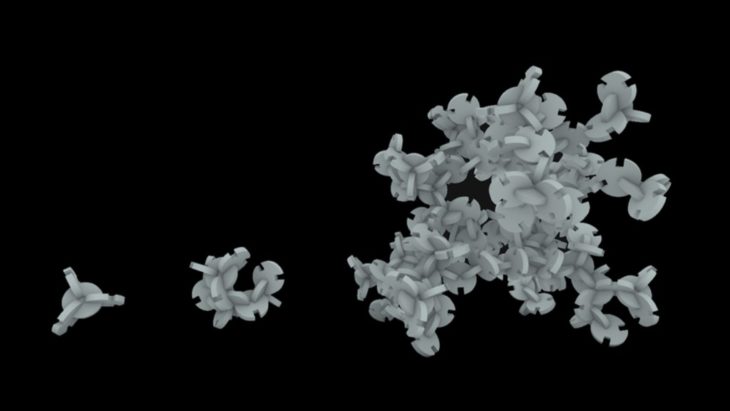

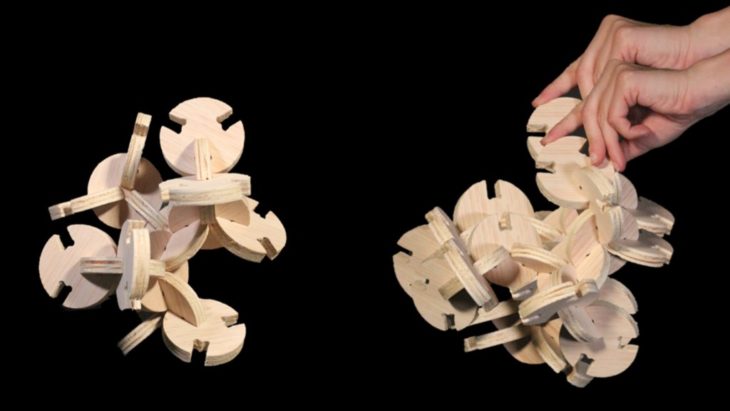

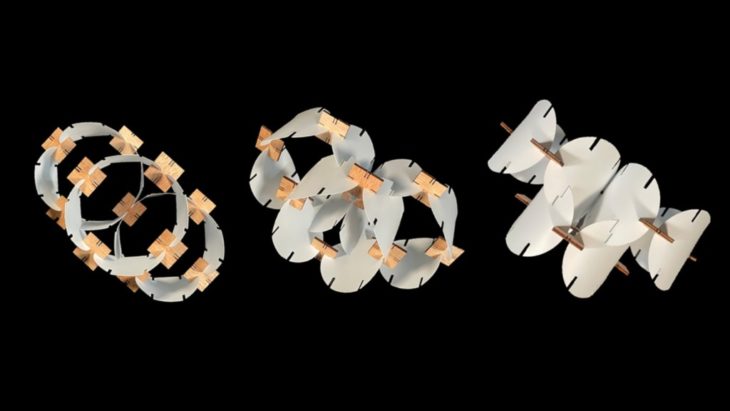

CNC Milling

In this fabrication process, we worked on reducing the number of nodes required to fabricate a recursive geometry. Through this process, we tested abstract methods to achieve a single node based module that can be repeated. The playful aggregation promotes this idea that the form itself can grow and expand in all three dimensional directions.

// Technical

Material: Plywood 12mm

Machine: 2 Axis

Post Processor: T Rex

Workpiece volume: 200 cm x 200 cm x 200 cm

Total mill time: 20,76 minutes

Engraving, Pocketing and Outside Profiling:

Upcut Mill

Flute: 1

Diameter: 6 mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepover distance: 70%

Stock: -0.1 mm

// Digital Exploration of Recursive Growth

// Final Recursive Geometry

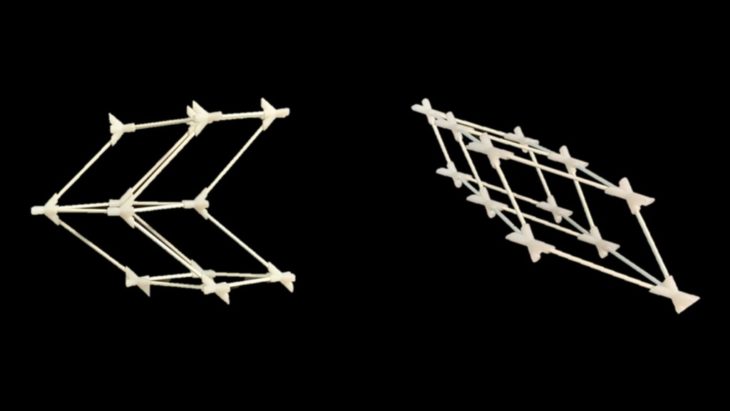

Laser Cutting

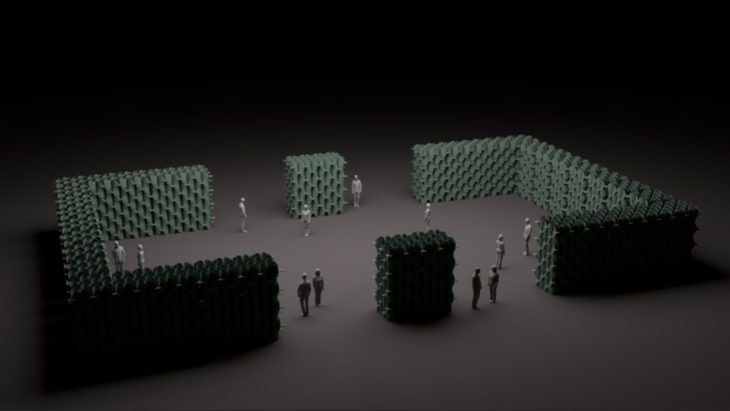

In the laser cutting fabrication method, we explored a strategy that would use two nodes where one element would be more flexible and the other rigid. This when put together gave us flexible options to produce a recursive geometry. The process allowed us to expand on the idea of how a rigid and flexible combination could be applied to fabricate light weight and aggregated spatial dividers that could be used in expo/events.

// Technical

Machine: Rayjet 500

Joint type: Interlocking

Material: Polypropylene 0.5mm white opaque

Speed: 3.50

Power: 50

Total prints: 16 units

Material: Poplar plywood 4mm

Speed: 1.80

Power: 42

Total prints: 12 units

// Final Recursive Geometry

// Visualization of the Recursive Geometry

The visual representation shows how this recursive geometry can be repurposed as spatial dividers

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in (2021) by:

Students: Emily Rackstraw, Mira Housen, Aaron Pereira

Faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca