Introduction

The course for introduction to the digital fabrication was floated in order to understand the relation between the machines and the computer data, how the algorithms used to create the forms in computer can be generated using specific fabrication techniques. The main focus of the course was oriented on the recursive geometry, starting with the base geometry which can be aggregated in all directions. Main techniques we are working on are Laser cutting, 3d printing & CNC Milling.

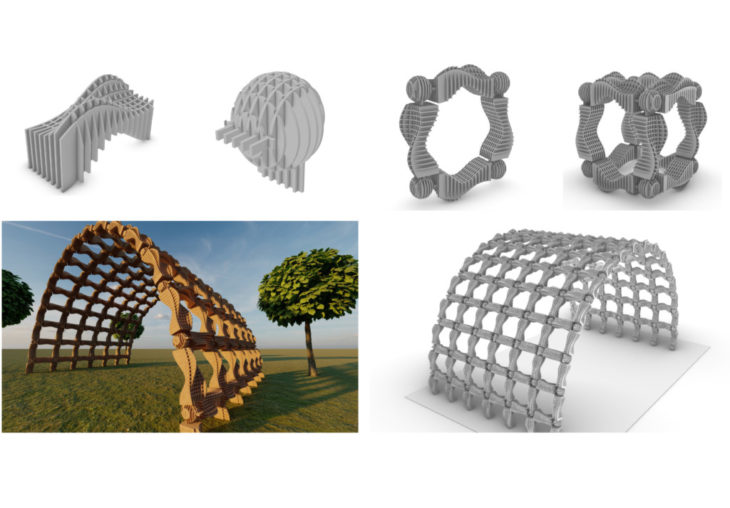

Laser cutting- Waffle Multiverse

The main criteria in this topic was the use of laser cutting machine and different techniques that can be used with this fabrication approach. We decided to use waffling as our main approach, in which the most important criteria that we were supposed to tackle was the tolerance of interlocking in between material plates in order to achieve a rigid structure which is strong enough to stay in the position.

Material: Poplar Plywood

Technique: Laser cutting

Joint type: Secctioning (waffle)

Machine: Epilog 50-75w

Working Parameters:

Speed: 10

Power: 95

Frequency: 250

Cutting Time: 42 min 38 secWe tried different small interlocking modules to figure out the optimal distance between 2 units and ultimately in the end we

kept the interlocking gap 3.85mm in reference to the thickness of our material which was 4mm.

Process:

Aggregation:

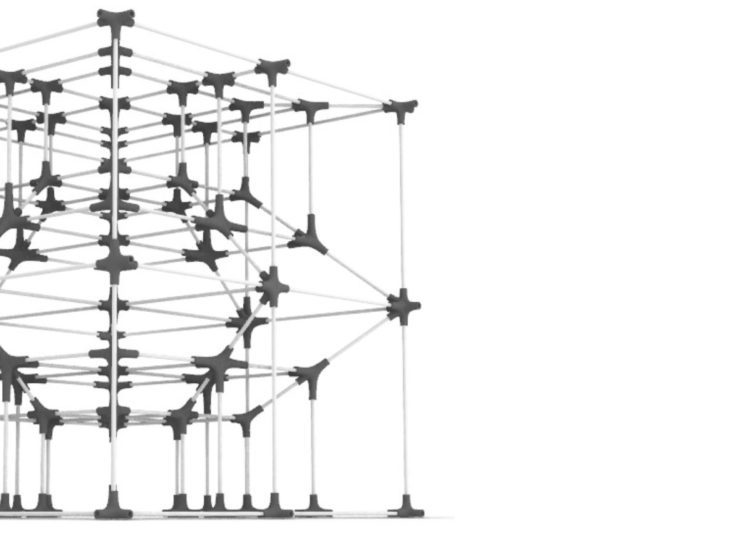

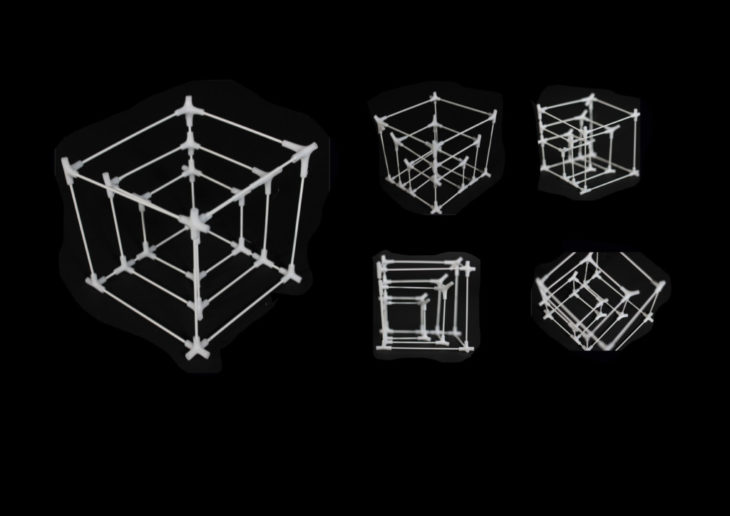

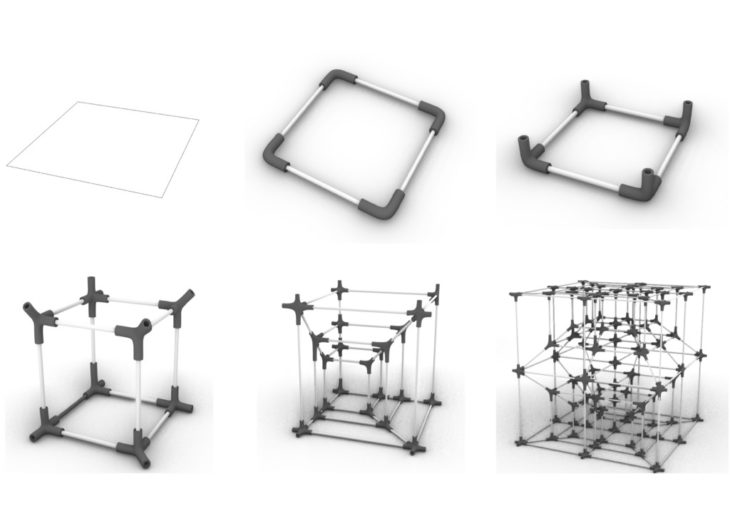

3D Printing – Endless Cube

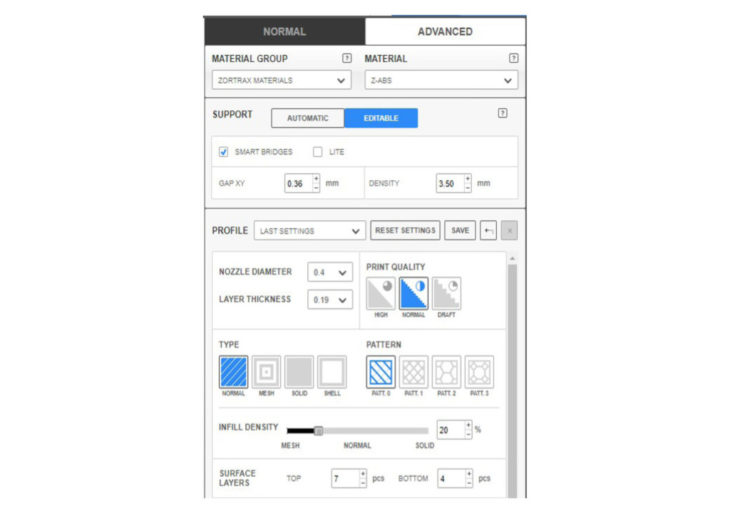

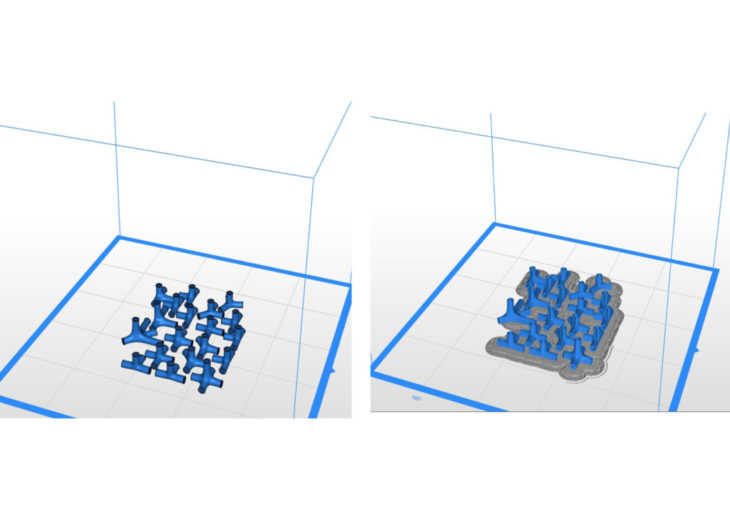

The approach of this technique was quite different, as we were supposed to create a recursive geometry with a nodal joinery system. Here, we worked with 2 mm thick metal wire used to create a recursive geometry with the help of this nodes. The major aspect to focus on this machine was how to optimize the model in the software itself to reduce the time and material usage, with the appropriate tolerance in the nodes.

Working parameters:

Total number of nodes: 22

Total print time: 3 hours 38 minutes

Total material quantity: 21 grams

Material type: Z-ABC

Machine specifications: Zortax 200 plus

Layer thickness:0.19 mm

Support type, angles and specifications: Editable;only

from raft; 19

Infill type, percentage, & pattern: 20%,

Print Quality: normal

Seam: normal

Mesh errors and fixes: none

Important point to take into consideration while using z- suite.

• Optimize the geometry in order to reduce the printing time.

• Import the optimized geometry, it should always be on 0 of Z axis.

• Orient the geometry in order to reduce the supports

• Simulate the supports and change the settings to the most accurate output. Add or remove supports if needed

Concept:

The idea was to work with a basic shape. Starting with a square, converting it into a cube connected by nodes. To

create the recursiveness in the geometry, we tried to elaborate a sense of infinity. Having as an outcome an¨ endless

cube¨

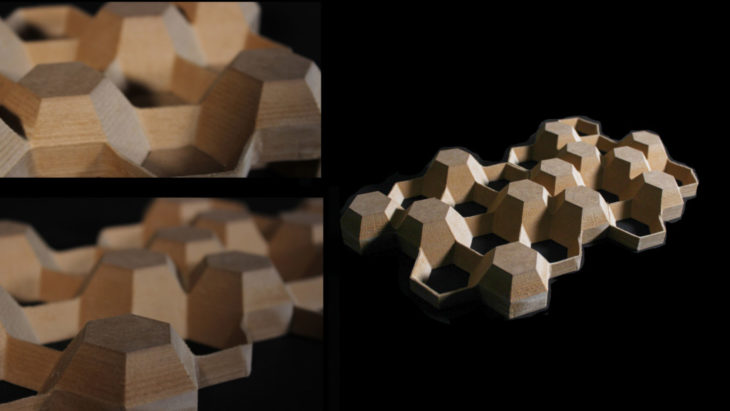

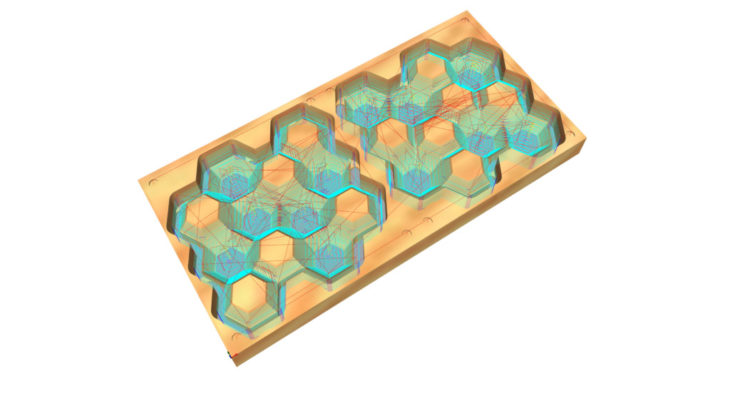

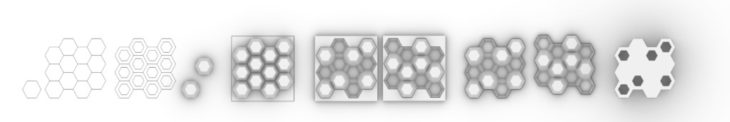

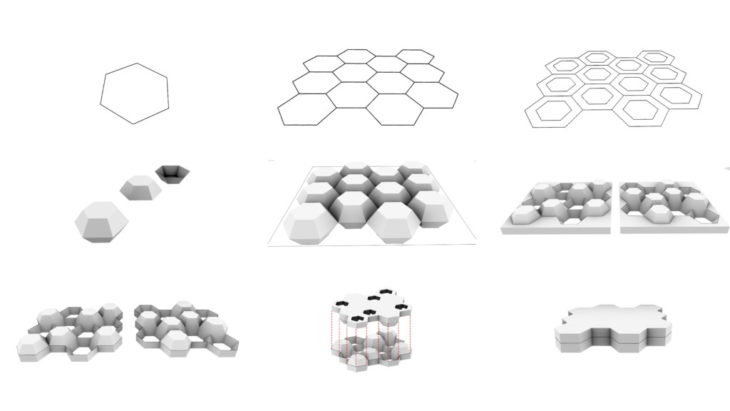

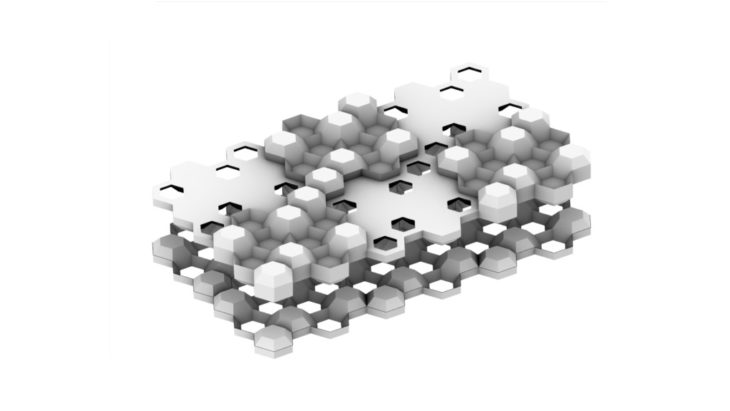

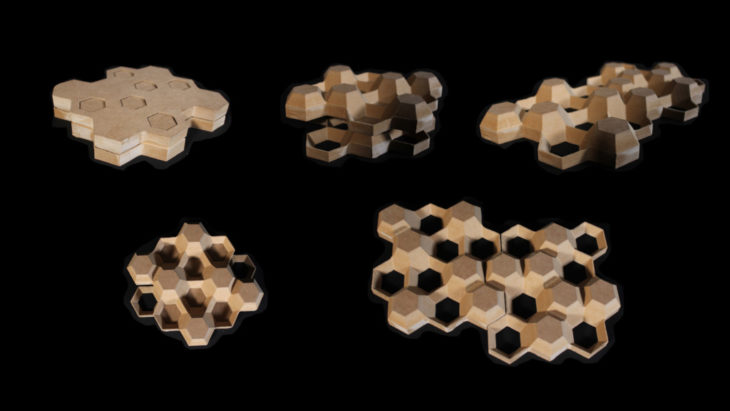

CNC Milling – Hexagon structure

The aggregation of recursive geometry in CNC milling was one of toughest approach, as we had liberty to work multidirectional. We took hexagon as our base geometry to create 2 modules that interlock with each other as a positive – negative geometry which can aggregate in all the direction based on their interlocking pattern. The main challenge in this technique was the use of different types of mill bids and what output does that specific mill bid provide

RhinoCam parameters:

Material: MDF

Machine: T-Rex (P59)

Porst Processor: CNC_Step_BCN

Workpiece volume: 200x200x30mm

CNC Stratagies (3-Axis)

Horisontal Roughing

Flat Mill

Flute: 1

Diameter: 10mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepdown Control (dZ):50%

Stepover Distance:40%

Total mill time: 21.04 minutes

CNC Stratagies (3-Axis)

Horisontal Finishing

Ball Mill

Flute: 1

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepdown Control (dZ):10%

Stepover Distance:25%

Total mill time: 32.70 Minutes

CNC Stratagies (2-Axis)

2 ½ Axis Profiling

Flat Mill

Flute: 1

Diameter: 10mm

Spindle Speed: 12000

Cut Direction: Upcut

Total mill time: 9.03 Minutes

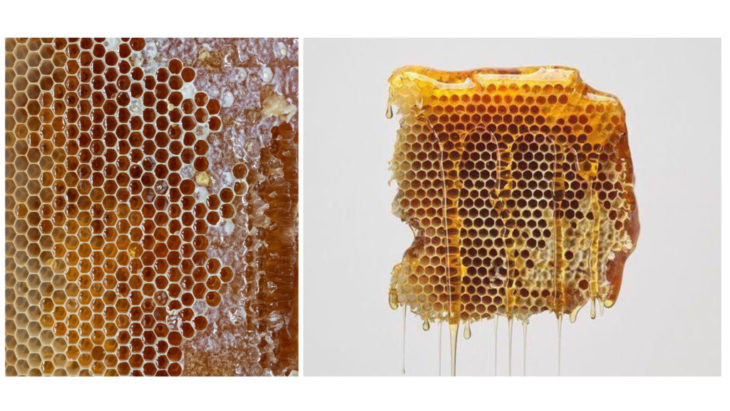

Concept honeycomb:

Modeling process:

Aggregation:

Final model:

Introduction to Digital Fabrication – Recursive Geometries

Students: Divya Shah, María Fernanda Rodríguez Orviz, Angelina Ovsyannikova, Sabina Javanli

Faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca